pdf download

pdf download

pdf download

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

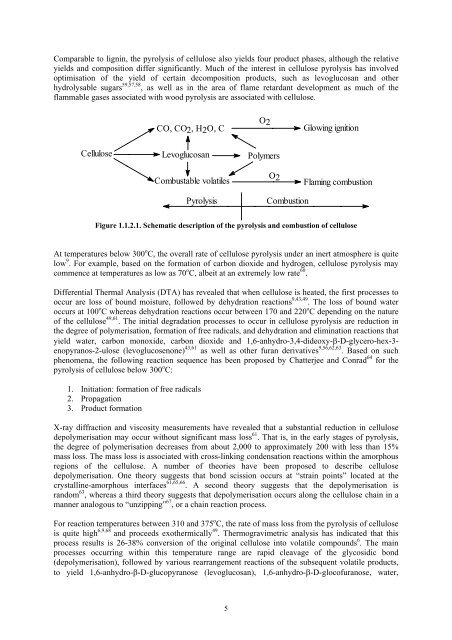

Comparable to lignin, the pyrolysis of cellulose also yields four product phases, although the relative<br />

yields and composition differ significantly. Much of the interest in cellulose pyrolysis has involved<br />

optimisation of the yield of certain decomposition products, such as levoglucosan and other<br />

hydrolysable sugars 59,57,58 , as well as in the area of flame retardant development as much of the<br />

flammable gases associated with wood pyrolysis are associated with cellulose.<br />

CO, CO2, H2O, C<br />

O2<br />

Glowing ignition<br />

Cellulose<br />

Levoglucosan<br />

Polymers<br />

Combustable volatiles<br />

O2<br />

Flaming combustion<br />

Pyrolysis<br />

Combustion<br />

Figure 1.1.2.1. Schematic description of the pyrolysis and combustion of cellulose<br />

At temperatures below 300 o C, the overall rate of cellulose pyrolysis under an inert atmosphere is quite<br />

low 9 . For example, based on the formation of carbon dioxide and hydrogen, cellulose pyrolysis may<br />

commence at temperatures as low as 70 o C, albeit at an extremely low rate 60 .<br />

Differential Thermal Analysis (DTA) has revealed that when cellulose is heated, the first processes to<br />

occur are loss of bound moisture, followed by dehydration reactions 9,43,49 . The loss of bound water<br />

occurs at 100 o C whereas dehydration reactions occur between 170 and 220 o C depending on the nature<br />

of the cellulose 49,61 . The initial degradation processes to occur in cellulose pyrolysis are reduction in<br />

the degree of polymerisation, formation of free radicals, and dehydration and elimination reactions that<br />

yield water, carbon monoxide, carbon dioxide and 1,6-anhydro-3,4-dideoxy-β-D-glycero-hex-3-<br />

enopyranos-2-ulose (levoglucosenone) 43,61 as well as other furan derivatives 9,56,62,63 . Based on such<br />

phenomena, the following reaction sequence has been proposed by Chatterjee and Conrad 64 for the<br />

pyrolysis of cellulose below 300 o C:<br />

1. Initiation: formation of free radicals<br />

2. Propagation<br />

3. Product formation<br />

X-ray diffraction and viscosity measurements have revealed that a substantial reduction in cellulose<br />

depolymerisation may occur without significant mass loss 61 . That is, in the early stages of pyrolysis,<br />

the degree of polymerisation decreases from about 2,000 to approximately 200 with less than 15%<br />

mass loss. The mass loss is associated with cross-linking condensation reactions within the amorphous<br />

regions of the cellulose. A number of theories have been proposed to describe cellulose<br />

depolymerisation. One theory suggests that bond scission occurs at “strain points” located at the<br />

crystalline-amorphous interfaces 61,65,66 . A second theory suggests that the depolymerisation is<br />

random 63 , whereas a third theory suggests that depolymerisation occurs along the cellulose chain in a<br />

manner analogous to “unzipping” 67 , or a chain reaction process.<br />

For reaction temperatures between 310 and 375 o C, the rate of mass loss from the pyrolysis of cellulose<br />

is quite high 6,9,68 and proceeds exothermically 49 . Thermogravimetric analysis has indicated that this<br />

process results is 26-38% conversion of the original cellulose into volatile compounds 6 . The main<br />

processes occurring within this temperature range are rapid cleavage of the glycosidic bond<br />

(depolymerisation), followed by various rearrangement reactions of the subsequent volatile products,<br />

to yield 1,6-anhydro-β-D-glucopyranose (levoglucosan), 1,6-anhydro-β-D-glocofuranose, water,<br />

5