Advance Terminal Planning Study Program Criteria Document

Advance Terminal Planning Study Program Criteria Document

Advance Terminal Planning Study Program Criteria Document

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

DRAFT

KANSAS CITY NEW TERMINAL STUDY<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

TABLE OF CONTENTS<br />

Page<br />

INTRODUCTION ................................................................................. 1<br />

BACKGROUND .................................................................................... 1<br />

PURPOSE ........................................................................................... 2<br />

1 ADVANCED PLANNING PARAMETERS......................................... 2<br />

1.1 Goals and Objectives .................................................................... 2<br />

1.2 Passenger Surveys ....................................................................... 4<br />

1.3 Aviation Demand Forecast ............................................................ 5<br />

1.4 Benchmarking ........................................................................... 13<br />

2 AIRFIELD REQUIREMENTS ...................................................... 15<br />

2.1 Design Aircraft .......................................................................... 15<br />

2.2 Aircraft Gates and Loading Bridge Requirements ............................ 17<br />

2.3 Apron Service Road .................................................................... 22<br />

2.4 Airside Security Requirements ..................................................... 22<br />

2.5 Aircraft Deicing .......................................................................... 23<br />

2.6 Fueling Requirements ................................................................. 30<br />

3 TERMINAL REQUIREMENTS ..................................................... 36<br />

3.1 Methodologies ........................................................................... 36<br />

3.2 <strong>Terminal</strong> Facility Requirements .................................................... 39<br />

3.3 Concessions Requirements .......................................................... 68<br />

3.4 Specialty Systems and New Technology ........................................ 83<br />

3.5 Utilities, Infrastructure and MEP Requirements ............................. 115<br />

DRAFT<br />

4 LANDSIDE REQUIREMENTS ................................................... 124<br />

4.1 Regional Access ........................................................................ 125<br />

4.2 <strong>Terminal</strong> Area Landside Requirements ......................................... 142<br />

4.3 Vehicular Parking ...................................................................... 146<br />

5 TERMINAL SUPPORT REQUIREMENTS ................................... 149<br />

5.1 Fleet Maintenance ..................................................................... 150<br />

5.2 Fuel/Wash Facility ..................................................................... 151<br />

5.3 Aviation Facilities Maintenance ................................................... 152<br />

5.4 Airport Police Department .......................................................... 152<br />

5.5 Flight Kitchens .......................................................................... 153<br />

5.6 Airport Hotel ............................................................................ 154<br />

5.7 Ground Service Equipment (GSE) Facilities .................................. 154<br />

5.8 Airside Snow Storage and Melting Areas ...................................... 155<br />

5.9 Ramp Control Tower .................................................................. 157<br />

5.10 Remain Overnight (RON) Parking ................................................ 160<br />

Landrum & Brown<br />

April 2013<br />

Page i

KANSAS CITY NEW TERMINAL STUDY<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

TABLE OF CONTENTS (Continued)<br />

Page<br />

6 REFINE CONCEPTUAL TERMINAL COMPLEX SITE PLAN .......... 161<br />

6.1 Airside Site Plan ....................................................................... 161<br />

6.2 Ground Access Site Plan for the New <strong>Terminal</strong> .............................. 178<br />

6.3 <strong>Terminal</strong> Support and Collateral Development Site Plan ................. 198<br />

6.4 FAA Navigational Aids ................................................................ 214<br />

7 REFINE CONCEPTUAL TERMINAL BUILDING PLANS ............... 216<br />

7.1 Conceptual <strong>Terminal</strong> and Concourse Plans.................................... 216<br />

7.2 Refined Alternative 1B Building Plans .......................................... 235<br />

7.3 Conceptual <strong>Terminal</strong> Building Cross Sections ................................ 245<br />

7.4 Conceptual Building Mass Elevations ........................................... 252<br />

7.5 Conceptual Illustrations ............................................................. 253<br />

7.6 New <strong>Terminal</strong> Mechanical & Electrical Improvements/<br />

Alternatives.............................................................................. 260<br />

7.7 Baggage Handling System (BHS) ................................................ 288<br />

8 ENVIRONMENTAL CONSIDERATIONS .................................... 293<br />

8.1 Alternative Evaluation – Environmental Resources ........................ 293<br />

8.2 Implementation <strong>Planning</strong> – Environmental Considerations .............. 293<br />

8.3 Sustainability <strong>Planning</strong> .............................................................. 295<br />

9 PROGRAM IMPLEMENTATION ................................................ 306<br />

9.1 Introduction ............................................................................. 306<br />

9.2 <strong>Terminal</strong> Development Phasing Summary .................................... 306<br />

9.3 Capital Costs of the New <strong>Terminal</strong> <strong>Program</strong> .................................. 308<br />

9.4 Enabling Projects ...................................................................... 308<br />

9.5 LEED Gold Certification .............................................................. 310<br />

9.6 Implementation Timeline ........................................................... 312<br />

9.7 <strong>Program</strong> Delivery Methods ......................................................... 313<br />

DRAFT<br />

10 FINANCIAL IMPLEMENTATION PLAN ..................................... 316<br />

10.1 Cost and Affordability of New Replacement <strong>Terminal</strong> ..................... 316<br />

10.2 Determinations of Affordability ................................................... 320<br />

Landrum & Brown<br />

April 2013<br />

Page ii

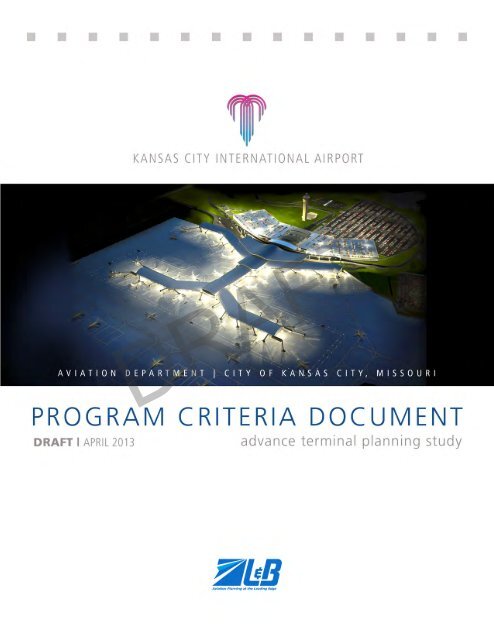

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

PROGRAM CRITERIA DOCUMENT (PCD)<br />

INTRODUCTION<br />

This <strong>Program</strong> <strong>Criteria</strong> <strong>Document</strong> (PCD) provides the overall guidance for the design<br />

of the New <strong>Terminal</strong> Complex (New <strong>Terminal</strong>) facilities at the Kansas City<br />

International Airport (KCI or Airport). The New <strong>Terminal</strong> is envisioned as a<br />

consolidated single facility that will replace the existing three unit terminal used<br />

today. The PCD contains all of the pertinent information identified and researched<br />

for the development of the project including any infrastructure enabling projects<br />

needed to allow implementation of the New <strong>Terminal</strong> and the necessary regulatory<br />

information. The conceptual plans for the refined airside, terminal, and landside<br />

requirements are the basis for the PCD, which is designed to serve as the guidelines<br />

for the design and implementation of the New <strong>Terminal</strong> facilities.<br />

BACKGROUND<br />

The Airport was built by the City of Kansas City, Missouri (KCMO or City) and has<br />

served the needs of air travelers in the Midwest since the opening in 1972.<br />

The KCI complex spans more than 10,000 acres, making it one of the largest<br />

airports in the U.S.<br />

The Airport is situated 15 miles northwest of the City’s central business district and<br />

currently, the closest scheduled commercial passenger service airport is Omaha<br />

Eppley Airfield (OMA), located 152 miles away. The Metropolitan Statistical Area<br />

(MSA) for the City, as defined by the U.S. Census Bureau for Kansas City,<br />

encompasses 15 counties including Bates, Caldwell, Cass, Clay, Clinton, Jackson,<br />

Lafayette, Platte, and Ray counties in Missouri; and Franklin, Johnson,<br />

Leavenworth, Linn, Miami, and Wyandotte counties in Kansas. The Kansas City<br />

Aviation Department (KCAD) defines KCI’s Air Service Area (ASA) as all counties in<br />

the MSA, and additionally Buchanan County in Missouri and Douglas County in<br />

Kansas.<br />

DRAFT<br />

KCAD completed an Airport Master Plan (MP) in 2008 that provided a vision for the<br />

growth and development of KCI over the following 20 years, and established a<br />

framework for the development of facilities and a guide for long-term on-airport<br />

land use and development decisions. The MP identified the need for an updated<br />

passenger terminal complex to serve a projected increase in passenger demand<br />

and provide a passenger processing facility that would meet and exceed customer<br />

service expectations.<br />

Several terminal options were selected for development sites and design<br />

alternatives were developed and presented to KCAD for review. The MP identified a<br />

South <strong>Terminal</strong> project that included a new 59-gate terminal south of Runway 9/27<br />

and a new terminal curb front and loop roadway system, a new south access<br />

roadway from Missouri Route 152 (M-152), and an upgrade of I-435 and I-29<br />

ramps connecting to M-152.<br />

Landrum & Brown Page 1<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

As a result of the MP, the New <strong>Terminal</strong> <strong>Advance</strong> <strong>Planning</strong> <strong>Study</strong> (the <strong>Study</strong>) was<br />

initiated November 28, 2011 to research, explore, and consider the new South<br />

<strong>Terminal</strong> option developed in the MP. However, in June 2012 KCI officials, due to<br />

the high cost of the South <strong>Terminal</strong> project, announced that the existing <strong>Terminal</strong> A<br />

site was being considered for the proposed main terminal location. This site would<br />

take advantage of infrastructure that currently exists and as a result would cost<br />

significantly less and be implemented more quickly.<br />

PURPOSE<br />

The desired result of the <strong>Study</strong> is to identify, programmatically define, and<br />

conceptually depict a planning and design direction for the Preferred Alternative’s<br />

future phase developments. Therefore, this PCD provides all of the key background<br />

research and analysis, facility requirements, and detailed planning and design<br />

guidelines to facilitate the design and construction needs of the new passenger<br />

terminal complex.<br />

1. ADVANCED PLANNING PARAMETERS<br />

Identifying advanced planning parameters will lay the foundation for the project.<br />

To address the unique operating needs of KCI, the specific goals, objectives, and<br />

passenger demand characteristics that guided the development of alternatives and<br />

the choice of the Preferred Alternative are identified in this section.<br />

1.1 Goals and Objectives<br />

The project information contained in the MP was supplemented by new and more<br />

detailed information for this <strong>Study</strong>. Meetings and discussions with key City<br />

Stakeholders, the FAA, three of the primary airlines serving KCI, and key<br />

concessionaires were conducted. The goals and objectives formulated from these<br />

meetings and discussions combined with comments provided by KCAD, are the<br />

basis for determining the various goals and objectives of the <strong>Study</strong>.<br />

The overall Project Goal is to develop a plan for the design and construction of a<br />

new terminal at KCI, which will enhance the City’s ability to provide a high level of<br />

air service, as well as a source of community pride for the City and the Metro<br />

Region. This will be accomplished by providing a first class arrivals destination and<br />

new, efficient, and technologically advanced airside, terminal, and landside facilities<br />

that promote the highest level of passenger processing conveniences and customer<br />

service. The primary goals and their associated objectives of the <strong>Study</strong> are:<br />

<strong>Terminal</strong> Goals:<br />

<br />

<br />

<br />

DRAFT<br />

Most importantly, replace the three existing passenger terminals with one<br />

integrated state-of-the-art facility<br />

Achieve a balanced capacity of gates, terminal processing, and landside<br />

facilities<br />

Incorporate the latest in passenger processing technology<br />

Landrum & Brown Page 2<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Plan facilities that meet a minimum Level of Service (LOS) C during peak<br />

hours<br />

Plan for flexibility to expand as demand changes<br />

Develop facilities that can adapt to a rigorous and changing security<br />

environment<br />

Design passenger-friendly flows and way-finding<br />

Minimize walking distances<br />

Develop operationally efficient gates for the airlines<br />

Provide efficient baggage handling and delivery<br />

Improve international facilities and their connection to domestic service<br />

Minimize the complexity of construction phasing<br />

Airside Goals:<br />

<br />

<br />

<br />

<br />

Maximize the uses of the new terminal site and airfield efficiencies<br />

Plan facilities that meet or exceed FAA design standards<br />

Accommodate aircraft that utilize the Airport, both now and in the future<br />

Provide efficient operational requirements such as vehicle service roads and<br />

uncongested ramp areas<br />

Regional and Landside Access Goals:<br />

<br />

<br />

<br />

<br />

<br />

<br />

Financial:<br />

<br />

<br />

<br />

<br />

<br />

Integrate the New <strong>Terminal</strong> into the existing roadway and regional<br />

transportation system with minimal interruption to on-going operations<br />

DRAFT<br />

Maximize on-airport parking<br />

Provide for convenient passenger access and transfers<br />

Minimize walking distances to the New <strong>Terminal</strong><br />

Provide a high LOS for rental car patrons<br />

Provide a high LOS at Arrivals and Departures curbsides<br />

Periodically evaluate a Rough Order of Magnitude to ensure the New <strong>Terminal</strong><br />

is a financially feasible plan<br />

Develop a cost-effective and realistically affordable plan<br />

Utilize common-use systems to minimize capital and operating costs<br />

Maximize non-aviation revenue opportunities including concessions and<br />

parking<br />

Maximize eligibility for FAA funding of proposed improvements<br />

Landrum & Brown Page 3<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

1.2 Passenger Surveys<br />

Passenger surveys were conducted at the Airport between March 4 th and<br />

March 10 th , 2012 to gain an understanding of the passengers using KCI and develop<br />

a current passenger profile. The surveys confirmed KCI’s ASA and provided<br />

additional data such as check-in, baggage check, parking, and concessions<br />

planning, to name a few. All of the information collected from the surveys is<br />

beneficial and will be used in the future for demand forecasting, airport planning,<br />

and policy and investment decisions.<br />

The passenger surveys were conducted in the holdrooms at the gates prior to flight<br />

departure. Passengers were selected from a balanced mix of flights in all of the<br />

current terminals, and flights were selected by airlines, day of week, time of day,<br />

and destination market, providing a statistically valid method of identifying a<br />

representative passenger profile for departing passengers at KCI.<br />

Thirty questions including passenger characteristics, local trip origin, ground<br />

transportation mode and parking, concessions, resident or visitor status, purpose<br />

and propensity for travel, airline elite status, check-in location, number of bags<br />

carried on or checked, bag check location, travel group size, and final destination<br />

were included in the survey. Twenty-one hundred surveys were collected and<br />

analyzed.<br />

The survey results confirmed many facts and statistics that helped to describe<br />

current passengers at KCI. These results, summarized below, provide important<br />

information for the planning of the future New <strong>Terminal</strong>.<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

DRAFT<br />

80 percent travel from a local origin within the ASA<br />

62 percent are considered residents and 38 percent are visitors<br />

56 percent are male and 44 percent female<br />

The largest percentage were between 45 and 54 and the largest percentage<br />

of household income was between $50,000 and $99,999<br />

93 percent had a final destination in the U.S and seven percent had an<br />

international final destination<br />

56 percent were traveling for business and 42 percent were on leisure travel<br />

with more than half of leisure travelers visiting friends and family<br />

85 percent came in a private car or rental car and 63 percent of those in a<br />

private car (excluding rental cars) used one of the on- or off-airport parking<br />

lots with 42 percent using the KCI economy lot<br />

Almost two-thirds were on non-stop flights<br />

The majority of destinations on connecting flights were to Chicago, Denver,<br />

and Dallas<br />

42 percent used on-line check-in, 29 percent checked in with ticket agents,<br />

and 28 percent used E ticket kiosks<br />

Landrum & Brown Page 4<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

<br />

<br />

46 percent checked bags at the ticket counter, while 44 percent did not<br />

check any bags<br />

The average number of bags checked by each passenger was 0.6 bags<br />

Most passengers used highways I 29 and I-435<br />

<br />

<br />

Approximately 31 percent made a purchase at one of the food concessions<br />

and 11 percent made purchases from a retail store<br />

Average passenger dwell time in the terminals was approximately 1 hour<br />

40 minutes, although residents and business travelers allowed for less time<br />

due to familiarity and frequency of use<br />

Information from these surveys will be discussed throughout this document.<br />

1.3 Aviation Demand Forecast<br />

Comprehensive aviation demand forecasts were developed for KCI for the years<br />

2015, 2020, 2025, and 2030. Annual passenger enplanements, annual aircraft<br />

operations, and aircraft fleet mix have been projected, as well as aircraft and peak<br />

period activity projections. The aviation activity projections are a critical<br />

component in the facility planning process and serve as a basis for:<br />

• Determining the role of the Airport with respect to the type of aircraft to be<br />

accommodated in the future,<br />

• Evaluating the capacity of existing Airport facilities and its ability to<br />

accommodate projected aviation demand, and<br />

DRAFT<br />

• Estimating the development requirements of the future terminal, airside, and<br />

landside facilities.<br />

1.3.1 ENPLANED PASSENGERS<br />

Table 1.3-1, Summary of Enplaned Passenger Forecast, shows a summary<br />

projection of enplaned passengers through 2030. Total enplaned passengers are<br />

forecast to grow from 5.1 million enplanements in 2011 to 7.2 million by 2030,<br />

representing an average annual growth rate of 1.9 percent. Almost all of the traffic<br />

at KCI is expected to be originating (i.e. passenger trips beginning or ending at the<br />

Airport) with only limited connecting activity. The enplanement forecast is<br />

presented in Figure 1.3-1, Summary of Enplaned Passenger Forecast.<br />

Landrum & Brown Page 5<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

Table 1.3-1<br />

SUMMARY OF ENPLANED PASSENGER FORECAST<br />

Source:<br />

Landrum & Brown<br />

Figure 1.3-1<br />

SUMMARY OF ENPLANED PASSENGER FORECAST<br />

DRAFT<br />

Source:<br />

Landrum & Brown<br />

1.3.2 PASSENGER OPERATIONS<br />

Passenger aircraft operations were derived from the enplaned passenger forecast.<br />

The aggregate number of commercial passenger operations at an airport depends<br />

on three factors: total passengers, average aircraft size, and average load factor<br />

(percent of seats occupied).<br />

In order to develop reasonable load factor and aircraft gauge assumptions, the<br />

same categories of activity were used as in the enplaned passenger forecast<br />

(see Table 1.3-1 above). To derive the passenger operations forecast, assumptions<br />

Landrum & Brown Page 6<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

are inherently different at airports due to differences in how airlines choose to<br />

strategically serve the demand for air travel at each airport. At KCI, aircraft size,<br />

passenger load factors, and Average Seats per Departure (ASPD) were used.<br />

Airlines continually work to align capacity with demand. At KCI, average aircraft<br />

size reflects a mix of narrowbody and regional jet aircraft. Since 2007, average<br />

aircraft size has increased as Low Cost Carriers (LCCs) have continued to capture a<br />

larger share of the KCI market and network airlines have deployed a higher<br />

percentage of large regional jets. Enplaned passenger load factors have increased<br />

24 percent from 60 percent in 2000 to almost 75 percent in 2011 as airlines make<br />

better use of their aircraft assets.<br />

ASPD for each of the major groups of passenger activity was calculated from total<br />

departures and total departing seats. Aircraft load factors were calculated for each<br />

group of passenger operations by dividing total enplaned passengers by total<br />

departing seats. To calculate total operations, the total number of departures was<br />

multiplied by a factor of two. Figure 1.3-2, Historical Passenger Operations<br />

with ASPD, displays historical passenger operations and average seats per flight.<br />

Figure 1.3-2<br />

HISTORICAL PASSENGER OPERATIONS WITH ASPD<br />

DRAFT<br />

Source:<br />

Landrum & Brown<br />

Landrum & Brown Page 7<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

1.3.3 FLEET MIX<br />

As passenger traffic volumes increase at KCI, airlines will shift to larger, more<br />

efficient aircraft, where possible, to reduce unit costs and increase revenues.<br />

Significant fleet renewal is expected to occur over the forecast period. The average<br />

number of seats per flight is projected to increase from 104 seats in 2011 to<br />

114 seats by 2030. Enplaned load factors are projected to increase from<br />

75 percent in 2011 to 80 percent in 2012 and remain relatively constant thereafter.<br />

Narrowbody aircraft are expected to account for an increasing share of passenger<br />

flights as LCCs continue to increase market share at KCI. Legacy carriers will<br />

increasingly use large regional jets as a replacement for small regional jets. Fleet<br />

mix and load factor assumptions result in a 1.0 percent average annual growth rate<br />

for passenger flights at KCI over the forecast period. The change in projected fleet<br />

mix is represented in Figure 1.3-3, Aircraft Fleet Mix.<br />

Figure 1.3-3<br />

AIRCRAFT FLEET MIX<br />

DRAFT<br />

Source:<br />

Landrum & Brown<br />

1.3.4 AIR CARGO<br />

The cargo tonnage forecast is predicated on the assumption that changes to the air<br />

cargo industry and emerging trends for air cargo security will continue.<br />

Additionally, it is assumed that long-term economic growth in the Kansas City MSA<br />

and the broader U.S. economy will increase the demand for the shipment of goods<br />

and services over the forecast period. The air cargo tonnage forecast also reflects<br />

the current global economic outlook from the Boeing, Airbus, and FAA Aerospace<br />

forecasts.<br />

Landrum & Brown Page 8<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

Average annual growth of 2.2 percent per year was applied from 2011 to 2030,<br />

resulting in total KCI cargo volumes increasing to 130,817 metric tons in 2030.<br />

Figure 1.3-4, Cargo Tonnage Forecast Results, shows cargo forecast results.<br />

Figure 1.3-4<br />

CARGO TONNAGE FORECAST RESULTS<br />

Source:<br />

Landrum & Brown<br />

DRAFT<br />

In 2011, 86,001 cargo metric tons were handled at KCI. Integrated cargo carriers,<br />

FedEx and UPS, account for 89 percent of total air cargo handled at KCI. A shift to<br />

widebody aircraft such as the A300 and MD11 has occurred at KCI over the past<br />

five years as integrated carriers have shifted away from narrowbody B727 and DC9<br />

aircraft. Figure 1.3-5, 2011 Air Cargo Tonnage by Carrier, depicts the tonnage<br />

splits by carrier.<br />

Figure 1.3-5<br />

2011 AIR CARGO TONNAGE BY CARRIER<br />

Source:<br />

Landrum & Brown<br />

Landrum & Brown Page 9<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

1.3.5 AIRCRAFT OPERATIONS<br />

Aircraft operations are forecast to increase from 141,700 operations in 2011 to<br />

172,611 operations in 2030, which is an average growth of 1.0 percent per year as<br />

seen in Figure 1.3-6, Summary of Aircraft Operations Forecast. Commercial<br />

passenger operations are expected to grow 1.0 percent per year which will drive<br />

growth in aircraft operations at KCI. However, passenger enplanements are<br />

expected to grow 1.9 percent per year, reflecting an expected increase in average<br />

aircraft size and higher average load factors. The other four primary components<br />

of operations - all-cargo, non-commercial air taxi, general aviation, and military -<br />

are expected to experience positive activity growth at KCI over the forecast period.<br />

Figure 1.3-6<br />

SUMMARY OF AIRCRAFT OPERATIONS FORECAST<br />

Source: Landrum & Brown<br />

DRAFT<br />

Landrum & Brown Page 10<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

1.3.6 PEAK ACTIVITY FOR ENPLANEMENTS<br />

Airport traffic demand patterns are subject to seasonal, monthly, daily, and hourly<br />

variations. These variations result in peak periods when the greatest amount of<br />

demand is placed upon facilities required to accommodate passenger and aircraft<br />

movements. Peaking characteristics are critical in the assessment of existing<br />

facilities to determine the ability to accommodate forecast increases in passenger<br />

and operational activity throughout the study period. The objective of developing<br />

peak period forecasts is to provide facility designs that are not under-utilized nor<br />

over-crowded too often.<br />

Table 1.3-2, KCI Peak Period Enplanement Forecast, shows the peak month,<br />

design day, and peak hour ratios used to develop the peak period enplanement<br />

forecasts for KCI. July is the peak month for passenger enplanements at KCI,<br />

accounting for 9.8 percent of annual traffic. The flight schedule for Thursday,<br />

July 14, 2011 was identified as being representative of a typical day of the peak<br />

month activity and analyzed to determine the hourly peaking patterns at KCI.<br />

Departing seats were used as a proxy for enplanements. The flight schedule data<br />

suggested that the peak hour accounts for 11.3 percent of daily passenger<br />

enplanements. It was assumed that the monthly, daily, and peak hour factors<br />

would remain constant over the forecast period. As a result, peak hour<br />

enplanements are forecast to increase from 1,900 enplanements in 2011 to<br />

2,700 enplanements in 2030.<br />

Table 1.3-2<br />

KCI PEAK PERIOD ENPLANEMENT FORECAST<br />

DRAFT<br />

Source:<br />

Landrum & Brown<br />

1.3.7 PEAK ACTIVITY FOR OPERATIONS<br />

Like passenger traffic, the operations peak has historically occurred in July. Design<br />

day factors were developed to provide activity that represented a typical day in the<br />

peak month. For the passenger activity, Official Airline Guide (OAG) flight<br />

schedules were used to determine peak hour operations. For cargo, general<br />

aviation, air taxi, and military, radar data was used to determine design day and<br />

peak hour factors. Table 1.3-3, KCI Peak Period Aircraft Operations<br />

Forecast, presents the peak month, design day, and peak hour ratios used to<br />

develop the peak period aircraft operations forecast for each of the key operation<br />

segments at KCI: commercial passenger, air cargo, general aviation including noncommercial<br />

air taxi, and military.<br />

Landrum & Brown Page 11<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

Table 1.3-3<br />

KCI PEAK PERIOD AIRCRAFT OPERATIONS FORECAST<br />

DRAFT<br />

Source:<br />

Landrum & Brown<br />

Landrum & Brown Page 12<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

1.4 Benchmarking<br />

In order to better understand and identify the future needs of KCI, a Benchmarking<br />

<strong>Study</strong> was performed that compared the existing facilities at KCI to nine<br />

comparable domestic airports. The following airports were used for comparison in<br />

the study:<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Cincinnati / Northern Kentucky International Airport (CVG)<br />

Indianapolis International Airport (IND)<br />

San Jose International Airport (SJC)<br />

Memphis International Airport (MEM)<br />

Sacramento International Airport (SMF)<br />

Austin-Bergstrom International Airport (AUS)<br />

Cleveland Hopkins International Airport (CLE)<br />

Raleigh-Durham International Airport (RDU)<br />

Kansas City International Airport (KCI)<br />

Lambert – St. Louis International Airport (STL)<br />

The parameters compared in the study included:<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Million Annual Passengers (MAP)<br />

Number of gates<br />

Number of terminals<br />

Number of Security Screening Checkpoints (SSCP)<br />

<strong>Terminal</strong> square feet<br />

Concession square feet<br />

DRAFT<br />

Number of parking spaces, by type<br />

Figure 1.4-1, Existing Facilities At Comparable Domestic Airports,<br />

summarizes the data collected for each airport and used as the basis for the results<br />

from the Benchmarking <strong>Study</strong>. Also included in the table are images of the airfield<br />

layout and terminal layout at each airport. The results of the study were used to<br />

assist in the planning and design of the size and location of the New <strong>Terminal</strong> and<br />

associated facilities, such as on- and off-airport parking, gates, security, and<br />

concessions, to name a few.<br />

Landrum & Brown Page 13<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT PROGRAM CRITERIA DOCUMENT<br />

ADVANCE TERMINAL PLANNING STUDY DRAFT<br />

MAP Level 6.9 7.4 8.3 8.6 8.7 9.0 9.0 9.1 10.4 12.5<br />

Gates 36 40 28 79 32 25 62 45 66 88<br />

<strong>Terminal</strong>s 2 1 2 3 2 1 1 2 3 2<br />

Number of SSCP 2 2 2 3 3 3 3 2 13 3<br />

<strong>Terminal</strong> SQFT 2,000,000 1,200,000 1,050,000 1,300,000 740,000 600,000 1,073,357 550,000 1,100,000 1,500,000<br />

Concession SQFT 109,200 59,738 12,784 68,046 42,885 37,976 40,024 56,465 61,186 71,979<br />

Parking - Short/Economy/Valet 7,750 13,918 2,358 870 9,890 4,212 5,170 6,087 21,555 4,097<br />

Parking - Long 6,000 4,403 3,991 3,550 10,059 5,923 2,746 9,925 1,750 4,672<br />

Parking - Total 12,000 18,268 6,349 4,425 19,949 10,135 7,916 18,763 23,305 8,769<br />

Landrum & Brown Page 14<br />

April 2013<br />

Figure 1.4-1<br />

EXISTING FACILITIES AT COMPARABLE DOMESTIC AIRPORTS<br />

Totals<br />

Airport Name CVG IND SJC MEM SMF AUS CLE RDU KCI STL<br />

Airfield Layout<br />

DRAFT<br />

<strong>Terminal</strong> Layout<br />

Source: Landrum & Brown

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

2. AIRFIELD REQUIREMENTS<br />

The proposed New <strong>Terminal</strong> is to be constructed at the existing <strong>Terminal</strong> A location.<br />

This section includes discussions of the following:<br />

<br />

<br />

<br />

<br />

<br />

<br />

Design Aircraft<br />

Aircraft Gates and Passenger Loading Bridges<br />

Service Roads<br />

Airfield Security<br />

Aircraft Deicing<br />

Fueling<br />

2.1 Design Aircraft<br />

When planning changes and/or improvements to an airport, a “design aircraft” must<br />

be identified that represents the size of aircraft typically using the airport, based on<br />

information from the airport and the airlines that use the airport. There are three<br />

parameters used in the selection of a design aircraft at KCI that include: Aircraft<br />

Approach Category (AAC), Airplane Design Group (ADG), and Taxiway Design<br />

Group (TDG). AAC is used for airspace planning, and approach and departure<br />

paths. For apron, taxilane, and taxiway design, the ADG and TDG define the design<br />

parameters for horizontal and vertical alignments.<br />

AAC is based on a speed of 1.3 times the stall speed in the landing configuration at<br />

maximum gross landing weight. The categories are summarized in Table 2.1-1,<br />

Aircraft Approach Categories, as defined in 14 Code of Federal Regulations<br />

(CFR) Part 97.<br />

Table 2.1-1<br />

AIRCRAFT APPROACH CATEGORIES<br />

Category<br />

A<br />

B<br />

C<br />

D<br />

E<br />

Speed<br />

≤ 91 knots<br />

≥ 91 knots and ≤ 121 knots<br />

≥ 121 knots and ≤ 141 knots<br />

≥ 141 knots and ≤ 166 knots<br />

≥ 166 knots<br />

Source: FAA AC 5300-13A, Table 1-1<br />

DRAFT<br />

ADGs are based on wingspan and tail height that determine separation<br />

standards. Table 2.1-2, Airplane Design Groups (ADG), summarizes the<br />

dimensions for each classification of ADGs, as defined in FAA Advisory Circular (AC),<br />

150/5300-13A, Airport Design. Based on information from the Airport and airlines,<br />

the typical airplane using KCI is an ADG III. Therefore, the design aircraft used for<br />

planning at KCI is an ADG III. Table 2.1-3, Design Aircraft, describes aircraft<br />

types and the percentage used at KCI.<br />

Landrum & Brown Page 15<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

Table 2.1-2<br />

AIRPLANE DESIGN GROUPS (ADG)<br />

Group # Tail Height (ft) Wingspan (ft)<br />

I < 20ʹ < 49ʹ<br />

II 20ʹ - < 30ʹ 49ʹ - < 79ʹ<br />

III 30ʹ - < 45ʹ 79ʹ - < 118ʹ<br />

IV 45ʹ - < 60ʹ 118ʹ - < 171ʹ<br />

V 60ʹ - < 66ʹ 171ʹ - < 214ʹ<br />

VI 66ʹ - < 80ʹ 214ʹ - < 262ʹ<br />

Source: FAA Advisory Circular (AC), 150/5300-13A, Table 1.2.<br />

Table 2.1-3<br />

DESIGN AIRCRAFT<br />

DRAFT<br />

Aircraft Type ADG TDG Wingspan (ft) Length (ft) Percent of Operations<br />

Widebody<br />

B-767-400 IV 5<br />

170.3<br />

201.4<br />

>1%<br />

B787-8<br />

V 5<br />

197.3<br />

186.1<br />

Narrowbody<br />

58%<br />

B-7373-900ER III 3 117.5 138.2<br />

Large Regional<br />

CRJ-900 III<br />

81.5<br />

119.3<br />

29%<br />

Embraer 190 III<br />

94.3<br />

118.9<br />

Small Regional<br />

CRJ-200 II<br />

69.6<br />

87.8<br />

11%<br />

Embraer 145 II<br />

65.7<br />

98.0<br />

Source: HNTB<br />

TDGs are based on main gear width and cockpit-to-main gear distance, and<br />

determine taxiway width and fillet design (See Figure 2.1-1, Taxiway Design<br />

Groups). Although wingspan typically determines taxiway/taxilane to<br />

taxiway/taxilane separations, in some instances, the separation is determined by<br />

TDG due to turning requirements. At least one Taxiway route should meet the<br />

requirements of the most demanding TDG, not only to the design aircraft TDG<br />

requirements.<br />

Landrum & Brown Page 16<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

Figure 2.1-1<br />

TAXIWAY DESIGN GROUPS<br />

Source:<br />

FAA AC 150/5300-13A<br />

2.2 Aircraft Gates and Loading Bridge Requirements<br />

2.2.1 METHODOLOGY<br />

One of the most reliable methodologies for projecting the number of aircraft<br />

parking positions at a terminal facility involves analyzing the projected peak hour<br />

aircraft operations in the form of an aircraft ramp chart. The ramp chart attempts<br />

to optimally schedule aircraft operations at all available terminal gate parking<br />

positions or at a Remain Overnight (RON) parking positions. The ramp chart<br />

methodology assumes an average ground occupancy time at the gate for the<br />

various types of aircraft to be serviced combined with a minimum time between<br />

when that aircraft leaves and when another aircraft can arrive at the same aircraft<br />

parking position. This methodology assumes that the airlines will attempt to<br />

maximize aircraft turns during its peak periods of operations within these base<br />

parameters of aircraft servicing times and a reasonable time allowance between<br />

turns referred inter gate time<br />

DRAFT<br />

The Ramp Chart relies heavily on the future flight schedules that are based on the<br />

existing July 14, 2011 flight schedule. The future flight schedules for 2025 and<br />

2030 are developed by growing the existing arrival and departure patterns of<br />

aircraft flights taking into account their seat capacities based on the future aircraft<br />

fleet mix needed to reach the future passenger and aircraft operation volumes.<br />

The peak hour aircraft operations used in preparing the ramp chart are shown in<br />

Section 1.3.7, Peak Activity for Operations; Table 1.3-3, KCI Peak Period Aircraft<br />

Operations Forecast; and the peak month, average day, and peak hour passengers<br />

are provided in Table 1.3-2, KCI Peak Period Enplanement Forecast.<br />

Landrum & Brown Page 17<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

Aircraft ramp charts for the New <strong>Terminal</strong> were developed using the 2025 and 2030<br />

design day flight schedules. Ramp charts were used to determine the number and<br />

size of aircraft parking positions both at the terminal as a contact gate or as a<br />

remote aircraft stand. Contact gates are serviced by a passenger loading bridge<br />

that connects the aircraft to the terminal holdroom while a remote aircraft is<br />

serviced by a busing connection that moves passengers to and from the terminal<br />

holdroom.<br />

The facility requirements analysis in this <strong>Study</strong> focused on using a combination of<br />

Preferential and Common Use peak passenger levels for the gate requirements.<br />

Preferential Use refers to those portions of the terminal, concourse, aircraft loading<br />

bridges, aircraft parking positions, apron, etc., that a single airline has priority over<br />

other airline users. Conversely, Common Use refers to those same facilities of the<br />

terminal, concourses and apron that are not assigned by lease to a single airline,<br />

but are used in common by multiple airlines. These areas include common use<br />

ticket counters, gates, and associated support space not otherwise held under an<br />

exclusive or preferential airline lease agreement with the Airport.<br />

The specific use assumptions in the development of facility requirements for the<br />

KCI Airport were that the three primary market share airlines would be assumed to<br />

be preferential users and that all other airlines would be treated as common use<br />

carriers. It should be noted that if all airlines at KCI were assumed as common use<br />

carriers the holdroom and gate areas could be reduced as a result of a higher<br />

utilization factor associated with shared facilities.<br />

Other functional projections are determined their relationship to the number and<br />

type of aircraft or the number of gates/seats serving the terminal area.<br />

Standardization of aircraft utilization and apron requirements are developed by<br />

using the Narrowbody Equivalent Gate (NBEG) index. This index converts the gate<br />

requirements of diverse aircraft types, from commuter aircraft to new large aircraft,<br />

so that they are equivalent to the apron capacity of a narrowbody aircraft gate.<br />

The amount of space or linear frontage each aircraft requires is based on the<br />

maximum wingspan of aircraft in its respective Aircraft Design Group (ADG).<br />

Aircraft are classified according to FAA Taxiway Design Groups as shown in<br />

Table 2.2-1, Narrowbody Equivalent Gate (NBEG) Index.<br />

DRAFT<br />

Landrum & Brown Page 18<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

Table 2.2-1<br />

NARROWBODY EQUIVALENT GATE (NBEG) INDEX<br />

FAA TAXIWAY DESIGN<br />

GROUP<br />

MAXIMUM<br />

WINGSPAN<br />

TYPICAL AIRCRAFT<br />

NBEG<br />

INDEX<br />

I Small Commuter 49’ Cessna 0.4<br />

II Medium Commuter 79’ SF340/CRJ 0.7<br />

III<br />

Narrowbody/Large<br />

Commuter<br />

118’ A320/B737/MD-80/ATR 1.0<br />

IIIa B757 125’ B757 1.1<br />

IV Widebody 171’ DC-10/MD-11/B767 1.5<br />

V Jumbo 214’ B747/A330,340/B777/B787 1.9<br />

VI NLA 262’ A380 2.3<br />

Source:<br />

FAA AC 150/5300-13 and Hirsh & Associates<br />

Physical location and proximity to the gate are important factors to consider when<br />

estimating the spatial requirements of gate holdrooms. The available holdroom<br />

area needs to be in close proximity to the gate being used. There is an advantage<br />

to having a configuration that locates holdroom seating in an open and contiguous<br />

manner since it allows the potential overflow of one holdroom into the adjacent<br />

holdroom, particularly if the adjacent holdroom does not have passengers at that<br />

moment awaiting a near term aircraft departure. These factors were taken into<br />

consideration when evaluating the future KCI requirements. The majority of the<br />

future KCI aircraft fleet mix is envisioned as narrowbody aircraft, however, select<br />

aircraft contact positions have the flexibility to accommodate widebody aircraft.<br />

For these infrequent occurrences it is assumed that the additional holdroom seating<br />

capacity needed for these infrequent widebody operations will be accommodated<br />

with a shared holdroom philosophy and nearby food and beverage seating capacity.<br />

DRAFT<br />

2.2.2 CURRENT CONDITIONS<br />

Currently, KCI operates out of its three separate terminals. The original terminals<br />

opened in 1972 with the capability of 30 gate doors on each terminal for a total of<br />

90 loading positions. The signage at the gates still reflects this original numbering<br />

system from 1 through 90. In actuality, KCI is only using 30 gates today out of a<br />

total of 62 available gates from all three terminals. There are 66 aircraft parking<br />

positions in total immediately adjacent to the three terminals but four of these<br />

positions are loaded from ground level. KCI has one international gate located at<br />

<strong>Terminal</strong> C. Narrowbody aircraft were 56 percent of passenger operations in 2012<br />

with less than one percent B757s, and the remaining 43 percent regional jets.<br />

The use of multiple terminals has become inefficient due to the number of unused<br />

gates (32 gates).<br />

Holdroom space within the KCI terminals is limited in size due to narrow overall<br />

depth of all three terminals at roughly 75 feet. The narrow depth comes from the<br />

original narrow curvilinear design of the Drive-to-Gate concept which attempted to<br />

minimize the walking distances between the vehicle curb and the gates.<br />

Landrum & Brown Page 19<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

This original design did not anticipate the need for passenger and hand luggage<br />

security screening. Today’s retrofit of the terminals now divides this limited 75 feet<br />

into separate non-secure landside and secure airside operations. In order to<br />

minimize the number of Transportation Security Administration’s (TSA) mandated<br />

Security Screen Checkpoints (SSCP), holdrooms were grouped together in small<br />

clusters and then each cluster was equipped with its own SSCP. This retrofit is<br />

cumbersome for several reasons:<br />

<br />

<br />

Separate secured holdroom clusters still generate the need for 14 SSCPs.<br />

Passengers are required to pass back through the SSCP after leaving the<br />

holdroom cluster.<br />

Due to the limited space in the holdroom clusters, the retrofitted<br />

configuration trades off holdroom space for secure restrooms and limited<br />

concessions.<br />

This tradeoff results in inadequate holdroom space, severely limited restroom<br />

facilities, and substandard concession offering inside the cluster resulting in a<br />

low LOS for passengers and a restricted ability to generate concession<br />

revenues for the Airport.<br />

2.2.3 FUTURE AIRCRAFT PARKING POSITIONS<br />

Domestic Service Requirements<br />

Based on the 2030 forecast, 41 contact gate aircraft parking positions are needed<br />

to accommodate the anticipated peak hour operations demands. For 2025, a total<br />

of 37 contact gate parking positions are needed. The future fleet mix envisioned<br />

for 2030 is not anticipated to vary significantly from the 2013 fleet which is<br />

dominated by narrowbody and smaller wingspan aircraft which was over 99 percent<br />

in 2012. As a consequence, all aircraft parking positions are planned to<br />

accommodate a minimum of an ADG III aircraft to allow for gate use flexibility.<br />

The maximum ADG III aircraft (B737-800/900 aircraft with a wingspan of 117 feet<br />

5 inches) was assumed for gate planning along with an associated wingtip clearance<br />

of 25 feet.<br />

DRAFT<br />

International Service Requirements<br />

The exception to having all narrowbody contact gates at KCI is the international<br />

arrivals capable gates. In the New <strong>Terminal</strong>, four gates will provide access to a<br />

sterile corridor leading to the Customs and Border Protection facilities. These four<br />

international-arrivals capable contact gates will be configured with multiple doors to<br />

allow for a “swing” capability between either a domestic or international operation.<br />

Two of these gate positions will also be configured to allow as large as an ADG V<br />

aircraft (B787-800) and will be paired with adjacent narrowbody aircraft positions<br />

to form a Multi-Aircraft Ramp System (MARS) gate. This will allow two narrowbody<br />

aircraft parking positions to accommodate a single widebody aircraft in the same<br />

apron location. Providing “swing” gates provides the Airport with a facility that can<br />

grow international air service to the passenger capacity of four simultaneous<br />

narrowbody aircraft or two widebody aircraft. The Federal Inspection Services (FIS)<br />

facilities were sized in relationship to this theoretical demand.<br />

Landrum & Brown Page 20<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

Remain Overnight (RON) Requirements<br />

Based on the 2030 forecast, 31 RON aircraft parking positions will be needed to<br />

stage access to the 41 contact gates at the New <strong>Terminal</strong> during the morning peak.<br />

For 2025 the number of RONs drops to 28. RON operations will require aircraft<br />

movement to an open contact gate for passenger loading and unloading<br />

Summary of Future Aircraft Parking Positions<br />

As shown in Table 2.2-2, Summary of Future Aircraft Parking Positions, a<br />

total of 41 contact gates and 31 RON aircraft parking positions will be necessary at<br />

KCI to handle the forecast 14 Million Annual Passengers (MAP) in 2030. All contact<br />

gates need to be capable of handling the majority of narrowbody aircraft types<br />

designated by the 2030 forecast in order to maximize flexibility of a common use<br />

operation. In 2025 a total of 37 contact gate parking positions and 28 RON parking<br />

positions are needed. Four out of the initial 37 gates will need to be capable of<br />

accommodating international operations. The passenger loading bridges on these<br />

four international-capable aircraft parking positions will also be configured to allow<br />

two of the gates to be used by a potential ADG V aircraft, the largest of which is<br />

anticipated to be a B787-800 aircraft.<br />

Table 2.2-2<br />

SUMMARY OF FUTURE AIRCRAFT PARKING POSITIONS<br />

Aircraft Parking Positions<br />

Forecast Year<br />

2025 2030<br />

<strong>Terminal</strong> Contact Gates 37 41<br />

Remote Overnight Stands (RONs) 28 31<br />

Source:<br />

Landrum & Brown<br />

DRAFT<br />

2.2.4 PASSENGER LOADING BRIDGE REQUIREMENTS<br />

The pathway to and from the contact gate door to the parked aircraft must meet<br />

Americans with Disabilities Act (ADA) requirements. This means that any fixed<br />

section and the passenger loading bridge at any of the contact gate positions may<br />

not exceed a 1-in-12 (8.33 percent) slope along its pathway. With ADG III aircraft<br />

(B737s) and smaller as the predominant aircraft through 2030, a finished floor<br />

height for gates of approximately 13 feet 6 inches above the apron has been<br />

assumed in order to minimize the length of the loading bridge required to reach the<br />

lowest and highest door sill height of the primary passenger loading of the aircraft<br />

types serving the Airport. Door sill heights for forecast aircraft range from five feet<br />

(CRJ-200) to 15 feet 2 inches (B787-800). Currently, used Jetbridge models,<br />

predominantly the A3-58/110, would be able to accommodate these sill heights<br />

with a maximum extension of 102 feet. Currently, 30 contact gates are used but<br />

by 2025 37 gates will be required and 41 contact gates are projected for 2030, all<br />

of which will require passenger loading bridges. Currently, there are no bussing<br />

operations to remote aircraft parking positions for commercial passenger operations<br />

and none are anticipated over the forecast horizon.<br />

Landrum & Brown Page 21<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

2.3 Apron Service Road<br />

Designated service roads are provided on or near aprons to restrict service vehicle<br />

movements to a confined area(s) where the pilot is familiar with seeing vehicle<br />

activity. Proper layout of service roads on an airfield contributes to airport safety<br />

and the reduction in runway incursions.<br />

Factors to consider when designing service roads include items such as<br />

current/future vehicle and ground-service equipment movement, space, bearing<br />

strength, height clearance, separation standards from runways/taxiways, and<br />

access. The width of service roads depends on the projected traffic levels, and the<br />

widest equipment expected to use the service road, etc.<br />

A proposed service road, for vehicles permitted to operate within the terminal area<br />

such as ground support equipment and other vehicles, will be located behind the<br />

aircraft parking positions and outside the taxilane object free areas 1 for access to<br />

aircraft. The service road should be designed to avoid crossing runways and<br />

taxiways/taxilanes to the extent possible. However, when a crossing is necessary,<br />

proper marking must be in place to ensure vehicles stop or yield to aircraft.<br />

2.4 Airside Security Requirements<br />

Airfield security will be maintained throughout the construction of the New <strong>Terminal</strong><br />

and continue when the new facilities are in operation. Security screening of<br />

construction personnel to meet FAA, Department of Homeland Security (DHS), and<br />

KCAD requirements will continue to be implemented. KCAD will develop a staffing<br />

plan to support the increased security screening of construction personnel for the<br />

program.<br />

DRAFT<br />

Where possible, facilities that require separate landside and airside access should<br />

be constructed along the Airport perimeter fence line to reduce unnecessary access<br />

to the airfield and potential security breaches. Temporary security fencing can be<br />

installed around the proposed terminal construction area during construction<br />

outside the AOA. Maximizing the amount of construction outside the AOA would<br />

result in an additional benefit: more personnel eligible to perform construction.<br />

Permanent AOA security fence and gates will be composed of chain link fence<br />

materials with barbed wire overguard to meet FAA and KCAD requirements. Chain<br />

link fences will be a minimum of eight feet tall with a three-strand barbed wire<br />

overguard. Any fence and gate modifications will interface with the Airport’s<br />

existing access control and monitoring system.<br />

1<br />

A two dimensional ground area surrounding taxiways and taxilanes which is clear of objects except<br />

for Navigation Aids (NAVAIDs) and objects whose location is fixed by function.<br />

Landrum & Brown Page 22<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

2.5 Aircraft Deicing<br />

Currently at KCI, aircraft are pushed back from the gate to deice. The glycol<br />

contaminated runoff is collected in trench drains along the perimeter of each<br />

terminal apron. Based on the apron pavement grades, the trench drains collect<br />

runoff from a significant portion of the apron as well as the gate deicing areas.<br />

Collection from a large area dilutes the concentration of the glycol-contaminated<br />

runoff and also increases the capacity need of the retention basins used for initial<br />

storage of glycol-contaminated runoff.<br />

KCI operates in accordance with the requirements of a National Pollutant Discharge<br />

Elimination System (NPDES) permit issued by the Missouri Department of Natural<br />

Resources (MDNR). The NPDES permit imposes controls intended to ensure that<br />

stormwater discharges at KCI meet applicable water quality standards. Conditions<br />

of the permit are implemented at the Airport through a Storm Water Pollution<br />

Prevention Plan (SWPPP). Under the terms of the permit, the Airport is responsible<br />

to the State of Missouri for all industrial and stormwater discharges originating on<br />

the property with the exception of the former American Airline Overhaul Base.<br />

KCAD is currently in negotiations with the MDNR regarding the outfall permit.<br />

The MDNR permit is a numerical limit-based permit focused on Biochemical Oxygen<br />

demand (BOD), Chemical Oxygen demand (COD), Total Suspended Solids (TSS),<br />

Oil and Grease (O/G), and Total Petroleum Hydrocarbons (TPH). Table 2.5-1,<br />

MDNR Operating Requirements, summarizes the current KCI MDNR Operating<br />

Permit.<br />

DRAFT<br />

In an effort to collect glycol-impacted stormwater during deicing operations at KCI,<br />

KCAD has installed an underground drainage system that directs<br />

glycol-contaminated runoff from the existing terminal aprons to a 2.4-million<br />

gallon, concrete lined retention basin. At this basin the glycol concentrations are<br />

measured to determine how the runoff should be discharged off of airport property.<br />

Landrum & Brown Page 23<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

Table 2.5-1<br />

MDNR OPERATING REQUIREMENTS<br />

Effluent Parameter<br />

Unit<br />

Final Effluent<br />

Limitations<br />

Daily<br />

Max.<br />

Monthly<br />

Average<br />

Monitoring Requirements<br />

Monitoring<br />

Frequency<br />

Sample<br />

Type<br />

Flow MGD * * once/month 24 hr. est.<br />

Precipitation Inches * * once/month 24 hr. est.<br />

BOD mg/L 45 30 once/month grab<br />

COD mg/L 120 90 once/month grab<br />

TSS mg/L 100 50 once/month grab<br />

TPH mg/L 15 10 once/month grab<br />

O/G mg/L 15 10 once/month grab<br />

pH-Units SU ** ** once/month grab<br />

Total BETX mg/L 0.75 0.75 once/month grab<br />

Benzene mg/L 0.07 0.07 once/month grab<br />

Methyl Tertiary Butyl<br />

Ether (MTBE)<br />

mg/L * * once/month grab<br />

Total Glycols mg/L * * once/month*** grab<br />

Ethylene Glycol mg/L * * once/month*** grab<br />

Propylene Glycol mg/L * * once/month*** grab<br />

Notes: * Monitoring Requirement Only<br />

** pH is measured in pH units and is not to be averaged.<br />

*** The pH is limited to the range of 6.0 9.0 pH units.<br />

Source: HNTB Corporation<br />

DRAFT<br />

Low concentrations of glycol are discharged into a pond east of the retention basins<br />

and ultimately into the Berlin Reservoir. At the north end of the reservoir, the<br />

overflow discharges into a tributary of Todd Creek. A monitoring station is located<br />

on the north end of the reservoir to measure compliance to KCI’s MDNR permit.<br />

Medium concentrations are gravity fed through a series of pipes to the Todd Creek<br />

wastewater treatment facility. Highly concentrated runoff is pumped from the<br />

retention basins into trucks and hauled directly to the Todd Creek wastewater<br />

treatment facility.<br />

The goal of the proposed aircraft deicing operations is to reduce the amount of<br />

surface area collecting glycol-contaminated runoff and increase the concentration of<br />

deicing fluids in the runoff. The higher concentrations will allow KCAD to develop a<br />

program that has one type of discharge method. Methods for achieving the goals<br />

are discussed in the following paragraphs.<br />

Landrum & Brown Page 24<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

2.5.1 CENTRALIZED DEICING OPERATIONS<br />

A centralized deicing facility is an aircraft deicing facility located at the terminal<br />

apron or along taxiways serving departure runways. Gate deicing operations will<br />

not be permitted at the New <strong>Terminal</strong> but centralized deicing locations will be<br />

utilized that will reduce the area to collect glycol-contaminated runoff.<br />

All centralized deicing facilities will meet the requirements of FAA Advisory Circular<br />

(AC) 150/5300-14B, Design of Aircraft Deicing Facilities.<br />

The design of deicing facilities should, to the extent practicable, meet the needs of<br />

air carriers, as outlined in FAA-approved aircraft ground deicing/anti-icing<br />

programs, and all other aviation community users. A key element in this effort is<br />

designing a facility that is efficient and offers users operational flexibility.<br />

Coordination of an airport owner’s Snow and Ice Control Plan and user’s ground<br />

deicing/anti-icing programs, with input from the FAA, will ensure that icing<br />

conditions affecting the safety of flight are better met.<br />

The forecasted peak hour of aircraft departures is from 06:05 to 07:05, with<br />

thirty-four departures. To determine the total number of deicing pads necessary to<br />

accommodate the peak hour traffic, it is necessary to understand the aircraft<br />

deicing process. Through discussions with aircraft deicing experts and analysis of<br />

deicing pad throughput at commercial service airports, it was determined that an<br />

average time for an aircraft to enter a deicing pad, complete the deicing process,<br />

and exit is 20 minutes.<br />

Based on the 20-minute deicing pad occupancy duration, three aircraft can be<br />

deiced per hour per pad. With a peak hour of thirty-four departures, twelve deicing<br />

pads will accommodate the peak hour. The proposed aircraft utilizing the deicing<br />

pads is summarized in Table 2.5-2, Projected Aircraft Fleet Mix, and the last<br />

column details the number of deicing pads required to accommodate each aircraft<br />

type.<br />

Table 2.5-2<br />

PROJECTED AIRCRAFT FLEET MIX<br />

Aircraft Type ADG Wingspan (ft) Length (ft)<br />

Wide Body<br />

B-767-400<br />

B787-8<br />

Narrow Body<br />

B-737-900ER<br />

Large Regional<br />

CRJ-900<br />

Embraer 190<br />

Small Regional<br />

CRJ-200<br />

Embraer 145<br />

DRAFT<br />

IV<br />

V<br />

170.3<br />

197.3<br />

201.4<br />

186.1<br />

Percent of<br />

Operations<br />

Necessary<br />

Deicing Pads<br />

>1% 1<br />

III 117.5 138.2 58% 8<br />

III<br />

III<br />

II<br />

II<br />

81.5<br />

94.3<br />

69.6<br />

65.7<br />

119.3<br />

118.9<br />

87.8<br />

98.0<br />

29% 3<br />

11% 1<br />

Source:<br />

HNTB Corporation<br />

Landrum & Brown Page 25<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

2.5.2 DEICING PAD SIZE REQUIREMENTS<br />

The size of an aircraft deicing pad is determined by the aircraft parking area and<br />

the maneuvering area for mobile deicing vehicles. The aircraft parking area is the<br />

inner area used for parking aircraft to receive deicing/anti-icing treatment.<br />

The width of the parking area equals the upper wingspan of the most demanding<br />

aircraft ADG using the deicing pad. The length of the parking area equals the<br />

fuselage length of the most demanding aircraft using the deicing pad.<br />

Widebody deicing pads will be sized based on the B787-8 aircraft dimensions.<br />

The 11 deicing pads to serve ADG III aircraft will be sized based on the B737-<br />

900ER aircraft. Deicing pads for the small regional jets (ADG II) will be sized based<br />

on the CRJ-200 aircraft.<br />

The Vehicle Maneuvering Area (VMA) for mobile deicing vehicles is the outer area<br />

that provides the “vehicle lane width” necessary for two or more mobile deicing<br />

vehicles to satisfactorily perform simultaneous, and complete left- and right-side<br />

uniform fluid distribution techniques for removing deposits of frost, ice, slush, and<br />

snow from aircraft surfaces and for anti-icing operations. The vehicle lane width<br />

must be 12.5 feet (3.8 m) and be mutually exclusive of any adjacent deicing pad.<br />

Adjacent deicing pads will be separated by a ten-foot wide vehicle safety zone<br />

(VSZ). A VSZ will also be located on the outboard edge of any outer deicing pad.<br />

Centralized deicing facilities will be located within the non-movement area in close<br />

proximity to the adjacent taxiway network. Deicing pads will be sized to<br />

accommodate the critical aircraft detailed previously. Table 2.5-3, Deicing Pad<br />

Dimensional <strong>Criteria</strong>, summarizes the deicing pad separation requirements<br />

defined in AC 150/5340-14A, Design of Aircraft Deicing Facilities.<br />

Table 2.5-3<br />

DEICING PAD DIMENSIONAL CRITERIA<br />

ADG<br />

DRAFT<br />

Outer Deicing Pads<br />

Taxi Centerline to Edge of Vehicle<br />

Safety Zone (VSZ)<br />

Interior Deicing Pads<br />

Taxi Centerline to Taxi Centerline<br />

V 138 ft. 286 ft.<br />

IV 112.5 ft. 235 ft.<br />

III 81 ft. 172 ft.<br />

II 57.5 ft. 125 ft.<br />

Source:<br />

FAA AC 150/5340-1B<br />

Aircraft deicing pads for off-gate facilities will have parallel taxiway centerlines to<br />

permit flow-through deicing operations. Separation criteria provided in Table 2.5-3<br />

takes into account the need for individual deicing pads to provide adequate wingtip<br />

clearance, sufficient maneuvering area around the aircraft to allow simultaneous<br />

treatment by two or more mobile deicing vehicles, and sufficient non-overlapping<br />

space for the VSZ between adjacent deicing pads and for outer deicing pads.<br />

Landrum & Brown Page 26<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

2.5.3 DEICING SUPPORT FACILITIES<br />

The proposed centralized deicing pad will require an efficient support network for<br />

chemical off-loading from transport vehicles and loading to deicing trucks.<br />

These facilities should provide close proximity to the centralized deicing pads to<br />

maintain efficient deicing operations. Described below are the required de-icing<br />

support facilities.<br />

Nighttime/Low-Visibility Lighting: All facilities will require permanent nighttime<br />

lighting structures or portable nighttime lighting systems are available so ground<br />

crews have the necessary illumination for deicing/anti-icing operations and<br />

pre-takeoff inspections during night or low-visibility conditions. One portable<br />

alternative is mobile deicing vehicles with modified lights that provide sufficient<br />

illumination for deicing/anti-icing treatments and pre-takeoff inspections during<br />

night or low visibility. AC 150/5360-13, <strong>Planning</strong> and Design Guidelines for Airport<br />

<strong>Terminal</strong> Facilities, Table 4-1, provides general lighting requirements for<br />

apron-related functions. The height of lighting poles must be in accordance with<br />

AC 150/5300-13, Object Clearing <strong>Criteria</strong>. Permanent nighttime lights should be<br />

aimed and shielded to avoid glare to pilots and the Air Traffic Control Tower (ATCT)<br />

line-of-sight without reducing the illumination of critical areas.<br />

Electronic Message Boards: The use of electronic message boards (EMBs) at<br />

off-gate deicing facilities by the service provider have increased the overall<br />

efficiency of deicing aircraft and improved the transfer of information between flight<br />

crews and service providers. In general, the primary purpose for installing EMBs is<br />

to: (1) reduce verbal communication between all involved parties; (2) provide<br />

flight crews with clear, concise information; (3) improve deicing pad operational<br />

safety and efficiency; and (4) reduce ground congestion by removing personnel and<br />

equipment from the deicing pad area after completing deicing/anti-icing operations.<br />

If EMBs are installed, they should be installed in accordance with SAE AS 5635,<br />

Message Boards (Deicing Facilities). The SAE aerospace standard defines the<br />

minimum content and appearance of the electronic display, functional capabilities,<br />

design requirements, and inspection and testing requirements for EMBs.<br />

One acceptable location for EMBs is within the VSZ.<br />

DRAFT<br />

Administrative Building: An administrative building is necessary to support the<br />

deicing operations that can include administrative areas, training rooms, and break<br />

areas for the deicing vehicle operators.<br />

Maintenance Building: A maintenance building is necessary for maintenance of the<br />

deicing vehicles that will include ample service bays. The building will also need to<br />

provide parking for the deicing vehicles.<br />

Loading Areas: A location for deicing vehicles to be loaded with glycol and water.<br />

Glycol Storage Tanks: Storage tanks are necessary to support the glycol loading<br />

and blending operations. The tanks need to be accessed from the landside to<br />

support delivery operations. To protect the performance characteristics of deicing<br />

fluids from degradation, storage tanks and fluid transfer systems installed at<br />

Landrum & Brown Page 27<br />

April 2013

KANSAS CITY INTERNATIONAL AIRPORT<br />

ADVANCE TERMINAL PLANNING STUDY<br />

PROGRAM CRITERIA DOCUMENT<br />

DRAFT<br />

deicing facilities must be designed in accordance with the fluid manufacturer’s<br />

recommendations. Fluid transfer systems must be dedicated to the specific fluid<br />

being handled to prevent the inadvertent mixing of fluids of different types or<br />

different manufactures.<br />

Access Road: A dedicated access road from the deicing pads to the truck loading<br />

area and maintenance building is necessary for the de-icing vehicle use.<br />

Employee Parking: An employee parking lot, outside the AOA fence, is needed for<br />

administration, maintenance, and deicing service operation employees.<br />

2.5.4 DEICING COLLECTION SYSTEM REQUIREMENTS<br />

Collection of glycol-contaminated runoff begins with reducing the application area of<br />

deicing fluids, grading the application area to collect the entirety of the deicing<br />

pad(s) runoff, and incorporating collection areas and pipe networks to convey the<br />

contaminated runoff to a retention facility for ultimate treatment or disposal.<br />

Pavement: The pavement must be either concrete or asphalt and designed for the<br />

aircraft fleet mix. The pavement should be grooved to assist in channeling deicing<br />

fluids for collection and to provide aircraft and personnel better traction.<br />

Apron grades and adjacent surface gradients are a maximum of one percent in<br />

accordance with AC 150/5300-13, Airport Design. Apron areas should direct flows<br />

away from deicing pad centerlines, fixed-fluid applicators, vehicle safety zones, and<br />

crew shelter. If interior covered drains are used, they must not create a hazard to<br />

aircraft and personnel.<br />

DRAFT<br />

The perimeter of the deicing pad must extend beyond the aircraft so no aircraft<br />

surface being deiced extends beyond the perimeter.<br />

Collection System: Diversion manholes will be installed within or immediately<br />

adjacent to the deicing pad, which will divert seasonal glycol runoff to the glycol<br />