Cummins Power Generation & the UK's new - Global Media ...

Cummins Power Generation & the UK's new - Global Media ...

Cummins Power Generation & the UK's new - Global Media ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

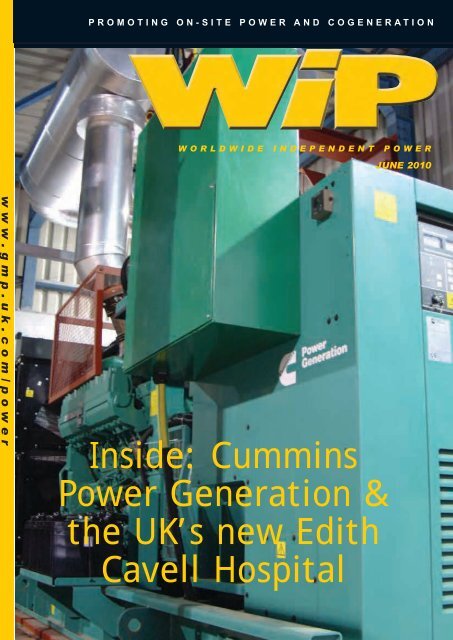

PROMOTING ON-SITE POWER AND COGENERATION<br />

WORLDWIDE INDEPENDENT POWER<br />

JUNE 2010<br />

www.gmp.uk.com/power<br />

Inside: <strong>Cummins</strong><br />

<strong>Power</strong> <strong>Generation</strong> &<br />

<strong>the</strong> UK’s <strong>new</strong> Edith<br />

Cavell Hospital

The Total Energy Solution Provider:<br />

- Feasibility Consultancy<br />

- Innovative Finance Options<br />

- Design & Construction<br />

- Full Turnkey Contracts<br />

- Project Management<br />

- Commissioning<br />

- Operation & Maintenance<br />

Proven Technical Solutions for:<br />

- Combined Heat and <strong>Power</strong><br />

-Trigeneration<br />

- Syn Gas - Gasification<br />

- Anaerobic Digestion<br />

- Bio Gas<br />

- Landfill Gas<br />

- Sewage Gas<br />

- Coal Mine Methane<br />

Gas Engine Modules from 100kW - 4000kW<br />

Sole Distributor in <strong>the</strong> UK & Ireland for<br />

Edina UK<br />

Unit 13 Rugby Park, Bletchley Road, Stockport SK4 3EF<br />

T: +44 (0) 161 432 8833 F: +44 (0) 161 975 1499<br />

E: sales@edinauk.com

Editor:<br />

Aidan Turnbull<br />

powereditorial@gmp.uk.com<br />

PROMOTING ON-SITE POWER AND COGENERATION<br />

WORLDWIDE INDEPENDENT POWER<br />

JUNE 2010<br />

Sales Director:<br />

Neb Saric<br />

nsaric@gmp.uk.com<br />

Publisher:<br />

Richard Teasdale<br />

rteasdale@gmp.uk.com<br />

Journal Assistant:<br />

Zoë Taylor<br />

ztaylor@gmp.uk.com<br />

Accounts Division:<br />

Linda Applin<br />

accounts@gmp.uk.com<br />

Far East Sales:<br />

C H Park,<br />

Far East Marketing Inc<br />

femchp@unitec.co.kr<br />

German/Danish/Swedish Sales:<br />

Mario Dobresko<br />

mdobresko@gmp.uk.com<br />

Russia Sales:<br />

Sergy Stanovkin<br />

stanovkin@dars.ru<br />

US Sales & Subscriptions:<br />

Alex Carter<br />

acarter@gmp.uk.com<br />

Asia-Pacific Correspondent:<br />

John Goss<br />

john.goss@ceejay.com.hk<br />

Contributors<br />

MAN Diesel, Rolls-Royce, GE Energy,<br />

DOOSAN, Siemens, <strong>Cummins</strong>, ABB,<br />

Doosan, Foster Wheeler AG, Alstom.<br />

Hitachi <strong>Power</strong> Europe, FG Wilson,<br />

HAASE Energietechnik, Eclipse<br />

Magnetic<br />

Published by:<br />

<strong>Global</strong> <strong>Media</strong> Publishing Ltd<br />

<strong>Global</strong> House, 13 Market Square,<br />

Horsham, West Sussex, RH12 1EU,<br />

UK. Tel: +44 (0)1403 220750<br />

Fax: +44 (0)1403 220751<br />

Website: www.gmp.uk.com<br />

© Worldwide Independent <strong>Power</strong><br />

(ISSN 1468-7100).<br />

Subscription price £120 (UK),<br />

£180 (overseas) per year.<br />

Please send address changes to<br />

Worldwide Independent <strong>Power</strong>,<br />

<strong>Global</strong> House, 13 Market Square,<br />

Horsham, RH12 1EU, UK.<br />

Printed by Manor Creative, UK<br />

In <strong>the</strong> next issue<br />

• Gas engines<br />

• Gas turbines<br />

• Hire & rental<br />

• Switchgear<br />

• Operations & Maintenance<br />

• Cabling<br />

• <strong>Power</strong> Projects<br />

• Windfarms & PV<br />

• Gen-sets<br />

GMP<br />

<strong>Global</strong> <strong>Media</strong> Publishing Ltd<br />

J U N E 2 0 1 0<br />

C O N T E N T S<br />

Diesel engines 14<br />

We feature <strong>the</strong> MAN Diesel & Turbo’s first upgraded 20-cylinder<br />

28/33D prototype gen-set engine which has just passed a<br />

series of tests at <strong>the</strong> company’s works in St. Nazaire, France.<br />

It has also won DNV type approval.<br />

Gas turbines 16<br />

Rolls-Royce has just launched its latest model from <strong>the</strong> RB211<br />

family: <strong>the</strong> H63, a 44MW engine designed to deliver at least<br />

30% more power, more efficiently than earlier models.<br />

HRSG 18<br />

DOOSAN’s HRSG Division - which specialises in manufacturing<br />

HRSG units to form <strong>the</strong> core components of any combined<br />

<strong>the</strong>rmal power plants - has completed 370 energy-recovery<br />

facilities worldwide.<br />

Gen-Sets 20<br />

For <strong>the</strong> <strong>new</strong> world-class Peterborough City Hospital, <strong>the</strong><br />

Peterborough and Stamford Hospitals NHS Foundation Trust<br />

ordered a stanby gen-set from <strong>Cummins</strong> <strong>Power</strong> <strong>Generation</strong>.<br />

<strong>Power</strong>plants 21<br />

Brofind SPA firmly believes that in <strong>the</strong>rmal treatments <strong>the</strong><br />

pollutant (VOC) can be used as <strong>the</strong> main source of energy used<br />

by <strong>the</strong> system to support <strong>the</strong> purification process.<br />

Boilers 22<br />

Hitachi <strong>Power</strong> Europe is working to bring a coal-based solution<br />

to South Africa’s energy shortfall. This year <strong>the</strong> company has<br />

established a boiler column at <strong>the</strong> Medupi site as a basis for a<br />

future 48,000MW utility plant.<br />

Controls for gen-sets 24<br />

WIP looks at FG Wilson’s <strong>new</strong> <strong>Power</strong>Wizard control panels.<br />

CHP 26<br />

We look at HAASE Energietechnik’s biogas plant with CHP.<br />

Filtration 28<br />

Eclipse Magnetic’s Filtramag is key to <strong>the</strong> Drax power plant.<br />

R E G U L A R S<br />

News/Sharewatch 6<br />

Contracts/Products 30<br />

www.gmp.uk.com/power<br />

Inside: <strong>Cummins</strong><br />

<strong>Power</strong> <strong>Generation</strong> &<br />

<strong>the</strong> UK’s <strong>new</strong> Edith<br />

Cavell Hospital<br />

Rolls-Royce is offering <strong>the</strong> <strong>new</strong> H63<br />

44MW engine [above]. See p16.<br />

Our power portfolio includes:<br />

W O R L D W I D E I N D E P E N D E N T P O W E R<br />

<strong>Cummins</strong><br />

<strong>Power</strong><br />

<strong>Generation</strong> &<br />

<strong>the</strong> UK’s <strong>new</strong><br />

Edith Cavell<br />

Hospital<br />

<strong>Cummins</strong> <strong>Power</strong> <strong>Generation</strong> matches <strong>the</strong> right<br />

generator set and transfer and control<br />

technologies to <strong>the</strong> client’s specific power<br />

needs: Standby emergency power, distributed<br />

power generation, prime power, waste to<br />

energy cogeneration - <strong>Cummins</strong> has <strong>the</strong><br />

solutions. [See page 20].<br />

Full report: Hitachi <strong>Power</strong> Europe<br />

plans a 48,000MW unit for SA. p22.<br />

Drax depends on oil filters. p28.<br />

M I D D L E E A S T P O W E R

Loss of Mains Protection<br />

ELECTRONIC CONTROL AND INSTRUMENTATION<br />

www.megacon.com<br />

Megacon's products for use in Loss of Mains or Mains<br />

Decoupling applications are built on <strong>the</strong> very latest digital<br />

designs and meet all <strong>the</strong> requirements of TWO stage tripping.<br />

All <strong>the</strong> technical requirements are covered: Check Sync,<br />

Reverse <strong>Power</strong>, Loss of Mains G59/1 & G59/2, Neutral Voltage<br />

Displacement, Phase Current Imbalance and Automatic<br />

Synchronisation.<br />

Each and every product is built on a digital design platform with<br />

ease of installation and simplicity of use at it's core.<br />

The KCG597/8 Loss of Mains Relay covers all <strong>the</strong> G59/1 & G59/2<br />

requirements for Volts, Frequency, ROCOF, Vector Shift and Phase<br />

Imbalance in one unit. It is programmed ei<strong>the</strong>r via a PC or a Hand<br />

Held Programmer. Once <strong>the</strong> chosen method of programming is<br />

finished and removed <strong>the</strong> unit is totally tamper proof and is a<br />

secure installation.<br />

Simpler it couldn't be - Megacon it is.<br />

MEGACON AS, NORWAY<br />

Tel: +47 5511 7510<br />

Fax: +47 5511 7530<br />

Email: megacon@megacon.com<br />

MEGACON AS, UNITED KINGDOM<br />

Tel: +44 (0) 1206 767655<br />

Fax: +44 (0) 1206 574345<br />

Email: tony.robinson@megacon.com<br />

www.megacon.com<br />

MEGACON AS, DENMARK<br />

Tel: +45 3542 6969<br />

Fax: +45 3542 6959<br />

Email: pns@megacon.com

EDITOR’S LETTER<br />

WELCOME<br />

A warm welcome to this month’s<br />

issue of Worldwide Independent<br />

<strong>Power</strong> - as always bringing you<br />

closer to <strong>the</strong> stories and issues<br />

affecting on-site power and<br />

cogeneration around <strong>the</strong> world.<br />

For editorial comments, please do<br />

not hesitate to contact <strong>the</strong> editor.<br />

BIENVENUE<br />

Soyez le bienvenu à cette issue de<br />

Worldwide Independent <strong>Power</strong>.<br />

Comme d'habitude, nous vous<br />

apportons toujours plus près des<br />

sujets qui affectent l'énergie et la<br />

co-generation sur place autour du<br />

monde.<br />

N'hésitez pas contacter le<br />

rédacteur pour des commentaires<br />

éditoriaux.<br />

WILLKOMMEN<br />

Herzlich Willkommen zur Ausgabe<br />

dieses Monates von Worldwide<br />

Independent <strong>Power</strong>. Wie immer<br />

bringen wir Sie näher heran an die<br />

Ereignisse und Geschichten der<br />

Stromerzeugungsindustrie rund um<br />

die Welt.<br />

Für redaktionelle Kommentare und<br />

Anregungen wenden Sie sich bitte<br />

an den Autor.<br />

BIENVENIDO<br />

Bienvenido a esta edición de<br />

Worldwide Independent <strong>Power</strong>.<br />

Como siempre, acercándolo a los<br />

temas que afectan a la energía y a<br />

la cogeneración in-situ. No dude<br />

en contactar con nuestro editor<br />

para cualquier cuestión editorial.<br />

BENVENUTI<br />

Benvenuti a questa nuova edizione<br />

di Worldwide Independent <strong>Power</strong>.<br />

Come sempre cercheremo di<br />

offrirvi storie e questioni<br />

riguardanti on-site power e<br />

cogeneration a livello globale. Per<br />

commenti editoriali, si prega di<br />

contattare l'editore.<br />

Aidan Turnbull<br />

- Editor<br />

Adisaster for <strong>the</strong> world is looming - and <strong>the</strong>re’s nothing we can do to prevent it. But isn’t that<br />

what <strong>the</strong>y said about <strong>the</strong> so-called ‘Millenium Bug’ back in 1999? Here’s <strong>the</strong> story.<br />

NASA’s scientists have been advising that in 2013 <strong>the</strong> Earth will suffer - from a greater to a lesser<br />

extent - from <strong>the</strong> effects of a magnetic energy storm produced by solar flares. It’s likely that Europe<br />

will face power brownouts and blackouts. National power grids could overheat and air travel is likely to<br />

be severely disrupted while essential electronic items - from navigation devices to major satellites -<br />

could stop working after <strong>the</strong> Sun reaches its maximum power in a few years.<br />

This super storm could hit like “a bolt of lightning” and may affect <strong>the</strong> world’s power generating<br />

sectors unless <strong>the</strong> proper precautions are taken, a NASA official warns.<br />

Dr Richard Fisher, <strong>the</strong> director of Nasa's Heliophysics division, a department of <strong>the</strong> Science Mission<br />

Directorate at Nasa headquarters in Washington DC, commented: “We know this period of intense solar<br />

activity is coming but we don’t know how bad it is going to be. It will disrupt communication devices<br />

such as satellites, air travel, <strong>the</strong> banking system, computers, everything that is electronic. It will cause<br />

major problems for <strong>the</strong> world. Large areas will be left without power and to repair that damage will be<br />

hard as it will take time.”<br />

Remote regions of <strong>the</strong> Earth, such as sub-Saharan Africa, could be deprived of power for several<br />

months before transmission systems can be rebuilt, predicts Dr Fisher. “Systems will just not work. The<br />

solar flares change <strong>the</strong> magnetic field on <strong>the</strong> earth - that will be rapid and like a lightning bolt. That is<br />

<strong>the</strong> solar affect.”<br />

Even in a ‘best-case’ scenario, he considers that substantial areas, including nor<strong>the</strong>rn Europe and<br />

Britain which have relatively fragile power grids, would be without electricity for hours, possibly even<br />

days. Dr Fisher has drawn parallels with preparations being made in a US hurricane season, where <strong>the</strong><br />

authorities k<strong>new</strong> a problem was imminent but did<br />

not know how serious it would be.<br />

“There will be a severe economic impact from<br />

this solar storm. We take it very seriously. The<br />

economic impact could be like a major hurricane<br />

or storm, only scaled-up in size.”<br />

In 2008 <strong>the</strong> US-based National Academy of<br />

Sciences first suggested that power grids could<br />

“be knocked out by intense solar activity”. It was<br />

said that a powerful solar storm could cause<br />

“twenty times more economic damage than<br />

Hurricane Katrina” - <strong>the</strong> 2005 storm which left a<br />

damage bill of more than US $125bn (£85bn).<br />

Creating more backup energy-generating systems<br />

for hospitals and power grids is <strong>the</strong> only practical<br />

answer, says Dr Fisher.<br />

“If you know that a hazard is coming and you<br />

have time enough to prepare and take<br />

precautions, <strong>the</strong>n you can avoid trouble,” he<br />

concluded.<br />

What a revelation. Thank you, Dr Fisher.<br />

Pic: HUBBLE faces all <strong>the</strong> ferocity of a 2013 solar<br />

storm. [Image - courtesy NASA]<br />

EUROPE ASIA-PACIFIC MIDDLE EAST<br />

W ORLDWIDE I NDEPENDENT P OWER • JUNE 2010<br />

5

NEWS<br />

In brief...<br />

GDF Suez consortium<br />

to develop $1.8bn<br />

Barka, Sohar power<br />

projects<br />

A consortium led by<br />

France's GDF Suez has<br />

won <strong>the</strong> right to build a<br />

pair of gas fired power<br />

projects at a combined<br />

estimated cost of $1.8bn.<br />

At roughly 744 MW<br />

apiece, <strong>the</strong> two schemes<br />

will rank among <strong>the</strong><br />

largest greenfield power<br />

projects to be developed<br />

in <strong>the</strong> Sultanate.<br />

GDF Suez led a field of<br />

three consortiums that<br />

were shortlisted in a<br />

keenly contested<br />

international competitive<br />

bid for <strong>the</strong> two<br />

Independent <strong>Power</strong><br />

Projects (IPPs), known as<br />

Barka III and Sohar II.<br />

Enel Green <strong>Power</strong>,<br />

Simest to build<br />

hydropower plant in<br />

Guatemala<br />

Italy's Enel Green <strong>Power</strong><br />

in association with<br />

Simest, <strong>the</strong> public-private<br />

company which promotes<br />

<strong>the</strong> development of<br />

Italian foreign enterprise,<br />

is to build an 84 MW runof-river<br />

hydropower plant<br />

in Guatemala.<br />

The project involves <strong>the</strong><br />

construction and<br />

operation of <strong>the</strong> Palo<br />

Viejo hydropower plant in<br />

<strong>the</strong> Department of<br />

Quiche.<br />

The 84 MW plant, which<br />

will rely on <strong>the</strong> natural<br />

water flow of <strong>the</strong> Cotzal<br />

river and its three tributaries,<br />

will cost €185m<br />

($226m).<br />

Massimo D'Aiuto, CEO of<br />

Simest, said:<br />

"The public venture<br />

capital fund, will total 6%<br />

with a financial<br />

commitment of €10m."<br />

Caledonia generator at Blanket Gold Mine<br />

Zimbabwe’s Blanket Gold Mine has<br />

just installed and commissioned <strong>the</strong><br />

first of several 2.5MVA diesel<br />

generators. Until recently, <strong>the</strong> mine<br />

relied exclusively on a Zimbabwe<br />

Electricity Supply Authority 33kV<br />

electricity supply to run all of its<br />

operations. However, average daily<br />

power outages at Blanket have<br />

increased from approximately 5 hours<br />

per day in February 2010 to over 9<br />

hours per day - <strong>the</strong> latter recorded in<br />

May 2010. The increased frequency<br />

of power loss, coupled with <strong>the</strong><br />

unpredictabilty and duration of<br />

power outages, has an adverse effect<br />

on gold production, and also on <strong>the</strong><br />

underground installations essential<br />

for <strong>the</strong> completion of <strong>the</strong> No. 4 Shaft<br />

Expansion Project. Caledonia has<br />

decided to accelerate Blanket's program to install<br />

sufficient diesel generating capacity to allow mining<br />

operations to continue at <strong>the</strong> current rate of<br />

production.<br />

The first standby generator allows <strong>the</strong> continuous<br />

operation of <strong>the</strong> Four Shaft Winders to operate<br />

without interruption during outages. Blanket plans<br />

to install additional generators after completion of<br />

<strong>the</strong> No. 4 Project.<br />

These additional generators will give Blanket<br />

sufficient standby generating capacity to maintain<br />

its target production of 40,000 ounces of gold per<br />

annum even if <strong>the</strong> current level of electricity<br />

outages continues.<br />

Bowman <strong>Power</strong>’s <strong>new</strong> turbogenerator award<br />

The UK-based Bowman <strong>Power</strong><br />

Group has won <strong>the</strong> 2010 European<br />

New Product Innovation Award<br />

from Frost & Sullivan.<br />

The award was for <strong>the</strong><br />

development of electrical turbogenerators<br />

which convert exhaust<br />

gases from engines into useful<br />

energy. Although developed<br />

primarily for <strong>the</strong> commercial<br />

P<br />

automotive sector, Bowman has<br />

also been working with several<br />

generator manufacturers and<br />

packagers in order to offer <strong>the</strong><br />

best efficiency through its<br />

products.<br />

In an industry which is<br />

challenged by emission and fuel<br />

consumption regulations, <strong>the</strong>re is<br />

constant need for innovative and<br />

affordable<br />

technologies to<br />

tackle toxic<br />

emissions, says<br />

Frost & Sullivan.<br />

It later added<br />

that <strong>the</strong><br />

efficiency of <strong>the</strong><br />

electrical turbogenerators<br />

from<br />

Bowman <strong>Power</strong><br />

is far higher<br />

than that of <strong>the</strong><br />

mechanical ones<br />

from its competitors.<br />

“While Bowman <strong>Power</strong>'s<br />

competitors have introduced<br />

mechanical turbocompounding<br />

that convert <strong>the</strong> exhaust gas into<br />

mechanical energy that is fed<br />

back to <strong>the</strong> crankshaft, <strong>the</strong><br />

exhaust heat recovery system<br />

from Bowman <strong>Power</strong> is unique in<br />

its ability to convert some of <strong>the</strong><br />

heat energy from exhaust gases<br />

into useful electrical energy,”<br />

says Frost & Sullivan Research<br />

Analyst, Arif Basheer.<br />

“Running <strong>the</strong> turbogenerator at<br />

controlled speeds, which is one of<br />

Bowman's pending patents,<br />

optimises <strong>the</strong> efficiency across a<br />

wider range of engine conditions<br />

and delivers significantly higher<br />

fuel efficiency. This is <strong>the</strong> key<br />

advantage it has over <strong>the</strong><br />

mechanical turbogenerators from<br />

its competitors.”<br />

6<br />

JUNE 2010 • WORLDWIDE I NDEPENDENT P OWER

<strong>Power</strong> Solutions for <strong>the</strong> UK and Ireland<br />

<strong>Cummins</strong> <strong>Power</strong> <strong>Generation</strong> offer <strong>the</strong> <strong>Power</strong>-of-One solution, by using its group partners for<br />

supply of engines, alternators, controls, exhaust filtration and switchgear achieving a proven<br />

design concept for improved performance and reliability.<br />

Our product range includes diesel powered generating sets and Generator-Drive (G-Drive)<br />

engines from 8kVA to 3325kVA single or three phase, low or medium voltage and into a wide<br />

range of application. In addition we offer a complete range of components, parts and service.<br />

<strong>Cummins</strong> UK provide comprehensive nationwide support on all generators across <strong>the</strong> UK<br />

and Ireland. This includes maintenance (scheduled and non-scheduled), general servicing<br />

(all makes and models of generator supported), 24 / 7 service and repair (contracted<br />

customers), parts and consumables, customer service contracts and <strong>new</strong> equipment sales.<br />

Our Projects Division offers a comprehensive service to customers from initial advice at <strong>the</strong><br />

feasibility and proposal stages, through to project handover and lifetime support. These include<br />

project management, site management, M & E design and installation, commissioning, logistics,<br />

preventative maintenance, repairs and refurbishments.<br />

For all enquiries please contact<br />

<strong>Cummins</strong> UK<br />

Tel: 08705 32 92 02<br />

Email: uk.powergen@cummins.com<br />

www.cummins-uk.com

NEWS<br />

In brief...<br />

Nexans wins €72.7m Gulf cable contract<br />

Incap and ABB sign a<br />

supply contract<br />

Incap Corporation and ABB<br />

Oy, Machines have signed a<br />

supply contract for <strong>the</strong><br />

manufacture of rotor<br />

components. According to<br />

<strong>the</strong> contract Incap will<br />

deliver ABB rotor<br />

components of electrical<br />

motors and generators,<br />

which are used in <strong>the</strong><br />

power generation and in<br />

re<strong>new</strong>able energy sectors.<br />

Dewey Electronics<br />

wins US$4.5m order<br />

for 2kW Tactical<br />

Generators<br />

The Dewey Electronics<br />

Corporation won a delivery<br />

order for its 2kW diesel<br />

operated Military Tactical<br />

Generators (MTG) worth<br />

US$4.5m.<br />

This order was made under<br />

<strong>the</strong> 10 year indefinitedelivery/indefinite<br />

quantity<br />

contract awarded in<br />

September 2001 by <strong>the</strong> U.S.<br />

Army, CECOM, Ft.<br />

Monmouth, NJ. Both <strong>the</strong><br />

AC and DC versions of <strong>the</strong><br />

generator are currently<br />

being shipped and supplies<br />

will continue for<br />

approximately one year.<br />

The 2kW diesel- operated<br />

MTG is used throughout <strong>the</strong><br />

US Department of Defense,<br />

with over 14,000 fielded by<br />

Dewey since 1996.<br />

Chile’s power project<br />

Chilean hydropower<br />

company, HydroChile, plans<br />

to invest US$8.7m (€7.2m)<br />

in a power transmission<br />

project in <strong>the</strong> O'Higgins<br />

region. The project includes<br />

<strong>the</strong> installation of a 110 kV<br />

line of 20.6 km (12.8<br />

miles), a 220 kV line of 150<br />

m (492 ft) and a power substation<br />

to connect<br />

HydroChile's future San<br />

Andres run-of-river power<br />

plant to <strong>the</strong> existing power<br />

transmission network.<br />

Nexans, a worldwide leader in <strong>the</strong><br />

cable industry, has been awarded<br />

a €72.7m contract by <strong>the</strong> Abu<br />

Dhabi Transmission and Despatch<br />

Company (TRANSCO) for a turnkey<br />

project to upgrade <strong>the</strong> high voltage<br />

underground power cable<br />

infrastructure in Abu Dhabi City,<br />

UAE. The project for TRANSCO, a<br />

Prysmian wins Borwin2 contract<br />

Prysmian, a worldwide leading<br />

player in <strong>the</strong> energy and telecomcables<br />

industry, has been awarded<br />

a major project worth €200m by<br />

<strong>the</strong> German transmission system<br />

operator transpower - a subsidiary<br />

of <strong>the</strong> Dutch grid operator TenneT.<br />

The contract is for <strong>the</strong> grid<br />

connection project BorWin2<br />

linking two offshore wind farms in<br />

<strong>the</strong> North Sea to mainland<br />

Germany. Prysmian will provide<br />

complete supply, installation and<br />

commissioning of <strong>the</strong> submarine<br />

and land cable connections as<br />

part of a larger contract worth<br />

more than half a billion Euros,<br />

awarded to <strong>the</strong> consortium<br />

between Prysmian and Siemens<br />

subsidiary of ADWEA (Abu Dhabi<br />

Water & Electricity Authority),<br />

will involve <strong>the</strong> design,<br />

manufacture, supply, installation<br />

and commissioning of 210 km of<br />

132 kV XLPE (cross linked<br />

polyethylene) underground power<br />

cables. Single-phase cables will<br />

have copper cross-sections of<br />

Energy. Siemens will deliver <strong>the</strong><br />

Voltage Sourced Converter (VSC)<br />

system, with an accordant<br />

capacity of 800 MW. The turnkey<br />

connection will link <strong>the</strong> Offshore<br />

Wind Parks Veja Mate and <strong>Global</strong><br />

Tech 1, located 125 km offshore,<br />

to <strong>the</strong> mainland with <strong>the</strong> purpose<br />

of transmitting wind generated<br />

re<strong>new</strong>able power into <strong>the</strong> German<br />

Grid. The project sets a number<br />

of milestones in <strong>the</strong> industry as it<br />

will be <strong>the</strong> first commercial ± 300<br />

kV DC cable project using<br />

extruded technology (highest<br />

direct current voltage level ever<br />

reached), and <strong>the</strong> first 800 MW<br />

connection to offshore wind<br />

parks.<br />

800, 1000 and 1200 mm2.<br />

"This latest contract for TRANSCO<br />

reinforces Nexans' position as a<br />

key supplier for high voltage<br />

power infrastructure projects in<br />

<strong>the</strong> Gulf region" says Dirk<br />

Steinbrink, Managing Director of<br />

Nexans Land High Voltage<br />

Business Group.<br />

"Our presence in Abu Dhabi goes<br />

back to <strong>the</strong> 1970s, and we have<br />

recently completed two major<br />

projects for ADWEA including a<br />

400 kV underground link and a<br />

132 kV submarine link to Delma<br />

Island".<br />

The TRANSCO cables will be<br />

manufactured at <strong>the</strong> Nexans<br />

facilities in Belgium and<br />

Switzerland and should be<br />

supplied and installed over an 18-<br />

month period, starting late 2010.<br />

DIARY DATES<br />

JULY<br />

* Heat Transfer 2010 - 11th<br />

International Conference, Tallinn,<br />

Estonia.<br />

Held on July 14th, 15th & 16th.<br />

* Hydrovision2010. Charlotte,<br />

NC, USA. July 26th-30th.<br />

AUGUST<br />

* 2nd International Conference<br />

on Oli Palm Biomass, Bangkok,<br />

Thailand. August 2nd & 3rd.<br />

* COAL-GEN 2010, Pittsburgh,<br />

USA. August 10th, 11th & 12th.<br />

SEPTEMBER<br />

* 25th Photovoltaic SOLAR<br />

ENERGY Conference & Exhibition,<br />

Valencia, Spain. September 6th -<br />

10th.<br />

* 21st World Energy Congress,<br />

WEC Montreal, Canada.<br />

September 12th - 16th.<br />

* 10th International Clean<br />

Energy Conference, Famagusta,<br />

Cyprus. September 15th-17th.<br />

OCTOBER<br />

* POWER-GEN Middle East on<br />

October 4-6, 2010, held in Doha,<br />

Qatar.<br />

* ENERGY INDIA, Mumbai, India.<br />

October 7th-9th.<br />

* EP CHINA, EPA, ECEPT CHINA,<br />

ELECTRICAL CHINA 2010 - Beijing,<br />

China. October 19th-21st.<br />

8<br />

JUNE 2010 • WORLDWIDE I NDEPENDENT P OWER

WORLDWIDE LOADBANK SPECIALISTS<br />

Crestchic loadbanks maximum power<br />

when you really need it<br />

■<br />

SALES ■ RENTAL ■<br />

When power generation is vital, when backup<br />

systems must be fully tested to make sure<br />

<strong>the</strong>y’re up to <strong>the</strong> job - you need a stable,<br />

continuous and variable power generation<br />

test to imitate real loads, in real time. You<br />

need a load test solution you can rely on.<br />

No o<strong>the</strong>r company specialises in worldwide<br />

load test solutions like Crestchic.<br />

Manufacturing loadbanks for sale and rental<br />

for over 20 years, we have delivered reliable<br />

and effective test solutions to all seven<br />

continents.<br />

Crestchic Tailor-made load test<br />

solutions from 30kW to 100MVA<br />

Why look anywhere else?<br />

For more information, contact us on<br />

(+44) 01283 531645<br />

Or find us on <strong>the</strong> Internet at www.crestchic.co.uk<br />

You can also email us: sales@crestchic.co.uk<br />

or hires@crestchic.co.uk

NEWS<br />

In brief...<br />

GMP Awards at IPE&EE/Electrex<br />

New Wind initiative<br />

for Europe<br />

As <strong>the</strong> Spanish EU<br />

Presidency launched <strong>the</strong><br />

'European Wind Initiative<br />

(EWI) - a €6 billion ten year<br />

research and development<br />

roadmap for <strong>the</strong> wind<br />

energy sector - <strong>the</strong><br />

European Wind Energy<br />

Association (EWEA) said<br />

that, if properly funded, it<br />

would give European<br />

companies a competitive<br />

boost.<br />

"The European Wind<br />

Initiative is a big step<br />

forward in our efforts to<br />

maintain and streng<strong>the</strong>n<br />

Europe's global leadership<br />

in wind energy technology,"<br />

Christian Kjaer, Chief<br />

Executive of <strong>the</strong> European<br />

Wind Energy Association<br />

(EWEA), told WIP.<br />

"The industry is ready to<br />

invest in accelerated R&D<br />

but <strong>the</strong> challenge is for <strong>the</strong><br />

European Commission to<br />

come up with a plan to<br />

ensure its contribution.<br />

O<strong>the</strong>r regions of <strong>the</strong> world<br />

are investing significantly<br />

more in public research<br />

than <strong>the</strong> EU and its Member<br />

States and it remains to be<br />

seen how <strong>the</strong> EU will make<br />

its contribution."<br />

Siemens to supply five<br />

gas turbine-generator<br />

packages<br />

Siemens Energy has been<br />

awarded contracts to<br />

supply a total of five stateof-<strong>the</strong>-art<br />

gas turbinegenerator<br />

packages for two<br />

combined cycle power<br />

plants in <strong>the</strong> USA. The<br />

purchaser of <strong>the</strong> equipment<br />

is Progress Energy<br />

Carolinas, Inc., a subsidiary<br />

of Progress Energy Inc. The<br />

<strong>new</strong> power plants will be<br />

replacing old coal-fired<br />

generation, resulting in an<br />

estimated 60% reduction in<br />

<strong>the</strong> facilities' CO2 emission<br />

rate, a 100% decrease in<br />

mercury emissions, and<br />

nearly 100% decrease in <strong>the</strong><br />

sulfur-dioxides emissions<br />

rate.<br />

This year’s IP&EE/Electrex Show<br />

atttracted more than 72<br />

exhibitors from 8 different<br />

nations to Birmingham’s NEC<br />

venue between June 8th & 10th.<br />

The three-day event brought in a<br />

mix of both national and<br />

international visitors. At <strong>the</strong><br />

official AMPS/ IP&EE Awards<br />

Dinner at <strong>the</strong> Hilton Metropole on<br />

June 9th, GMP’s publishers - Sales<br />

Directors, Richard Teasdale and<br />

Neb Saric - handed out <strong>the</strong><br />

official prizes. Winner of <strong>the</strong> Best<br />

Stand Award went to <strong>the</strong><br />

Cukurova Jenerator team [right]<br />

while <strong>the</strong> o<strong>the</strong>r awards were<br />

picked up by Crestchic, Deif and<br />

Wardpower, respectively.<br />

[Left to right] GMP’s<br />

Neb Saric, Roger<br />

Watterson of DEIF (UK)<br />

Ltd, and GMP Sales<br />

Director, Richard<br />

Teasdale.<br />

The Cukurova team.<br />

Pick a duck on <strong>the</strong><br />

spectacular<br />

Wardpower stand.<br />

10<br />

JUNE 2010 • WORLDWIDE I NDEPENDENT P OWER

NEWS<br />

Success for <strong>the</strong> IP&EE Conference at <strong>the</strong> NEC<br />

The head of <strong>the</strong> Claverton Think-Tank and<br />

<strong>the</strong> organiser of <strong>the</strong> IP&EE Conference, Dave<br />

Andrews, was upbeat about <strong>the</strong> strengths of<br />

<strong>the</strong> IP&EE Conference. He reports that a<br />

total of 28 speakers, leading energy<br />

professionals in <strong>the</strong>ir own right, delivered<br />

an average of 12 papers per day.<br />

“We were overwhelmed by <strong>the</strong> response and<br />

we had many packed Conference sessions.<br />

Delegates came from as far away as Africa<br />

to hear papers on a wide variety of power<br />

topics. Many contacts were made.”<br />

He said: “Ade Adekoya of Jemray Nigeria<br />

Ltd clinched a deal with Andrew Chinnery of<br />

UK-based Yellow <strong>Power</strong> Ltd for <strong>the</strong> supply of<br />

diesel & gas power generation systems at<br />

<strong>the</strong> Conference. So you can see this<br />

Conference was not simply an opportunity<br />

to learn about <strong>new</strong> techniques &<br />

technology, but formed a proper forum<br />

where business could be accomplished.”<br />

The 2010 Conference reflects <strong>the</strong> Claverton<br />

Energy Group’s growing status within<br />

Europe’s energy circle, serving as a link<br />

between practical end-users and cuttingedge<br />

<strong>new</strong> technology.<br />

According to Dave Andrews, <strong>the</strong> speakers<br />

were ‘uniformly excellent’. The most<br />

popular papers were those concerned with<br />

diesel generators and <strong>the</strong> National Grid, in<br />

particular one seminal paper from Mark<br />

Duffield. William Orchard’s presentation<br />

about gas engines & CHP also proved<br />

popular.<br />

Explosion prevention was a core topic in a<br />

technical paper presented by Tetyana<br />

Vynnyk of Sergi France. Her paper on<br />

Transformer Explosions demonstrated how<br />

such incidents can cripple power supply<br />

operations. Her paper outlined some of <strong>the</strong><br />

latest cutting-edge strategies and<br />

technology available to minimise <strong>the</strong> risk to<br />

industry.<br />

Illaria Peretti of Turboden also delivered a<br />

well-attended study focussing on <strong>the</strong> latest<br />

research involving <strong>the</strong> Organic Rankine<br />

Cycle and <strong>the</strong> use of small decentralised<br />

biomass plants.<br />

For any enquiries about <strong>the</strong> past Conference<br />

or speaker details please call Dave Andrews<br />

directly on Mobile number: +44 (0) 755 265<br />

9166 or via his direct line on Tel: +44 (0)<br />

1225 837978. To dowload <strong>the</strong> Conference<br />

Papers please click onto <strong>the</strong> Claverton<br />

website: www.claverton-energy.com<br />

Gas Turbine Plants<br />

205-590-3505<br />

sales@maegen.com<br />

• Over 100 MW of gas turbines • IN STOCK •<br />

• New & Used Solar Turbine units available<br />

• Complete turn key plants offered on a “Fast-Track” basis<br />

• 50 Hz or 60 Hz • Low NOx<br />

• Liquid fuel and Dual Fuel available<br />

W ORLDWIDE I NDEPENDENT P OWER • JUNE 2010<br />

11

SHAREWATCH<br />

Cuts &<br />

cautions<br />

It's a month now since an election<br />

precipitated <strong>the</strong> first coalition<br />

government in Britain since WWII, and<br />

<strong>the</strong> first ever Lib-Con alliance, reports<br />

Chris Hopkins.<br />

What’s <strong>the</strong> result so far? It's all been<br />

ra<strong>the</strong>r quiet on <strong>the</strong> economics front.<br />

Or at least it has been for Britain, sidelined<br />

as it is by uproar in <strong>the</strong> eurozone<br />

markets prompted by Greece's (and now<br />

perhaps Hungary) debt worries. These<br />

events have left <strong>the</strong> pre-election rhetoric<br />

over cuts and budget deficit seeming<br />

ra<strong>the</strong>r anti-climactic.<br />

All in all, <strong>the</strong> only real bad <strong>new</strong>s for <strong>the</strong><br />

coalition government, economically, has<br />

been <strong>the</strong> sudden and unfortunate<br />

departure of David Laws.<br />

The highly regarded Chief Secretary to<br />

<strong>the</strong> Treasury has been offloaded amidst a<br />

scandal about his expenses and attempts<br />

to keep his sexuality a secret.<br />

Apart from <strong>the</strong> obvious loss of a<br />

respected minister, <strong>the</strong> question remains<br />

about who will now prevent our <strong>new</strong> and<br />

most qualified chancellor George Osborne<br />

from spilling hot coffee over himself or<br />

attempting to nationalise cheese?<br />

We can only hope Law's replacement<br />

Danny Alexander can transfer <strong>the</strong> skills<br />

acquired dealing with his small children to<br />

managing precious Osborne's<br />

economic quirks.<br />

WIP<br />

Company<br />

(Currency)<br />

Monthly<br />

share price<br />

52 week<br />

high/low<br />

ABB (CHF) 19.81 15.92/<br />

24.08<br />

Ansaldo (EUR) 12.24 11.48/<br />

15.48<br />

Atlas Copco (SEK) 101.70 63.00/<br />

111.80<br />

Caterpillar (USD) 60.76 30.01/<br />

72.83<br />

Chloride (GBX) 278.50 128.75/<br />

308.40<br />

<strong>Cummins</strong> (USD) 67.98 30.55/<br />

76.95<br />

Doosan Heavy<br />

Industries (KRW)<br />

Foster Wheeler<br />

(USD)<br />

71800 54100/<br />

97000<br />

24.01 18.33/<br />

35.82<br />

Change over<br />

month<br />

Change<br />

over year<br />

Change since<br />

Jan. 2008<br />

-6.25% +13.33% -29.00%<br />

-12.94% +2.68% +41.67%<br />

-5.66% +51.79% +15.24%<br />

-11.90% +75.66% -15.33%<br />

-7.32% +77.39% +57.12%<br />

-7.90% +109.62% +44.82%<br />

-12.55% -1.91%<br />

-21.72% -8.36% -66.56%<br />

GE (USD) 16.35 10.50/ -13.72% +23.96% -54.78%<br />

John Deere (EUR) 1360 999.00/ +0.00% -9.33% +10.12%<br />

Kirloskar (INR) 175.20 350.00/<br />

973.75<br />

MAN (EUR) 69.78 40.22/<br />

73.90<br />

Mitsubishi (JPY) 2052 1552/<br />

2542<br />

MTU Detroit 44.39 22.17/<br />

48.79<br />

-79.90% -61.07%<br />

+4.46% +60.97% -14.62%<br />

-8.56% +14.06% -24.56%<br />

+8.55% +87.91% +32.11%<br />

Rolls-Royce (GBX) 589.50 316.00/ +2.34% +84.51% +21.23%<br />

631.50<br />

Siemens (EUR) 74.02 45.77/ +2.83% +40.83% -17.19%<br />

78.36<br />

Volvo Penta (SEK) 81.80 44.10/ -7.36% +70.42% -8.86%<br />

94.50<br />

Wärtsilä (EUR) 35.18 21.20/ -8.05% +39.00% -18.72%<br />

39.70<br />

Monthly figures taken at <strong>the</strong> end of May 2010<br />

Hans-Böckler-Str. 20 D-30851 Langenhagen Tel. +49(0)511-12 32 07-0 info@ehb-electronics.de www.ehb-electronics.de<br />

12<br />

JUNE 2010 • WORLDWIDE I NDEPENDENT P OWER

PERFORMANCE THAT MAKES IT’S MARK<br />

<br />

<br />

<br />

<br />

<br />

<br />

ENGINES FOR POWER GENERATION APPLICATIONS<br />

More<br />

control –<br />

less<br />

fuel<br />

– excellent l ent value<br />

Designed for<br />

base load<br />

applications<br />

and<br />

emergency<br />

power<br />

supply,<br />

<strong>the</strong><br />

<strong>new</strong><br />

AGC<br />

200<br />

ensures<br />

continuous<br />

optimised<br />

fuel consumption<br />

under<br />

<strong>the</strong><br />

harshest<br />

conditions.<br />

A cutting<br />

edge<br />

hardware<br />

platform, a<br />

fully integrated<br />

operating<br />

system<br />

and<br />

a<br />

number of<br />

o<strong>the</strong>r future-proof<br />

features will<br />

protect and<br />

control<br />

your<br />

gen-sets like<br />

no<br />

o<strong>the</strong>r power management system.<br />

Features:<br />

•<br />

-40°C minimum<br />

operating temperature<br />

e<br />

•<br />

Multi-language interfaces<br />

•<br />

16 gen-sets parallel<br />

in 10 seconds<br />

•<br />

Integrated e<strong>the</strong>rnet<br />

communication<br />

The DEIF Group – Head office in Denmark with subsidiaries in Germany,<br />

Norway,<br />

UK, France, China, USA, Brazil and India<br />

DEIF A/S<br />

· Frisenborgvej 33<br />

·<br />

DK-7800 Skive<br />

· Tel.: +45 9614 9614<br />

· Fax: +45 9614 9615<br />

· info@deif.com ·<br />

www.deif.com

DIESEL ENGINES<br />

New engine is most powerful and<br />

fuel-efficient in its class<br />

MAN Diesel & Turbo's first upgraded, twenty-cylinder 28/33D prototype gen-set engine<br />

has passed a series of tests at <strong>the</strong> company's St. Nazaire works, and has been awarded<br />

type approval by Det Norske Veritas (DNV) classification society.<br />

A<strong>new</strong> engine designed by MAN Disesel<br />

& Turbo as a gen-set for <strong>the</strong><br />

offshore industry has received a<br />

type approval which covers a rating of<br />

9,100 kW at 1,000 rpm for 100% MCR and<br />

an additional 10% overload capacity for<br />

one hour every six hours of 10,000 kW at<br />

1,032 rpm.<br />

The four-stroke, medium speed engine<br />

is, accordingly, <strong>the</strong> most powerful and<br />

fuel-efficient diesel engine in its class<br />

worldwide, says MAN Diesel.<br />

The V28/33D engine range has 12-, 16-<br />

and 20-cylinder configurations, a state-of<strong>the</strong>-art<br />

design featuring a high power<br />

density, and maintains full compliance<br />

with IMO-II and EPA Tier-II legislation.<br />

The 280-mm bore and 330-mm stroke<br />

engine with its simple, functional and<br />

compact design has a minimal number of<br />

components and is tailored for three main<br />

segments: as a genset for offshore<br />

applications; multiple propulsion<br />

The <strong>new</strong>, high-efficiency TCA33<br />

turbocharger, which has been<br />

especially tuned for <strong>the</strong> V28/33D<br />

engine.<br />

applications ; and an STC<br />

(sequential turbocharging)<br />

edition.<br />

The <strong>new</strong> engine is<br />

characterised by its<br />

‘perfectly balanced ratio<br />

between power and<br />

weight, high performance,<br />

shock resistance, quiet<br />

running and high reliability<br />

for maximised availability’,<br />

says MAN.<br />

With its ease of<br />

installation & maintenance,<br />

it is a textbook example of<br />

a diesel engine featuring<br />

low operation and lifecycle<br />

costs, claims <strong>the</strong><br />

manufacturer.<br />

Additional design features<br />

include <strong>the</strong> <strong>new</strong>, in-housedeveloped<br />

safety and<br />

control system - SaCoSone -<br />

and <strong>the</strong> <strong>new</strong>, highefficiency<br />

TCA33<br />

turbocharger, which has<br />

been especially tuned for<br />

<strong>the</strong> V28/33D engine.<br />

A higher pressure rate<br />

means <strong>the</strong> turbocharger can<br />

reach values of up to 500<br />

kW per cylinder.<br />

The challenge of meeting<br />

<strong>the</strong> <strong>new</strong>, IMO-II and EPA Tier-II emission<br />

regulations, while maintaining <strong>the</strong><br />

excellent fuel-consumption and minimal<br />

smoke-emission levels enjoyed by <strong>the</strong><br />

28/33D, has been overcome through <strong>the</strong><br />

development of an Emission Tier II<br />

package which includes:<br />

* An optimised injection system<br />

* An optimised combustion chamber<br />

* Miller cycling<br />

*A high-efficiency, charge-air cooler<br />

The 28/33D from MAN Diesel & Turbo - which<br />

has applications as an offshore gen-set -<br />

recently received a DNV type approval rating.<br />

The unit features <strong>the</strong> <strong>new</strong>, in-house-developed<br />

safety and control system - SaCoSone.<br />

* An improved NOx/SFC/soot trade-off<br />

* Simple customer connections (easy<br />

installation).<br />

Type approval from <strong>the</strong> remaining<br />

classification societies is planned for later<br />

this year and <strong>the</strong> first upgraded<br />

20V28/33D engines on order will be<br />

delivery in Autumn 2010.<br />

WIP<br />

Internet link<br />

www.mandieselturbo.com<br />

14<br />

JUNE 2010 • WORLDWIDE I NDEPENDENT P OWER

POWER<br />

to generate t e both<br />

current<br />

and d business.<br />

An emergency case in<br />

an operating <strong>the</strong>atre.<br />

A construction site in a remote area. A 747<br />

approaching <strong>the</strong> airport rt as <strong>the</strong> runway<br />

lights begin to flicker.<br />

Around <strong>the</strong> world, access to electrical<br />

power – prime or stand-by – is crucial.<br />

Regardless of <strong>the</strong> application, you are<br />

always looking for <strong>the</strong> same qualities in<br />

your genset engines – strong and reliable<br />

workhorses that require a minimum of<br />

service and maintenance.<br />

nce.<br />

Scania offers a wide<br />

range of engines<br />

covering power requirements rements up to 600<br />

kVA for prime power and 650 kVA for<br />

stand-by. Reliable power gensets, ready<br />

to produce electricity continuously, round<br />

<strong>the</strong> clock, 365 days a year.<br />

Read more at www.scania.com

GAS TURBINES<br />

Superior gas turbine offering fuel<br />

efficiency & operational flexibility<br />

Rolls-Royce has announced <strong>the</strong> launch of its latest model from <strong>the</strong> industrial RB211<br />

family, <strong>the</strong> H63, a 44MW engine designed to deliver at least 30% more power, more<br />

efficiently than earlier models, reports <strong>the</strong> company. WIP has <strong>the</strong> story.<br />

Developed and engineered using<br />

technology from Rolls-Royce’s aeroengines,<br />

<strong>the</strong> H63 will deliver<br />

significant operational and environmentalbenefits<br />

to customers.<br />

The H63 will provide operators with an<br />

additional 11MW of power, higher fuel<br />

efficiency and operational flexibility. The<br />

H63 will provide higher power and<br />

improved benefits to customers in both<br />

<strong>the</strong> electrical power generation and oil<br />

and gas industries and has <strong>the</strong> capability<br />

for fur<strong>the</strong>r improvements, including<br />

power growth of up to 13%, explains <strong>the</strong><br />

manufacturer.<br />

Steve Richards, Rolls-Royce, RB211<br />

Product Director, told WIP: “The RB211-<br />

H63 integrates <strong>the</strong> reliability & ruggedness<br />

of our current RB211 gas turbines<br />

with <strong>the</strong> proven technology from <strong>the</strong><br />

Group’s Trent aero engines to create <strong>the</strong><br />

next evolution in <strong>the</strong> industrial RB211 gas<br />

turbine family.”<br />

He comments: “By combining <strong>the</strong> best<br />

features from <strong>the</strong> RB211 and Trent<br />

engines we are able to deliver an engine<br />

designed for reliable operation, ease of<br />

maintenance and quick installation and at<br />

<strong>the</strong> same time provide increased levels of<br />

efficiency and power.”<br />

Rotatives in <strong>the</strong> RB-211-H63.<br />

Rolls-Royce now has The H63 - <strong>new</strong> from<br />

a wider range of high Rolls- Royce.<br />

efficiency gas turbines<br />

capable of fully<br />

meeting customers’<br />

operational requirements<br />

from peaking<br />

to base load power,<br />

reports <strong>the</strong> company.<br />

Versions of <strong>the</strong><br />

RB211 are available in<br />

a power range from<br />

29MW to a possible<br />

50MW. Industrial Trent<br />

models can also<br />

supply from 51MW to 64MW in simple<br />

cycle and up to 107MW in combined cycle,<br />

With <strong>the</strong> same footprint as <strong>the</strong> current<br />

RB211-GT61 and RB211-G62 models, <strong>the</strong><br />

<strong>new</strong> gas turbine, when operating with a<br />

Wet Low Emissions (WLE) combustion<br />

system, will be rated at 44MW at ISO<br />

conditions, an 11MW improvement. Using<br />

a Dry Low Emissions (DLE) system, <strong>the</strong><br />

rating will be 38MW.<br />

Combine this with a <strong>new</strong> high efficiency,<br />

high speed RT63 power turbine, and<br />

operators will benefit from a gas turbine<br />

with a simple cycle efficiency of 41.5 %,<br />

<strong>the</strong> best in <strong>the</strong> 35MW to 45MW power<br />

range.<br />

By introducing proven Trent<br />

aero technology, <strong>the</strong> H63 has<br />

<strong>the</strong> capability for fur<strong>the</strong>r<br />

improvements including<br />

power growth of up to 13%,<br />

says <strong>the</strong> company.<br />

The improved performance<br />

of this engine is made<br />

possible by <strong>the</strong> use of proven<br />

engineering from <strong>the</strong> RB211<br />

plus technology from <strong>the</strong><br />

Trent 60. This technology<br />

includes high-pressure turbine rotor<br />

blades [see above] and <strong>the</strong> intermediate<br />

compressor stators and rotors.<br />

For mechanical drive applications, Rolls-<br />

Royce is also developing a <strong>new</strong> high speed<br />

gas pipeline compressor with a maximum<br />

pressure of 3,220 psig.<br />

The RFBB-30 will be capable of housing<br />

up to five stages with an efficiency of 88%<br />

and will be matched to <strong>the</strong> <strong>new</strong> RT63<br />

power turbine.<br />

The <strong>new</strong> H63 gas turbine will achieve<br />

full load power in ten minutes from a cold<br />

start and will be capable of changing<br />

between liquid and gas fuels at all power<br />

levels without any interruption to load.<br />

Internet link<br />

www.rolls-royce.com<br />

WIP<br />

16<br />

W ORLDWIDE I NDEPENDENT P OWER • JUNE 2010

0 10<br />

ON<br />

We are a world leader in <strong>the</strong> design and<br />

manufacture of high technology cooling equipment<br />

for all types of diesel engine applications<br />

COVRAD offers a comprehensive range of reliable and high<br />

performance radiators to cool diesel engines with power outputs up<br />

to 10mw. These radiators will perform in adverse climatic conditions<br />

or hostile environments for extended periods.<br />

COVRAD offers a variety of standard or special heat transfer surfaces<br />

to meet <strong>the</strong>se conditions.<br />

COVRAD designs & manufactures high quality<br />

equipment which is individually optimised<br />

to match <strong>the</strong> application requirement.<br />

For fur<strong>the</strong>r<br />

information please<br />

contact our sales<br />

department at<br />

COVRAD<br />

HEAT TRANSFER LTD<br />

Sir Henry Parkes Road, Canley,<br />

Coventry, CV5 6BN, United Kingdom<br />

Tel: +44 (0) 24 7667 5544<br />

Fax:+44 (0) 24 7667 6029<br />

E-mail: sales@covrad.co.uk<br />

www.covrad.co.uk<br />

Diesel - Gas Generators<br />

<strong>Power</strong> Plants up to 120MWe<br />

FlexGen for Efficient Cogeneration<br />

C/B Control<br />

GRID<br />

Island / Grid Parallel Mode<br />

Master Freq & Volt Control<br />

The SELCO FlexGen is a range of genset controllers.<br />

It offers extended flexibility making it<br />

an optimum choice in numerous applications<br />

within power generation. E.g. where diesel<br />

generators are used for grid stabilisation in<br />

wind/solar farms.<br />

Select between <strong>the</strong> models; Basic, Compact<br />

and Advanced. Each offering different levels<br />

of functionality, thus ensuring an optimum<br />

match to specific user requirements.<br />

23 1 4<br />

Paralleling<br />

Scheme<br />

Selector<br />

C/B Control<br />

C/B Control<br />

Busbar<br />

FlexGen is well suitable for use in:<br />

- Back-up power systems<br />

- Island mode applications<br />

- Co-generation applications, including peak<br />

shaving or base load operation<br />

POWER REF. UNIT<br />

B9300<br />

<strong>Power</strong><br />

Distribution<br />

(Generators / Grid)<br />

G1<br />

G2<br />

Load Balance Lines<br />

FlexGen User Interface<br />

www.selco.com<br />

Phone: +45 70 26 11 22<br />

e-mail: selco@selco.com<br />

om

HRSG<br />

HRSG: cutting edge technology &<br />

high-calibre production facilities<br />

A total of 370 energy recovery plants situated around <strong>the</strong> world have been installed by<br />

DOOSAN’s HRSG Division which specialises in manufacturing HRSG units to form<br />

<strong>the</strong> core components of any combined <strong>the</strong>rmal power plant, WIP reports.<br />

Established in 1962, Doosan Heavy<br />

Industries & Construction Co.,<br />

Ltd.(DOOSAN) has played major<br />

roles in <strong>the</strong> development of Korea’s power<br />

Plant business with <strong>the</strong> cutting edge<br />

technology and high-calibre production<br />

facilities.<br />

Not many people realise DOOSAN also<br />

has extensive experience in supplying<br />

HRSG. The company has its own HRSG<br />

centres in Korea and Vietnam with a<br />

production capacity over 40 units per<br />

year.<br />

The company has also received 13<br />

Certificates of Authorisation from <strong>the</strong><br />

ASME, allowing <strong>the</strong> company to use <strong>the</strong><br />

ASME Code stamp for components and was<br />

awarded ISO 9000 series and ISO 14000<br />

certifications for all its power plants<br />

components including, HRSG.<br />

DOOSAN’s HRSG Division specialises in<br />

manufacturing HRSG to form one of <strong>the</strong><br />

core components of a combined <strong>the</strong>rmal<br />

power plant. It manufactures<br />

corresponding boilers for its national<br />

combined <strong>the</strong>rmal power plants in places<br />

such as Boryeong, Busan, and also supplies<br />

various power plants in Europe, Asia and<br />

even Africa.<br />

Energy recovery heat exchangers like<br />

<strong>the</strong>se are designed to recovers heat from<br />

a hot gas stream. An HRSG unit produces<br />

steam which can be used in a process or<br />

used to drive a steam turbine.<br />

A common application for an HRSG is in<br />

a combined-cycle power station, where<br />

hot exhaust from a gas turbine is fed to<br />

an HRSG to generate steam which in turn<br />

drives a steam turbine. This combination<br />

produces electricity more efficiently than<br />

ei<strong>the</strong>r <strong>the</strong> gas turbine or steam turbine<br />

alone.<br />

Ano<strong>the</strong>r application for an HRSG is in<br />

diesel engine combined cycle power<br />

plants, where hot exhaust from a diesel<br />

engine, as primary source of energy, is fed<br />

to an HRSG to generate steam which, in<br />

turn, drives a steam turbine.<br />

The HRSG is also an important<br />

component in cogeneration plants. All<br />

cogeneration plants typically have a higher<br />

overall efficiency in comparison to a<br />

combined cycle plant. This is due to <strong>the</strong><br />

loss of energy associated with <strong>the</strong> steam<br />

turbine.<br />

DOOSAN’s most famous HRSGs include<br />

<strong>the</strong> Peterhead Combined Cycle Plant in<br />

<strong>the</strong> UK, EPM La Sierra in Colombia, Al<br />

Ezzel CCP in Bahrain and LG Bugok II in<br />

Korea. At each location, <strong>the</strong> plant<br />

consists of three major components.<br />

These are <strong>the</strong> Evaporator, Superheater,<br />

and Economiser. DOOSAN puts <strong>the</strong><br />

different components toge<strong>the</strong>r to meet<br />

<strong>the</strong> particular operating requirements of<br />

<strong>the</strong> unit in a particular country.<br />

The company has so far supplied around<br />

370 units of HRSG for combined cycle<br />

power plants around <strong>the</strong> globe.<br />

WIP<br />

Internet link<br />

www.doosan.com<br />

18<br />

JUNE 2010 • WORLDWIDE I NDEPENDENT P OWER

Wyman Gordon Pipe and Fittings is proud to announce its equity<br />

ownership in Chengde Steel Tube Company in Jiangsu Province,<br />

PRC. With its dominant position in <strong>the</strong> Chinese power market,<br />

Chengde is a leading seamless steel pipe manufacturer,<br />

complimenting WG extruded pipe capabilities.<br />

With facilities in Europe, North America and Asia, Wyman Gordon<br />

now offers global pipe manufacturing solutions for <strong>the</strong> power and<br />

industrial energy markets.<br />

Market Focus<br />

<strong>Power</strong> <strong>Generation</strong><br />

HRSG and gas plant pipe, Boiler proper and interconnect pipe<br />

Oil and Gas Applications<br />

Offshore, Refineries, Petro Chem<br />

Mechanical / Structural / Construction<br />

CNG cylinder, Ship building, Mechanical / Equipment applications<br />

Matching Fittings Applications<br />

Please feel free to visit our web site for more information about<br />

our latest acquisition. We think you will agree, what we have put<br />

toge<strong>the</strong>r is a very nice fit.

GEN-SETS<br />

<strong>Cummins</strong> provides generators for<br />

<strong>the</strong> UK’s Peterborough Hospital<br />

For its <strong>new</strong> world-class Peterborough City Hospital <strong>the</strong> Peterborough and Stamford<br />

Hospitals NHS Foundation Trust needed a completely reliable emergency standby system<br />

<strong>Cummins</strong> <strong>Power</strong> <strong>Generation</strong> came up with <strong>the</strong> right equipment to serve <strong>the</strong> site.<br />

What would you prescribe to<br />

deliver reliable emergency back<br />

up power to <strong>the</strong> UK’s <strong>new</strong> Edith<br />

Cavell Hospital? <strong>Cummins</strong> <strong>Power</strong><br />

<strong>Generation</strong> provided three integrated 6<br />

MVA prime-rated gensets to provide standby<br />

power system - all individually<br />

controlled <strong>Cummins</strong> <strong>Power</strong> <strong>Generation</strong><br />

(C2250 D5) generator sets, plus a DMC 300<br />

digital master control system<br />

The Edith Cavell Hospital has been<br />

transformed as part of a £335m Greater<br />

Peterborough Health Investment Plan<br />

(GPHIP) with <strong>the</strong> construction of <strong>the</strong> <strong>new</strong><br />

Peterborough City Hospital.<br />

Covering a surface area of 95,383 square<br />

metres, <strong>the</strong> healthcare campus houses<br />

612 beds and state-of-<strong>the</strong>-art facilities<br />

including a high-tech diagnostics unit, an<br />

emergency care centre, and a <strong>new</strong> mental<br />

health unit operated by <strong>the</strong> local trust.<br />

Continuous and reliable power is critical<br />

to <strong>the</strong> successful treatment of patients at<br />

<strong>the</strong> <strong>new</strong> hospital. The three <strong>new</strong> <strong>Cummins</strong><br />

2000 kVA Prime rated C2250 D5 generator<br />

sets are 60-litre V16 turbocharged QSK60-<br />

G4 engine, with fuel day tanks fitted with<br />

a 'double knock' safety system to prevent<br />

and minimise any spillages.<br />

One of <strong>the</strong> <strong>Cummins</strong> 2000 kVA Prime rated<br />

C2250 D5 generator sets.<br />

Pictured alongside <strong>the</strong> <strong>Cummins</strong> power generation unit are Norman Su<strong>the</strong>rland,<br />

Brookfields Construction (UK) Ltd (left), and Declan O'Donovan of Mercury<br />

Engineering (right).<br />

Also supplied were air<br />

inlet and discharge systems,<br />

exhaust gas silencers and<br />

flue runs for <strong>the</strong> safe<br />

dispersal of emissions, fuel<br />

supply system which<br />

included day tanks, pipework,<br />

leak detection and<br />

fire wire monitoring.<br />

Each of <strong>the</strong> generator sets<br />

feature an onboard<br />

synchroniser and controller,<br />

able to operate independently<br />

from one ano<strong>the</strong>r.<br />

A user-friendly touchscreen<br />

DMC 300 digital master control,<br />

configured specifically for <strong>new</strong><br />

Edith Cavell Hospital, allows<br />

<strong>the</strong> rapid paralleling of <strong>the</strong><br />

mains supply and generators,<br />

load management and <strong>the</strong><br />

recording of data.<br />

In <strong>the</strong> event of an electricity<br />

supply failure, power can be<br />

automatically restored to<br />

critical systems within 15<br />

seconds, fulfilling <strong>the</strong> C44<br />

Hospital Specification.<br />

The Edith Cavell Hospital has been transformed as<br />

part of a £335m Greater Peterborough Health<br />

Investment Plan.<br />

The generator control system has been<br />

programmed to allow <strong>the</strong> first generator<br />

to come online, and energise <strong>the</strong> whole<br />

11 kV ring whilst <strong>the</strong> remaining two units<br />

are synchronising with <strong>the</strong> first set.<br />

Finally, <strong>Cummins</strong> fitted a DMC 300 digital<br />

master control with a ‘hot PLC standby<br />

system’ to eliminate <strong>the</strong> risk of any<br />

complete equipment failure, minimising<br />

any problems with <strong>the</strong> primary PLC.<br />

Internet link<br />

www.cummins.com<br />

WIP<br />

20<br />

JUNE 2010 • WORLDWIDE I NDEPENDENT P OWER

POWERPLANTS<br />

Can you turn your VOC abatement<br />

plant into an energy source?<br />

Brofind SPA has been installing steam recovery plants in Europe for some years now.<br />

Now <strong>the</strong> company firmly believes that in <strong>the</strong>rmal treatment <strong>the</strong> pollutant (VOC) can be<br />

<strong>the</strong> main source of energy used by <strong>the</strong> system to support <strong>the</strong> purification process.<br />

Could your plant be ‘self-supporting’<br />

or, ‘auto<strong>the</strong>rmal’ in operation?<br />

That’s <strong>the</strong> question being asked by<br />

Brofind SPA. Wasting energy means<br />

wasting money in <strong>the</strong> company’s view.<br />

For a plant to be self-supporting it<br />

should be using <strong>the</strong> pollutant (VOC) as <strong>the</strong><br />

only - or at least <strong>the</strong> main - source of<br />

energy supporting <strong>the</strong> purification<br />

process, says Brofind.<br />

In <strong>the</strong> last few years Brofind has carried<br />

out research and development projects to<br />

combine minimising ecological problems<br />

with those of reducing energy<br />

consumption and production<br />

requirements. The company suggests five<br />

approaches to do this more effectively:<br />

* CLOSED LOOP: In many cases <strong>the</strong> outlet<br />

air at <strong>the</strong> stack of <strong>the</strong> purification plant<br />

may still contain some useful heat. In<br />

some cases, it is possible to recycle 100%<br />

of <strong>the</strong> treated air in <strong>the</strong> production<br />

process.<br />

* COOLING: It is possible to achieve<br />

cooling using <strong>the</strong> heat obtained after a<br />

purification process. Experience has<br />

taught Brofind that plants with lithium<br />

Steam recovery provides<br />

valuable energy which would<br />

o<strong>the</strong>rwise be lost. [Pic: Brofind]<br />

salts - using hot water,<br />

steam or hot air directly<br />

from <strong>the</strong> purification plant<br />

- can store calories and<br />

turn this energy into chilled<br />

water at 7°C.<br />

This application is most<br />

suitable on recuperative<br />

<strong>the</strong>rmal combustion<br />

processes, as <strong>the</strong><br />

temperature of <strong>the</strong> purified<br />

air at <strong>the</strong> stack is around<br />

400°C, which leads to a<br />

better efficiency and faster<br />

return on investment.<br />

* THERMAL OIL HEATING:<br />

A plant’s existing heating<br />

system, (i.e. direct or<br />

indirect burners), can be<br />

replaced with a <strong>new</strong> <strong>the</strong>rmal oil circuit to<br />

save energy.<br />

In some cases a refractory butterfly<br />

valve allows air to be extracted at 800-<br />

900°C and to regulate <strong>the</strong> amount of<br />

recovery according to <strong>the</strong> heat available<br />

in <strong>the</strong> purification plant .<br />

It is also possible to provide a heat<br />

recovery system with a direct <strong>the</strong>rmal oil<br />

heater designed to meet production<br />

demands.<br />

* STEAM RECOVERY: This works best in<br />

solvent recovery plants using activated<br />

carbon and steam regeneration. Brofind<br />

has learned to optimise this process in<br />

order to minimise <strong>the</strong> consumption of<br />

steam during carbon regeneration. It has<br />

done this by developing a recovery<br />

process based on <strong>the</strong> enthalpy of <strong>the</strong> used<br />

steam.<br />

STEAM PRODUCTION: In cases where<br />

steam recovery is not possible, e.g.<br />

because of <strong>the</strong> high acidity of <strong>the</strong><br />

combustion gases from <strong>the</strong> destruction of<br />

chlorinated or brominated organic<br />

One of Brofind’s energy-through-vapur-recovery<br />

projects.<br />

Improved <strong>the</strong>rmal oil heating<br />

can also create energy savings.<br />

compounds, Brofind has installed a firetube<br />

boiler to produce steam. This<br />

technology is able to work, (due to <strong>the</strong><br />

water evaporation temperature and <strong>the</strong><br />

operating pressure), where <strong>the</strong>se acids<br />

are not aggressive.<br />

In some cases <strong>the</strong> steam, in addition to<br />

being recycled in production, is used to<br />

preheat <strong>the</strong> combustion gases. Gas cooling<br />

in <strong>the</strong> boiler makes any fur<strong>the</strong>r posttreatment<br />

phase - quench+scrubber - far<br />

easier and less expensive, reports Brofind.<br />

Internet link<br />

www.brofind.it<br />

WIP<br />

W ORLDWIDE I NDEPENDENT P OWER • JUNE 2010<br />

21

BOILERS<br />

steelwork sections) are manufactured in<br />

South Africa. By <strong>the</strong> beginning of 2016 six<br />

power plant units will have arisen in<br />

Medupi. Six more will be constructed at<br />

<strong>the</strong> neighboring Kusile location.<br />

The next few months will see <strong>the</strong> boiler<br />

supporting structure being put up for <strong>the</strong><br />

first power plant unit in Medupi to be followed<br />

by construction of <strong>the</strong> actual utility<br />

steam generator.<br />

As for <strong>the</strong> rest of <strong>the</strong> units at Medupi,<br />

<strong>the</strong>y will go up one by one separated by<br />

several months in-between. Going on<br />

stream at <strong>the</strong> beginning of 2016 will be<br />

<strong>the</strong> final utility steam generator - this will<br />

be built at Kusile in 2017.<br />

"The two projects at Medupi and Kusile<br />

represent just <strong>the</strong> start of our long-term<br />

commitment in South Africa and <strong>the</strong><br />

neighboring countries", according to Klaus<br />

Dieter Rennert.<br />

He concluded: "In this region <strong>the</strong>re is a<br />

considerable demand for <strong>the</strong> construction<br />

of highly efficient power plants and <strong>the</strong><br />

firm will to see it through. This is a<br />

potential which we intend to exhaust to<br />

<strong>the</strong> full with our expertise and excellent<br />

Medupi: Brian Dames (left), Eskom's Chief Officer for <strong>Generation</strong> Business,<br />

and Klaus-Dieter Rennert, Chief Executive Officer of HPE at <strong>the</strong> boiler tower<br />

site.<br />

products - and that includes full<br />

environmental protection."<br />

Hitachi <strong>Power</strong> Europe GmbH (HPE), a<br />

subsidiary of Hitachi, Ltd., designs and<br />

constructs fossil fuel-fired power plants<br />

and is one of <strong>the</strong> key market leaders.<br />

HPE also supplies key components such<br />

as utility steam generators, environmental<br />

technology equipment, turbines and<br />

pulverisers. The company has been based<br />

at <strong>the</strong> Inner Port in Duisburg (North-Rhine<br />

Westphalia) since 2007 and has a<br />

workforce (including associated companies<br />

and manufacturing facilities) of<br />

approximately 1,900. Within <strong>the</strong> Hitachi<br />

Group, Hitachi <strong>Power</strong> Europe is<br />

responsible for <strong>the</strong> markets in Europe, <strong>the</strong><br />

former CIS states and in Africa.<br />

Internet link<br />

www.hitachi-power.com<br />

WIP<br />

W ORLDWIDE I NDEPENDENT P OWER • JUNE 2010<br />

23

CONTROLS FOR GEN-SETS<br />

<strong>Power</strong>Wizard – providing safe<br />

controls for your generating set<br />

A number of unique features are available on <strong>Power</strong>Wizard control panels include<br />

10.5-32V DC power for a single module to cover <strong>the</strong> whole FG Wilson generating set<br />

range. There’s also a ingenious menu layout for ease of navigation & monitoring.<br />

The FG Wilson <strong>Power</strong>Wizard range of<br />

digital control panels combine<br />

straightforward menu navigation<br />

with advanced metering and protection<br />

technology, says <strong>the</strong> company.<br />

This range of panels has been speciallydesigned<br />

for use in automatic mains<br />

failure applications in conjunction with<br />

transfer panels.<br />