F-0046 VENDOR SURVEY - Knott Brake Company

F-0046 VENDOR SURVEY - Knott Brake Company

F-0046 VENDOR SURVEY - Knott Brake Company

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

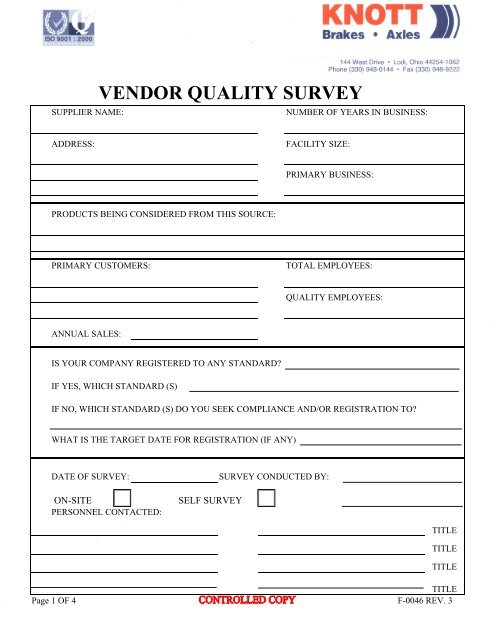

SUPPLIER NAME:<br />

<strong>VENDOR</strong> QUALITY <strong>SURVEY</strong><br />

NUMBER OF YEARS IN BUSINESS:<br />

ADDRESS:<br />

FACILITY SIZE:<br />

PRIMARY BUSINESS:<br />

PRODUCTS BEING CONSIDERED FROM THIS SOURCE:<br />

PRIMARY CUSTOMERS:<br />

TOTAL EMPLOYEES:<br />

QUALITY EMPLOYEES:<br />

ANNUAL SALES:<br />

IS YOUR COMPANY REGISTERED TO ANY STANDARD?<br />

IF YES, WHICH STANDARD (S)<br />

IF NO, WHICH STANDARD (S) DO YOU SEEK COMPLIANCE AND/OR REGISTRATION TO?<br />

WHAT IS THE TARGET DATE FOR REGISTRATION (IF ANY)<br />

DATE OF <strong>SURVEY</strong>:<br />

ON-SITE<br />

PERSONNEL CONTACTED:<br />

SELF <strong>SURVEY</strong><br />

<strong>SURVEY</strong> CONDUCTED BY:<br />

TITLE<br />

TITLE<br />

TITLE<br />

TITLE<br />

Page 1 OF 4 F-<strong>0046</strong> REV. 3

<strong>SURVEY</strong> RESULTS<br />

SCORE SCORE<br />

AVAILABLE EARNED SECTIONS REVIEWED<br />

40 QUALITY SYSTEM<br />

20 INSPECTION SYSTEM<br />

25 RECEIVING<br />

30 CALIBRATION<br />

25 PROCESS AND DOCUMENT CONTROL<br />

20 MATERIAL HANDLING AND STORAGE<br />

30 NONCONFORMING MATERIAL AND CORRECTIVE ACTION<br />

TOTAL SCORE AVAILABLE : 190<br />

TOTAL SCORE EARNED:<br />

OVERALL ASSESSMENT SCORE = SCORE EARNED = %<br />

SCORE AVAILABLE<br />

<strong>SURVEY</strong> RATING SYSTEM<br />

EXCELLENT 90% - 100%<br />

GOOD 80% - 89%<br />

MARGINAL<br />

POOR<br />

UNACCEPTABLE<br />

70% - 79%, Good rating required by next survey<br />

60% - 69%, Corrective action required, 120 days to achieve a marginal rating<br />

59% or less, 60 days to achieve a poor rating or Purchasing will find an alternate<br />

source.<br />

Page 2 of 4 F-<strong>0046</strong> REV. 3

<strong>SURVEY</strong> RATING SYSTEM<br />

5 - Meets or exceeds requirements (very good execution and documentation)<br />

4 - Meets most requirements (adequate execution and documentation)<br />

3 - Some improvement is required (some execution is in place, documentation is in place)<br />

2 - Major improvements required (informal system in place; no documentation)<br />

1 - Current system does not assure prevention of error (inadequate documentation and execution)<br />

0 - No coverage (no documented procedure or execution in place)<br />

N/A - section does not apply<br />

AN EXPLANATION MUST BE GIVEN IF THE SCORE IS "3" OR LOWER.<br />

QUALITY SYSTEM<br />

A Is there a written management approved Quality Assurance Manual?<br />

Comments:<br />

B Does the quality department have the authority to stop nonconforming shipments or process?<br />

Comments:<br />

C Are all quality records (test, inspection reports, certs, etc) maintained? How long?_______<br />

Comments:<br />

D Does the quality system require internal audits be performed at established intervals?<br />

Comments:<br />

E Is there a procedure in place for first articles for a new part or new process?<br />

Comments:<br />

F Is there a preventative maintenance procedure in place to ensure machines and tools used to manufacture<br />

parts has continuous maintenance performed?<br />

Comments:<br />

G Is there a system in place for employee training?<br />

Comments:<br />

H Are the customer requirements formally reviewed?<br />

Comments:<br />

INSPECTION SYSTEM<br />

A Is inspection performed through the use of written instructions?<br />

Comments:<br />

B Do records show finished product conforms to specified requirements?<br />

Comments:<br />

C Is appropriate inspection performed during or following manufacturing to maintain the level of quality throughout<br />

entire process, including shipping?<br />

Comments:<br />

D Is there a system for maintaining traceability?<br />

Comments:<br />

RECEIVING<br />

A Is there a system in place to evaluate and approve new vendors?<br />

Comments:<br />

B Is there a receiving inspection system?<br />

Comments:<br />

C Is there a system to evaluate suppliers ability to deliver conforming material on time?<br />

Comments:<br />

D Is there a procedure to identify all received material?<br />

Comments:<br />

E Is there a procedure to ensure material will not be used if it is nonconforming or has not been inspected?<br />

Comments:<br />

SCORE<br />

Page 3 of 4 F-<strong>0046</strong> REV. 3

CALIBRATION<br />

A Are there written procedures for the control and calibration of all equipment used for inspection and<br />

acceptance purposes?<br />

Comments:<br />

B Are all of the inspection equipment labeled with the calibrations status? (including date calibrated, date due and<br />

calibrated by)<br />

Comments:<br />

C Are certifications on file reflecting standards calibration traceable to NIST?<br />

Comments:<br />

D Is new or reworked inspection equipment calibrated prior to use?<br />

Comments:<br />

E Is employee owned tools/gages subject to the same procedures as company owned equipment?<br />

Comments:<br />

F Are all calibration documents kept on file?<br />

Comments:<br />

PROCESS AND DOCUMENT CONTROL<br />

A Are the work transfers/routers preplanned and have adequate inspection points?<br />

Comments:<br />

B Are traceability records maintained for each lot of parts processed?<br />

Comments:<br />

C Is there a procedure to ensure that only current drawings, specifications and procedures are utilized?<br />

Comments:<br />

D Are obsolete, marked up drawing specifications and procedures removed from the production areas, so as to<br />

prelude their use during processing and inspection functions?<br />

Comments:<br />

E Are there procedures to handle Engineering change requests on work orders that are in process?<br />

Comments:<br />

MATERIAL HANDLING AND STORAGE<br />

A Are age controlled items properly maintained and labeled as required?<br />

Comments:<br />

B Are there controls in place to properly segregate customer material to ensure its use in the intended end item?<br />

Comments:<br />

C Is there a system for the positive identification of discrepant material?<br />

Comments:<br />

D Is there a procedure for the safe handling, storage and packaging of the product processed ?<br />

Comments:<br />

NONCONFORMING MATERIAL AND CORRECTIVE ACTION<br />

A Are there procedures on the proper handling and identification of conforming material?<br />

Comments:<br />

B Is there a material review area to store nonconforming material from the line of production?<br />

Comments:<br />

C Is there a documented corrective action system?<br />

Comments:<br />

D Are corrective action requests issued to your suppliers upon receipt of nonconforming material?<br />

Comments:<br />

E Does the corrective action system have a procedure for handling customer complaints?<br />

Comments:<br />

F Are customer corrective action requests handled within the specified time frame? What is the time frame?<br />

Comments:<br />

SCORE<br />

Page 4 of 4 F-<strong>0046</strong> REV. 3