Hydraulic Servo Drum Brakes - Knott Brake Company

Hydraulic Servo Drum Brakes - Knott Brake Company

Hydraulic Servo Drum Brakes - Knott Brake Company

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

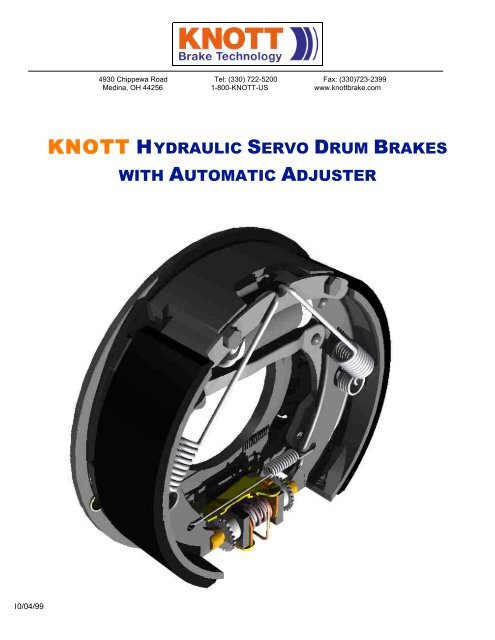

4930 Chippewa Road Tel: (330) 722-5200 Fax: (330)723-2399Medina, OH 44256 1-800-KNOTT-US www.knottbrake.comKNOTT HYDRAULIC SERVO DRUM BRAKESWITH AUTOMATIC ADJUSTER10/04/99

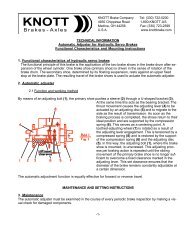

4930 Chippewa Road Tel: (330) 722-5200 Fax: (330)723-2399Medina, OH 44256 1-800-KNOTT-US www.knottbrake.comHOW DOES THE KNOTTAUTOMATIC ADJUSTER WORK?Adjustment occurs in both the forward and reverse direction.10/04/99

4930 Chippewa Road Tel: (330) 722-5200 Fax: (330)723-2399Medina, OH 44256 1-800-KNOTT-US www.knottbrake.comThe shoe movesaway from theanchor plate.The shoe restson the anchorplate.Pressure applied to the wheel cylinder (A) rotates the drum (B), which initiates rotation of thebrake shoes (D) & (E). These rotate in the same direction and float through the adjuster (F)until the trailing shoe rests against the anchor plate (G).10/04/99

4930 Chippewa Road Tel: (330) 722-5200 Fax: (330)723-2399Medina, OH 44256 1-800-KNOTT-US www.knottbrake.comApplying pressureto the cylinderReleasing pressurefrom the cylinderWhen plate (H) travels far enough to contact lever (N), the lever is pushed downwards until itpicks up a tooth of the star wheel (I). When the brake is released, the force of spring (M)in the adjuster, plus the force of the return springs in the shoe, drives the lever (N)upwards. This rotates the star wheel (I) by 1 tooth. Shoe wear is compensatedfor as the thread moves between (I) and (L) and the brakes are readjusted.10/04/99

4930 Chippewa Road Tel: (330) 722-5200 Fax: (330)723-2399Medina, OH 44256 1-800-KNOTT-US www.knottbrake.comAutomatic adjustmenttakes place separatelyin both directions ofdrum rotation.<strong>Drum</strong>ClearanceClearanceA specific clearance is necessary between the shoes and the drumfor the adjuster to function. If the initial clearance is TOO SMALL, theadjuster will not function until the necessary clearance is achieved. If theinitial clearance is TOO GREAT, the adjuster will start functioning immediatelyand will bring the brake into adjustment after braking a few times in each direction.PLEASE NOTEPrior to the clearance increasing to a point where the adjuster will readjust, the driver maynotice a slight increase in pedal travel. Excessive clearance may damage the adjuster.10/04/99

4930 Chippewa Road Tel: (330) 722-5200 Fax: (330)723-2399Medina, OH 44256 1-800-KNOTT-US www.knottbrake.comTHEORETICAL BRAKE DIAMETERS OF THEVARIOUS BRAKE SIZESMeasured overthe center axisClearanceClearanceAdjustment measurementThe adjuster will maintain a preset measurement, dependent upon:• ActivationPressure Applied• Type ofAdjuster• <strong>Brake</strong>Size• TemperaturesReached• Elasticity &<strong>Drum</strong> StabilityBRAKE SIZEPRESET MEASUREMENT170 x 40 Hydro <strong>Servo</strong> 169.2 - 0.2200 x 40 “ “ 199 - 0.4203 x 40/60 “ “ 201.8 ± 0.2230 x 50 “ “ 228.7 ± 0.2245 x 60 “ “ 243.6 ± 0.3250 x 40/ 45/ 55 /60 “ “ 248.8 ± 0.3270 x 60 “ “ 268.6 ± 0.3300 x 55 /60 “ “ 298.5 ± 0.3315 x 80 “ “ 313.5 + 0.7 - 0.3325 x 80 “ “ 323.5 ± 0.4400 x 80 /120 “ “ 398.4 ± 0.410/04/99

4930 Chippewa Road Tel: (330) 722-5200 Fax: (330)723-2399Medina, OH 44256 1-800-KNOTT-US www.knottbrake.comREPLACE ONLY THECOMPLETE ADJUSTER10/04/99

4930 Chippewa Road Tel: (330) 722-5200 Fax: (330)723-2399Medina, OH 44256 1-800-KNOTT-US www.knottbrake.comASSEMBLING THE BRAKE TO THE AXLE (I)Unhook the springs withsuitable tools.WARNINGSprings MUST NOT be damaged.Remove the brake shoes.Mount the backing plate to the axle,then refit the shoesand brake cable (if applicable).10/04/99

4930 Chippewa Road Tel: (330) 722-5200 Fax: (330)723-2399Medina, OH 44256 1-800-KNOTT-US www.knottbrake.comFITTING THE BRAKE TO THE AXLE (II)If necessary, remove the two star wheel assemblies with the adjuster bolts.After inserting the fixing screws,refit the star wheels.Care must be taken to ensure that these are reassembledin the same position, using the yellow dots for reference.10/04/99

4930 Chippewa Road Tel: (330) 722-5200 Fax: (330)723-2399Medina, OH 44256 1-800-KNOTT-US www.knottbrake.comREPLACE ONLY THECOMPLETE WHEEL CYLINDER10/04/99

4930 Chippewa Road Tel: (330) 722-5200 Fax: (330)723-2399Medina, OH 44256 1-800-KNOTT-US www.knottbrake.comUSE ONLYKNOTT ORIGINAL SPARESThese are safety-related components.KNOTT accepts no liability for the use ofnon-approved spare parts.10/04/99

4930 Chippewa Road Tel: (330) 722-5200 Fax: (330)723-2399Medina, OH 44256 1-800-KNOTT-US www.knottbrake.comREPLACE ONLYCOMPLETE SHOES10/04/99

4930 Chippewa Road Tel: (330) 722-5200 Fax: (330)723-2399Medina, OH 44256 1-800-KNOTT-US www.knottbrake.comFITTING THE ADJUSTERUse only KNOTT-approved fasteningscrews and washers.Fix the adjusterto the backing plate by tightening thescrews to the following torques:Torque WrenchTightening torques for hexagonal-headed screws (grade 8.8)<strong>Brake</strong> Size Screw Type Torque (Nm)200x40203x40/60230x50245x60300x55M12 90 +10315x80325x80 M14 120 +2010/04/99

4930 Chippewa Road Tel: (330) 722-5200 Fax: (330)723-2399Medina, OH 44256 1-800-KNOTT-US www.knottbrake.comMECHANICAL PARKINGCheck that when releasing the handbrake, the lever inside the brakereturns to the rest position, so that the shoes at the end near thewheel cylinder are resting completely on the anchor plate.PLEASE NOTEIf this is not the case, the brake cable is pre-tensionedand will cause the adjuster to malfunction.10/04/99