ENERGY - Odebrecht Informa

ENERGY - Odebrecht Informa

ENERGY - Odebrecht Informa

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

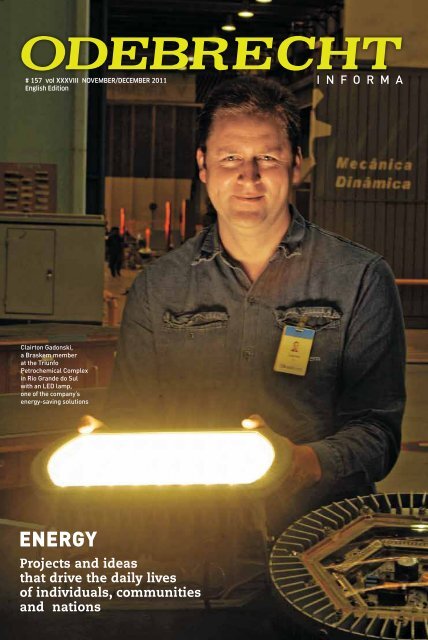

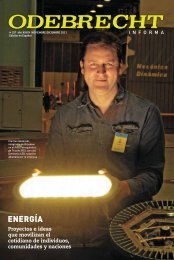

# 157 vol XXXVIII NOVEMBER/DECEMBER 2011<br />

English Edition<br />

Clairton Gadonski,<br />

a Braskem member<br />

at the Triunfo<br />

Petrochemical Complex<br />

in Rio Grande do Sul<br />

with an LED lamp,<br />

one of the company’s<br />

energy-saving solutions<br />

<strong>ENERGY</strong><br />

Projects and ideas<br />

that drive the daily lives<br />

of individuals, communities<br />

and nations<br />

informa<br />

I

II<br />

informa

informa<br />

1

www.odebrechtonline.com.br<br />

Read <strong>Odebrecht</strong> <strong>Informa</strong> on your iPad and smartphone.<br />

Features, articles, videos, photos, animations and infographics.<br />

The achievements of the <strong>Odebrecht</strong> Organization on your tablet and smartphone.<br />

Online edition Online archive Innovations Video reports Blog<br />

> You can view<br />

this entire issue<br />

in HTML<br />

and PDF<br />

> Brazil’s Light for All Program brings better<br />

living conditions to rural communities in<br />

the state of Minas Gerais<br />

> Hydropower plant makes the water and<br />

sewer system in Cachoeiro de Itapemirim,<br />

Espírito Santo, energy self-sufficient<br />

> Augusto Roque Dias Fernandes, CEO<br />

of <strong>Odebrecht</strong> Energia, is the third member<br />

interviewed for the Savvy Project<br />

> Access all back issues of <strong>Odebrecht</strong><br />

<strong>Informa</strong> since no. 1, and download full<br />

issues in PDF<br />

> <strong>Odebrecht</strong> Annual Reports since 2002<br />

> Special publications (Special Issue on Social<br />

Programs, 60 years of the <strong>Odebrecht</strong> Group,<br />

40 Years of the <strong>Odebrecht</strong> Foundation and<br />

10 Years of Odeprev)<br />

On the right path<br />

Complexo do Alemão, in Rio de Janeiro,<br />

is undergoing social transformation where peace<br />

and development now go hand in hand<br />

> Expansion of Line 4 of the São<br />

Paulo Metro brings new mass<br />

transit options to the downtown<br />

area of Brazil’s largest city<br />

> In Rio de Janeiro, <strong>Odebrecht</strong><br />

and the Brazilian Navy partner<br />

up to prepare youth to practice<br />

Olympic sports<br />

> Braskem reports the best<br />

environmental performance in<br />

its history<br />

> <strong>Odebrecht</strong> Realizações<br />

Imobiliárias has one of the<br />

largest numbers of green<br />

buildings in Brazil<br />

> Dos Mares hydroelectric project<br />

supplies 118 MW of clean energy<br />

to the people of Panama<br />

> Follow <strong>Odebrecht</strong> <strong>Informa</strong><br />

on Twitter and get the<br />

latest news in real time<br />

@odbinforma<br />

> Comment on blog entries<br />

and participate by sending<br />

suggestions to the editors<br />

> Read posts on the<br />

<strong>Odebrecht</strong> <strong>Informa</strong><br />

blog by the magazine’s<br />

reporters and editors,<br />

including Cláudio Lovato<br />

Filho, Fabiana Cabral,<br />

José Enrique Barreiro,<br />

Karolina Gutiez, Renata<br />

Meyer, Rodrigo Vilar,<br />

Thereza Martins, Zaccaria<br />

Júnior and collaborators.

<strong>ENERGY</strong><br />

6<br />

12<br />

14<br />

16<br />

20<br />

24<br />

28<br />

32<br />

38<br />

44<br />

48<br />

52<br />

55<br />

58<br />

#157<br />

Braskem invests in diversifying its energy mix<br />

and increasing efficiency<br />

Braskem adopts LED lighting – more economical,<br />

efficient, and eco-friendly<br />

Petrobras’s new headquarters in Vitória uses innovative<br />

energy technologies<br />

By building an SHP, Foz becomes energy self-sufficient<br />

in Cachoeiro de Itapemirim<br />

Complex of three factories in Suape gives the Brazilian<br />

textile industry a boost<br />

Henrique Valladares discusses <strong>Odebrecht</strong>’s role<br />

as an investor in the energy sector<br />

Teles Pires: innovative ways of mobilizing people<br />

to work on a remote project in Brazil<br />

<strong>Odebrecht</strong> debuts in the wind power generating segment<br />

with wind farms in southern and northeastern Brazil<br />

The drive in Angola to take electricity to people<br />

in a larger swath of the country<br />

From mine to seaport, the long and essential road<br />

of coal produced in Mozambique<br />

Light for All: heartwarming stories of people switching<br />

on electric lights for the first time<br />

A simple, creative and effective energy-saving<br />

project from La Candelaria, Argentina<br />

In La Plata, the strategic expansion of a YPF refinery’s<br />

production capacity<br />

José Luiz Alquéres and the energy sector’s prospects<br />

in Brazil and worldwide<br />

photo: Carlos Júnior<br />

&<br />

News<br />

People<br />

Capa<br />

Ilustração de Rico Lins<br />

62<br />

67<br />

70<br />

73<br />

74<br />

76<br />

78<br />

81<br />

82<br />

2014 FIFA WORLD CUP<br />

HOUSING<br />

TRANSPORTATION<br />

FOLKS<br />

PROFILE<br />

ARTS & CULTURE<br />

SUSTAINABLE DEVELOPMENT<br />

HISTORY<br />

SAVVY<br />

informa informa<br />

3

4<br />

informa

EDITORIAL<br />

Energy that<br />

empowers dreams<br />

and ventures<br />

“With a track record in<br />

the industry that started<br />

in the 1950s, when the<br />

company built dams in<br />

the Brazilian Northeast,<br />

<strong>Odebrecht</strong> is not only a<br />

provider of engineering<br />

and construction<br />

services but also a<br />

producer and investor.<br />

Through its teams<br />

around the world, the<br />

<strong>Odebrecht</strong> Organization<br />

is harnessing and<br />

sharing its accumulated<br />

experience and<br />

knowledge to give its<br />

local communities the<br />

best it has to offer.”<br />

Lopes Sebastião and Dilma Marçal. He lives in the Angolan<br />

province of Uíge; she lives in the Brazilian state<br />

of Minas Gerais. Both have only just recently started<br />

using electricity in their homes because their communities<br />

are the beneficiaries of government initiatives involving<br />

<strong>Odebrecht</strong>.<br />

Gustavo Checcucci and Fernando Chein. Gustavo works at Braskem,<br />

leading the team responsible for managing the energy the company<br />

uses. Fernando works at <strong>Odebrecht</strong> Energia and is spearheading the<br />

company’s debut in the wind power segment.<br />

And there are more people like them in this issue of <strong>Odebrecht</strong><br />

<strong>Informa</strong>: José Piquetai, from Mozambique, Julio Romano, from Argentina,<br />

Pablo Andreão and José Dalvi, from Espírito Santo, Brazil,<br />

and many others who, one way or another, have seen their lives<br />

change through <strong>Odebrecht</strong>’s work in the energy sector. They are<br />

either the beneficiaries or the people responsible for making those<br />

benefits happen, and their stories of work and life attest to the fact<br />

that the spirit of service and hope are two sides of the same coin,<br />

and each is vital to the other.<br />

With a track record in the industry that started in the 1950s, when<br />

the company built dams in the Brazilian Northeast, <strong>Odebrecht</strong> is not<br />

only a provider of engineering and construction services but also<br />

a producer and investor. Through its teams around the world, the<br />

<strong>Odebrecht</strong> Organization is harnessing and sharing its accumulated<br />

experience and knowledge to give its local communities the best it<br />

has to offer. Whether it is the placement of an outlet, switch or lamp,<br />

the deployment of a wind farm or the construction of an industrial<br />

complex, what matters most is the difference it makes in people’s<br />

lives – wherever they are, no matter how many they may be – people<br />

with dreams and everyday lives, inspired by the belief that life should<br />

be lived to the fullest, with joy, persistence and passion.

maximum<br />

yield,<br />

minimum<br />

waste<br />

6

A company that uses<br />

2% of all the power<br />

consumed in Brazil,<br />

Braskem is investing<br />

in the diversification<br />

of its energy mix<br />

and boosting selfproduction<br />

capacity<br />

Braskem Unit at the<br />

Camaçari Complex:<br />

seeking energy efficiency<br />

in production processes<br />

written by Thereza Martins<br />

photos by Dario de Freitas<br />

<strong>Odebrecht</strong> Archives

To run the equipment at its plants in<br />

the Brazilian states of Alagoas, Bahia,<br />

Rio de Janeiro, São Paulo and Rio<br />

Grande do Sul, Braskem uses roughly<br />

2% of all the power consumed in<br />

Brazil. Compared to the consumption of the nation’s<br />

industrial sector as a whole, that percentage<br />

reaches nearly 5%. What’s more, when analyzing<br />

the chemical industry, which includes Braskem,<br />

the company’s demand exceeds 50% of the total,<br />

demonstrating Braskem’s important role in the national<br />

energy scene.<br />

“The chemical and petrochemical industries are<br />

key users of energy inputs, along with mining, steel<br />

and glass producers,” explains electrical engineer<br />

Gustavo Checcucci, the officer Responsible for<br />

Electricity Management at Braskem.<br />

Using a wide range of technologies and processes,<br />

the company’s 28 plants in Brazil consume<br />

energy from numerous sources. Braskem’s energy<br />

mix includes natural gas, fuel oil, coal, electricity<br />

and residual fuels (oil and gas generated by industrial<br />

processes at the plants).<br />

The company has a specific body that manages<br />

all these inputs: the Energy Directorate, including<br />

three managers, one dedicated to the regulation<br />

and sale of electricity, another focused on fuels and<br />

energy efficiency, and the third responsible for the<br />

self-production program.<br />

Gustavo Checcucci, in front, with members of<br />

his team (Mauro Koiti Kumahara, Lucas Garcia<br />

Nishioka, Fabio Yanaguita and Kelly Sayuri<br />

Yamaki): responsible for managing the energy<br />

Braskem uses. Below, transporting coal in<br />

Triunfo: a diversified mix<br />

used every month and the user receives an invoice<br />

at the end of each period.<br />

As with any other type of trade, free market prices<br />

fluctuate according to supply and demand. During<br />

the rainy season, for example, water reservoirs<br />

Monitoring performance<br />

The management of electricity use at Braskem<br />

is consolidated on the 25th floor of the building<br />

where the company has its headquarters in São<br />

Paulo. Linked to the company’s plants through a<br />

network, it is the home base of the Energy Operations<br />

area, where three engineers led by Gustavo<br />

Checcucci are hard at work. By scrutinizing TV and<br />

computer screens, they keep track of the real-time<br />

consumption and supply needs of each of the company’s<br />

factories to ensure that they get the best<br />

possible service.<br />

Their team is also responsible for purchasing energy<br />

on the open market, an alternative to the “captive<br />

market” (Regulated Environment), to which the<br />

vast majority of consumers are accustomed. This<br />

way, the supplier measures the amount of energy<br />

Photo: Mathias Kramer<br />

8<br />

informa

are full and prices fall, rising again in the dry season.<br />

Likewise, the cost of energy is higher at times<br />

of peak demand - for example, from 6 pm to 9 pm.<br />

“To purchase electricity at the most competitive<br />

prices you have to know the future needs of<br />

the plants’ operations and plan your procurement<br />

in advance,” says Gustavo, adding: “In this sense,<br />

the free market benefits us with a choice. In 2010,<br />

the Energy Operations area’s negotiations saved<br />

Braskem BRL 23.5 million.”<br />

The annual cost of energy inputs for the company<br />

totals roughly BRL 750 million. Braskem’s share of<br />

electricity purchased from the power grid is 10%,<br />

and in the second half of 2011, it represented 3.2%<br />

of the cost of goods sold.<br />

Finding better prices, deadlines, contracts, payment<br />

terms and partners is a daily effort, but there<br />

are other fields to be explored. Market regulation is<br />

one of them. With this aim in mind, Braskem forms<br />

part of the Brazilian Association of Large Industrial<br />

Energy Consumers (ABRACE) and keeps a close eye<br />

on discussions of issues such as possible tariff reductions,<br />

one of the factors which most affect the<br />

cost of energy.<br />

Client support<br />

While negotiations on the free market benefit<br />

Braskem, they can also add value to its clients’<br />

informa<br />

9

usinesses. Based on this reasoning and assumptions<br />

supported by the Visio program, the Polymers<br />

(Sales) and energy areas are taking their<br />

experience to Borealis Brasil, a Braskem affiliate<br />

(the company owns a 20% stake through a joint<br />

venture).<br />

“Like TEO [the <strong>Odebrecht</strong> Entrepreneurial Technology],<br />

the Visio program, which is specific to<br />

Braskem, is based on the principle of building<br />

and maintaining partnerships with individual clients,”<br />

says Octávio Pimenta, Sales Leader for the<br />

compounds segment, which participated in negotiations<br />

with Borealis. “By teaming up to purchase<br />

electricity, we are putting the spirit of service and<br />

innovation into practice to help our clients overcome<br />

the challenges they face.”<br />

For some time now, Borealis has seen migration<br />

to the free market as a competitive option.<br />

“We were not sure if the move would be feasible<br />

because it would require the additional work of<br />

planning and management, and we did not have a<br />

specialized team for that,” says chemical engineer<br />

Laudemir Sarzeta da Silva, the company’s Director<br />

of Operations. “Now we can count on this partnership<br />

with Braskem and will have time to evaluate<br />

the experience,” he adds.<br />

Working with a partner that sells power, Braskem<br />

purchased electricity for Borealis. The agreement<br />

is valid for one year, enough time for the company<br />

to decide if it will go ahead with the partnership<br />

or return to the “captive market.” The energy inputs<br />

purchased are for Borealis’s unit in Itatiba,<br />

São Paulo, which has a production capacity of 24<br />

tonnes per year of polypropylene compounds, raw<br />

materials for the auto industry and household appliances.<br />

Borealis has another plant in Brazil, at<br />

the Triunfo Petrochemical Complex in Rio Grande<br />

do Sul, which already benefits from a competitive<br />

energy supply.<br />

In Itatiba, Borealis’s power consumption totals<br />

approximately 2,320 kW per month. According<br />

to the regulatory requirements for this market,<br />

companies with a demand of 500 kW to 3,000 kW<br />

can participate in the free market as long as the<br />

supply comes from renewable energy sources<br />

such as small hydropower plants (SHPs), biomass<br />

electricity cogeneration plants and wind<br />

Ludemir Sarzeta<br />

da Silva, from<br />

Borealis: partnership<br />

guarantees energy<br />

acquisition<br />

farms. “For us, this is an added incentive. In addition<br />

to getting more competitive energy, we are<br />

choosing the path of sustainability,” says Laudemir.<br />

Borealis currently spends up to BRL 6 million per<br />

year on energy inputs and expects to save approximately<br />

BRL 400,000 by migrating to the free market.<br />

Energy efficiency<br />

Thermal energy generated by natural gas, coal, fuel<br />

oil and residual fuel represents 90% of Braskem’s energy<br />

mix. These inputs are burned in the furnaces and<br />

boilers of the plants’ Utilities areas and converted<br />

into steam to drive the processes of the petrochemical<br />

industry.<br />

Purchasing inputs under contract, managing<br />

energy and complying with regulatory standards<br />

are some of the tasks of the team led by engineer<br />

Marcelo Wasem, who is responsible for fuels and<br />

energy efficiency in the Energy Operations area.<br />

10<br />

informa

want to have an overview of all Braskem initiatives<br />

related to energy efficiency to find the best way<br />

to support the teams that are spearheading these<br />

projects,” he says.<br />

Soon, every project introduced by company members<br />

– whether its focus is innovation, productivity<br />

or quality – will also include some information about<br />

its potential impact on energy efficiency.<br />

“The company is investing in projects to increase<br />

its capacity for self-production and improve the<br />

energy efficiency of the inputs it consumes,” says<br />

Marcelo. By efficiency, he means maximizing use<br />

and minimizing waste, while ensuring quality, cost<br />

competitiveness and reducing negative environmental<br />

impacts, among other features.<br />

“We are working to develop a systemic view of<br />

efficiency, that is, mapping the production units to<br />

understand how each device and each routine operates<br />

and can make the most of its potential. We<br />

also identify bottlenecks, provide solutions, establish<br />

monitoring indicators and compare them with<br />

the market,” says Marcelo.<br />

A consultant will come on board by the end of<br />

2011 to help with these activities, with a view to<br />

achieving results by 2012. Marcelo Wasem explains<br />

that, so far, the gains in energy efficiency<br />

achieved are due to specific projects carried out<br />

by the Maintenance and Productivity teams. “We<br />

Sustainable option<br />

Because of logistics, the Braskem Basic Petrochemicals<br />

Unit (UNIB) in Triunfo is the company’s<br />

only plant that uses coal as an energy source.<br />

“More than 90% of the coal reserves in Brazil are<br />

located in the South, mostly in Rio Grande do Sul,”<br />

says Marcelo Wasem. “And Braskem uses a significant<br />

part of that input, due to its competitive price,”<br />

he emphasizes.<br />

However, Brazilian coal gives off large amounts<br />

of ash (35% of total volume). Fly ash, which is dry, is<br />

sold to the cement industry. However, a sustainable<br />

alternative to tailing ponds has yet to be found for<br />

the wet bottom ash removed from boilers after the<br />

burning process.<br />

One viable option could be on the horizon as<br />

a result of a pilot project, already underway, that<br />

uses bottom ash to make brick blocks. Entrepreneur<br />

Mauro Pezzi Parode based the design on<br />

technology developed almost 30 years ago by the<br />

Science and Technology Foundation (Cientec) of Rio<br />

Grande do Sul.<br />

With the help of the City of Triunfo, which provided<br />

a warehouse in the industrial zone of the city,<br />

and of Braskem, which provided guidance on legal,<br />

environmental and occupational safety matters,<br />

Mauro Parode is already producing at pilot scale.<br />

“I’ve equipped the factory with its own resources,<br />

and hired and trained people to work there. Today,<br />

our production capacity is up to 4,000 units daily,”<br />

he says. Production is not yet at full capacity, because<br />

Mauro is looking for a partner interested in<br />

using the blocks to build brick houses. Braskem<br />

provides the ash used to make the bricks free of<br />

charge.<br />

Cientec studies show that bottom ash can also be<br />

used to manufacture sleepers for railway projects,<br />

as well as serving as a base for paving roads.<br />

informa<br />

11

12<br />

A bright<br />

idea<br />

Braskem decides<br />

to install LED lighting<br />

in all its facilities<br />

written by Luciana Móglia photos by Ricardo Chaves<br />

In this case, it is more appropriate to say that<br />

when the idea came, a light bulb went off. And<br />

LED (Light Emitting Diode) lighting switched<br />

on instead. Technologically advanced, this<br />

kind of light helps reduce power consumption,<br />

offers more durability compared to other solutions,<br />

and does not contain mercury. There were more than<br />

enough reasons for Braskem to decide to invest in<br />

LED at one of its units in Rio Grande do Sul, making<br />

the company a pioneer in the use of this type of lighting<br />

on an industrial scale.<br />

This move, taken in 2009 to improve the lighting<br />

conditions of the Basic Petrochemicals Unit at<br />

the Triunfo Complex in Rio Grande do Sul, was just<br />

the first step. Fifteen thousand tubular fluorescent<br />

lights will be replaced with LED lights by the end<br />

of 2012, marking the completion of the first phase<br />

of the project. The company’s investment will total<br />

USD 1.8 million. The projected payback period is 12<br />

months, and the project will soon be replicated in<br />

other Braskem units.<br />

The group formed to suggest improvements used<br />

a period of transition to seek a sustainable solution.<br />

“Gas discharge lamps, which were the type most<br />

commonly used, contain mercury and generate more<br />

waste by using reactors and having a short life,” says<br />

Clairton Gadonski, a member of the Electrical and<br />

Maintenance area and the person responsible for<br />

forming the group.<br />

The first stage of the work of the multidisciplinary<br />

team composed of representatives from the Electrical,<br />

Instrumentation and Procurement areas, and<br />

Braskem’s partner electrical company, was studying<br />

available solutions. Among those evaluated were LED,<br />

T5 fluorescent and sodium vapor lamps. The main features<br />

the group tested were temperature, light output,<br />

efficiency, electrical parameters, user acceptance,<br />

cost effectiveness and environmental impact.<br />

Five to 70 times more durable<br />

LED lamps beat out the rest in virtually every point.<br />

“They last five to 70 times longer, depending on the<br />

12<br />

informa

Clairton Gadonski,<br />

a Braskem member<br />

based in Triunfo:<br />

LED produces less<br />

waste<br />

technology you’re comparing them with, generate energy<br />

savings of 20% to 80% and have a smaller impact<br />

on the environment,” says technology researcher<br />

Flávio Dieterich, also a member of the group. However,<br />

there was one drawback: the price.<br />

But the group did not give up. “As time went on,<br />

prices went down and quality improved, so the technology<br />

has become competitive with other options,” says<br />

Thiago Oliveira, a representative of the Procurement<br />

area. He takes the lead in negotiations with suppliers of<br />

lights, lamps and fixtures. “Suppliers have realized that<br />

Braskem could be a major partner and a showcase for<br />

this alternative,” he says. Braskem chose Philips, one<br />

of the world’s leading manufacturers, as the supplier<br />

for its first major purchase of LED tube lamps.<br />

The plant started making the switch in January<br />

2011. Braskem’s program to replace conventional<br />

lighting with LED is taking place on four fronts. One<br />

is the replacement of lamps in UNIB’s administrative<br />

area, control rooms and substations. Two thousand<br />

fluorescent tubes have already been replaced with<br />

LED lamps. In the pilot tests conducted, the result<br />

has been 35% higher luminous flux (measurement of<br />

the perceived power of light) and a 40% reduction in<br />

energy consumption.<br />

The introduction of LED fixtures in street lighting<br />

is also being tested as a pilot project. Twenty 20 LED<br />

lamps have been installed, which are now lighting the<br />

José Eduardo:<br />

operating area and the streets of the company’s aprendizados units.<br />

The next step is to replace all the 500 precisam mercury se vapor<br />

converter em<br />

lamps used for that purpose.<br />

The operational areas where the new lighting<br />

will be installed include the boilers, which are being<br />

adapted for LED. Specific lighting will be installed for<br />

the furnaces, using LED technology. Finally, the project<br />

will move on to the warehouses and workshops:<br />

the investment made so far at UNIB totals BRL<br />

800,000, with a projected payback period of one year,<br />

considering all the benefits the new system will bring.<br />

Meanwhile, Braskem has decided that its butadiene<br />

plant, scheduled to go online in 2013 in Rio<br />

Grande do Sul, will be entirely lit with LED.<br />

informa<br />

13

oof<br />

A model for sustainability, the new Petrobras building<br />

in eastern Brazil is equipped with high-tech<br />

energy-saving features<br />

Creativity goes<br />

through the<br />

written<br />

The state of Espírito Santo is the secondlargest<br />

oil producer in Brazil and is expected<br />

to attain production of 400,000<br />

barrels per day by the end of the year.<br />

In 1957, Petrobras was the first to explore<br />

for oil in that state. Since then, several fields have<br />

been discovered, and in 2001 the company established<br />

its headquarters in the state capital, Vitória. Due to the<br />

4<br />

growth of production, especially in the 2000s, Petrobras<br />

decided to build a new headquarters<br />

there. Consórcio OCCH, a<br />

joint venture of<br />

by Fabiana Cabral photos by Lívia Aquino<br />

<strong>Odebrecht</strong> Infraestrutura, Camargo Corrêa and Hochtief,<br />

was chosen to take the project off the drawing board<br />

and deliver a building that is a model of sustainability<br />

and energy efficiency.<br />

The chosen site was a hill in the Barro Vermelho<br />

neighborhood. The main entrance is on Avenida<br />

Nossa Senhora da Penha. With a built area of<br />

95,000 m2, the complex comprises two office towers<br />

connected by a central building, a Virtual Reality<br />

Center, a Data Processing Center, a restaurant<br />

and a utilities building. About 600 professionals are<br />

currently working at the jobsite, which will eventually<br />

be used by 2,000 people.<br />

The complex was designed to make the<br />

most of the region’s natural ad-<br />

Petrobras’s new<br />

headquarters<br />

in Vitória and,<br />

opposite, some<br />

of the pipes used<br />

to keep chilled<br />

water circulating<br />

between floors:<br />

a modern<br />

air-conditioning<br />

system

vantages, such as abundant sunshine and cooling<br />

breezes, and will be equipped to make it eco-efficient.<br />

“This building is a showroom for sustainable<br />

processes and high technology, including the<br />

use of solar energy and low heat absorption glass,<br />

100% sewage treatment and water recycling to<br />

water the garden and flush toilets, as well as an<br />

economic air-conditioning system,” observes <strong>Odebrecht</strong><br />

Project Director Sidney dos Passos Ramos.<br />

With the energy efficiency of the enterprise in<br />

mind, Petrobras and the OCCH joint venture opted<br />

for a modern air-conditioning system that uses<br />

water to cool every room. The Radiant Ceiling<br />

system was installed in the offices and the main<br />

building. “This is the first real estate development<br />

in Espírito Santo to use this kind of technology,”<br />

says Sidney.<br />

According to Antônio Morais Telesforo, the Utilities<br />

and Electromechanical Installations Manager<br />

at the joint venture, water is more efficient than air<br />

when it comes to heat exchange, and requires less<br />

energy to cool the building. “The Radiant Ceiling<br />

reduces water and power consumption by about<br />

30%, and keeps out drafts and noise. It regulates<br />

the temperature and humidity, providing more<br />

comfort for the building’s users,” he explains.<br />

It is a closed-circuit system composed of 5 km of<br />

insulated pipes, which hold 200,000 liters of chilled<br />

water that circulate between the floors of the complex<br />

and the chillers in the utilities building, where<br />

the process begins.<br />

The new Petrobras Building’s Chilled Water Plant<br />

contains four chillers of three types: electric, where<br />

heat is expelled (similar to the process of cooling a<br />

refrigerator), absorption, using chemical reactions<br />

to absorb heat, and air, for emergencies, equipped<br />

with 12 fans. “The temperature of the water is 5°C<br />

when it leaves the plant and 15°C with returns,”<br />

says Edimauro Conde Arouca, Project Coordinator<br />

at Eleven Systems, one of the joint venture’s partner<br />

companies.<br />

After being chilled, the water is pumped through<br />

the pipes until it reaches coils coupled to metal plates<br />

in the Radiant Ceiling. “The coils radiate the cold to<br />

the surface of the plate, which radiates it into the<br />

room,” explains Edimauro. The water then returns to<br />

the chiller and the process starts all over again.<br />

To control humidity and the amount of CO2 in the<br />

air, the Radiant Ceiling also uses an air-cooled system.<br />

“Since there is no air exchange with the external<br />

environment, a device called a fan-coil removes<br />

the dirty cold air and clean fresh air comes in,” says<br />

Antônio Morais. “The rooms have been divided into<br />

comfort zones to maintain the same temperatures<br />

and save energy. Users will not even notice that the<br />

place is air-conditioned,” he adds.<br />

informa<br />

15

A benchmark<br />

called<br />

cachoei<br />

Construction of a small hydroelectric plant<br />

bolsters the city’s standing as a role model<br />

for overcoming the challenges of supplying<br />

water and sewer services<br />

written by Irene Vucovix photos by Bruna Romaro<br />

16<br />

Foz’s SHP on the<br />

Itapemirim River:<br />

a milestone for the<br />

company and the city

o<br />

From the windows of his office, Pablo Andreão,<br />

Director of Foz’s Cachoeiro de<br />

Itapemirim Unit in the eastern Brazilian<br />

state of Espírito Santo, has a magnificent<br />

view of the Itapemirim River<br />

and a good part of a pioneering project. The Small<br />

Hydropower Plant (SHP) built on Ilha da Luz (Island<br />

of Light) began operations in early November, making<br />

the city’s water and sewer utility energy self-sufficient.<br />

The SHP is a milestone for Foz and Cachoeiro de<br />

Itapemirim, Espírito Santo’s “Princess of the South.”<br />

For the company, this is because it reinforces its role<br />

as a hub of excellence in providing an essential service<br />

while using energy more efficiently. For the city,<br />

it is because it has retrieved the history of Ilha da<br />

Luz, which got its name in 1903, the year when the<br />

original power plant began operations there and became<br />

the driving force that made Itapemirim the first<br />

city in Espírito Santo and the third in Brazil to have<br />

electric street lights.<br />

Precisely 108 years later, Foz has invested BRL 30<br />

million in the construction of an SHP that includes<br />

the restoration of part of the structure built at the<br />

time of the old power plant, which also spotlights a<br />

history that is a source of pride for the entire community.<br />

Ilha da Luz is once again living up to its name<br />

through a venture that generates 500 times more energy<br />

than the old plant did in the early 20th century.<br />

The SHP is designed to generate 3.8 MW of power,<br />

36% more than the 2.8 MW planned in the initial design,<br />

and enough energy to power a city of 40,000 inhabitants.<br />

“Electricity is the biggest part of a water and sewer<br />

utility’s budget,” says Pablo Andreão. “The commercial<br />

operation of the SHP makes <strong>Odebrecht</strong>’s<br />

environmental solutions company a role model for<br />

energy efficiency and sustainability. This will be highly<br />

positive for the local community and partnerships<br />

with suppliers by creating value for shareholders and<br />

the entire water and sewer business in Brazil.”<br />

Andreão took the helm at Foz in Cachoeiro de Itapemirim<br />

in June. A 10-year member of the <strong>Odebrecht</strong><br />

Organization, he has actively participated in the entire<br />

process of implementing the SHP, which began in<br />

2003 with the initial feasibility studies. Later, in 2005,<br />

he oversaw the licensing process and, as of June 2010,<br />

informa 17

he has supervised construction of the plant. Because<br />

it is being built in an urban area, it required extensive<br />

dialogue with the community and an intense social<br />

and environmental education program.<br />

The biggest beneficiaries of the plant’s commercial<br />

operations will be residents of the urban area, which is<br />

home to more than 90% of Cachoeiro de Itapemirim’s<br />

190,000 inhabitants. Foz supplies drinking water to<br />

99.5% of the properties in that region, and 92.5% are<br />

also serviced by sewer systems. Andreão observes:<br />

“The SHP will ensure the steady operations of the utility,<br />

whose services require continuous operation of<br />

facilities and equipment located throughout the urban<br />

area that is the municipal seat of Cachoeiro, as well as<br />

in the other nine districts that make up the city.”<br />

Cachoeiro’s economy will also get a tremendous<br />

boost from the SHP’s operations because it will allow<br />

Foz to stop sourcing all the energy it uses from the<br />

local public system, as the utility is one of the 10 largest<br />

electricity purchasers in the city. Because this input<br />

is critical for industry, the local infrastructure will<br />

become even more attractive for new and significant<br />

developments that will create more jobs and sources<br />

of income.<br />

“The SHP will strengthen the status Cachoeiro<br />

de Itapemirim already enjoys as a benchmark for<br />

its water and sewer system, which has made our<br />

city one of the first in Brazil to address the issues of<br />

water supply and sewer services through a publicprivate<br />

partnership,” says Pablo Andreão.<br />

World class<br />

“Foz has the water and sewer service concession<br />

until 2035 and is responsible for operating,<br />

maintaining, modernizing and expanding Cachoeiro<br />

de Itapemirim’s water and sewer system.<br />

The goal is to steadily develop a system that was<br />

already good, thereby enhancing <strong>Odebrecht</strong>’s values<br />

and philosophy,” says Mário Amaro da Silveira,<br />

former COO of Foz in Cachoeiro and now Director<br />

of Saneatins, the Tocantins state sanitation company,<br />

Foz’s latest achievement, which in October<br />

obtained a stake in the company’s private-sector<br />

shareholdings (76.52%).<br />

Foz took over the operation of the city’s water and<br />

sewer services in 2008. Between 2009 and 2012, the<br />

company’s investments will total BRL 75 million,<br />

compared with BRL 50 million spent over the pre-<br />

18<br />

informa

Installing a turbine<br />

at the SHP: electricity<br />

is the most expensive<br />

input for a water and<br />

sewer utility<br />

vious 10 years. The BRL 75 million have been distributed<br />

on three fronts: water loss reduction and<br />

automation; expanding the coverage of the sewer<br />

system; and construction of the Ilha da Luz SHP.<br />

“Foz has an institutional client, the city government,<br />

which is the grantor, but the client is actually<br />

the end consumer, who receives drinking water<br />

with world-class treatment standards from a utility<br />

ranked among the top seven providers of water and<br />

sewer services in Brazil,” adds Mário Amaro da Silveira,<br />

referring to the ranking the company obtained<br />

through the National Quality in Sanitation Award in<br />

2010.<br />

Luiz Carlos de Oliveira, CEO of the City Regulation<br />

Agency for Public Utilities in Cachoeiro (Agersa),<br />

says he is satisfied: sanitation in the city is<br />

“well-rounded.” “This makes it possible to focus<br />

our efforts on overcoming challenges related to<br />

other municipal services, and the city can invest<br />

in areas like health and education.” He also points<br />

out that the Ilha da Luz SHP allows the utility to<br />

provide services more efficiently, which directly<br />

benefits the public by reducing the cost of water<br />

and sewer rates.<br />

Oliveira observes that the plant’s construction and<br />

the visual impact of the works have stirred public interest<br />

and sparked the popular imagination. “Some<br />

people even thought the Itapemirim River would be<br />

filled in,” he jokes. All the rumors were cleared up,<br />

and the inhabitants were reassured. The Itapemirim,<br />

a source of pride for Cachoeiro’s residents, is just as<br />

it always was, but much cleaner since Foz installed<br />

the sewer system.<br />

Barber Joseph Dalvi, 71, six-time president of<br />

the Teixeira Leite District Residents Association and<br />

willing to serve many more terms in office, can attest<br />

to that. He has lived in the same house overlooking<br />

the Itapemirim for over 40 years, and has<br />

spent many weekends collecting debris floating<br />

in the polluted waters of the river. Over time, his<br />

daughters grew up, his grandson was born, his hair<br />

turned white and he has learned to understand the<br />

soul of Itapemirim even better. “Before, the stench<br />

was unbearable, the fish disappeared, and you could<br />

hear the river groaning for her life. Now, thanks to<br />

the sewer system, the stench is gone, the fish came<br />

back and it’s full of fingerlings jumping in the water.<br />

The river is alive again.”<br />

informa<br />

19

A complex<br />

of three<br />

factories in<br />

Suape will be<br />

Brazil’s largest<br />

integrated hub<br />

for polyester<br />

production<br />

ener<br />

Project<br />

Director<br />

José Gilberto<br />

Mariano and<br />

part of the<br />

complex’s<br />

facilities:<br />

innovation<br />

and education<br />

through work<br />

20<br />

20<br />

informa

gizing<br />

the textile industry<br />

written by Renata Meyer photos by Tiago Lubambo<br />

Organizing the largest integrated polyester<br />

production hub in Latin America polymers and filaments; resin for PET packaging;<br />

complex, which will contain three plants: polyester<br />

at the Suape Industrial and Port Complex<br />

in Ipojuca, Pernambuco. This is material for polyester products.<br />

and Purified Terephthalic Acid (PTA), the basic raw<br />

the goal of Companhia Petroquímica When all three plants are fully operational by the<br />

de Pernambuco – PetroquímicaSuape, a subsidiary end of 2012, the complex’s electricity consumption<br />

of Petroquisa, the petrochemical arm of Petrobras.<br />

Three integrated industrial units will be built in a<br />

550,000-m2 area with the aim of giving fresh impetus<br />

to the Brazilian textile industry.<br />

To put the plan into effect, <strong>Odebrecht</strong> Engenharia<br />

Industrial has been hard at work since 2007, as the<br />

company responsible for detailed engineering, supply<br />

of the materials and equipment, construction<br />

and the assembly of electromechanical units. The<br />

Organization’s industrial engineering arm is also responsible<br />

for managing the construction of the entire<br />

could reach 4.5% of the state of Pernambuco’s entire<br />

demand, a total of 100 MW. The client is taking<br />

several measures to ensure the rational use of energy<br />

resources on this project, with technical support<br />

from <strong>Odebrecht</strong> teams.<br />

Cogeneration plant<br />

One of those measures is the installation of a central<br />

cogeneration plant using heat generated by the<br />

PTA production process. The Process Air Compressor<br />

(PAC) system will allow the unit to reuse energy<br />

informa<br />

21

and, therefore, will ensure a savings of approximately<br />

12% in the PTA plant’s power consumption.<br />

The main raw material in the production process<br />

for PTA is paraxylene, a petroleum product which undergoes<br />

oxidation when subjected to high pressure<br />

in the presence of air and heat, releasing gases with<br />

temperatures in excess of 200 o C. “Under no circumstances<br />

can these gases be released into the atmosphere,<br />

because the impacts on the environment<br />

would be very harmful. So the heat extracted during<br />

the cooling process is used in the cogeneration plant<br />

to produce electric power for the plant’s own use,”<br />

says Mauro Ambrosano, General Manager for Maintenance<br />

at PetroquímicaSuape.<br />

The PAC compresses the air feeding the PTA<br />

plant’s oxidation reactor. The compressor is driven by<br />

an engine/reactor, which contains a turbine and an<br />

expander connected to the same system, driven respectively<br />

by steam and hot gases generated during<br />

the oxidation process.<br />

“The electricity generated by the heat that results<br />

from this process is considerably greater than the<br />

amount required to run the PAC, so the surplus is<br />

exported to the grid and used at the PTA unit,” explains<br />

Ambrosano.<br />

Pioneering technology in Brazil<br />

Imported by the client, this technology was developed<br />

by Invista, a British technology company, in<br />

partnership with Siemens of Germany. This is the first<br />

time it will be deployed in the Brazilian petrochemical<br />

industry. Thanks to the PAC, PetroquímicaSuape<br />

no longer needs to purchase 30.6 MW from the primary<br />

energy grid, providing a savings of up to BRL 5<br />

million per month. “Using conventional technologies,<br />

all this energy would be wasted,” Mauro Ambrosano<br />

explains.<br />

<strong>Odebrecht</strong> Engenharia Industrial is responsible<br />

for installing the equipment in a process that requires<br />

a high level of expertise. Weighing about 300<br />

tonnes, the PAC is a rotating assembly in which each<br />

component acts on the rest. “The assembly and installation<br />

of the PAC is a process that requires tremendous<br />

precision. Our biggest challenge is to ensure<br />

perfect alignment of the parts so that everything<br />

works as planned,” says Project Director José Gilberto<br />

Mariano. “Participating in pioneering project<br />

of this magnitude allows us to groom more and more<br />

people who will be qualified to work on ever more<br />

complex projects,” he adds.<br />

In addition to the PAC, the Suape Petrochemical<br />

Complex will use other strategies to ensure the rational<br />

use of energy. All the civil engineering and architectural<br />

designs for the plants ensure maximum use<br />

of sunlight, which helps reduce the number of light<br />

fixtures used. This measure, combined with ultra-high<br />

performance equipment, is viewed as a priority in all<br />

operations, allowing an estimated energy savings of<br />

about 5%.<br />

The synergistic integration of the industrial units,<br />

seen as a significant competitive advantage in this<br />

venture, is also a factor in resource optimization. Using<br />

a central utility to supply the entire complex with<br />

informa<br />

22

Inside one of the<br />

factories: benefiting the<br />

textile industry’s entire<br />

supply chain<br />

compressed air and cooling water reduces operating<br />

costs and energy wastage.<br />

The complex also has a central chilled water facility<br />

for all the plants. The high-performance, automated<br />

air-conditioning process continuously monitors temperature<br />

and humidity inside and outside the plants,<br />

and ensures the ideal mix of air to provide suitable conditions<br />

for the units’ operations while saving energy.<br />

Quality power<br />

The power supply is one of the factors that have<br />

the greatest impact on the textile industry’s operations<br />

due to the high demand for this input in production<br />

processes, and especially the quality required in<br />

energy transmission, which is crucial to ensuring<br />

that the equipment runs smoothly.<br />

“The slightest voltage variation, imperceptible in<br />

most industrial uses of electricity, could break textile<br />

fibers and force the plant to interrupt its operations.<br />

A shutdown of this nature is very harmful for<br />

the resumption of the production process, which<br />

could take weeks,” says Mauro Ambrosano. To ensure<br />

the stability of the electric current, both the<br />

equipment and the substation serving the complex<br />

are equipped with a sophisticated power quality control<br />

system.<br />

Thanks to a total investment of BRL 4.9 billion, the<br />

plants at the Suape Petrochemical Complex should<br />

work nonstop, every day of the year, except during<br />

planned maintenance shutdowns. The expectation is<br />

that this project will benefit the entire supply chain<br />

for the Brazilian textile industry.<br />

informa<br />

23

interview<br />

“Here we are, as<br />

investor<br />

written by Zaccaria Junior<br />

photo by André Valentim<br />

Recently created to manage <strong>Odebrecht</strong>’s investments<br />

and operate power generating assets with a focus on<br />

renewable sources, <strong>Odebrecht</strong> Energia has inherited<br />

the legacy of the Organization’s long connection with the<br />

electric power generation industry, which dates back to<br />

1952, the year it began building the Ituberá and Candengo hydropower<br />

plants in Bahia. It has also been an investor since 1994, starting with<br />

the Itá hydro in Santa Catarina, which marked the resumption of private<br />

investment in that sector in Brazil. In this interview with <strong>Odebrecht</strong><br />

<strong>Informa</strong>, Henrique Valladares, CEO of <strong>Odebrecht</strong> Energia, discusses<br />

the Organization’s achievements and future in this sector. “We are<br />

committed to living up to our Shareholders’ confidence in us and to<br />

providing energy solutions for other Organization companies and our<br />

Clients in Brazil and other countries,” he says.<br />

24<br />

24<br />

informa

s”<br />

Henrique Valladares:<br />

“We have the<br />

installed capacity<br />

to be investors and<br />

operators inside<br />

and outside Brazil”<br />

informa<br />

25

<strong>Odebrecht</strong> <strong>Informa</strong> – <strong>Odebrecht</strong> has a long track<br />

record as a contractor, participating in the construction<br />

of about half of the power generating facilities in Brazil,<br />

both on its own and in joint ventures. Did that lead to the<br />

natural decision to bolster its investment arm?<br />

Henrique Valladares – <strong>Odebrecht</strong> has a long<br />

history in this area. And the fact that we have extensive<br />

experience in the construction of electric power assets<br />

positions us differently in the generation segment. Most of<br />

Capanda hydroelectric plant, a major vector for<br />

the development of the Angolan economy. Also,<br />

we began our operations in Argentina and Mexico<br />

with the Pichi-Picún-Leufú and Los Huites plants,<br />

respectively. <strong>Odebrecht</strong> has been ranked as the<br />

largest international builder of hydroelectric dams<br />

eight times, according to ENR – Engineering News-<br />

Record, a publication that is a benchmark in the<br />

industry.<br />

<strong>Odebrecht</strong>’s investment opportunities have resulted from<br />

thorough knowledge of two key variables: time and costs.<br />

And we have learned from our roots: providing excellent<br />

engineering and construction services and meeting the<br />

Client’s needs. Moreover, long experience in financial<br />

OI – Is <strong>Odebrecht</strong> Energia also focusing on international<br />

investments?<br />

Valladares – Absolutely. We now have the installed capacity<br />

to be investors and operators both inside and outside Brazil.<br />

engineering, especially<br />

We have also applied this<br />

in the form of project<br />

finance, also makes a<br />

capability in other promising<br />

markets, such as Peru,<br />

difference in our role as<br />

investors in electricity<br />

generation, particularly in<br />

greenfield projects. The<br />

drive to better serve their<br />

Clients has enabled our<br />

entrepreneur-partners<br />

to acquire a thorough<br />

knowledge of the value<br />

chain for the power generation<br />

business, which<br />

enables them to grow<br />

our holdings. So here we<br />

are, positioning ourselves<br />

as investors, through the<br />

“<strong>Odebrecht</strong> has a long<br />

track record in the<br />

energy area.<br />

And the fact that we have<br />

extensive experience<br />

in the construction<br />

of assets in that area<br />

is very important”<br />

where we were awarded<br />

the Chaglla Hydroelectric<br />

Plant project, the second<br />

largest in the country, which<br />

broke ground in the first<br />

half of this year. That project<br />

represents an investment<br />

of USD 1.2 billion and<br />

marks the beginning of the<br />

performance of <strong>Odebrecht</strong><br />

Energia as an investor and<br />

operator of power generation<br />

assets outside<br />

Brazil.<br />

creation of <strong>Odebrecht</strong> Energia S.A., with operations in OI – What about the Brazilian market? What is the<br />

Brazil and other countries. It is important to point out company doing to keep pace with the growth of<br />

that our operations in the hydropower plant market have investments in the energy sector?<br />

also been a key factor for the Organization’s international Valladares – For decades, investments in the energy<br />

expansion.<br />

sector were predominantly made by the Brazilian<br />

government. We’ve continued investing in power<br />

OI – Why is that?<br />

generation in the case of the Santo Antônio hydropower<br />

Valladares – Dam construction has always been plant on the Madeira River in Rondônia, where<br />

an important vector for growth outside Brazil. Peru <strong>Odebrecht</strong> is not only building the plant but <strong>Odebrecht</strong><br />

was the starting point of <strong>Odebrecht</strong>’s international Energia has a significant stake in the investment and<br />

expansion. We have been present in that country management of the concession.<br />

since 1979, starting with the Charcani V hydro in<br />

Arequipa, built under the Misti volcano. Another OI – Is Santo Antônio a milestone?<br />

milestone in our internationalization process was Valladares – It certainly is! We have adopted<br />

Angola, where we arrived in 1984 to build the the strategy of investing in inventories and feasibility<br />

26

studies for hydropower projects, contributing to the<br />

development of industry while participating as investors<br />

in auctions held by the Federal Government. And the<br />

biggest auction of all, without a doubt, was for the<br />

Madeira River Complex. Santo Antônio has cemented<br />

our role as investors in this sector. Since we were<br />

in professionals from other parts tends to have on a<br />

region. Today, 80% of the workforce at Santo Antônio<br />

consists of locally hired skilled professionals, 10% of<br />

whom are women, which represents a paradigm shift in<br />

the construction of hydroelectric dams in the Amazon<br />

region.<br />

awarded the concession for the Santo Antônio plant,<br />

our view of the energy market is now primarily as an<br />

investor, without detriment to <strong>Odebrecht</strong>’s operations<br />

as a provider of engineering and construction services,<br />

as in Belo Monte and Teles Pires.<br />

OI – Does the company’s strategy include other sources<br />

of power?<br />

Valladares – In addition to already counting on<br />

the generating assets of the Chaglla and Santo<br />

Antônio hydroelectric dams, we are also aware of the<br />

OI – Santo Antônio, which is in the middle of the Amazon<br />

Basin, is a project that is now viewed a benchmark for<br />

opportunities afforded by a range of alternative sources<br />

such as wind, biomass, small hydros and solar power.<br />

inducing sustainable development.<br />

Talking about wind<br />

Does this<br />

power generation,<br />

the<br />

“The fact that the<br />

greatest potential for<br />

hydropower generation<br />

in Brazil is located in the<br />

Amazon biome requires<br />

outstanding performance<br />

in social and environmental<br />

management”<br />

auction held in August<br />

this year enabled us to<br />

deploy four wind farms<br />

in Rio Grande do Sul,<br />

totaling 116 MW. We also<br />

have 13 more farms (290<br />

MW) on hand that are<br />

qualified to participate<br />

in upcoming auctions,<br />

as well as prospects for<br />

greenfield projects in<br />

the states of Bahia and<br />

Ceará. Furthermore, we<br />

are beginning to develop<br />

other projects involving<br />

all kinds of alternative<br />

provide more security<br />

for investment?<br />

Valladares – It is no<br />

accident that we have<br />

achieved this level of<br />

trust and governance.<br />

The entire Santo Antônio<br />

venture is based<br />

on six years of studies<br />

conducted jointly by Furnas<br />

and <strong>Odebrecht</strong>,<br />

which analyzed the<br />

social, economic and<br />

environmental aspects<br />

of the project in depth.<br />

The fact that the greatest<br />

potential for hydropower generation in this energy sources. We want to have a very significant stake<br />

country is located in the Amazon biome dictates the in this segment.<br />

need for outstanding performance in environmental<br />

management, ranging from project design to the OI – What is your overall assessment of <strong>Odebrecht</strong><br />

implementation of programs to mitigate and offset the Energia’s operations thus far?<br />

environmental impacts of projects and promote the Valladares – We are optimistic about business opportunities<br />

in Brazil and abroad. We are confident that Brazil’s<br />

development of the people living in the vicinity of the<br />

project. The best example is the Acreditar Professional regulatory model will be increasingly attractive for private<br />

Education Program, which was first introduced in investors, and that we can help provide a safe, stable supply of<br />

Santo Antônio and is now being deployed throughout electricity, which is vital to our country’s development. We also<br />

the <strong>Odebrecht</strong> Organization. The greatest legacy of this hope to provide solutions that will enable <strong>Odebrecht</strong> Energia<br />

program is the fact that more than 37,000 residents to grow organically, consolidating a generating capacity that<br />

of Porto Velho and the surrounding region now have consists of additional sources of energy in Brazil and other<br />

job skills that have created fresh prospects in their countries, generating results for Clients, Shareholders, Organization<br />

members and society as a lives and minimized the negative impact that bringing<br />

whole.<br />

informa<br />

27

28<br />

The logistics of building the<br />

Teles Pires hydroelectric plant<br />

and forming the management<br />

team in a remote part of northern<br />

Brazil are a major challenge,<br />

overcome with innovation<br />

Encountering<br />

Brazil<br />

written by Rodrigo Vilar photos by Geraldo Pestalozzi<br />

28<br />

informa

In Salvador, Bahia, the work day began at dawn<br />

for the <strong>Odebrecht</strong> <strong>Informa</strong> team reporting on the<br />

magazine’s first feature story about the construction<br />

of the Teles Pires Hydroelectric Plant, on the<br />

border of the Brazilian states of Mato Grosso and<br />

Pará. Our journey started with a flight to Cuiabá with<br />

a stop in Brasilia. After arriving in the state capital of<br />

Mato Grosso, we traveled for another hour and a half<br />

on a smaller plane to the town of Alta Floresta. There,<br />

we were met by a car the project’s management team<br />

had sent to take us on the final 52 km stretch, half of it<br />

on dirt roads, and we finally reached Paranaíta, a town<br />

of 7,000 that now houses the administrative base for the<br />

project. It was late afternoon by the time we arrived at<br />

the head office, and during our first conversation, the<br />

officer Responsible for Communication for the project,<br />

Ana Paula Silvestre, advised us: “Tomorrow we have to<br />

travel over 95 km, about two and a half hours by dirt<br />

road, to reach the construction site.”<br />

The long trek to the jobsite is just one of many challenges<br />

of carrying out a project for the Federal Government’s<br />

Growth Acceleration Program (PAC), a hydro with<br />

an installed capacity of 1,820 MW (megawatts) whose first<br />

generator unit will go online by 2014. The winner of the<br />

power generation auction held by the National Electrical<br />

Energy Agency (ANEEL) in December 2010, Companhia<br />

Hidrelétrica Teles Pires S/A, a Special Purpose Company<br />

formed by Neoenergia (50.1%), Eletrobras Furnas (24.5<br />

%), Eletrobras Eletrosul (24.5%) and <strong>Odebrecht</strong> Energia<br />

(0.9%), is responsible for building and operating the plant.<br />

Working under an EPC (engineering, procurement and<br />

construction and installation) contract, <strong>Odebrecht</strong> is the<br />

company in charge of civil construction and installation for<br />

the project, which will create 6,000 direct job opportunities.<br />

informa<br />

29

The work order for installation of the jobsite was issued<br />

in August 2011, but planning and mobilization began<br />

much earlier. “On the Teles Pires project, I can safely say<br />

that from the beginning of the financial engineering for the<br />

project to the point where we are today, we have carried<br />

out every item planned,” explains Project Director Antonio<br />

Augusto Santos.<br />

Thanks to the joint efforts of the project’s teams, by<br />

October, 200 machines – out of a total 265 – were already<br />

available at the company’s yard in Paranaíta. The equipment,<br />

all brand new, came from Brazil, Sweden, Argentina,<br />

the United States and Germany, representing a direct<br />

investment of BRL 152.5 million from <strong>Odebrecht</strong>.<br />

“In addition to the logistical challenge, the booming infrastructure<br />

sector, thanks to the [2014 FIFA] World Cup<br />

and major works in the energy sector, plus the overload<br />

faced by the nation’s seaports, made the entire process<br />

very complicated. Our success was mainly due to the competence<br />

of the teams that developed and carried out this<br />

plan,” says Antonio Augusto.<br />

According to Victor Carvalho Marques, the officer Responsible<br />

for Civil Works, Engineering and Equipment, the<br />

decision to buy instead of rent was strategic. “You’re in a<br />

remote area with limited access, so bringing in used equipment<br />

could cause serious problems in terms of maintenance<br />

and replacement. With new equipment, the possibility<br />

of achieving expected performance is much higher, and<br />

the sheer magnitude of the Teles Pires project should use<br />

up almost half the lifetime of this machinery,” he explains.<br />

A small city at the jobsite<br />

One of the main challenges was to bring in the right<br />

equipment, and another was attracting the right people<br />

The Teles Pires River, where<br />

the plant will be built. Below,<br />

married couples working together<br />

on the project, and the heavy<br />

equipment that has already arrived<br />

at the jobsite: planning and creativity<br />

overcome isolation<br />

for the project. “There will be 6,000 people housed at the<br />

permanent construction site. It’s a small city. We’re going<br />

to build recreational areas such as parks and sidewalks,<br />

and there will be green areas, gazebos, restaurants, a<br />

beauty salon and other facilities. These measures are<br />

meant to be motivating, to enable people to live well, realize<br />

their potential and develop through work,” explains<br />

Antonio Augusto.<br />

Because the jobsite is so remote, recruiting strategic<br />

team members was a major issue. Antonio Augusto<br />

himself came up with one solution: “We worked to identify<br />

the skills and experience of the spouses of <strong>Odebrecht</strong><br />

members to match their expertise with the project’s<br />

needs and invite them to work here as a couple.”<br />

Spouses do not work on the same programs to avoid<br />

any hitches in the assessment and development process.<br />

Just counting the newlyweds, there are 12 married<br />

couples at the jobsite. On October 12, at the request<br />

of <strong>Odebrecht</strong> <strong>Informa</strong>, they all got together for dinner at<br />

the group’s favorite restaurant.<br />

30<br />

informa

Coexistence and adaptation<br />

Juliana Lima, 30, who has been with the Organization<br />

for a year and four months, is responsible for People<br />

and Organization at the Teles Pires Plant construction<br />

project, which she joined at the feasibility study stage<br />

in November 2010. She was also one of the first people<br />

to arrive in Paranaíta in January 2011. For her, the biggest<br />

challenge in those early months was being far away<br />

from her family, especially her husband, Alberto Fraga,<br />

30, whom she married six months ago. “I was over the<br />

moon when the opportunity arose for Alberto to come<br />

here as well,” she says, unable to hide the twinkle in her<br />

eye. Alberto has a degree in fishing engineering and a<br />

specialization in Safety Engineering, and joined the team<br />

in April. Since then, he has been Responsible for Left<br />

Bank Workplace Safety.<br />

Unlike other colleagues in the same situation, who<br />

preferred to rent houses while the residential village at the<br />

jobsite is being built, the couple has been sharing a hotel<br />

room in the quiet town of Paranáita for the last three<br />

months. What might be hard for some is like shooting<br />

fish in a barrel for Alberto. “I spent a year<br />

and a half at sea on nine trips on fishing<br />

boats. I lived and worked<br />

alongside Chinese and<br />

Spanish people<br />

who were total strangers. Now, I’m living together with<br />

my wife in a hotel room. It’s wonderful,” he says. “There’s<br />

no comparison!” he adds, with a smile, hugging his wife<br />

Juliana. She agrees. “He is very organized, and that makes<br />

things easier for me. Being together is a motivating factor.”<br />

Civil engineer Luciane Daltro, 32, the officer Responsible<br />

for Costs, and her husband, Alessandro<br />

Peixoto, 30, a sanitation and environmental engineer<br />

who is working on the project’s Environment program,<br />

have always wanted to harmonize their professional<br />

and personal lives. They have been together for 10<br />

years and married for three. Alessandro has worked<br />

in the Brazilian cities of Manaus, Belém and Belo<br />

Horizonte as well as in Argentina. Then, to top it off,<br />

Luciane went to work for <strong>Odebrecht</strong> Angola in Africa<br />

two years ago,.<br />

“Now we have breakfast, lunch and dinner together.<br />

Now we appreciate small details that we’ve never had<br />

the chance to experience together,” she says. Sitting<br />

beside her, Alessandro notes that some colleagues<br />

are still adapting to life in such a small town, which<br />

comes naturally for him. However, he emphasizes<br />

that the important thing is to focus on the positive<br />

side of this experience and the opportunities it offers.<br />

“This large gathering that you are seeing here today<br />

is normal for us. In our social lives, we might<br />

want to get away from the difficulties of<br />

the job, but not from the people<br />

we work with. Bit by bit, we<br />

are building one big<br />

family.”<br />

informa<br />

31

frien<br />

32<br />

32<br />

informa

dly<br />

<strong>Odebrecht</strong><br />

makes its<br />

debut in the<br />

wind power<br />

segment,<br />

a priority<br />

resource for<br />

Brazil<br />

<strong>Odebrecht</strong> Archives<br />

winds<br />

Bwritten by Cláudio Lovato Filho<br />

razil wants to harness the winds that<br />

blow in its favor. And soon, because<br />

the pace and need for economic<br />

growth require it. Investments in wind<br />

power generation, among other renewable<br />

energy sources such as ethanol and biomass,<br />

will consolidate Brazil’s energy mix as the<br />

cleanest and one of the most diversified in the<br />

world. More options reduce the risk of dependence<br />

on a single source. The wise old saying that you<br />

shouldn’t put all your eggs in one basket is very<br />

apt in this case.<br />

The nation is preparing to establish wind farms<br />

in several regions, especially the South and Northeast,<br />

where the winds have the most suitable characteristics<br />

for energy generation. The sight of row<br />

upon row of wind turbines will be increasingly common<br />

in this country. To help energize this Brazilian<br />

campaign to harness wind power, the <strong>Odebrecht</strong><br />

Organization has made its debut in this segment<br />

through <strong>Odebrecht</strong> Energia, and <strong>Odebrecht</strong> Energias<br />

Alternativas, an alternative energy company<br />

created by <strong>Odebrecht</strong> Energia, is responsible for<br />

wind power operations.<br />

“Brazil wants to expand its wind energy generation<br />

capacity from 1 gigawatt, recorded in 2010,<br />

to 11.5 gigawatts by 2020,” says Fernando Chein,<br />

the Director responsible for the Wind, Solar and<br />

informa<br />

33

SHP (small hydro) segment at <strong>Odebrecht</strong> Energia.<br />

“The country’s wind power potential is over 150<br />

gigawatts according to today’s figures,” he adds.<br />

The goal of the Federal Government, set forth in<br />

its Ten-Year Plan for Energy Expansion (PDE 2020),<br />

is to make renewable sources total 46.3% of the<br />

energy mix by 2020. In 2010, that percentage was<br />

44.8%, behind oil and petroleum derivatives.<br />

Future production<br />

As the owner of the Corredor dos Senandes<br />

Complex project in Rio Grande, Rio Grande do Sul,<br />

<strong>Odebrecht</strong> Energia sold future energy production<br />

from four wind farms at the Federal Reserve Auction<br />

held on August 18, 2011. These farms include<br />

Corredor dos Senandes 2, 3 and 4 and the Vento<br />

Aragano 1. At the auction, <strong>Odebrecht</strong> sold 50.5<br />

megawatts (MW) average at a rate of BRL 99.50 per<br />

MWh (megawatt/hour). To do so, it will have to install<br />

116.9 MW of total capacity in wind farms. The<br />

contract signed with the CCEE (Chamber of Electric<br />

Energy Sales) is for 20 years. The wind farms<br />

will be established as of June 2012. Initial generation<br />

is expected to begin by June 2014.<br />

At the moment, the company is covering several<br />

fronts at once under the direct leadership of Walter<br />

Tatoni, the officer Responsible for Wind Energy Investments<br />

at <strong>Odebrecht</strong> Energia: obtaining permis-<br />

34<br />

informa

Illustration<br />

This montage shows what <strong>Odebrecht</strong>’s wind farms in Rio<br />

Grande will look like. Smaller photo: Mayor Fábio Branco: “We<br />

need to make the most of our resources as soon as possible”<br />

sion for exploration from the grantor, consolidation<br />

of all documentation necessary to obtain the permits<br />

required for the deployment of wind farms (particularly<br />

environmental permits), forming and grooming<br />

the management team and setting up the farms,<br />

awarding contracts for goods and services, including<br />

wind turbines supplied by Alstom (the company<br />

responsible for the manufacturing, operations and<br />

maintenance of turbines), and seeking approval of<br />

funding from BNDES, Brazil’s national socioeconomic<br />

development bank.<br />

“In its role as an investor, operator and seller<br />

of energy, <strong>Odebrecht</strong> Energia wants to reach<br />

10,000 MW of own generation by 2020,” says Wal-<br />

Photo: Eduardo Beleske<br />

informa<br />

35

Alstom’s new factory in<br />

Camaçari: investing in<br />

technology to develop wind<br />

turbines<br />

Photo: Márcio Lima<br />

ter. “Wind energy will provide a major boost to<br />

achieve this goal.”<br />

The company’s specific expertise and knowledge<br />

related to wind power is a result of the immersion<br />

of its members in this new world, and their<br />

experience in other segments of the energy sector.<br />

“We’ve been studying this area for over a year,”<br />

says Marco Rabello, CFO of <strong>Odebrecht</strong> Energia. “It<br />

has its own unique characteristics,” he explains,<br />

referring to the wind power industry. They include<br />

new requirements for documents and wind measurement,<br />

which are key to determining whether a<br />

business is viable or not.<br />

Fernando Chein is very pleased with the present<br />

stage of the stimulus program for alternative energy<br />

sources, particularly wind, but has one caveat:<br />

“I believe that auctions should be held for specific<br />

sources or regions, so that they can balance the<br />

energy mix. We should encourage investments in<br />

all sources. Competition among them may not be<br />

beneficial in the long term. These sources need to<br />

be complementary.” Marco Rabello adds: “Wind farms<br />

should only compete with each other.” Today, the<br />

auctions cover all energy sources, and a momentary<br />

price advantage for one source over another<br />

(or others) could harm one of them and, consequently,<br />

its supply chain.<br />

Seventy turbines<br />

on four wind farms<br />

The four wind farms whose energy was sold at<br />

auction on August 18 will receive a total of 70 wind<br />