Quick Selection

Quick Selection

Quick Selection

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

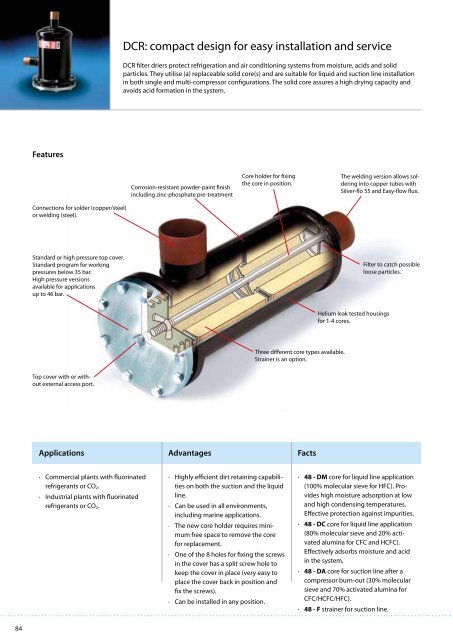

DCR: compact design for easy installation and service<br />

DCR filter driers protect refrigeration and air conditioning systems from moisture, acids and solid<br />

particles. They utilise (a) replaceable solid core(s) and are suitable for liquid and suction line installation<br />

in both single and multi-compressor configurations. The solid core assures a high drying capacity and<br />

avoids acid formation in the system.<br />

Features<br />

Corrosion-resistant powder-paint finish<br />

including zinc-phosphate pre-treatment<br />

Core holder for fixing<br />

the core in position.<br />

The welding version allows soldering<br />

into copper tubes with<br />

Silver-flo 55 and Easy-flow flux.<br />

Connections for solder (copper/steel)<br />

or welding (steel).<br />

Standard or high pressure top cover.<br />

Standard program for working<br />

pressures below 35 bar.<br />

High pressure versions<br />

available for applications<br />

up to 46 bar.<br />

Filter to catch possible<br />

loose particles.<br />

Helium leak tested housings<br />

for 1-4 cores.<br />

Three different core types available.<br />

Strainer is an option.<br />

Top cover with or without<br />

external access port.<br />

Applications Advantages Facts<br />

· Commercial plants with fluorinated<br />

refrigerants or CO 2.<br />

· Industrial plants with fluorinated<br />

refrigerants or CO 2.<br />

· Highly efficient dirt retaining capabilities<br />

on both the suction and the liquid<br />

line.<br />

· Can be used in all environments,<br />

including marine applications.<br />

· The new core holder requires minimum<br />

free space to remove the core<br />

for replacement.<br />

· One of the 8 holes for fixing the screws<br />

in the cover has a split screw hole to<br />

keep the cover in place (very easy to<br />

place the cover back in position and<br />

fix the screws).<br />

· Can be installed in any position.<br />

· 48 - DM core for liquid line application<br />

(100% molecular sieve for HFC). Provides<br />

high moisture adsorption at low<br />

and high condensing temperatures.<br />

Effective protection against impurities.<br />

· 48 - DC core for liquid line application<br />

(80% molecular sieve and 20% activated<br />

alumina for CFC and HCFC).<br />

Effectively adsorbs moisture and acid<br />

in the system.<br />

· 48 - DA core for suction line after a<br />

compressor burn-out (30% molecular<br />

sieve and 70% activated alumina for<br />

CFC/HCFC/HFC).<br />

· 48 - F strainer for suction line.<br />

84