bizhub PRESS C8000 Specification & Installation Guide

bizhub PRESS C8000 Specification & Installation Guide

bizhub PRESS C8000 Specification & Installation Guide

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Konica Minolta <strong>bizhub</strong> <strong>PRESS</strong> <strong>C8000</strong><br />

<strong>Specification</strong> & <strong>Installation</strong> <strong>Guide</strong><br />

Component Considerations<br />

2nd Fusing Unit EF-101<br />

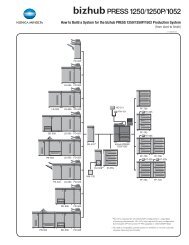

05 RU-508 EF-101 <strong>PRESS</strong> <strong>C8000</strong><br />

PK-<br />

512<br />

PI-502<br />

RU-508<br />

Type<br />

Function<br />

Paper weight<br />

Paper size<br />

Paper type<br />

Printing speed<br />

Warm-up time<br />

(20°C, 50% RH, 230 V)<br />

Dimensions<br />

Weight<br />

External finish fusing device<br />

• Even out the glossy surface of coated paper.<br />

• Enables fusing on both sides in one pass by adopting the upper/<br />

lower belt fusing system.<br />

• Feeding thin paper is available by setting a bypass that excludes<br />

the 2nd fusing unit.<br />

2nd fusing line: 37 lb. Bond or more (Plain), 28 lb. Bond or more (Coated)<br />

Bypass line: less than 37 lb. Bond (Plain), less than 28 lb. Bond (Coated)<br />

Conforms to that of main body.<br />

Conforms to that of main body.<br />

80 ppm: 36 lb. Bond or less<br />

70 ppm: 37 to 80 lb. Bond<br />

40 ppm: 81 lb. or more<br />

Printing speed is common to Plain and Coated paper, A4/Letter<br />

or smaller.<br />

6.5 minutes or less<br />

19.6" (W) x 30.5" (D) x 40.1" (H); (497 (W) x 774 (D) x 1,019 (H) mm)<br />

Approx. 210.5 lbs. (95.5 kg)<br />

-503 FS-612<br />

GP-501<br />

HM-101<br />

Power requirements<br />

Rated voltage: AC 208 to 240 V<br />

Rated current: 16 A<br />

Rated frequency: 60 Hz<br />

NEMA: 6-20R<br />

6<br />

HT-506<br />

Power consumption<br />

2,970 W<br />

Relay Unit RU-508<br />

HD-514<br />

PH-101 Type<br />

Relay unit with paper-cooling and curl adjustment functions<br />

PF-705<br />

IC-306<br />

Mechanical curl adjustment Adjust paper curl by letting it through a zigzag path, then deliver<br />

paper accelerating it according to the basic line speed determined<br />

for finishing operation.<br />

Humidifying curl adjustment Humidify paper using Humidifier HM-101 (option), then deliver<br />

paper accelerating it according to the basic line speed determined<br />

for finishing operation.<br />

LS-505 RU-508 EF-101 <strong>PRESS</strong> <strong>C8000</strong><br />

PI-502<br />

Straight delivery<br />

Reverse delivery<br />

Color density adjustment<br />

RU-508<br />

Conveyance speed<br />

Deliver paper accelerating it according to the basic line speed<br />

determined for finishing operation, without making mechanical<br />

or humidifying curl adjustment.<br />

Reverse and deliver paper accelerating it according to the basic line<br />

speed determined for finishing operation.<br />

Measure the color density of the density patch printed on paper,<br />

in order to use it as the data for image stabilization adjustment.<br />

80 sheets/min. (8.5" x 11"P, A4P)<br />

PK-<br />

512<br />

Paper size<br />

13" x 19.2"L, 12" x 18"L, 11" x 17"L, 8.5" x 14"L, 8.5" x 11"L/P,<br />

5.5" x 8.5"L/P, SRA3L, A3L, B4L, SRA4L/P, A4L/P, B5L/P,<br />

A5L/P, B6L, A6L, Foolscap, a9" x 11"P, Custom, Tab Paper<br />

Max. 13" x 19.2" (331 mm x 488 mm) to min. 3.74" x 5.47"<br />

(95 mm x 139 mm)<br />

FD-503<br />

FS-612<br />

GP-501<br />

HM-101<br />

19<br />

HT-506<br />

HT-506

![User's Guide [Facsimile Operations]](https://img.yumpu.com/25068839/1/184x260/users-guide-facsimile-operations.jpg?quality=85)

![Quick Guide [Print Operations]](https://img.yumpu.com/25068750/1/184x260/quick-guide-print-operations.jpg?quality=85)