Healthy Flavors of Science - pcaarrd - Department of Science and ...

Healthy Flavors of Science - pcaarrd - Department of Science and ...

Healthy Flavors of Science - pcaarrd - Department of Science and ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

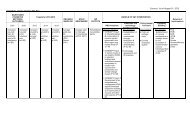

Computer vision system<br />

for milled rice quality analysis<br />

St<strong>and</strong>ardization is a strategy<br />

to improve efficiency <strong>and</strong> global<br />

competitiveness <strong>of</strong> the grain<br />

industry. Under the national<br />

st<strong>and</strong>ards on grains, milled<br />

rice is classified based on its<br />

size, degree <strong>of</strong> milling, <strong>and</strong><br />

amount <strong>of</strong> broken <strong>and</strong> other<br />

defective grains in the sample.<br />

The current practice <strong>of</strong><br />

classifying grains is by visual<br />

inspection <strong>and</strong> manual separation<br />

<strong>of</strong> each grain according to its<br />

quality category <strong>and</strong> the result<br />

is calculated on a percentage<br />

weight basis. This type <strong>of</strong> analysis<br />

is subjective <strong>and</strong> depends on<br />

the skill <strong>of</strong> the classifier <strong>and</strong><br />

the working conditions.<br />

To provide an objective,<br />

accurate, <strong>and</strong> quick method <strong>of</strong><br />

analyzing milled rice, a group <strong>of</strong><br />

researchers led by Dr. Manolito C.<br />

Bulaong <strong>of</strong> the Philippine Center<br />

for Postharvest Development <strong>and</strong><br />

Mechanization (PhilMech) developed<br />

the low-cost computer vision system<br />

(CVS). It is composed <strong>of</strong> image<br />

acquisition <strong>and</strong> processing systems.<br />

The flatbed scanner is found to be<br />

technically feasible as a low-cost<br />

image acquisition device. Using the<br />

flatbed scanner reduced the price<br />

<strong>of</strong> the computer vision system by<br />

94%. The set up using the flatbed<br />

scanner is also simpler because the<br />

scanner has its own light source.<br />

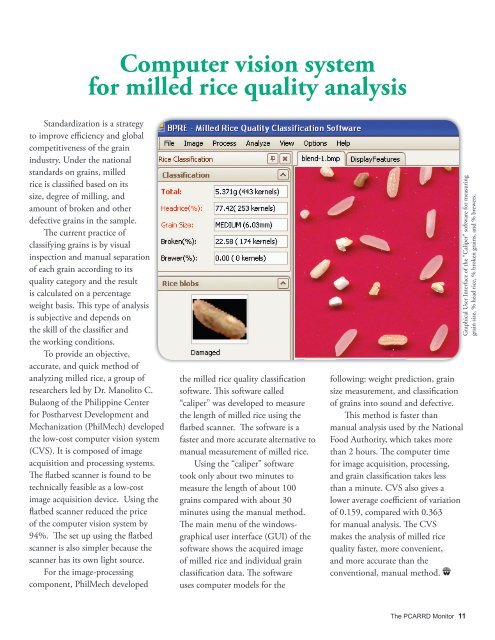

For the image-processing<br />

component, PhilMech developed<br />

the milled rice quality classification<br />

s<strong>of</strong>tware. This s<strong>of</strong>tware called<br />

“caliper” was developed to measure<br />

the length <strong>of</strong> milled rice using the<br />

flatbed scanner. The s<strong>of</strong>tware is a<br />

faster <strong>and</strong> more accurate alternative to<br />

manual measurement <strong>of</strong> milled rice.<br />

Using the “caliper” s<strong>of</strong>tware<br />

took only about two minutes to<br />

measure the length <strong>of</strong> about 100<br />

grains compared with about 30<br />

minutes using the manual method.<br />

The main menu <strong>of</strong> the windowsgraphical<br />

user interface (GUI) <strong>of</strong> the<br />

s<strong>of</strong>tware shows the acquired image<br />

<strong>of</strong> milled rice <strong>and</strong> individual grain<br />

classification data. The s<strong>of</strong>tware<br />

uses computer models for the<br />

following: weight prediction, grain<br />

size measurement, <strong>and</strong> classification<br />

<strong>of</strong> grains into sound <strong>and</strong> defective.<br />

This method is faster than<br />

manual analysis used by the National<br />

Food Authority, which takes more<br />

than 2 hours. The computer time<br />

for image acquisition, processing,<br />

<strong>and</strong> grain classification takes less<br />

than a minute. CVS also gives a<br />

lower average coefficient <strong>of</strong> variation<br />

<strong>of</strong> 0.159, compared with 0.363<br />

for manual analysis. The CVS<br />

makes the analysis <strong>of</strong> milled rice<br />

quality faster, more convenient,<br />

<strong>and</strong> more accurate than the<br />

conventional, manual method.<br />

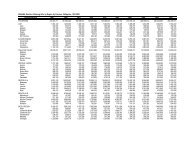

Graphical User Interface <strong>of</strong> the “Caliper” s<strong>of</strong>tware for measuring<br />

grain size, % head rice, % broken grains, <strong>and</strong> % brewers.<br />

The PCARRD Monitor 11