After Heparin: - The Pew Charitable Trusts

After Heparin: - The Pew Charitable Trusts

After Heparin: - The Pew Charitable Trusts

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

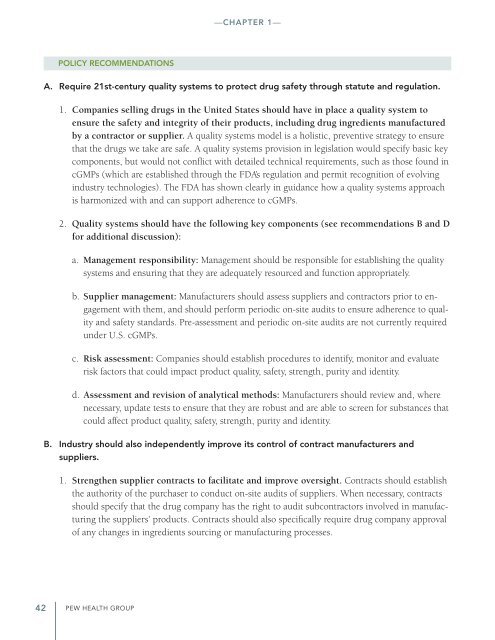

—Chapter 1—<br />

Policy recommendations<br />

A. Require 21st-century quality systems to protect drug safety through statute and regulation.<br />

1. Companies selling drugs in the United States should have in place a quality system to<br />

ensure the safety and integrity of their products, including drug ingredients manufactured<br />

by a contractor or supplier. A quality systems model is a holistic, preventive strategy to ensure<br />

that the drugs we take are safe. A quality systems provision in legislation would specify basic key<br />

components, but would not conflict with detailed technical requirements, such as those found in<br />

cGMPs (which are established through the FDA’s regulation and permit recognition of evolving<br />

industry technologies). <strong>The</strong> FDA has shown clearly in guidance how a quality systems approach<br />

is harmonized with and can support adherence to cGMPs.<br />

2. Quality systems should have the following key components (see recommendations B and D<br />

for additional discussion):<br />

a. Management responsibility: Management should be responsible for establishing the quality<br />

systems and ensuring that they are adequately resourced and function appropriately.<br />

b. Supplier management: Manufacturers should assess suppliers and contractors prior to engagement<br />

with them, and should perform periodic on-site audits to ensure adherence to quality<br />

and safety standards. Pre-assessment and periodic on-site audits are not currently required<br />

under U.S. cGMPs.<br />

c. Risk assessment: Companies should establish procedures to identify, monitor and evaluate<br />

risk factors that could impact product quality, safety, strength, purity and identity.<br />

d. Assessment and revision of analytical methods: Manufacturers should review and, where<br />

necessary, update tests to ensure that they are robust and are able to screen for substances that<br />

could affect product quality, safety, strength, purity and identity.<br />

B. Industry should also independently improve its control of contract manufacturers and<br />

suppliers.<br />

1. Strengthen supplier contracts to facilitate and improve oversight. Contracts should establish<br />

the authority of the purchaser to conduct on-site audits of suppliers. When necessary, contracts<br />

should specify that the drug company has the right to audit subcontractors involved in manufacturing<br />

the suppliers’ products. Contracts should also specifically require drug company approval<br />

of any changes in ingredients sourcing or manufacturing processes.<br />

42<br />

<strong>Pew</strong> Health Group