solid edge machinery design brochure - Siemens PLM Software

solid edge machinery design brochure - Siemens PLM Software

solid edge machinery design brochure - Siemens PLM Software

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

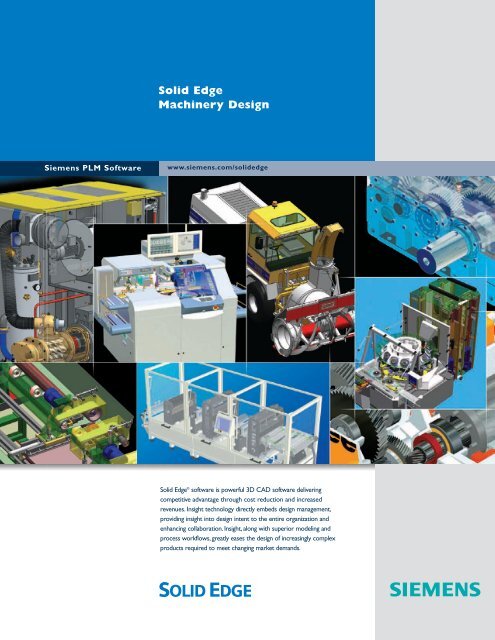

Solid Edge<br />

Machinery Design<br />

<strong>Siemens</strong> <strong>PLM</strong> <strong>Software</strong><br />

www.siemens.com/<strong>solid</strong><strong>edge</strong><br />

Solid Edge ® software is powerful 3D CAD software delivering<br />

competitive advantage through cost reduction and increased<br />

revenues. Insight technology directly embeds <strong>design</strong> management,<br />

providing insight into <strong>design</strong> intent to the entire organization and<br />

enhancing collaboration. Insight, along with superior modeling and<br />

process workflows, greatly eases the <strong>design</strong> of increasingly complex<br />

products required to meet changing market demands.

As a machine <strong>design</strong>er today you<br />

are constantly facing one very<br />

clear but difficult issue: the ever<br />

increasing complexity of your<br />

product <strong>design</strong>s. Driven by market<br />

demand for new and innovative<br />

products with an increasing array<br />

of options, product complexity has<br />

multiplied exponentially in the last<br />

decade. Add the need to apply<br />

new technologies before your<br />

competitors do, customer demand<br />

for faster delivery – and the need<br />

to fit more and more capability<br />

into smaller and smaller spaces<br />

while delivering increasingly<br />

functional shapes with optimized<br />

material costs – and product<br />

complexity becomes almost<br />

impossible to manage.<br />

Enter Solid Edge and its Design with<br />

Insight approach to machine <strong>design</strong>.<br />

Straightforward yet robust, simple<br />

but elegant, Solid Edge eases the<br />

<strong>design</strong> of complex machines.

Easing the <strong>design</strong> of complex <strong>machinery</strong><br />

Your products are becoming more complex,<br />

but that doesn’t mean your processes or your<br />

tools have to follow. Solid Edge can help you to<br />

Design with Insight, simplifying <strong>design</strong> complexity<br />

by providing insight into <strong>design</strong> intent throughout<br />

the machine <strong>design</strong> process.<br />

Solid Edge helps you capture and re-use pertinent<br />

information starting at layout and moving through<br />

to complete digital mockup, while providing<br />

you with industry-best practices for <strong>machinery</strong>specific<br />

processes such as weldments, sheet metal,<br />

wiring, tubing, shape creation and assembly.<br />

By extending this valuable insight to all of the<br />

users of <strong>design</strong> information through Solid Edge’s<br />

unique built-in collaborative environment, you<br />

will soon be managing product complexity<br />

without adding to the complexity of your<br />

machine <strong>design</strong> processes.<br />

Results that count<br />

Solid Edge is one of the few investments you<br />

can make that will impact the top line of your<br />

business. By maximizing <strong>design</strong> re-use and innovation,<br />

Solid Edge will help you evaluate more<br />

variations in less time, clearly differentiate your<br />

product and quickly adapt to change – ultimately<br />

leading to improved customer proposals and<br />

higher win rates.<br />

And, at the same time, Solid Edge helps to keep<br />

your product development costs under control<br />

through effortless re-use of components and<br />

systems from previously completed projects,<br />

streamlined <strong>design</strong> reviews, faster supplier<br />

turnaround and fewer prototyping cycles.This all<br />

leads to reduced rework and clearly identifiable<br />

increases in engineering productivity that make<br />

you more competitive in the marketplace.<br />

Significant cost savings from lower material<br />

costs and inventory optimization do not mean a<br />

reduction in quality. Solid Edge lets you quickly<br />

and easily explore new materials and shapes for<br />

optimized functionality, while improving documentation<br />

for your manufacturing team, customers<br />

and suppliers.<br />

It’s no accident that Solid Edge is the <strong>design</strong><br />

tool of choice for thousands of <strong>machinery</strong><br />

organizations around the world.These companies<br />

rely on Solid Edge to make complex machine<br />

<strong>design</strong> easier. Using Solid Edge, they build<br />

functionally accurate <strong>machinery</strong> models and<br />

eliminate costly errors and rework.They quickly<br />

develop new and improved <strong>design</strong>s that exceed<br />

customer expectations and help to keep their<br />

order book full.<br />

1

A proven workflow for the machine <strong>design</strong> process<br />

Detail<br />

<strong>design</strong><br />

Design<br />

reviews<br />

Documentation<br />

Conceptual<br />

<strong>design</strong><br />

Manufacturing<br />

Winning<br />

business<br />

Assembly<br />

and verification<br />

Promoting<br />

capabilities<br />

Post-project<br />

archive<br />

Installation and<br />

custom training<br />

From the moment you implement Solid Edge, you are on the way to<br />

differentiating your business from your competitors. First, enhance your<br />

sales and marketing efforts using Solid Edge for web publishing, product<br />

renderings and animations that demonstrate your capabilities.Then, take<br />

advantage of Solid Edge’s unique ability to offer increased insight into<br />

your <strong>machinery</strong> <strong>design</strong> process, from initial layouts for proposals through<br />

complete digital mockup and final documentation. From concept to final<br />

<strong>design</strong>, Solid Edge will help you explore and validate more variations,<br />

confirm that the product performs as intended and facilitate the re-use<br />

of proven components and systems to optimize costs and assure the<br />

highest quality, on-time delivery.<br />

Faster customer proposals<br />

Existing machine <strong>design</strong>s often form the basis for new proposals<br />

and Solid Edge helps you quickly generate a new project. Powerful<br />

interrogation tools help your <strong>design</strong> team investigate the impact of any<br />

necessary modifications and better evaluate the costs of these early<br />

<strong>design</strong> decisions. By quickly finding all documents that will be affected<br />

and giving you a more accurate understanding of the modifications<br />

involved, Solid Edge helps you generate detailed customer proposals<br />

faster and improves your chances for receiving the purchase order.<br />

Conceptual <strong>design</strong> to full digital mockup and documentation<br />

With Solid Edge, you <strong>design</strong> <strong>machinery</strong> the same way you think about it.<br />

For speed and simplicity, 2D layouts provide a framework from which<br />

more detailed part and subassemblies are developed.Then, unique<br />

hybrid 2D/3D capabilities let you easily assure accurate fit of all parts.<br />

As the <strong>design</strong> progresses, you can take advantage of Solid Edge’s proven<br />

strengths in massive assembly <strong>design</strong> to develop a full digital mockup.<br />

Solid Edge customers are creating digital mockups containing more<br />

than 100,000 parts.These functionally realistic <strong>machinery</strong> models allow<br />

you to emulate the real-world situations for which your products are<br />

being <strong>design</strong>ed.<br />

2D drawings continue to be the most common deliverable for documenting<br />

a completed <strong>machinery</strong> <strong>design</strong> and Solid Edge leads the market<br />

in drawing creation productivity. Solid Edge dramatically accelerates the<br />

production of assembly drawings by automatically creating exploded<br />

views, balloons, parts lists and BOMs.You will quickly create fully<br />

dimensioned drawings and maintenance documentation that is always<br />

up to date with reference to the <strong>machinery</strong> models.<br />

2

Maximizing re-use of existing <strong>design</strong> information<br />

New <strong>machinery</strong> <strong>design</strong>s often evolve from existing products and, with<br />

Solid Edge as your <strong>design</strong> knowl<strong>edge</strong> resource, new product lines and<br />

modifications to existing modules can be produced in less time and at<br />

less cost. Following completion of each Solid Edge project, the entire<br />

product data set and the intellectual property it contains are captured,<br />

securely archived and remain easily accessible for future projects so you<br />

can quickly understand the impact of proposed <strong>design</strong> modifications and<br />

present accurate knowl<strong>edge</strong>-rich proposals that shorten the time to<br />

final purchase orders.<br />

Quickly find and re-use data<br />

Solid Edge Insight helps you better evaluate the impact of <strong>design</strong><br />

decisions by quickly finding all documents that will be affected by a<br />

change, including all related 2D drawings.You can quickly locate <strong>design</strong><br />

data using any defined criteria and SQL indexing means searches take<br />

seconds. Fast “where used” reporting also helps your <strong>design</strong> team<br />

determine all the product and subassembly models that contain a<br />

specific component, giving them a more accurate understanding of<br />

the impact of replacing or modifying components of the machine.<br />

Leveraging existing <strong>design</strong>s<br />

Machinery <strong>design</strong>ers commonly use 2D layouts to provide a framework<br />

for more detailed part and subassembly <strong>design</strong>. Solid Edge lets you use<br />

existing 2D <strong>machinery</strong> layouts or create new ones with familiar 2D<br />

concepts and then add 3D as you progress.With these unique hybrid<br />

2D/3D capabilities, you can mix and match 2D and 3D representations of<br />

parts, only adding 3D detail when required. By modifying or updating an<br />

existing 2D <strong>machinery</strong> <strong>design</strong> without having to first remodel all of the<br />

individual components in 3D, you can quickly re-purpose existing <strong>design</strong>s<br />

to meet the needs of new customers. And you will still be capturing<br />

enough intelligence to ensure the finished machine comes together<br />

smoothly and accurately.<br />

Machinery modules as functional systems<br />

Solid Edge lets you simulate the interaction of <strong>machinery</strong> components in<br />

a real-world environment through Systems Design, a unique Solid Edge<br />

approach that enables you to create and store functionally realistic<br />

<strong>machinery</strong> sub-systems that emulate the real-world situations for which<br />

they are being <strong>design</strong>ed. Once you have simulated and validated the<br />

behavior of assemblies and mechanisms used in your <strong>machinery</strong> <strong>design</strong>s,<br />

you can save them as re-usable systems that you know will maintain<br />

this built-in knowl<strong>edge</strong> and function correctly when re-used in future<br />

<strong>machinery</strong> <strong>design</strong>s. Solid Edge’s Systems Design capabilities are powerful<br />

enablers for “what-if” scenarios, allowing you to incorporate modular<br />

<strong>design</strong> changes and quickly adapt existing machine <strong>design</strong>s to meet<br />

changing customer requirements.<br />

3

Detail <strong>design</strong><br />

Quickly create a full digital mockup of the new<br />

product, optimizing use of materials and<br />

inventory for lower costs. Solid Edge resolves<br />

fit and interference issues long before any parts<br />

are manufactured. Unique systems <strong>design</strong><br />

capabilities develop functional models that<br />

simulate real-world environments, enabling<br />

better <strong>design</strong> decisions that ultimately lead to<br />

clearly differentiated products at a lower cost.<br />

Design reviews<br />

Use Solid Edge’s built-in managed collaboration<br />

capabilities to improve communication throughout<br />

the entire <strong>design</strong> process. Engineers, <strong>design</strong>ers,<br />

external suppliers, customers and others can track<br />

progress, view and mark up drawings and initiate<br />

change orders that are seamlessly recorded,<br />

managed and communicated, leading to fewer<br />

downstream changes and lower costs through<br />

earlier component definition.<br />

Conceptual <strong>design</strong><br />

Use Solid Edge’s flexible 2D/3D capabilities to<br />

arrange the machine layout, using a mix of<br />

existing 2D drawings and 3D models and further<br />

speeding time-to-completion by distributing<br />

<strong>design</strong> tasks throughout the team. Assure<br />

accurate fit of parts without having to model<br />

every individual component. Leverage Solid<br />

Edge’s proven strengths in massive assembly<br />

<strong>design</strong> to develop <strong>machinery</strong> models containing<br />

tens or even hundreds of thousands of parts.<br />

Winning business<br />

Quickly understand the impact of proposed<br />

<strong>design</strong> modifications and present accurate<br />

knowl<strong>edge</strong>-rich proposals that shorten the<br />

time to final purchase orders. Take advantage<br />

of systems <strong>design</strong> capabilities to easily study<br />

the impact of <strong>design</strong> variations and offer a<br />

clearly differentiated solution at a price<br />

that keeps your customers happy and your<br />

business profitable.<br />

Promoting capabilities<br />

Use digital mockups created in Solid Edge for<br />

previous projects to raise awareness and build<br />

immediate customer confidence in your engineering<br />

capabilities. Photo realistic renderings<br />

remove the need for expensive photography,<br />

while 3D animations bring your products to life<br />

and can be published directly to your company<br />

web pages.<br />

4

Documentation<br />

Effortlessly create 2D drawings from <strong>machinery</strong><br />

assemblies containing thousands of parts.<br />

Add standard, section, detail, broken and<br />

isometric views with the click of a button.<br />

Accelerate the production of assembly drawings<br />

by automatically creating exploded views,<br />

balloons, parts lists and BOMs.<br />

Manufacturing<br />

Leverage the integration of world-class<br />

partners in Solid Edge’s Voyager program for<br />

seamless communications with CAM and other<br />

downstream applications. Improve collaboration<br />

between engineering, shop floor and external<br />

suppliers using practical view and markup tools<br />

and managed workflows for release control.<br />

Assembly and verification<br />

Use clearly understandable assembly drawings<br />

and 3D animations to speed assembly time.<br />

Enjoy the results of Solid Edge’s full digital<br />

mockup and systems <strong>design</strong> capabilities that<br />

ensure the finished product fits and functions<br />

“right the first time.”<br />

Installation and customer training<br />

Create higher quality user and maintenance<br />

guides, including 3D exploded views and<br />

animations that can be easily customized to<br />

suit the need of individual customers.<br />

Post-project archive<br />

Solid Edge captures and securely archives the<br />

entire product data set and the intellectual<br />

property it contains, so that it remains easily<br />

accessible for future projects. By easing <strong>design</strong><br />

complexity, new products can be produced in<br />

less time and at less cost.<br />

5

Managing change<br />

Integrated data vaulting<br />

Solid Edge Insight manages your valuable <strong>machinery</strong> <strong>design</strong> data<br />

in secure vaults. Document check-in and check-out processes<br />

are seamlessly embedded inside standard Solid Edge file commands<br />

and Solid Edge provides continual and instant feedback on the<br />

status of files, their availability and who is working on them.<br />

These secure, SQL server-based vaulting features prevent<br />

unauthorized or conflicting changes and allow individual team<br />

members to confidently work on the same machine, knowing<br />

that the components they are referencing from other members<br />

are always up to date.<br />

Full ECR/ECO workflow management<br />

Insight simplifies the release process for <strong>machinery</strong> <strong>design</strong>s, using<br />

automated workflows to ensure that everyone is receiving the<br />

information they need, when they need it. From pre-released, to<br />

released and throughout any step in the complete product lifecycle,<br />

industry leading collaboration and data management tools ensure<br />

that changes can be enacted, checked and approved as swiftly and<br />

accurately as possible. Insight supports both serial and parallel<br />

approval processes and you can either use the out-of-the-box<br />

workflow templates delivered with Solid Edge or customize your<br />

own to suit your specific requirements.<br />

Comprehensive revision management<br />

Solid Edge Insight helps your <strong>design</strong> team keep abreast of <strong>design</strong><br />

changes as they develop.Throughout the lifecycle of each machine,<br />

team members can subscribe to product data – individual files,<br />

folders and even discussion groups – to receive automatic email<br />

notification whenever changes are made. As <strong>design</strong>ers complete<br />

their work, Solid Edge automatically checks in the files, assigns new<br />

version numbers and updates related files to reflect the changes.<br />

Solid Edge saves and tracks multiple revisions of a <strong>design</strong> and Insight<br />

provides powerful recursive searching so you can review the full<br />

<strong>design</strong> history, determine the source of revisions and replace<br />

<strong>design</strong>s with previous revisions.<br />

6

Machinery-specific <strong>design</strong> applications<br />

Solid Edge delivers tools and workflows that offer specific solutions<br />

to the challenges of <strong>machinery</strong> <strong>design</strong>.Tailored environments,<br />

specific to processes at hand, reduce development costs by<br />

eliminating errors to assure <strong>design</strong>s are right the first time.With<br />

optimized drawing production and manufacturing considerations<br />

built directly into each process, you engineer and build complex<br />

machines in less time.<br />

Sheet metal<br />

Solid Edge’s sheet metal environment uses standard sheet metal<br />

and fabrication terminology, with streamlined modeling commands<br />

for tabs, flanges, louvers, dimples, cutouts, mitered corners, corner<br />

breaks and other sheet metal-specific part features.With automated<br />

placement of bend relief, bend allowance calculations and<br />

punch- and laser-ready flat pattern development, Solid Edge<br />

delivers the most advanced sheet metal CAD package available.<br />

Weldments<br />

The weldment environment assists in defining the constituent<br />

parts of weldments, as well as weld beads, pre-weld surface<br />

treatments and machining operations after the welds are applied.<br />

Solid Edge drafting documents the entire weldment manufacturing<br />

process, with component drawings as well as pre-weld and<br />

post-machining views.Weldment <strong>design</strong>s can be placed and manipulated<br />

as single components in <strong>machinery</strong> models.<br />

Wiring and tubing<br />

Solid Edge XpresRoute is an integrated add-on package that<br />

rapidly routes and models wires, cables and rigid or flexible<br />

tubing for hydraulic or pneumatic systems.Tubing and wiring<br />

components are dynamically associative to the components they<br />

connect, so that they automatically adjust when changes are<br />

made to a machine’s related parts.<br />

Standard Parts<br />

Solid Edge Standard Parts is a powerful parts management<br />

system that allows your <strong>design</strong>ers to define, store, select and<br />

position commonly used parts – like fasteners, bearings and<br />

structural steel members – quickly and efficiently, enabling rapid<br />

and precise completion of <strong>machinery</strong> <strong>design</strong>s.With Solid Edge<br />

Standard Parts, you can establish and share company standards,<br />

so your <strong>design</strong>ers can concentrate on <strong>design</strong>ing <strong>machinery</strong> and<br />

not on redundant modeling tasks. In addition to the baseline of<br />

components delivered with Solid Edge, an extensive <strong>machinery</strong><br />

parts library is available as an optional add-on package.<br />

7

Better engineering for higher quality <strong>machinery</strong><br />

Solid Edge boosts <strong>design</strong> productivity with specialized tools that<br />

encapsulate best practices for <strong>machinery</strong> <strong>design</strong>, helping you to<br />

make better decisions and capture valuable knowl<strong>edge</strong> as you refine<br />

a <strong>design</strong>. Captured intelligence means your original <strong>design</strong> intent is<br />

automatically preserved whenever you make changes, so you can<br />

continue to innovate beyond your competitors while maintaining<br />

the quality and serviceability of your products.<br />

Design rule sensors<br />

Analogous to physical sensing devices, sensors are unique Solid Edge<br />

<strong>design</strong> aids that provide continuing feedback on engineering rules<br />

and variables as the <strong>design</strong> develops. Sensors automatically monitor<br />

distances between components, surface areas, physical properties<br />

and other <strong>design</strong> variables and let you know when <strong>design</strong> rules and<br />

other criteria are not being met.<br />

Motion and interference analysis<br />

Solid Edge provides a range of tools that allow you to simulate moving<br />

parts within your <strong>machinery</strong> <strong>design</strong> and detect any interference<br />

that may result. By simply moving a component, you can detect<br />

collisions and observe the realistic effects of contacts and forces<br />

that will influence the part’s movement. As parts collide, they will<br />

either stop or push each other around, depending on how they<br />

have been defined in the assembly. In addition, a built-in motion<br />

analysis package can accurately simulate complex movement<br />

involving multiple parts at once, detect interferences and create<br />

AVI animations of the full range of assembly motion.<br />

Online engineering reference<br />

The Engineering Handbook is an integrated add-on package for<br />

Solid Edge that provides online reference and automatic mechanical<br />

part modeling. A calculation driven parts generator automatically<br />

builds part models from the engineering calculations, based on<br />

desired load and service criteria. Also included is a complete online<br />

reference that documents algorithms, formulas and theories.<br />

8

Solid Edge – Design with Insight for <strong>machinery</strong><br />

Solid Edge allows your machine <strong>design</strong>ers to Design with Insight<br />

by providing insight into <strong>design</strong> intent throughout your organization.<br />

Complement this with Solid Edge’s superior core modeling and<br />

process workflows and you can see how companies in the business<br />

of machine <strong>design</strong> have been able to reduce their engineering<br />

change orders and related rework by 50 percent or more.<br />

The engineering aids in Solid Edge help you evaluate more <strong>design</strong><br />

alternatives in less time.You can rapidly create and evaluate large<br />

numbers of <strong>design</strong> alternatives for your <strong>machinery</strong> – optimizing form,<br />

fit and function, while maintaining <strong>design</strong> intent and manufacturability<br />

of complete systems throughout the <strong>design</strong> process.<br />

By optimizing <strong>machinery</strong> performance and reliability, increasing<br />

engineering capacity, improving quality and reducing lead times<br />

and costs, Solid Edge is helping <strong>machinery</strong> makers achieve strategic<br />

business objectives of greater market share, revenue and profitability.<br />

Contact your local reseller to see the productivity advantages of<br />

Solid Edge and learn how Solid Edge delivers more insight into your<br />

<strong>design</strong>s and processes.Your business can benefit from the CAD<br />

industry’s most functional innovations for <strong>machinery</strong> <strong>design</strong>. Be first<br />

to complete your new <strong>machinery</strong> <strong>design</strong>s, first to market with<br />

an error-free product, the first to Design with Insight.<br />

9

About Solid Edge<br />

Solid Edge with Synchronous Technology is the most complete feature-based 2D/3D CAD<br />

system available to the market today that combines the speed and flexibility of direct modeling with<br />

precise control of dimension-driven <strong>design</strong>, to provide the fastest, most flexible <strong>design</strong> experience<br />

possible. With superior part and assembly modeling, drafting, transparent data management, and<br />

built-in finite element analysis, Solid Edge with Synchronous Technology is a core component<br />

of theVelocity Series portfolio that eases the growing complexity of product <strong>design</strong>.<br />

About <strong>Siemens</strong> <strong>PLM</strong> <strong>Software</strong><br />

<strong>Siemens</strong> <strong>PLM</strong> <strong>Software</strong>, a business unit of the <strong>Siemens</strong> Industry Automation Division, is a leading<br />

global provider of product lifecycle management (<strong>PLM</strong>) software and services with 4.6 million<br />

licensed seats and 51,000 customers worldwide. Headquartered in Plano,Texas, <strong>Siemens</strong> <strong>PLM</strong><br />

<strong>Software</strong>’s open enterprise solutions enable a world where organizations and their partners collaborate<br />

through Global Innovation Networks to deliver world-class products and services.<br />

For more information on <strong>Siemens</strong> <strong>PLM</strong> <strong>Software</strong> products and services, visit www.siemens.com/plm.<br />

Solid Edge – www.siemens.com/<strong>solid</strong><strong>edge</strong><br />

Americas<br />

800 807 2200<br />

Fax 314 264 8922<br />

Europe<br />

44 (0) 1202 243455<br />

Fax 44 (0) 1202 243465<br />

Asia-Pacific<br />

852 2230 3308<br />

Fax 852 2230 3210<br />

For more information, contact your local Solid Edge representative:<br />

© 2008 <strong>Siemens</strong> Product Lifecycle Management <strong>Software</strong> Inc. All rights reserved. <strong>Siemens</strong> and the <strong>Siemens</strong> logo are registered trademarks of <strong>Siemens</strong> AG. Teamcenter, NX, Solid Edge,Tecnomatix,<br />

Para<strong>solid</strong>, Femap, I-deas, JT, Velocity Series, Geolus and the Signs of Innovation trade dress are trademarks or registered trademarks of <strong>Siemens</strong> Product Lifecycle Management <strong>Software</strong> Inc.<br />

or its subsidiaries in the United States and in other countries. All other logos, trademarks, registered trademarks or service marks used herein are the property of their respective holders.<br />

1304-W 2 5/08