Anode Baking Furnace - Riedhammer

Anode Baking Furnace - Riedhammer

Anode Baking Furnace - Riedhammer

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

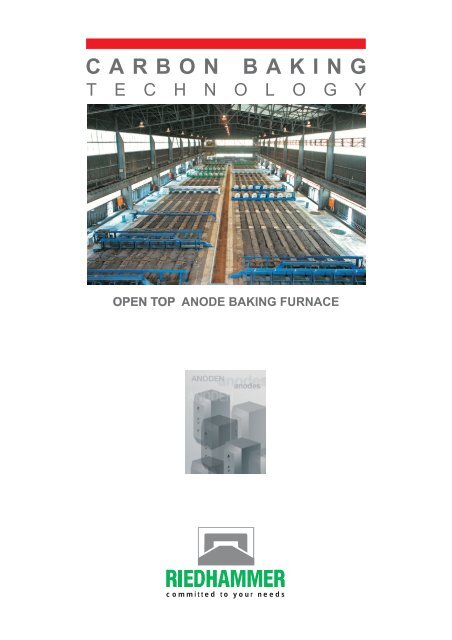

CARBON BAKING<br />

T E C H N O L O G Y<br />

OPEN TOP ANODE BAKING FURNACE<br />

committed to your needs

Fire advance d<br />

CARBON DIVISION<br />

Since 1924 <strong>Riedhammer</strong> has specialized in<br />

the design and construction of high<br />

performance <strong>Baking</strong> <strong>Furnace</strong>s for the<br />

production of first class anodes for the<br />

aluminum industry.<br />

THE RIEDHAMMER BAKING SYSTEM<br />

Technology<br />

<strong>Riedhammer</strong> OPEN Top anode baking<br />

furnace:<br />

Application in new or retrofitted/modernized<br />

baking furnaces.<br />

Proven refractory design with minimum<br />

number of different brick shapes.<br />

High performance:<br />

benchmarking productivity figures.<br />

Compliance with the most strict environmental<br />

standards<br />

The <strong>Riedhammer</strong> OPEN Top <strong>Baking</strong> <strong>Furnace</strong><br />

represents an important step towards<br />

customized technological solutions, offering<br />

the optimum solution for specific<br />

requirements, granting our customers with<br />

more flexibility with the already well known<br />

<strong>Riedhammer</strong> reliability.<br />

Extended refractory lifetime.<br />

- robust design<br />

- low maintenance<br />

Excellent baking profile controllability and<br />

temperature homogeneity ensuring<br />

outstanding final product quality and<br />

consistency as well as low energy<br />

consumption.<br />

Reference in the industry for low CAPEX<br />

& OPEX<br />

Typical anode baking furnace<br />

Flue gas ring mains<br />

Exhaust manifold<br />

Measuring ramp<br />

Burner ramps<br />

Crossover<br />

Preheating zone<br />

Main fire zone

Engineering<br />

Our team of specialist provide our customers<br />

with the most suitable technical and<br />

economical solution for specific requirements:<br />

Customized solutions for the industry<br />

worldwide<br />

Retrofit and modernization of existing<br />

plants<br />

Conceptual analysis and feasibility studies<br />

Design & engineering of baking furnaces<br />

according to the most modern technology<br />

and quality standards<br />

Supply of complete baking facilities<br />

including the baking furnace, firing<br />

system, fume treatment plant and<br />

ancillary equipment<br />

Project Execution<br />

From the supply of engineering packages<br />

to the execution of "turn-key" projects<br />

worldwide:<br />

Design & Engineering<br />

Material procurement & supply<br />

QA / QC<br />

Project administration<br />

Construction services and job site<br />

management<br />

Start-up & commissioning<br />

Optimisation of baking process and<br />

product quality survey (R&D – Carbon of<br />

Switzerland)<br />

After sales and customer support<br />

Flue wall<br />

Product<br />

Detail<br />

Cross-section of a<br />

furnace flue wall<br />

indicating the typical<br />

flue gas flow pattern.<br />

Cooling ramps<br />

Unloading<br />

Maintenance<br />

Loading<br />

Cooling zone<br />

irection

<strong>Baking</strong> profile - typical<br />

excellent temperature<br />

distribution<br />

reduced consumption<br />

figures<br />

optimized temperature<br />

profiles<br />

maximum burnout of<br />

volatile components -<br />

reduced level of emissions<br />

furnace and operative<br />

safety aspects<br />

<strong>Furnace</strong> characteristics - typical<br />

Number of fire-groups<br />

Sections per fire-group<br />

Pits per section<br />

Production per annum / fire-group<br />

Consumption figures:<br />

Fuel consumption<br />

Paking material<br />

Refractory & insulation material<br />

(maintenance figures in the first 10 years)<br />

Lifetime:<br />

Flue walls<br />

Headwalls<br />

2 4<br />

16<br />

6 9<br />

50 000 80 000 tba*<br />

1.9 2.3 GJ/tba*<br />

8 10 kg/tba*<br />

5 6 kg/tba*<br />

> 150 cycles<br />

> 250 cycles<br />

tba* = tonnes of baked anodes<br />

Technical Services & Support<br />

After sales service keeping our customers updated with technological developments<br />

as well as support with existing equipment and process.<br />

RIEDHAMMER GmbH • Industrial kiln plants<br />

Klingenhofstrasse 72 • 90411 Nürnberg • Germany<br />

Telephone: +49 911 52 18-0 • Telefax: +49 911 52 18-231<br />

e-mail: mail@riedhammer.de • www.riedhammer.de<br />

C101_e_04/04/10

DESIGN OF A RIEDHAMMER OPEN TOP ANODE BAKING FURNACE<br />

Temperature/draft measurement ramp<br />

Exhaust manifold<br />

Burner ramps<br />

Cooling ramps<br />

Unloading<br />

Loading<br />

Flue gas ring mains<br />

Flue wall<br />

Pit floor<br />

Product<br />

Concrete shell<br />

Crossover

For Your Notes<br />

RIEDHAMMER GmbH • Industrial kiln plants<br />

Klingenhofstrasse 72 • 90411 Nürnberg • Germany<br />

Telephone: +49 911 52 18-0 • Telefax: +49 911 52 18-231<br />

e-mail: mail@riedhammer.de • www.riedhammer.de