The drive you deserve - Schiff & Hafen

The drive you deserve - Schiff & Hafen

The drive you deserve - Schiff & Hafen

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

NOVEMBER<br />

DECEMBER | 4 | 2009<br />

www.shipandoffshore.net<br />

Classification:<br />

underwater noise 10<br />

Energy-effective technologies:<br />

Green Ship Project 18<br />

Offshore platform: Hurricane<br />

resistant design 32<br />

<strong>The</strong> international publication of<br />

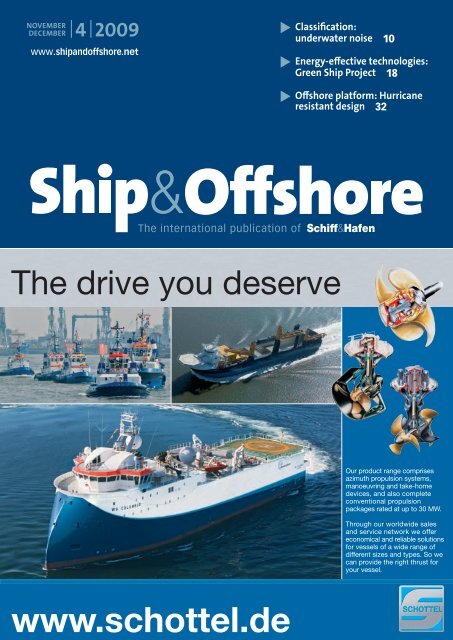

<strong>The</strong> <strong>drive</strong> <strong>you</strong> <strong>deserve</strong><br />

Our product range comprises<br />

azimuth propulsion systems,<br />

manoeuvring and take-home<br />

devices, and also complete<br />

conventional propulsion<br />

packages rated at up to 30 MW.<br />

Through our worldwide sales<br />

and service network we offer<br />

economical and reliable solutions<br />

for vessels of a wide range of<br />

different sizes and types. So we<br />

can provide the right thrust for<br />

<strong>you</strong>r vessel.<br />

www.schottel.de

supply industry | offshore wind energy<br />

maritime logistics | marine technology<br />

04-06 May 2010<br />

10:00 to 18:00 o’clock<br />

Rostock<br />

www.hansemesse.de<br />

International trade fair<br />

Fair forum<br />

for product presentation<br />

International logistics conference<br />

Offshore conference<br />

Foreign trade day of the<br />

German Association for Small and<br />

Medium-sized Businesses<br />

International contact forum<br />

B2B@BalticFuture<br />

Workshops and seminar on futureoriented<br />

topics of the sector<br />

<strong>The</strong> international trade fair of the maritime industry - BalticFuture - provides<br />

an ideal platform for this innovative sector. <strong>The</strong> key topics of the opening trade<br />

fair, marine supplier industry, offshore wind energy and marine logistics, will<br />

be supplemented by another seminal topic in 2010 - marine technology. Both<br />

trades cooperate intensively regarding interfering technology, development<br />

and implementation opportunities in the economic area Baltic Sea Region.<br />

Here, they get the chance to present themselves on a cross-sector basis.<br />

<strong>The</strong> topic offshore wind energy is of increasing importance for the Baltic Sea<br />

Region. Specialized vessels and professional project services are needed for<br />

the construction and operation of numerous wind farms. <strong>The</strong> BalticFuture<br />

is considered as a node for planners of innovative projects in the Baltic Sea<br />

Region. <strong>The</strong> State Fair Centre of Mecklenburg-Vorpommern with its proximity<br />

to the Baltic Sea and the maritime economy located there ensures optimum<br />

conditions for a sustainable establishment of the conference fair.<br />

Registrations and further information at:<br />

www.baltic-future.com

COMMENT | OFFSHORE<br />

Leon Schulz M.Sc.<br />

Managing Editor<br />

Malta<br />

leon.schulz@dvvmedia.com<br />

Dr.-Ing. Silke Sadowski<br />

Editor in Chief<br />

Hamburg<br />

silke.sadowski@dvvmedia.com<br />

20% steel –<br />

80% technology<br />

It is hardly surprising that many offshore<br />

companies are based around the North Sea. Its harsh<br />

environment has prompted the development of many<br />

technically advanced and innovative solutions. Norway<br />

is one of the thriving countries dedicated to the offshore<br />

industry and is optimistic about the outlook. With the oil<br />

price predicted to rise significantly in the next few years,<br />

the cluster of Norwegian offshore companies hopes for<br />

newbuilding orders to take off from the middle of next<br />

year.<br />

Apart from Norway and other established market players<br />

including Singapore, Korea and more recently Brazil,<br />

China has now also begun to build complex offshore<br />

vessels. In this issue, we describe the two sister ships<br />

Boa Thalassa and Boa Galatea built by Bergen Group Fosen<br />

in Norway (p. 30), as well as the Norwegian Ulstein PX105<br />

design, currently under construction in China (p. 36).<br />

<strong>The</strong> optimistic industry is looking beyond the North Sea to<br />

develop new challenging offshore areas, such as the deep<br />

sea off Brazil, the polar regions and offshore India. <strong>The</strong>re<br />

is a need for new technology, cost-efficient vessels and<br />

environmental awareness.<br />

Offshore survey operators have reported increased<br />

problems working in deep seas due to sound masking<br />

resulting from underwater noise. Furthermore, from the<br />

environmental point of view, mammals are said to be<br />

experiencing difficulties communicating because of an<br />

increasing level of underwater noise. <strong>The</strong> classification<br />

society DNV has taken due note of this problem and is<br />

to publish the first ever notation for underwater noise,<br />

which we describe on p. 10. Another classification societ y,<br />

Germanischer Lloyd, is supporting deep-sea mining with<br />

its new rules for underwater techno logy (p. 34).<br />

In order to meet future environmental requirements,<br />

engine manufacturers and equipment suppliers have<br />

invested intensively in improving and developing<br />

their products. This issue presents innovations such<br />

as new scrubbers to clean SO X<br />

emissions (p. 20) and a<br />

new turbocharger (p. 26). We round up our focus on<br />

propulsion with an interview with Søren H Jensen, vice<br />

president of R&D, Low Speed Engines, on the subject of<br />

the Green Ship of the Future (p. 18).<br />

<strong>The</strong> publishers are proud to announce the following two<br />

decisions taken in the interests of further strengthening our<br />

market position and highlighting our presence in deep-sea<br />

shipping as well as the pioneering offshore market. First,<br />

we will be slightly amending our title to Ship&Offshore,<br />

which better reflects our editorial content, and second,<br />

thanks to the encouragement we have had from the<br />

market, we will be continuing our successful course by<br />

increasing our publication frequency to six issues per year,<br />

thus becoming a bi-monthly.<br />

We trust <strong>you</strong> will continue to appreciate our detailed<br />

c overage of the latest technologies and breakthroughs in<br />

the maritime industry and will enjoy reading this i ssue of<br />

Ship&Offshore.

In Focus<br />

26<br />

Shipbuilding &<br />

Equipment<br />

Maritime environment<br />

10 Notation for underwater noise<br />

Industry news<br />

15 Concept for new-generation car<br />

carrier presented<br />

16 “Weak-but-steady growth”<br />

17 Pioneering technology in the<br />

FellowSHIP project<br />

Green shipping<br />

18 Danish <strong>drive</strong> towards greener<br />

power<br />

Propulsion<br />

20 Scrubbers combat marine<br />

sulphur oxide emissions<br />

22 Calculations on the oil film in<br />

sterntube bearing<br />

Propulsion<br />

Ship propulsion systems, using for instance alternative<br />

fuels or innovative propeller designs, make a major contribution<br />

to improving environmental protection. Fuel consumption<br />

and emissions can be significantly reduced<br />

thanks to new propulsion technology. And with attention<br />

to details, underwater noise can also be minimised.<br />

as from page 20<br />

Classification<br />

Nowadays, classification societies are innovative, pay<br />

attention to every detail and cooperate closely with the<br />

shipbuilding industry as well as deep-sea and offshore<br />

operators. <strong>The</strong>ir great expertise is highly sought after in<br />

the search for new solutions to current requirements,<br />

especially for Arctic und deep-sea offshore operations.<br />

page 10 and 34<br />

Compendium Marine Engineering<br />

Operation – Monitoring – Maintenance<br />

After the great success of the German edition now available in English!<br />

Find out more about this compendium and<br />

order <strong>you</strong>r copy at www.shipandoffshore.net/cme.<br />

4 Ship & Offshore | 2009 | N o 4

CONTENT | NOVEMBER/DECEMBER 2009<br />

30<br />

32<br />

Shipbuilding &<br />

Equipment<br />

Propulsion<br />

26 MAN-Diesel: Latest<br />

product developments<br />

Industry news<br />

28 Laser shaft alignment system<br />

28 Intelligent sensors<br />

28 Cooling pumps to cut energy<br />

consumption<br />

Please visit us at<br />

Marintec China<br />

Stand 2A55<br />

Offshore &<br />

Marine Technology<br />

Offshore oil & gas<br />

30 Electromagnetic sisters serving<br />

the oil & gas industry<br />

32 Hurricane resistant offshore<br />

platform design<br />

Ocean mining<br />

34 Support for deep-sea mining<br />

Newbuildings<br />

36 Flexible Platform Supply Vessels<br />

from China<br />

Renewable marine energy<br />

38 Efficient transition piece installation<br />

for wind farms<br />

Shipping &<br />

Ship Operation<br />

Navigation<br />

48 Satellite Reception of AIS Signals<br />

Industry news<br />

50 Weather warning by satellite<br />

52 KASI Malaysia extends its R&D<br />

capabilities<br />

53 New VSAT antenna<br />

54 Full-service counter-piracy<br />

organisation<br />

Regulars<br />

COMMENT ........................... 3<br />

NEWS & FACTS ................... 6<br />

BUYER‘S GUIDE ................ 39<br />

NEW SHIPS ....................... 58<br />

IMPRINT ............................. 59<br />

ABB Turbocharging.<br />

Don’t take chances.<br />

Original ABB spare parts are <strong>you</strong>r assurance of<br />

the highest quality and precision. For further<br />

information please contact <strong>you</strong>r nearest ABB<br />

Turbocharging service station.<br />

www.abb.com/turbocharging<br />

Ship & Offshore | 2009 | N o 4 5

INDUSTRY | NEWS & FAKTS FACTS<br />

ENC<br />

harmonisation<br />

Cruise ferry Cruise Europa now sails between Italy and Greece<br />

Cruise Europa has taken up service<br />

Minoan Lines | Fincantieri shipyard of Castellammare<br />

di Stabia delivered the Cruise Europa,<br />

third in a series of four innovative cruise ferries<br />

ordered by the Italian shipping group Grimaldi<br />

Group, Napoli, and co-financed by the European<br />

Investment Bank (EIB). For the EIB, the operation<br />

is in line with the policy of investing in the<br />

so-called Motorways of the Sea.<br />

With a length of 225 metres and a width of 31<br />

metres, the Cruise Europa offers 3,000 lane metres<br />

of trucks, trailers, coaches and vans, 250 passenger<br />

cars, and can carry up to 3,000 passengers.<br />

For accomodation the vessel has 413 cabins, of<br />

which there are 18 owner’s suites and 50 junior<br />

suites, in addition to 542 reclining seats. <strong>The</strong><br />

cruise ferry (54,310 gt) sails with a service speed<br />

of 28 knots.<br />

Cruise Europa now serves the daily route Ancona–<br />

Igoumenitsa–Patras v.v of Minoan Lines, a Greek<br />

shipping company and member of the Grimaldi<br />

Group.<br />

Cruise Europa has been set with high standards<br />

similar to those of a cruise ship, both regarding<br />

the public areas and the cabins, as well as for<br />

the entertainment services on board. Two restaurants,<br />

wellness and fitness areas, a supermarket,<br />

two lounges for truck <strong>drive</strong>rs, a conference<br />

centre, shops, internet point, a children’s playground<br />

are among the various amenities offered<br />

onboard.<br />

Navigation | <strong>The</strong> Norwegian<br />

H ydrographic Service (NHS)<br />

and the Directorate of Hydrography<br />

and Navigation (DHN)<br />

of the Brazilian Navy have<br />

signed a bilateral agreement to<br />

formalise the exchange of data,<br />

services, and sharing of expertise<br />

in the field of hydrography<br />

in order to enhance international<br />

maritime safety and protection<br />

of the environment and<br />

to avoid duplication of efforts<br />

between the participants.<br />

As a result of this agreement,<br />

Brazil now becomes a member<br />

of the PRIMAR regional ENC coordinating<br />

centre (RENC) operated<br />

by the NHS and will make<br />

the Brazilian ENCs directly<br />

available through the PRIMAR<br />

ENC service. Currently the ENC<br />

coverage in the Brazilian waters<br />

consists of 94 ENC cells.<br />

This agreement means that<br />

PRIMAR is now able to release<br />

the Brazilian ENCs directly.<br />

Brazil is a key partner for PRI-<br />

MAR and this cooperation will<br />

contribute to Primar’s efforts to<br />

harmonise ENCs globally.<br />

Modernization of the MRCC<br />

New sloshing guidelines<br />

GMDSS | Originally initiated by<br />

the Lithuanian Armed Forces<br />

the modernization of the Maritime<br />

Rescue Control Center<br />

(MRCC) Klaipeda and the infrastructure<br />

of the Lithuanian<br />

part of the Global Maritime<br />

Distress and Safety System<br />

(GMDSS) was finalized.<br />

Lithuanian GMDSS is a national<br />

scale solution and is intended<br />

for use in the interest of<br />

the Lithuanian Armed Forces<br />

<strong>The</strong> Lithuanian MRCC<br />

in Search and Rescue (SAR) operations,<br />

as well as sea border<br />

monitoring. <strong>The</strong> system consists<br />

of one control centre in<br />

Klaipeda and four remote sites<br />

and covers the entire GMDSS<br />

zone of Lithuania.<br />

<strong>The</strong> scope of modernization by<br />

Transas Scandinavia AB included<br />

re-equipping the sites, establishing<br />

of a new control centre<br />

and re-organizing the communication<br />

system. <strong>The</strong> complexity<br />

of the task is characterized<br />

by the need not only to supply<br />

and install new equipment, but<br />

also to relocate and integrate already<br />

existing equipment into<br />

the modernized system. <strong>The</strong><br />

main task was to provide a 24/7<br />

monitoring service using CCTV,<br />

VHF and MF/HF, supporting<br />

both voice as well as DSC communication<br />

channels.<br />

LNG | Lloyd’s Register has<br />

published a new guidance<br />

document for the design of<br />

membrane-technology liquid<br />

natural gas containment systems.<br />

<strong>The</strong> document is aimed at<br />

improving design procedures<br />

with respect to sloshing forces<br />

and has been used as part of<br />

the appraisal process for the<br />

approval of the largest LNG<br />

carriers built to date – the Q-<br />

Max type ships.<br />

<strong>The</strong> principal factors that affect<br />

the behaviour of the fluid<br />

motion are the tank shape, fill<br />

height and the ship’s motions.<br />

As a consequence of this motion,<br />

high impact forces can<br />

occur on the tank boundaries<br />

and this document concerns itself<br />

with the design procedures<br />

necessary to assess the strength<br />

of the tank boundary to these<br />

sloshing impacts.<br />

LNG sloshing is said to be a<br />

very complex issue as there are<br />

many aspects that are difficult<br />

to address explicitly by calculation<br />

or testing. Recently, there<br />

have been several incidents involving<br />

damage to LNG membrane<br />

tanks and the approach<br />

adopted in the document provides<br />

guidance on the processes<br />

necessary to ensure that these<br />

incidents will not recur.<br />

<strong>The</strong> guidance mainly applies<br />

to membrane tank LNG ships<br />

with a barred fill range typical<br />

of the vast majority of membrane<br />

tank LNG ships in current<br />

operation. It can also be<br />

applied for the assessment of<br />

membrane tank LNG ships at<br />

offshore terminals or for LNG<br />

ships with no barred fill range.<br />

6 Ship & Offshore | 2009 | N o 4

Jack-up barge under construction<br />

Gulf Marine Services | A uniquely<br />

designed self-propelled,<br />

self elevating jack-up barge is<br />

currently under construction<br />

in Abu Dhabi, United Arab<br />

Emirates. Gulf Marine Services<br />

(GMS) has developed the GMS<br />

Endurance along with Gusto<br />

MSC.<br />

<strong>The</strong> barge incorporates an operating<br />

water depth of up to<br />

65 metres, accommodation<br />

for 150 persons, deck space<br />

of 1,000m 2 , deck load of<br />

11,350 tonnes, self propelled<br />

DP2 (dynamic positioning),<br />

heavy lift crane capacity of up<br />

to 350 tonnes and four legs for<br />

faster jacking on location.<br />

This new self-propelled jackup<br />

barge design is set to operate<br />

in deeper waters and harsh<br />

environments. <strong>The</strong> design’s<br />

flexibility is said to be suited to<br />

a wider range of opportunities<br />

GMS Endurance, first of two new Gusto 2500X vessels<br />

than existing vessels currently<br />

in the market. Offshore accommodation<br />

& construction,<br />

well intervention & workovers<br />

and drilling completions are<br />

some of the key oil & gas sectors<br />

GMS Endurance has been<br />

targeted to work in.<br />

<strong>The</strong> GMS Endurance is the first<br />

of two new Gusto 2500X vessels<br />

planned by GMS over the<br />

next 12 months.<br />

New Austal high-speed catamaran<br />

Artist‘s impression of the new Austal catamaran<br />

Fast ferry | Austal will build<br />

its biggest catamaran to date<br />

following an order from Denmark’s<br />

Nordic Ferry Services.<br />

<strong>The</strong> order involves the design<br />

and construction of a 113-metre<br />

high-speed vehicle-passenger<br />

ferry, designed to carry<br />

1,400 passengers and 357 cars<br />

between Rønne, on the Danish<br />

island of Bornholm, and Ystad<br />

in south-east Sweden. <strong>The</strong> vessel<br />

will be built at the Austal<br />

facility in Henderson, Western<br />

Australia, and is scheduled for<br />

delivery in May 2011.<br />

<strong>The</strong> new vessel will be powered<br />

by four MAN Diesel 20V<br />

28/33D engines, each delivering<br />

9,100 kW at 1,000 rpm for<br />

100% MCR. Additionally, the<br />

engines have an overload capacity<br />

for a limited time (max.<br />

one hour every six hours)<br />

and can deliver 10,000 kW at<br />

1,032 rpm (110% MCR).<br />

<strong>The</strong> engines will be among<br />

the first to be turbocharged by<br />

MAN Diesel’s new TCA 33 (see<br />

page 26) generation. Due to a<br />

higher pressure rate, the new<br />

turbocharger is said to reach<br />

values of up to 500 kW per cylinder.<br />

<strong>The</strong> new vessel will have<br />

a maximum speed of 40 knots.<br />

Det Norske Veritas will survey<br />

the catamaran’s construction,<br />

ensuring compliance with the<br />

IMO’s HSC code.<br />

With a maximum speed of 40<br />

knots, the new vessel will deliver<br />

an improved transportation<br />

service to Bornholm residents<br />

while also meeting the seasonal<br />

demand generated by holiday-makers.<br />

<strong>The</strong> Rønne-Ystad<br />

route already employs another,<br />

86-metre, Austal catamaran –<br />

Villum Clausen – that entered<br />

service in 2000.<br />

Bornholm has some 43,000 inhabitants<br />

and is visited annually<br />

by about 630,000 tourists.<br />

IN BRIEF<br />

VSAT | <strong>The</strong> new Ku-band<br />

VSAT satellite called Telstar<br />

11N, launched earlier this<br />

year, has taken up service<br />

and its footprint has now<br />

been added to several<br />

satellite service providers.<br />

<strong>The</strong> Atlantic Ocean beam<br />

has meant a significant<br />

improvement for maritime<br />

VSAT communications,<br />

targeting the shipping<br />

industry sailing between<br />

North-America and Europe,<br />

including the Caribbean<br />

and West Africa.<br />

Wärtsilä | An agreement<br />

has been signed whereby<br />

Wärtsilä becomes the<br />

exclusive supplier of bilge<br />

water treatment units to<br />

the Stolt-Nielsen group.<br />

<strong>The</strong> agreement ensures<br />

that newbuildings and<br />

retrofits of existing Stolt<br />

vessels will be fitted with<br />

Wärtsilä Senitec M-series<br />

bilge water treatment<br />

units and Wärtsilä Senitec<br />

BilgeGuard(TM) bilge discharge<br />

monitoring systems.<br />

Cargotec | As part of the<br />

strategy to strengthen its<br />

global support for Mac-<br />

Gregor products, Cargotec<br />

has opened up new service<br />

stations in Zeebrugge<br />

in Belgium, Esbjerg in<br />

Denmark, Liverpool in the<br />

United Kingdom, Cadiz and<br />

Ferrol in Spain, Kaohsiung<br />

in Taiwan, and Balboa in<br />

Panama.<br />

ShipConstructor | In recognition<br />

of today’s challenging<br />

economic times,<br />

the newly released version<br />

of ShipConstructor®<br />

Software (2008 R4.4) is<br />

designed to allow customers<br />

using the level licensing<br />

option to have 50% more<br />

parts per level. <strong>The</strong> increase<br />

is targeted at small<br />

and mid-size clients who<br />

will now be able to design<br />

and model larger vessels<br />

and work on larger projects<br />

with other designers and<br />

shipyards, thus opening<br />

up new revenue streams.<br />

For enterprise level clients,<br />

ShipConstructor still offers<br />

“unlimited” level options.<br />

Ship & Offshore | 2009 | N o 4 7

INDUSTRY | NEWS & FACTS<br />

IN BRIEF<br />

Sale | Odense Steel Shipyard,<br />

Lindø, has entered<br />

into an agreement on the<br />

sale of Loksa Laevatehase<br />

AS (Loksa Shipyard) to a<br />

consortium consisting of<br />

AS Frelok, Crown Solution<br />

OÜ and OÜ Stako Diler, all<br />

Estonia. Lindø Shipyard’s<br />

orders at Loksa Shipyard<br />

will be delivered according<br />

to the original plan.<br />

Lloyd’s Register | A new<br />

global Energy business has<br />

been launched by Lloyd’s<br />

Register Group. This has<br />

been formed by merging<br />

its Oil & Gas and Chemicals<br />

& Power divisions and<br />

underlines Lloyd‘s Register‘s<br />

commitment to become<br />

the leading provider<br />

of independent assurance<br />

services to the energy and<br />

transportation industries.<br />

STX Europe | <strong>The</strong> keel of<br />

a ferry to be built for P&O<br />

Ferries was laid at STX<br />

Europe. When completed<br />

in 2010, this vessel will be<br />

the largest ferry in the English<br />

Channel. <strong>The</strong>re will be<br />

space for more than 180<br />

freight vehicles and, additionally,<br />

up to 195 tourist<br />

vehicles. <strong>The</strong> vessel will be<br />

capable of carrying up to<br />

1,750 passengers.<br />

Thorium LRIT | Collecte<br />

Localisation Satellites (CLS)<br />

and Iridium Communications<br />

Inc. announce that<br />

the U.S. Coast Guard has<br />

type-approved the CLS<br />

Thorium terminal for<br />

Long-Range Identification<br />

and Tracking (LRIT). <strong>The</strong><br />

type approval clears the<br />

way for CLS America to<br />

equip ships sailing under<br />

the U.S. flag to comply with<br />

the international LRIT carriage<br />

requirements.<br />

Hamworthy Krystallon |<br />

Fluid handling systems<br />

supplier Hamworthy has<br />

acquired Krystallon Limited,<br />

the company that<br />

pioneered gas scrubber<br />

development. Hamworthy<br />

Krystallon will be part of<br />

the Inert Gas Systems division.<br />

eInvoice<br />

platform<br />

E-Commerce | <strong>The</strong> French container<br />

shipping company CMA<br />

CGM is piloting INTTRA’s<br />

Web-based eInvoice solution<br />

with select customers in North<br />

America. <strong>The</strong> e-commerce platform<br />

for the ocean freight industry,<br />

INTTRA, enables CMA<br />

CGM and its customers to submit,<br />

receive, review and process<br />

invoices more efficiently and<br />

accurately. CMA CGM’s pilot<br />

program is said to introduce an<br />

industry invoicing platform for<br />

streamlining the submission,<br />

dispute resolution and payment<br />

processes for the ocean shipping<br />

industry. Until now, these processes<br />

included many manual<br />

steps that limited accuracy and<br />

increased operational costs. In<br />

addition, customers have had to<br />

navigate multiple systems across<br />

the industry when doing business<br />

with different carriers.<br />

Delivery of jack up drilling rig<br />

Perro Negro 6 | Jack-up drilling<br />

rig hull L202 or Perro Negro 6,<br />

which was built at Drydocks<br />

World – Graha, was recently<br />

delivered to Saipem (Portugal)<br />

Comercio Maritimo Sociedade<br />

Unipessoal LDA. Drydocks<br />

Perro Negro 6<br />

World – Graha is one of the<br />

three yards located on Batam<br />

Island, Indonesia, and is a part<br />

of Drydocks World-Southeast<br />

Asia Pte. Limited (DDW-SEA),<br />

the Southeast Asian subsidiary<br />

of Drydocks World<br />

Perro Negro 6 is a new generation<br />

MSC CJ46-X100D jack-up<br />

drilling rig, equipped for high<br />

pressure, high temperature<br />

drilling environments, with<br />

the capability of operating at<br />

110 metres water depth and<br />

9,100 metres drilling depth.<br />

<strong>The</strong> design features a large Variable<br />

Deck Load (VDL), extended<br />

deck space and 70 ft and<br />

20 ft X-Y cantilever with an automated<br />

pipe racking system.<br />

As one of the four identical<br />

Jack-Up Drilling Rigs at Drydocks<br />

World – Graha, Perro<br />

Negro 6 is said to conform to<br />

the latest standard of jack-up<br />

drilling rig requirements.<br />

New passenger boarding bridge<br />

Team Passenger Boarding Bridge at the port of Barcelona<br />

Port of Barcelona | Team, Barcelona<br />

based designer and manufacturer<br />

of passenger boarding<br />

bridges for cruise and ferry terminals,<br />

has recently completed<br />

the installation of the first of<br />

two new generation Passenger<br />

Boarding Bridges (PBBs) of the<br />

Creuers Barcelona class. <strong>The</strong>y<br />

are to operate at the A and B<br />

cruise terminals on the Adossado<br />

Quay in the port of Barcelona,<br />

Spain. <strong>The</strong> bridge was successfully<br />

placed into operation<br />

during the inaugural call of the<br />

Carnival Dream to the Mediterranean<br />

cruise port.<br />

Team was contracted by cruise<br />

operator Creuers del Port de<br />

Barcelona S.A. to design, manufacture<br />

and deliver these PBBs,<br />

capable of serving the current<br />

fleet of mega cruise ships like<br />

the Carnival Dream, the Norwegian<br />

Epic and the Oasis Class<br />

vessels of Royal Caribbean,<br />

which are equipped with overhanging<br />

life boats.<br />

Team’s new generation Creuers<br />

Barcelona class PBB can move<br />

along the whole quay and is<br />

able to connect with the various<br />

levels of the cruise ship entry<br />

doors. <strong>The</strong> seaside cabin of<br />

the PBB is equipped with an integrated<br />

hydraulically powered,<br />

telescopic tunnel and docking<br />

ramp that, when attached to<br />

the side of a cruise ship, automatically<br />

follows the vessel’s<br />

movements and will immediately<br />

undock in the event of an<br />

emergency. This PBB provides<br />

6 meters clearance for the overhanging<br />

life boats. <strong>The</strong> clearance<br />

underneath the structure<br />

allows continuous truck and<br />

supply traffic on the quayside.<br />

Team’s Passenger Boarding<br />

Bridges are compliant with all<br />

international safety and security<br />

standards.<br />

8 Ship & Offshore | 2009 | N o 4

Black-water<br />

order<br />

Jets Vacuum | Three times larger<br />

than the old Invincible class,<br />

the new British Royal Navy Aircraft<br />

Carriers HMS Queen Elisabeth<br />

and HMS Prince of Wales<br />

will be the largest warships ever<br />

built in Europe.<br />

Large ships of novel design, the<br />

building of these Carriers offers<br />

formidable challenges for all<br />

parties involved. Jets Vacuum<br />

AS, Hareid, Norway, has been<br />

involved in assisting Babcock<br />

Integrated Technology Limited<br />

with the design of the black<br />

water system and has been<br />

awarded the contract for both<br />

vessels.<br />

As manufacturer of the vacuum<br />

toilet systems for the new UK<br />

Type 45 AAW destroyer, this<br />

equipment contract for the<br />

new aircraft carriers is considered<br />

an important milestone<br />

for Jets Vacuum.<br />

<strong>The</strong> new PSV 09 CD design of STX Norway Offshore<br />

Eco-friendly platform supply vessel<br />

STX Europe | A contract on a<br />

new ”eco-friendly” platform<br />

supply vessel has been signed<br />

between STX Europe and Deep<br />

Sea Supply Navegação Maritima<br />

Ltda in Brazil, a subsidiary<br />

of Deep Sea Supply in Arendal,<br />

Norway. <strong>The</strong> vessel is scheduled<br />

for delivery in 2012, and will be<br />

built at STX Brazil Offshore SA,<br />

part of STX Europe Group.<br />

STX Norway Offshore say they<br />

have been through an extensive<br />

R&D programme over the last<br />

two years and have developed<br />

the new PSV 09 CD design for<br />

good sea keeping performance,<br />

low fuel consumption and<br />

environmental friendly operations.<br />

<strong>The</strong> patent pending<br />

hull design is optimized for<br />

eco-<strong>drive</strong> in all weather conditions,<br />

and is designed with<br />

high focus on reduction of<br />

water resis tance in various conditions.<br />

<strong>The</strong> 87.9m long and<br />

19.0m wide vessel will have a<br />

deadweight of 4,700 t and high<br />

standard accommodation for<br />

26 persons.<br />

<strong>The</strong> vessel is also said to incorporate<br />

tailor-made features in<br />

terms of range, speed, capacity<br />

and cargo flexibility to attend<br />

the challenging requirements<br />

of exploration and production<br />

support operations in the newly<br />

discovered Brazilian “presalt”<br />

oil fields.<br />

EU LRIT DC in production<br />

Long Range Identification | <strong>The</strong><br />

European Union Long Range<br />

Identification and Tracking of<br />

ships Data Centre (EU LRIT<br />

DC) entered in production following<br />

successful developmental<br />

testing.<br />

<strong>The</strong> EU LRIT DC is a combined<br />

effort of the European Commission,<br />

in cooperation with<br />

Member States, through the European<br />

Maritime Safety Agency<br />

(EMSA). <strong>The</strong> Agency is in charge<br />

of the data centre’s technical<br />

development, operation and<br />

maintenance. Currently, it is<br />

estimated that the EU LRIT DC<br />

is the biggest data centre of the<br />

whole international LRIT system.<br />

When all Member States’<br />

ships are phased in by the end<br />

of 2009 it will track around<br />

10,000 ships, which will generate<br />

a minimum of 40,000 position<br />

reports per day.<br />

At present, there are 32 Member<br />

States, EFTA countries and<br />

Overseas Territories participating<br />

in the EU LRIT DC. This<br />

number may increase if other<br />

third countries join in the future.<br />

<strong>The</strong> EU LRIT DC covers an<br />

estimated 20 to 25 percent of<br />

the world fleet subject to LRIT.<br />

In addition to tracking EUflagged<br />

ships, the EU LRIT DC<br />

also provides Member States, on<br />

request, with the LRIT information<br />

of any third country vessel<br />

bound to, or sailing within, EU<br />

waters. So it is possible to track<br />

any ship within a 1,000 nautical<br />

mile zone of a participating<br />

state’s coastline, no matter what<br />

flag the ship is flying.<br />

All maritime authorities of the<br />

Member States, such as those<br />

in charge of Search and Rescue,<br />

Port, Coastal and Flag State responsibilities,<br />

are authorised<br />

users of the system. <strong>The</strong>y can<br />

use the EU LRIT DC to better<br />

track their ships and consult or<br />

request position reports.<br />

To support the work of the<br />

competent maritime authorities<br />

of Member States, EMSA<br />

has set up a permanent monitoring<br />

function (Maritime Support<br />

Services).<br />

Transport of wind turbines on the BBC Konan<br />

Transport of wind turbines<br />

BBC Chartering | 140 wind turbine<br />

towers destined for the<br />

Greater Gabbard Wind Turbine<br />

Park, off the east coast of England,<br />

are in 36 shipments transported<br />

upright on board the<br />

BBC Chartering and Logistic<br />

ship BBC Konan. Fluor, the EPC<br />

responsible for the development<br />

of the wind park, requested<br />

that the nacelles be mounted<br />

with hubs, and the bottom tower<br />

sections be shipped with the<br />

electronics installed prior to the<br />

shipment. This meant that the<br />

tower sections had to be transported<br />

upright on custom-made<br />

transport foundations. Up until<br />

now, this has only been done<br />

on a barge in this way.<br />

Each bottom tower section,<br />

which is on deck in an upright<br />

position, weighs 90 tonnes and<br />

is 25m high. <strong>The</strong> forward position<br />

of the BBC Konan’s bridge<br />

means that the upright towers<br />

do not obstruct the crew’s view.<br />

<strong>The</strong> wind turbine blades measure<br />

52m in length, and the<br />

nacelles with the pre-mounted<br />

hubs are the heaviest pieces,<br />

weighing 177 tonnes each.<br />

Ship & Offshore | 2009 | N o 4 9

SHIPBUILDING & EQUIPMENT | MARITIME ENVIRONMENT<br />

Fig. 1: Certain types of vessels are very sensitive to underwater noise<br />

Notation for underwater noise<br />

ACOUSTICS A low underwater noise level is an essential design feature for operation of certain<br />

ship types as well as when operating in environmentally sensitive areas. On 1 January 2010<br />

the first ever notation on underwater noise will be published by Det Noske Veritas (DNV).<br />

Particularly operators of<br />

offshore survey vessels,<br />

fishery research vessels,<br />

ocean research vessels, seismic<br />

vessels, fishing vessels and<br />

military vessels have noticed increased<br />

problems due to sound<br />

masking resulting from underwater<br />

noise. Such vessels are extremely<br />

sensitive to underwater<br />

noise radiation because a high<br />

noise level will directly interfere<br />

with their operational ability.<br />

Research vessels employ hydroacoustic<br />

sensors to perform their<br />

work tasks, fishing and fishery<br />

research vessels depend on not<br />

frightening away the fish, luxury<br />

yachts and cruise vessels require<br />

a high degree of personal comfort,<br />

military vessels need to operate<br />

undetected and to avoid<br />

triggering of mines. Obviously,<br />

noise control will have to be<br />

given high priority throughout<br />

the design and construction<br />

phases for the vessels mentioned<br />

above.<br />

From an environmental point of<br />

view, the Marine Environmental<br />

Protection Committee (MEPC)<br />

of the International Maritime<br />

Organization (IMO) stated in<br />

July 2009: “<strong>The</strong> committee urges<br />

governments to review their<br />

commercial fleets to identify<br />

the ships that contribute most<br />

to underwater noise pollution”.<br />

At the same time, the International<br />

Fund for Animal Welfare<br />

(IFAW) estimates that the noisiest<br />

10% of ships contribute the<br />

most to the noise problem.<br />

DNV explains that an efficient<br />

noise and vibration control can<br />

be integrated in vessel design<br />

without increasing building<br />

costs significantly and identifies<br />

the propellers usually to be<br />

the most important source for<br />

noise. Radiation of structureborne<br />

noise is identified as the<br />

second most important source.<br />

<strong>The</strong> new optional class notation<br />

by DNV covers a complete set of<br />

criteria and rules for verification<br />

and is intended to ensure operational<br />

capability for four different<br />

types of ships. It is divided<br />

into five sub-notations:<br />

Acoustic (A)<br />

Requirements for vessels using<br />

hydro-acoustic equipment as<br />

an important tool in their operation,<br />

e.g. survey vessels, ocean<br />

research vessels, pipe layers,<br />

diving vessels, various offshore<br />

support vessels etc.<br />

Seismic (S)<br />

Vessels towing heavy streamers<br />

and airguns, hence having<br />

a high demand on propulsion<br />

power.<br />

Fishery (F)<br />

Requirement not to scare away<br />

the catch.<br />

Research (R)<br />

Requirement based on the existing<br />

ICES 209, however with<br />

a low frequency modification.<br />

This is an extremely demanding<br />

criteria requiring “submarine”<br />

type technology.<br />

Environmental (E)<br />

Environmental conscious owners<br />

may demonstrate environmental<br />

compliance through this<br />

“Environment Notation”. This<br />

voluntary class requirement,<br />

which comes in the two levels<br />

called “Transit” and “Passage”, is<br />

to be achieved without increasing<br />

costs beyond that caused<br />

by seeking good engineering<br />

advice with regard to propeller<br />

design and propulsion<br />

10 Ship & Offshore | 2009 | N o 4

vessels often have major differences<br />

with respect to machinery,<br />

arrangement and structure.<br />

Hence, the possibility to use an<br />

analytical approach at the design<br />

stage is valuable. This applies<br />

to the ability to calculate<br />

the propeller’s acoustic source<br />

strength as well as the ability<br />

to calculate the flow of acoustic<br />

energy in a ship hull.<br />

Fig. 2: ICES 209 underwater radiated noise specification at 11 kts<br />

Underwater noise radiated<br />

from commercial vessels operating<br />

in environmentally sensitive<br />

areas is becoming a concern<br />

and recently noise as a<br />

pollutant has received considerable<br />

attention. In dark ocean<br />

waters, marine mammals such<br />

as whales and dolphins rely<br />

on sound to communicate with<br />

each other, locate prey and find<br />

their way over long distances.<br />

All these activities, critical to<br />

their survival, are being interfered<br />

with by the increasing<br />

levels of underwater noise from<br />

ocean-going ships, sonar devices<br />

and seismic exploration.<br />

Sound travels nearly five times<br />

faster in water than in air and<br />

will cover large areas in seconds.<br />

Scientists have become<br />

increasingly aware of this threat<br />

to biodiversity and rate underwater<br />

noise pollution as the<br />

next global treat after climate<br />

change and chemical pollution.<br />

This is a rather diffuse and<br />

not very well understood field.<br />

However, it is already attracting<br />

significant attention from<br />

environmentalists and conservationists<br />

and it is likely that<br />

the field will receive increasing<br />

attention in the years to come.<br />

Examples on strict criteria for<br />

underwater noise radiation are<br />

requirements from the “International<br />

Council for the Exploration<br />

of the Sea” (ICES) cooperative<br />

research report no. 209<br />

(Fig. 2). <strong>The</strong>se are underwater<br />

source levels at a nominal distance<br />

of 1m, and at 11 kts freerunning.<br />

<strong>The</strong>se criteria have<br />

been derived in order to ensure<br />

that fishery research vessels do<br />

not frighten away the fish they<br />

want to count (1 Hz – 1000 Hz)<br />

and that they are not disturbing<br />

their own hydroacoustic instrumentation.<br />

For the ship types identified in<br />

the notation, the underwater<br />

noise control will have to be<br />

given high priority throughout<br />

the design and construction<br />

phase. DNV has developed underwater<br />

noise criteria to assess<br />

the noise level depending on<br />

type and task of vessel, which<br />

now has resulted in the new<br />

notation to be published on<br />

1 January 2010.<br />

Noise pattern<br />

Sound is easily transmitted<br />

in water and is therefore used<br />

for many of the functions that<br />

electromagnetism have in air.<br />

However, background noise<br />

can limit the operational range,<br />

induce errors and even completely<br />

block the acoustical instrumentation,<br />

which is called<br />

“masking”. <strong>The</strong> most significant<br />

noise sources are typically propellers,<br />

diesel engines/gas turbines,<br />

gears, electric propulsion<br />

motors, shafting systems, water<br />

flow along the hull, hydraulics,<br />

ventilation systems, HVAC, exhaust<br />

systems, pumps, auxiliary<br />

machinery and equipment.<br />

<strong>The</strong> noise originates at the<br />

source and is transmitted<br />

through the structure or<br />

through an air or a fluid path.<br />

Structure-borne noise transmission<br />

is the most important<br />

transmission path in the majority<br />

of cases for inboard noise<br />

and plays an important role<br />

also for underwater noise.<br />

Direct waterborne propagation<br />

from propellers is the most important<br />

path for underwater<br />

noise transmission.<br />

A clear understanding of the<br />

individual significance of each<br />

source, transmission path and<br />

radiating mechanism is important<br />

in order to perform meaningful<br />

noise control engineering.<br />

Otherwise a noise control<br />

effort may be unnecessary<br />

expensive, weight and space<br />

intensive or even wasted. <strong>The</strong><br />

necessary knowledge may be<br />

obtained through experience<br />

from measurements. However,<br />

in most cases vessels are built<br />

in small series and even sister<br />

Machinery selection<br />

Based on the acoustic criteria<br />

and source guarantee levels<br />

determined during the early<br />

review the choice of machinery<br />

may be somewhat restricted.<br />

Strict criteria may require that<br />

a diesel electric propulsion<br />

system is used. Diesel electric<br />

propulsion will allow a highly<br />

efficient resilient mounting<br />

system for the diesel generators<br />

without a shaft-line that<br />

could transmit noise from the<br />

diesel engines to a gear or even<br />

generate noise on its own. For<br />

the strictest criteria it may also<br />

be necessary to use a double<br />

resilient mounting system,<br />

which may reduce diesel generator<br />

noise substantially, or<br />

even noise controlled DC electric<br />

propulsion motors may be<br />

required. In some cases, noise<br />

controlled AC motors may be<br />

allowed.<br />

Depending on the criteria, a<br />

noise-reduced gear connected<br />

to a resiliently mounted <br />

Fig. 3: Waterborne noise measured near propeller of a high<br />

power cruise vessel<br />

Ship & Offshore | 2009 | N o 4 11

SHIPBUILDING & EQUIPMENT | MARITIME ENVIRONMENT<br />

diesel engine through a resilient<br />

rubber coupling may be<br />

allowed.<br />

Noise from auxiliary machinery<br />

and equipment, e.g. hydraulic<br />

systems, exhaust systems, steering<br />

gear, compressors, pumps,<br />

fans etc. will also have to be<br />

controlled. Noise from such<br />

systems can usually be controlled<br />

through conventional noise<br />

reducing measures such as resilient<br />

mounts on stiff foundations,<br />

mufflers, enclosures,<br />

resilient compensators and by<br />

locating the sources in locations<br />

well away from critical<br />

surfaces. All these sources need<br />

to be followed up throughout<br />

the project.<br />

Propeller noise<br />

<strong>The</strong> propellers are often the<br />

most important noise source<br />

for a ship. This applies to<br />

waterborne noise radiation<br />

for research, fishing and military<br />

vessels as well as for interior<br />

noise levels in the aftship<br />

of yachts and cruise vessels.<br />

Hence, it is vital to be able to<br />

calculate propeller noise and to<br />

possess knowledge on design<br />

of low noise propellers when<br />

needed.<br />

<strong>The</strong> knowledge in the industry<br />

on propeller excitation caused<br />

by transient cavitation at the<br />

propeller blades has increased<br />

during the last years. <strong>The</strong> magnitude<br />

of the blade pass frequency<br />

component of the hull pressures<br />

has gradually decreased over the<br />

last couple of decades.<br />

However, the broad-band pressure<br />

generated by the propellers,<br />

which is the most important<br />

noise mechanism, still<br />

causes problems. An illustrative<br />

example of measured waterborne<br />

noise near a propeller<br />

of a cruise vessel is shown in<br />

fig. 3. For this vessel, clearly the<br />

broad-band cavitation noise is<br />

stronger than the noise at the<br />

blade passing frequency.<br />

<strong>The</strong> propellers excite the hull<br />

in different ways. <strong>The</strong> low frequency<br />

excitation will be felt<br />

as vibrations and the higher<br />

frequencies perceived as noise<br />

inside the vessel. Both frequency<br />

regimes will be emitted into<br />

the water.<br />

It is possible to reduce or even<br />

avoid such problems, by applying<br />

novel knowledge on broadband<br />

pressure field generated<br />

by the propeller in the design<br />

of new propellers.<br />

<strong>The</strong> excitation from the propellers<br />

can be divided into different<br />

groups:<br />

Fluctuating forces and moments<br />

transferred from the<br />

propellers to the shaft system.<br />

This type of excitation consists<br />

mainly of 1st order blade frequency<br />

components and contributes<br />

to the vibration of the<br />

vessel, but not to the noise.<br />

Pressure fluctuations transferred<br />

through the water from<br />

the propellers to the hull or<br />

to a far field underwater location.<br />

This pressure fluctuations<br />

generated by the propellers can<br />

again be divided into three<br />

main groups: Pressure variations<br />

generated by propellers<br />

without cavitation, pressure<br />

generated by transient cavitation<br />

on the propeller blades<br />

and, finally and most importantly,<br />

the pressures generated<br />

by cavitating vortices.<br />

Pressure field generated by<br />

cavitating vortices contains a<br />

continuous pressure spectrum<br />

and is responsible for much of<br />

the audible inboard noise from<br />

the propellers as well as being<br />

an important source of underwater<br />

noise. Pressure field from<br />

strong vortices also contains<br />

pressures of low frequencies<br />

that create vibration. Vortices<br />

created by fixed pitch propellers<br />

as well as by controllable<br />

pitch propellers at the design<br />

pitch are tip vortices. <strong>The</strong> tip<br />

vortices and the pressure field<br />

generated by them, increase<br />

gradually with the propeller<br />

RPM. However, for controllable<br />

pitch propellers vortices from<br />

the pressure side of the blades<br />

are generated at reduced pitch.<br />

Hence, the noise may be more<br />

severe at reduced ship speed<br />

than at full speed if controllable<br />

pitch propellers are used.<br />

DNV has developed a method<br />

to predict the broad-band pressure<br />

field generated by the cavitating<br />

tip vortices, the so-called<br />

Tip Vortex Index method (TVI<br />

method).<br />

<strong>The</strong> magnitude and frequency<br />

content of the measured pressure<br />

depend strongly on the<br />

transducer position on the<br />

Fig. 4: Reduction in propeller noise through design optimisation<br />

hull since they are in the “near<br />

field”. <strong>The</strong>refore, it is difficult<br />

to establish the magnitude of<br />

the excitation based on a few<br />

hull pressure recordings. It is<br />

common in hydro-acoustics<br />

to describe a noise sources as<br />

an equivalent point sources.<br />

This can also be applied for<br />

the propeller. <strong>The</strong> advantage<br />

of considering the propeller as<br />

a hydro-acoustic noise source<br />

is that the propeller excitation<br />

can be evaluated alone without<br />

taking into consideration the<br />

clearances between the propeller<br />

and the hull.<br />

Propeller design<br />

Detailed propeller blade design<br />

can be used to reduce propeller<br />

noise. Basically a large diameter<br />

propeller with a blade<br />

design which is unloaded towards<br />

the tips will be advantageous<br />

in many cases. However,<br />

the blade design will often be<br />

a compromise between noise<br />

and efficiency. For noise sensitive<br />

vessels a moderate loss in<br />

efficiency can normally be accepted<br />

if a significant noise reduction<br />

can be achieved. Fig. 4<br />

shows an example from a noise<br />

optimisation process during<br />

propeller design.<br />

Obviously, the propeller wake<br />

influences propeller noise generation<br />

significantly. <strong>The</strong> hull<br />

lines and orientation of shaft<br />

brackets are important for the<br />

flow to the propellers and so is<br />

the propeller turning direction.<br />

<strong>The</strong> reason is the interaction of<br />

the axial and tangential wake<br />

components.<br />

<strong>The</strong> importance of propeller<br />

– hull clearances is exaggerated<br />

in most cases, due to the<br />

focus on maximum hull pressures<br />

rather than on the excitation<br />

forces. It is usually better<br />

to have a large lightly loaded<br />

propeller and small clearances<br />

than a small diameter propeller<br />

and large clearances.<br />

Fixed pitch propellers behave<br />

predictably with respect to development<br />

of noise and broadband<br />

vibration with ship speed.<br />

<strong>The</strong> propeller RPM is about<br />

proportional to the ship speed<br />

and therefore the propellers<br />

will operate at nearly the same<br />

hydrodynamic angle of attack<br />

at any ship speed. Consequently,<br />

the noise and broad-band<br />

vibration will increase gradually<br />

with the power.<br />

Controllable pitch propellers<br />

behave as fixed pitch propellers<br />

at design pitch. However,<br />

at reduced pitch and high<br />

RPM most propellers will<br />

start to generate cavitation on<br />

the pressure side. Such cavitating<br />

vortices can be as noisy<br />

as the tip vortices at full pitch.<br />

If shaft generators requiring<br />

constant RPM are coupled<br />

to the engines, the propellers<br />

can be very noisy over a broad<br />

speed range. If the propeller<br />

speed is gradually reduced<br />

with power, a controllable<br />

pitch propeller does not need<br />

to be noisier than a fixed pitch<br />

propeller.<br />

12 Ship & Offshore | 2009 | N o 4

Software for IACS<br />

Common Structural Rules<br />

ABS/LR | ABS and Lloyd’s<br />

Register have agreed to use<br />

a common software for the<br />

assessment of scantlings of<br />

bulk carriers and oil tankers<br />

designed to comply with the<br />

new IACS Common Structural<br />

Rules. <strong>The</strong> new common<br />

software draws on the existing<br />

applications of both societies<br />

with the Lloyd’s Register<br />

approach being used for the<br />

initial scantling evaluation<br />

(CSR Stage 1) and the ABS approach<br />

being used for the finite<br />

element assessment (CSR<br />

Stage 2).<br />

<strong>The</strong> announcement comes after<br />

two years of detailed work<br />

by dedicated teams from both<br />

classification societies to identify<br />

and implement the best<br />

amalgam of the strengths of<br />

both societies’ existing CSR<br />

software.<br />

ABS says that although shipyards,<br />

designers and shipowners<br />

have welcomed the adoption<br />

of the IACS Common<br />

Structural Rules, they have<br />

made repeated requests for a<br />

similar approach to be taken<br />

with the software needed for<br />

the application of the Rules.<br />

Richard Sadler, Chief Executive<br />

of Lloyd’s Register, says they<br />

have moved from ten sets of<br />

Rules for tankers and another<br />

ten sets for bulk carriers to a<br />

single standard for each ship<br />

type. Yet, the classification societies<br />

have developed multiple<br />

software programs for each<br />

of the new Rules, which he says<br />

dilutes the intent of the Rules<br />

and introduces an unnecessary<br />

element of confusion for the<br />

designers and shipyards.<br />

Testing of the new joint software<br />

is being finalised and<br />

design review engineers from<br />

both societies are scheduled<br />

to begin intensive training on<br />

its application. Once this process<br />

has been concluded, each<br />

of the societies will withdraw<br />

their existing CSR software<br />

and all new designs presented<br />

to either society will be evaluated<br />

using the new common<br />

software.<br />

In the interests of promoting<br />

technical consistency and<br />

maritime safety, the two societies<br />

have also announced that,<br />

once the exhaustive testing<br />

of the new software has been<br />

completed, it will be made<br />

available to other IACS members.<br />

<strong>The</strong> IACS Common Structural<br />

Rules for Tankers and Bulk<br />

Carriers were unanimously<br />

adopted by the ten member<br />

societies in December 2005.<br />

<strong>The</strong>y became effective for<br />

vessels contracted on or after<br />

1 April 2006. <strong>The</strong>y apply to all<br />

double hull tankers of 150m<br />

in length and above and to<br />

single and double side skin<br />

bulk carriers of 90m in length<br />

and upward, other than ore<br />

carriers.<br />

First fishing trawler with SkySails<br />

ALTERNATIVE PROPULSION |<br />

Parlevliet & Van der Plas B.V.,<br />

one of Europe’s biggest fishing<br />

companies, has signed a<br />

purchase agreement for the<br />

world’s first towing-kite wind<br />

propulsion system to be installed<br />

on a fishing trawler.<br />

SkySails propulsion is scheduled<br />

to be placed in operation<br />

early next year aboard<br />

the ROS-171 Maartje <strong>The</strong>adora<br />

fishing trawler. <strong>The</strong> fishing<br />

company says they are looking<br />

forward to significant fuel<br />

savings by using the SkySails-<br />

System, particularly during<br />

those extended transfer runs<br />

to the African coast and in the<br />

South Pacific, as well as to the<br />

potential savings during actual<br />

fishing operations. At the<br />

same time, this enables Parlevliet<br />

& Van der Plas to reduce a<br />

considerable amounts of CO 2<br />

emissions as a contribution to<br />

safeguarding the climate.<br />

At 141 meters in length, the<br />

Maartje <strong>The</strong>adora is Germany’s<br />

largest fishing vessel and<br />

is operated by the Sassnitzbased<br />

Westbank Hochseefischerei<br />

GmbH, a member of<br />

the Parlevliet & Van der Plas<br />

Group. <strong>The</strong> ship has two MaK<br />

main engines that produce a<br />

total of 8,640 kW of power.<br />

<strong>The</strong> vessel will be fitted with<br />

a 160m² SkySails propulsion<br />

system like those already in<br />

use on cargo ships. Parlevliet<br />

& Van der Plas and the systems<br />

manufacturer SkySails will be<br />

evaluating if and in what way<br />

the wind propulsion system<br />

needs to be modified for use<br />

on fishing vessels on board<br />

the Maartje <strong>The</strong>adora as part<br />

of a pilot project funded by<br />

the European Fisheries Fund<br />

(EFF) and the German state<br />

of Mecklenburg-Western Pomerania.<br />

SkySails propulsion previously<br />

underwent pilot testing<br />

for a year and a half aboard<br />

the cargo ships Beluga Sky-<br />

Sails, owned by the Beluga<br />

An impression on how SkySails would fit on Maartje <strong>The</strong>adora<br />

Group, and the Michael A. of<br />

the Wessels Shipping Company.<br />

Despite its unprecedented<br />

physical properties, the system<br />

is claimed to produce<br />

between 5 and 25 times more<br />

power per square meter than<br />

conventional sail propulsion.<br />

Even a 160m² SkySails is said<br />

to generate a tractive force of<br />

8 metric tons, which is comparable<br />

to the thrust of an<br />

Airbus A318 engine.<br />

SkySails is currently also fitting<br />

its innovative towing-kite<br />

propulsion system onto a series<br />

of three new cargo ships<br />

belonging to the Wessels<br />

Shipping Company of Haren<br />

an der Ems.<br />

Ship & Offshore | 2009 | N o 4 13

SHIPBUILDING & EQUIPMENT | INDUSTRY NEWS<br />

Caspian ice-breaking tugs<br />

CLASSIFICATION | Bureau<br />

Veritas has been chosen to<br />

class two different series of icebreaking<br />

tugs for service in the<br />

Caspian Sea.<br />

<strong>The</strong> first series is for three plus<br />

two 66m ice-breaking and<br />

ice management tugs with<br />

50 tonnes bollard pull (BP)<br />

and Ice Class IA Super Special<br />

Service – North Caspian Sea<br />

Icebreaker with ice breaking<br />

capability up to 0.6m level ice<br />

thickness. Designed by Aker<br />

Arctic, they will be built at the<br />

STX RO Offshore Braila yard<br />

in Romania for the Caspian<br />

Offshore Construction group<br />

project in the North Caspian<br />

Kashgan oil field.<br />

<strong>The</strong> design has been made for<br />

the shallow waters of the North<br />

Caspian Sea, where the vessels<br />

will break level ice and can<br />

operate year round in ice conditions<br />

up to 1m thickness. In<br />

addition to towing and pushing<br />

barges in open water and in ice<br />

conditions, they will be capable<br />

of ice management operations<br />

in astern working mode, clearing<br />

ice rubble. <strong>The</strong> vessels will<br />

be equipped for undertaking<br />

firefighting, rescue and evacuation<br />

tasks and have deck cargo<br />

capability for supply functions.<br />

<strong>The</strong> second series is currently<br />

out to tender and is for shallow<br />

Ice tug tests for the Caspian Sea<br />

draft ice-breaking Anchor Handling<br />

Tug Supply (AHTS) vessels<br />

to be built for Silverburn<br />

Shipping. Designed by <strong>The</strong><br />

Netherlands-based Offshore<br />

Ship Designers these vessels<br />

will be able to work in 0,7m<br />

of ice. <strong>The</strong>y have a significant<br />

load carrying capability on a<br />

shallow draft and provide a<br />

minimum 45 tonnes BP. Model<br />

tests at Aker Arctic showed the<br />

hull form can perform in ice to<br />

Finnish/Swedish Ice Class 1A<br />

Super standards. Main dimensions<br />

are LOA 49.6m, beam<br />

16.5m, seagoing draft 3.5m,<br />

shallow draft 2.5m.<br />

Ice-class FSO<br />

YURI KORCHAGIN | <strong>The</strong> first<br />

ice-class floating storage and<br />

offloading system (FSO) to be<br />

completed at a Caspian Sea<br />

shipyard and deployed for<br />

service in the Caspian Sea, the<br />

Yuri Korchagin, is destined for<br />

the Yuri Korchagin Field in the<br />

Russian sector of the Caspian<br />

Sea where it will operate for<br />

Lukoil.<br />

<strong>The</strong> FSO hull was constructed<br />

in two longitudinal halves by<br />

Keppel Singmarine in Singapore<br />

and was towed through<br />

the Volga-Don River Canal and<br />

assembled at Keppel Fels’ Caspian<br />

Shipyard Company (CSC)<br />

in Baku, Azerbaijan. According<br />

to classification society ABS, the<br />

size limitation of the Canal dictated<br />

that the unit be constructed<br />

in two modules for import<br />

into the region. <strong>The</strong> two hull<br />

sections were aligned and joined<br />

in drydock at the Caspian shipyard.<br />

<strong>The</strong> helideck and accommodation<br />

quarters, as well as<br />

other equipment, were loaded<br />

alongside the hull sections and<br />

also assembled at CSC.<br />

<strong>The</strong> unit has been built to the<br />

ABS class notation +A1, Floating<br />

Storage and Offloading System,<br />

Ice Class C0, +AMCCU,<br />

FL(20). Yuri Korchagin is 132.8m<br />

in length, 32m in width and<br />

has a depth of 15.7m. It has a<br />

fatigue life of 20 years and is<br />

dual classed with RS. <strong>The</strong> FSO<br />

can withstand ice conditions of<br />

minus 20 degrees Celsius and<br />

ice thickness of 0.6m.<br />

Russia’s Lukoil is targeting to<br />

start commercial oil production<br />

before long. When in operation,<br />

it will be the largest<br />

FSO in the Caspian Sea.<br />

BOOK REVIEW<br />

Compendium Marine Engineering:<br />

Operation – Monitoring – Maintenance Following the German<br />

edition “Handbuch <strong>Schiff</strong>sbetriebstechnik” in 2006,<br />

now the English version is available. <strong>The</strong> technical book is<br />

mainly directed towards marine engineers, principally within<br />

the marine industry. It is also addressed to ship operators,<br />

superintendents and surveyors, but also to those in training<br />

and research institutes as well as designers and consultants.<br />

Compendium Marine Engineering represents a compilation<br />

of marine engineering experience. It is based on the research<br />

of scientists and the reports of many field engineers<br />

all over the world. within the field of ship’s and engine operation<br />

subjects like cargo handling equipment, air-conditioning<br />

technology incl problems with reefer containers, safety<br />

equipment as well as envirionmental<br />

matters, maintenance and regulations<br />

are dealt with.<br />

Compendium Marine Engineering<br />

Hansheinrich Meier-Peter, Frank<br />

Bernhardt<br />

Seehafen Verlag<br />

1100 pages, hardcover<br />

978-3-87743-822-0<br />

98,- Euro plus postage<br />

14 Ship & Offshore | 2009 | N o 4

Concept for new-generation<br />

car carrier presented<br />

ISHIN-I CAR CARRIER | Mitsui<br />

O.S.K. Lines, Ltd. (MOL Lines)<br />

has developed a new type of<br />

car vessels. <strong>The</strong>y are said to be<br />

technically practical in the near<br />

future by building on and refining<br />

technologies it has already<br />

developed and adopted.<br />

<strong>The</strong> first of its next-generation,<br />

environment-friendly<br />

vesse l concepts is the car carrier<br />

ISHIN-I, which stands for<br />

“Innovations in Sustainability<br />

backed by Historically proven,<br />

INtegrated technologies.”<br />

ISHIN-I is said to have two main<br />

features: the goal is to achieve<br />

zero CO 2<br />

-emissions while in<br />

port, and during loading and<br />

unloading, mainly by adopting<br />

large-capacity solar-power panels<br />

and rechargeable batteries.<br />

While sailing, the CO 2<br />

-emission<br />

is to be reduced by 41% in<br />

comparison (per unit) to conventional<br />

vessels (PCTC with a<br />

capacity of 6,400 standard passenger<br />

cars). This is achieved<br />

by adopting multiple new technologies.<br />

When needs for larger<br />

vessels arise in the future, CO 2<br />

emissions is claimed to be reduced<br />

by as much as 50% on<br />

that assumption.<br />

To pur the two main features<br />

into practice, the concept is<br />

based on the following main<br />

technologies:<br />

Use of renewable energy<br />

Solar panels partly already<br />

adopted on the MOL-car-carriers<br />

Euphony Ace and Swift Ace will<br />

be used on the ISHIN-I. Zero<br />

emissions while in port and during<br />

loading and unloading is to<br />

be achieved by installing largecapacity<br />

rechargeable batteries<br />

(lithium ion) and combining<br />

them with an electric propulsion<br />

system.<br />

Optimization of propulsion<br />

efficiency<br />

<strong>The</strong> main-diesel engine is combined<br />

with an electric propulsion<br />

system. A pair of contrarotating<br />

propellers are installed<br />

facing each other at the stern.<br />

<strong>The</strong> new ISHIN-I concept minimising CO 2<br />

emissions<br />

<strong>The</strong> propellers share the burden<br />

of powering the ship and spin<br />

in opposite directions, allowing<br />

the rear propeller to absorb<br />

the rotation energy of the front<br />

propeller.<br />

As a result, the system is to increase<br />

efficiency. Furthermore,<br />

the advanced model of the<br />

MOL-developed Advanced Propeller<br />

Boss Cap Fins (PBCF) will<br />

be used. This device has been<br />

adopted on more than 1,700<br />

vessels all over the world.<br />

Wind resistance design<br />

A special design was developed<br />

by MOL, futher refining the<br />

hull shape to reduce wind pressure<br />

from the bow and sides.<br />

<strong>The</strong> shape of the stern also<br />

smoothes the flow of the wind.<br />

Reduction of friction drag<br />

Next-generation vessels will be<br />

covered with ultra-low friction<br />

ship bottom paint. By trapping<br />

water on the coated surface,<br />

this paint is said to eliminate<br />

friction drag caused by minute<br />

patterned indentations formed<br />

on conventionally painted surfaces.<br />

Optimum voyage support system<br />

<strong>The</strong> optimum voyage support<br />

system relies on the latest marine<br />

weather information while<br />

monitoring voyage conditions,<br />

and searches for the shortest,<br />

most fuel-efficient routes while<br />

taking into account the differences<br />

in various types and hull<br />

forms of ships.<br />

Optimization of engine system<br />

Fuel supply to the engine is<br />

electronically controlled, and<br />

the vessel operates with the<br />

optimum fuel supply. <strong>The</strong>rmal<br />

energy conventionally lost with<br />

exhaust gas will be efficiently<br />

recovered for reuse.<br />

Optimization of hull design<br />

<strong>The</strong> hull form has been improved,<br />

in pursuit of further<br />

improvements in fuel efficiency.<br />

Larger hull compatible with<br />

new Panama Canal<br />

When needs for larger vessels<br />

arise, the adoption of<br />

twin-shaft propellers shall allow<br />

greater improvement in<br />

propulsion performance and<br />

fuel efficiency.<br />

Ship & Offshore | 2009 | N o 4 15

SHIPBUILDING & EQUIPMENT | INDUSTRY NEWS<br />

“Weak-but-steady growth”<br />

<strong>The</strong> sixth edition of Inmex<br />

India in Mumbai<br />

Interest<br />

in India<br />

INMEX INDIA | 450 exhibitors<br />

from 39 countries are<br />

reported to have exhibited on<br />

the recent Inmex India exhibition<br />

at the Bombay Exhibition<br />

Centre held on 24–26<br />

September. Some 5,000 visitors<br />

attended the show and<br />

early reports show a high<br />

level of satisfaction. Over<br />

93% of the exhibitors stated<br />

that they wished to exhibit at<br />

Inmex India 2011 with both<br />

Indian and international exhibitors<br />

reporting a great deal<br />

of business activity.<br />

This international event hosted<br />

country pavilions for Germany,<br />

Korea, China, Singapore<br />

and Holland. <strong>The</strong> B-2-B<br />

Forum consisting of round<br />

table sessions and one-toone<br />

meetings under the<br />

motto “Transforming India<br />

into a maritime hub by the<br />

next decade” attracted more<br />

than 500 businessmen and<br />

captains. Senior level professional<br />

attendees debated<br />

and strategized to define the<br />

future of the maritime landscape.<br />

Inmex India 2011 will be<br />

held from 29 September to<br />

1 Octo ber 2011 in Mumbai.<br />

OIL AND GAS TANKER | <strong>The</strong><br />

world fleet of oil, chemical and<br />

gas tankers is predicted to continue<br />

to grow over the next five<br />

years, although at a much more<br />

sluggish rate than the previous<br />