Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>POWER</strong> <strong>STEERING</strong> 9-25<br />

DISASSEMBLY OF <strong>PUMP</strong><br />

Clean exterior of pump using care to prevent dirt<br />

and foreign material from entering pump. A clean<br />

sheet of paper should be used on bench to keep pump<br />

parts clean.<br />

1. Remove reservoir body from pump body and<br />

cover (Fig. 9-50). Use care not to lose spacers and<br />

reservoir to body and cover gaskets.<br />

2. Remove four pump cover to pump body attaching<br />

bolts, and carefully remove pump cover with flow<br />

control valve and spring.<br />

3. Lift pressure plate off dowel pins extending<br />

through rotor ring and remove rotor ring "0" ring<br />

seal.<br />

4. Remove rotor ring from dowel pins and remove<br />

rotor, vanes and second rotor ring "0" ring seal.<br />

Remove dowel pins from pump body.<br />

S. Remove outer bearing snap ring from groove<br />

in pump body using tool J -4245.<br />

6. Properly support pump body and remove drive<br />

shaft and outer bearing by tapping on end with soft<br />

hammer.<br />

7. If drive shaft seal or inner bearing is to be replaced,<br />

seal must be removed using a punch. The<br />

inner bearing is removed by lightly tapping on inner<br />

race.<br />

8. Disassemble flow control and relief valve, maintaining<br />

pressure on spring loaded plug to prevent loss<br />

of poppet ball. Use care not to score ground surfaces<br />

of flow control valve (Fig. 9-51).<br />

9. Union fittings in cover should only be removed<br />

if "0" ring seals leak or fittings are damaged.<br />

CLEANING <strong>AND</strong> INSPECTION OF<br />

<strong>PUMP</strong> PARTS<br />

1. Wipe bearing and shaft assembly with clean<br />

cloth; do not soak in cleaning solvent as the lubricant<br />

sealed into bearing may be diluted by solvent. Wash<br />

all other parts in clean kerosene or other solvent and<br />

wipe dry with clean lint-free cloth.<br />

2. Inspect drive shaft for wear and check both ball<br />

bearings for roughness or noisy operation. If outer<br />

bearings must be replaced, press off shaft with tool<br />

J-SS73 (Fig. 9-52).<br />

3. Check fit of vanes in slots of rotor; vanes must<br />

slide freely but snugly in slots. Tightness may be<br />

'r-"<br />

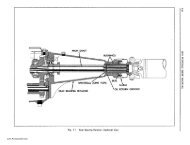

POPPET SPRING<br />

BALL<br />

J<br />

'LUG \ ~<br />

'<br />

1 r"""\o9'~ VALVE<br />

~ GUIDE<br />

SHIM WASHERS<br />

CALIBRATED ORIFICE<br />

fig. 9-51<br />

fig. 9-52<br />

flow Control Valve-Exploded View<br />

Installing Outer Bearing on Shaft<br />

relieved by thorough cleaning, or removal of irregularities.<br />

Replace rotor if excessive looseness exists<br />

between rotor and vanes, and replace vanes if worn<br />

or scored.<br />

4. Inspect all ground surfaces of rotor ring for<br />

roughness or irregular wear. Slight irregularities may<br />

be removed with a hard stone. Replace ring if inside<br />

cam surface is scored or worn.<br />

S. Inspect flat faces of the pressure plate and<br />

pump body for wear or scoring. Light scores may be<br />

smoothed by lapping, after which all lapping compound<br />

must be thoroughly washed away.<br />

6. Inspect ground surfaces of flow control valve,<br />

paying particular attention to seating surfaces. Check<br />

freedom of movement of flow control valve within its<br />

bore. Slight irregularities may be corrected by lapping<br />

or polishing.<br />

7. Inspect all passages in cover and body for obstructions<br />

or dirt.<br />

www.PontiacSafari.com