Nozzle Loads, Piping Stresses, and the Effect of Piping on Equipment

Nozzle Loads, Piping Stresses, and the Effect of Piping on Equipment

Nozzle Loads, Piping Stresses, and the Effect of Piping on Equipment

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

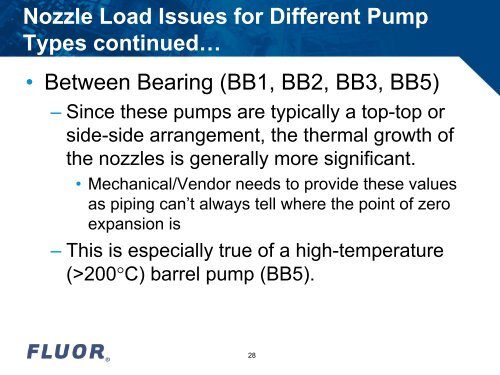

<str<strong>on</strong>g>Nozzle</str<strong>on</strong>g> Load Issues for Different Pump<br />

Types c<strong>on</strong>tinued…<br />

• Between Bearing (BB1, BB2, BB3, BB5)<br />

– Since <str<strong>on</strong>g>the</str<strong>on</strong>g>se pumps are typically a top-top or<br />

side-side arrangement, <str<strong>on</strong>g>the</str<strong>on</strong>g> <str<strong>on</strong>g>the</str<strong>on</strong>g>rmal growth <str<strong>on</strong>g>of</str<strong>on</strong>g><br />

<str<strong>on</strong>g>the</str<strong>on</strong>g> nozzles is generally more significant.<br />

• Mechanical/Vendor needs to provide <str<strong>on</strong>g>the</str<strong>on</strong>g>se values<br />

as piping can’t always tell where <str<strong>on</strong>g>the</str<strong>on</strong>g> point <str<strong>on</strong>g>of</str<strong>on</strong>g> zero<br />

expansi<strong>on</strong> is<br />

– This is especially true <str<strong>on</strong>g>of</str<strong>on</strong>g> a high-temperature<br />

(>200C) barrel pump (BB5).<br />

28