QLM and QLD Series DN125 to DN200 Three Port ... - Spirax Sarco

QLM and QLD Series DN125 to DN200 Three Port ... - Spirax Sarco

QLM and QLD Series DN125 to DN200 Three Port ... - Spirax Sarco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

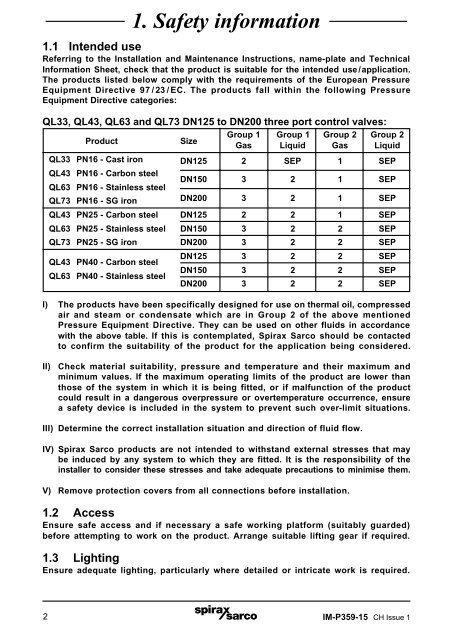

1.1 Intended use<br />

Referring <strong>to</strong> the Installation <strong>and</strong> Maintenance Instructions, name-plate <strong>and</strong> Technical<br />

Information Sheet, check that the product is suitable for the intended use/application.<br />

The products listed below comply with the requirements of the European Pressure<br />

Equipment Directive 97 /23 /EC. The products fall within the following Pressure<br />

Equipment Directive categories:<br />

QL33, QL43, QL63 <strong>and</strong> QL73 <strong>DN125</strong> <strong>to</strong> <strong>DN200</strong> three port control valves:<br />

Group 1 Group 1 Group 2 Group 2<br />

Product<br />

Size<br />

Gas Liquid Gas Liquid<br />

QL33 PN16 - Cast iron <strong>DN125</strong> 2 SEP 1 SEP<br />

QL43 PN16 - Carbon steel<br />

QL63 PN16 - Stainless steel<br />

DN150 3 2 1 SEP<br />

QL73 PN16 - SG iron <strong>DN200</strong> 3 2 1 SEP<br />

QL43 PN25 - Carbon steel <strong>DN125</strong> 2 2 1 SEP<br />

QL63 PN25 - Stainless steel DN150 3 2 2 SEP<br />

QL73 PN25 - SG iron <strong>DN200</strong> 3 2 2 SEP<br />

QL43 PN40 - Carbon steel<br />

QL63 PN40 - Stainless steel<br />

1. Safety information<br />

<strong>DN125</strong> 3 2 2 SEP<br />

DN150 3 2 2 SEP<br />

<strong>DN200</strong> 3 2 2 SEP<br />

I) The products have been specifically designed for use on thermal oil, compressed<br />

air <strong>and</strong> steam or condensate which are in Group 2 of the above mentioned<br />

Pressure Equipment Directive. They can be used on other fluids in accordance<br />

with the above table. If this is contemplated, <strong>Spirax</strong> <strong>Sarco</strong> should be contacted<br />

<strong>to</strong> confirm the suitability of the product for the application being considered.<br />

II)<br />

Check material suitability, pressure <strong>and</strong> temperature <strong>and</strong> their maximum <strong>and</strong><br />

minimum values. If the maximum operating limits of the product are lower than<br />

those of the system in which it is being fitted, or if malfunction of the product<br />

could result in a dangerous overpressure or overtemperature occurrence, ensure<br />

a safety device is included in the system <strong>to</strong> prevent such over-limit situations.<br />

III) Determine the correct installation situation <strong>and</strong> direction of fluid flow.<br />

IV) <strong>Spirax</strong> <strong>Sarco</strong> products are not intended <strong>to</strong> withst<strong>and</strong> external stresses that may<br />

be induced by any system <strong>to</strong> which they are fitted. It is the responsibility of the<br />

installer <strong>to</strong> consider these stresses <strong>and</strong> take adequate precautions <strong>to</strong> minimise them.<br />

V) Remove protection covers from all connections before installation.<br />

1.2 Access<br />

Ensure safe access <strong>and</strong> if necessary a safe working platform (suitably guarded)<br />

before attempting <strong>to</strong> work on the product. Arrange suitable lifting gear if required.<br />

1.3 Lighting<br />

Ensure adequate lighting, particularly where detailed or intricate work is required.<br />

2<br />

IM-P359-15 CH Issue 1