- Page 1 and 2:

!""# $%& '() *!

- Page 3 and 4:

D*7=4 0? """$ # 4%398

- Page 5 and 6:

!

- Page 7 and 8:

% $###:#%##&#%##& :*#A&**&*#*$&# %

- Page 9 and 10:

*bnd.dat " && *# #' tmp.dx " *#!

- Page 11 and 12:

) *# &# **& ## # *& # #* $%&*##.*&

- Page 13 and 14:

# This part defines the used script

- Page 15 and 16:

! ! !" # ! $! % & " '"

- Page 17 and 18:

− − &#!#!!!- !!# &#"!&#! &

- Page 19 and 20:

.1 ! ! #! ##! 1 # 1

- Page 21 and 22:

!#!&#!#&#! /#! # ! !#

- Page 23 and 24:

! ! # &#! #! ! !)0

- Page 25 and 26:

− − !# !*+$ !# !!# #!!# !##!

- Page 27 and 28:

− − *1 # #! ! .#

- Page 29 and 30:

!"# # $! ! " % " !" !! &$ %

- Page 31 and 32:

$&. "" ,'"$!! $! "$ !! "$ "C!$

- Page 33 and 34:

'" ! ! '" $ $! ' ! $!

- Page 35 and 36:

,G ! B ! $ B ,)! B %

- Page 37 and 38:

,;>F! ( '"B$ B$ $$"! 4 5 '

- Page 39 and 40:

J' %# K F$ " ' " ' $ " ' '

- Page 41 and 42:

.#/)3)0# 40*# (% ) ! #' # ## !!

- Page 43 and 44:

(%&% * 3$! ! ! ##' ## # #!($)*

- Page 45 and 46:

# ! ! # * 0 ! # ! !!!#/E=9E-E

- Page 47 and 48:

.%' !!!! !!! ! !# ! ' (#,*# # !$

- Page 49 and 50:

7 7 7 & 7 " = = =

- Page 51 and 52:

$ $ #$ $ ) # >+$ -:" #J

- Page 53 and 54:

" 5∆" A -∆" ∆" -∆ ∆

- Page 55 and 56:

!" # $! %&' ()(* !"# $%!&$'() ((

- Page 57 and 58:

+(@ + +, +,( - 0, 1 + ,

- Page 59 and 60:

(%CD9#%!# +(/#0#51+#( 3* - /82/-

- Page 61 and 62:

,-C+, A# I% I3 I 9#< %=3 35 . 9#=

- Page 63 and 64:

+,#=+ #(;01(,3(3 (4+ 3 %&(++:3(34+

- Page 65 and 66:

++ ++#(/ +,03(%+,!(5+,!(+1,# ,(

- Page 67 and 68:

+ + ++D9 82/- , :+ , -8

- Page 69 and 70:

$@ -8(7(88(F(OF--"(2(0%&&=1( -(+(

- Page 71:

9 !' ' ###'+') +'#! ! #!# ' ! (.

- Page 74 and 75:

! ' !'&* 9:;' ) 'A! '!'!&7 -#!9

- Page 76 and 77:

'H' 2? 2?D (#< :!1& *%&%* * 0

- Page 78 and 79:

D ! #!&*!!' ( ' ( #= ( 2? (( '

- Page 80 and 81:

5' ,6! !&* + , !!( ' , ( ) !#

- Page 82 and 83:

+% , +%$% 6,#! C '(# (!, (

- Page 84 and 85:

! ! " # $"%

- Page 86 and 87:

%"""" """D"""." "/""5""".""" "."

- Page 88 and 89:

+# ." "'()(39::/""" 0 0/3/

- Page 90 and 91:

"". /""""""34/ """ 0 "3"""""" 0 3"

- Page 92 and 93:

3F 36 0 " " . 0 " " 0 "0 '" "

- Page 94 and 95:

!"# $%&'()$ *+,&'() &-() ./01-(2 +'

- Page 96 and 97:

) ")# " 2 )9 $) "$%$ )$%!-# )25$

- Page 98 and 99:

9 $#+ # )# ))$# ") # ) ) >""!

- Page 100 and 101:

D +2"$"!! D +2"$" , "8 9 "8 ' 2

- Page 102 and 103:

"2+$#!% ## )$ !"* )"$) $ #N "N!)"#

- Page 104 and 105:

&.!(: ! &% % % #0 !'&"" #)"%$)

- Page 106 and 107:

106.0% WEIGHT 105.0% ∆w/3 ∆w/4

- Page 108 and 109:

! "

- Page 110 and 111:

5 # # ' # + ! "#

- Page 112 and 113:

+ ' # + ! + '#

- Page 114 and 115:

!I05 !# ! # 8! 12* 05 8 ++! +N

- Page 116 and 117:

03 #! !+# #3 '#' !# ?8 0 8

- Page 118 and 119:

!

- Page 120 and 121:

)* " * * ! ! ") 5 o 2"#

- Page 122 and 123:

o - " + 1 /)* *# ! ) ),

- Page 124 and 125:

o F "LL%$ " ! " $ $ o F

- Page 126 and 127:

' ' : 4P 3 >3 ' E E E ': E E E I P

- Page 128 and 129:

''51 $ , 1 ' J!# 1 4 6- 6- -

- Page 130 and 131:

;C4 , !4 4 . ( ( ; I , .@; ,!@5

- Page 132 and 133:

"! >3 F " # F + "

- Page 134 and 135:

5# ## # 6 2# ##2 # !74% ##

- Page 136 and 137:

#$ # # % $# .!(# # 2 2#$ #&'&

- Page 138 and 139:

# # # - % % # $ #0 %#! *&I&,JK

- Page 162 and 163:

!""#$%&"

- Page 164 and 165:

A% )* 3 3 "8'!8A9 5 "8'!8A9 ( (

- Page 166 and 167:

)* $ $' ' Q ; E A ? '? 'A '

- Page 168 and 169:

'% !!! ( * ( ) )* >

- Page 170 and 171:

."'" 7 879 ')) % ) 2*

- Page 172 and 173:

) !?! .5>C81 A%K>%+ ) ;" >&7C 7 *

- Page 174 and 175:

4>$>! "@ C!PC&A!"? 8@ >&'! $@ 4&!>8

- Page 176 and 177:

,11:- > ,119-!& ( "("% ,11:-

- Page 178 and 179:

,-,*-,"- ;D! B G?,-??,*-3???,"-D

- Page 180 and 181:

!(" 3 3 " 9?? !(" ) ( ;,- ,-

- Page 182 and 183:

8$/6#@>E8/ N&%(&( )) 0 ) 8

- Page 184 and 185:

&$ " /# ! &-.//.")#% " #"),

- Page 186 and 187:

($ ) ! /22 #'&"#)## %#"##

- Page 188 and 189:

)## ##&)# - # )*) # # #"#

- Page 190 and 191:

# ) # /& " # 4 #& ?L

- Page 192 and 193:

# # )* ) # %) #" ) & "%##)*%#)* ")

- Page 194 and 195:

# # )* ) # %) #" ) & "%# #)*%#)* ")

- Page 196 and 197:

!"#$ !%"%!& '#( )* $ *% *# + &%$

- Page 198 and 199:

- # ,,/ # . 6- # #,$%&'(

- Page 200 and 201:

'" & . , ,$%&'(&)*&+(./9 -#

- Page 202 and 203:

#,#--! " -, ( & 5 ,# (5-/% ( 9 ,

- Page 204 and 205:

# "# % %#("" "# " #%#

- Page 206 and 207:

#" > * % #%"# " "# " #" # "

- Page 208 and 209:

# #' %**# ( ""*## -( #' %

- Page 210 and 211:

! ! " ! "

- Page 212 and 213:

)" ! ) ! & @

- Page 214 and 215:

?7F @ %( 5 67 & & %&( ) &

- Page 216 and 217:

) %( ) -

- Page 218 and 219:

& (JK- !&- &3 - < '

- Page 220 and 221:

!" # $

- Page 222 and 223:

# $ :+ $ ",---%$ ".///%/$

- Page 224 and 225:

# & $

- Page 226 and 227:

:C :C7= ? ./ . :E7 /

- Page 228 and 229:

# " " " "

- Page 230 and 231:

%% & +E +- +

- Page 232 and 233:

@ C = / +C + C 3 = = 4 JB JB JB

- Page 234 and 235:

* 08;! BF /!B?8 46F #?8 6 1+,,,2

- Page 236 and 237:

, ** " % ) * * * %*) * * *" %

- Page 238 and 239:

** ) % ) ** " %* *%" 9 * *

- Page 240 and 241:

A * * * %)*.,*2>* &$+

- Page 242 and 243:

• )=#,= ** • H • • )

- Page 244 and 245:

. 0 4 0 (4 +' ( 0 "0 -22 ( 0 32

- Page 246 and 247:

• " ) @--1--% >, " % , * )

- Page 248 and 249:

!#$ % -!!3!!0 !!! :! !!*!+!*!!!!-

- Page 250 and 251:

#9#- !1'67 #79/1'1-"=%1"1!=8C==

- Page 252 and 253:

!*!!!*/1'1-8 " !0 !$%! !!" !!!!*!

- Page 254 and 255:

#6691!! /" J=8/ DK 51.,/J42 -J,

- Page 256 and 257:

- /01 201 ) " + &

- Page 258 and 259:

! @ 9 : $ "!#! ! - --

- Page 260 and 261:

$$ • % - • > -

- Page 262 and 263:

$/ - - ##*!!%# 5

- Page 264 and 265:

( 2!% K '

- Page 266 and 267:

• *% • .((*%*% • .(%**1&%(%%

- Page 268 and 269:

('( #(*)%*(%)#& %(*.((%%( *%*.('*%

- Page 270 and 271:

=2;*+(** (E(A *F % ) *(% )( *+/ .(

- Page 272 and 273:

.() '%%*(%) *(% )*%( ()*** (* (%*

- Page 274 and 275:

=2'%*(** ((%****(*+-2 • = * * (

- Page 276 and 277:

%%*%')#%))%* )% ))(%?+)?%()* )( (

- Page 278 and 279:

! " ! # ! ! !"#!$#"!%"#""&!"

- Page 280 and 281:

""!"!"'$!!!#!!!("$!1:"#"" "&&'!! &

- Page 283 and 284:

"( 0$"'&"E- C "!$#'"D- C4444,44444

- Page 285 and 286:

*!+!, - - +)' ##' &&' " & 0#&

- Page 287 and 288:

,#&&&#'# &#"# # "" '"#" $ " #

- Page 289 and 290:

VOYAGER This section describes wave

- Page 291 and 292:

#'# &# ># &# #"#""-' #$' ''## &'"

- Page 293 and 294:

'#$ ># $'" ' # & '" ' #

- Page 295 and 296:

$#"# & #&#$ "+#") ""#'## # #$$##"

- Page 297 and 298:

!

- Page 299 and 300:

& % & & ! # %& 4 A % & " * # $%

- Page 301 and 302:

'("(! ## # !% & ( % ! ' !

- Page 303 and 304:

! % " & # $ 0 !

- Page 305 and 306:

' 1 ' &@ %

- Page 307 and 308:

*0 & % & * 4

- Page 309 and 310:

= ⋅ + − = ⋅ + −

- Page 311 and 312:

:: = − + + + ρ

- Page 313 and 314:

: (( ! ( ($ -! '?.'@@? 8D

- Page 315 and 316:

! @-3::4 ( $ $! $ > $5 8< " #

- Page 317 and 318:

# (( ! $$=! @ ,@ ?.6,.6 A6+,E7

- Page 319 and 320:

-! !$ $! $! !# ( #! ! $ (

- Page 336 and 337:

! " #

- Page 338 and 339:

.8' $!"!( $%$'' "'''"! !!"$ !"$"$"

- Page 340 and 341:

( !!" !! -" $"$. " % !$ !$ "

- Page 342 and 343:

& '%! %$%&=%"'!!!( &K'L"K!-+F .%!/4

- Page 344 and 345:

$M7,!!&$""! $%$%% #; '()))* $7 8

- Page 346 and 347:

8%&!&"$'("$!!%!!$%!$%( "&%%& ;',---

- Page 348 and 349:

# ; =: BJF6: F B8+S6T( ,F ;-/444.

- Page 350 and 351:

!" !

- Page 352 and 353:

*'&* *5-'(*=% %' '3% .** " % *@

- Page 354 and 355:

)2***%**' * 2)!**.' 0%*?55',0%&&3

- Page 356 and 357:

' 11 2* > ' ?EFB** *%*** **

- Page 358 and 359:

45 !!F47" A-20-G2 45 **''#$ '*'*

- Page 360 and 361:

1' * * ' * *3% • 1*'3% ' '.*3%

- Page 362 and 363:

!"# $%

- Page 364 and 365:

$) 67=8$ $ 6;' >$8$ 6*; 6; 6?3

- Page 366 and 367:

-2 ?0#'$&'' 1 ! 8$ '&$ $' $&)$

- Page 368 and 369:

@($&''$ 3)$&(&$#$ 8' 6&& ; 4

- Page 370 and 371:

-. $) '$$& #'$ &$#$$7?6 $) #'

- Page 372 and 373:

2()) 5 ! -. $) # $&$ $& ' &$ &$

- Page 374 and 375:

614 7 $ $ $ #'$ )$ #$# # &

- Page 376 and 377:

-2?0#' $&)$$#$'&$ ( #' #'$ $))#$

- Page 378 and 379:

(:"#" #"" ""#"2$""$$. ""##$"#$ ""#

- Page 380 and 381:

""##"#$ """ ..#"# "##"###$"" """"#$

- Page 382 and 383:

:# #" J " ## 2 " ."""# #$"

- Page 384 and 385:

."-"# ""## " """ ""#$ #"# ##"# C A

- Page 386 and 387:

I,3K1FF4E***5( :!= 2 ! FFF	O#@)

- Page 388 and 389:

=9%> 3 #! !' # # $ & #!!!#####

- Page 390 and 391:

%

- Page 392 and 393:

)!!!#''!'' !'!%!'#!&!. !#!!#!'$0!#

- Page 394 and 395:

% !#' ! # ( '! ' 04B1 ! :!A %

- Page 396 and 397:

*# ''=9%>#!'!$!##!' !#!'!'&(. !(

- Page 398 and 399:

47D*>1( 477*?1' &&! #! 47A*?=,

- Page 400 and 401:

! !" ""!""!#"# #

- Page 402 and 403:

+ ""!$"0" "$!"!" $!""!" " 4 "

- Page 404 and 405:

$"* • #""!!""!"1!"2 • 9"""!"

- Page 406 and 407:

(&&' / 4!"#0""!"!"!+!"#0" $"#0" "

- Page 408 and 409:

Weight / Time - Diagram 120 % 100 %

- Page 410 and 411:

0 ! 0& 1 0&& $ $ " ""!

- Page 412 and 413:

0& """"!!"!!! #"/ !"!! ""!!""!*

- Page 414 and 415:

: ! "$"##""! &!!" ! $ !# "" %

- Page 416 and 417:

#!!() *+' +"""%'$$&-"%$ "2+67-$&$

- Page 418 and 419:

! /5*//-L "$$ ($$$%$/0 &$*//-$""3M

- Page 420 and 421:

% $ " '% 2$ $ " % "%

- Page 422 and 423:

2!#!!, &$$$$%"$ "$"1 "$ %$$"$$%$ +

- Page 424 and 425:

""$%""" 3+" 4+ " "$$/E %0$$$%%" "$

- Page 426 and 427:

!*% !%"! %" 1 "! ! 22 3456

- Page 428 and 429:

! / (B; " & " !"

- Page 430 and 431:

! " " $ 9"

- Page 432 and 433:

!" #$

- Page 434 and 435:

9#$%. 0$!#$%. ) 0 !!(!!!!!$% 9#$%

- Page 436 and 437:

'% $% ! ! !!;!1.;10 $% $2$! 1

- Page 438 and 439:

7

- Page 440 and 441:

7A21 2$ ! 4(!"5! !*0 4 !$ $ !

- Page 442 and 443:

• *+ (*7'/ • 7 • "'! 1+ (!$((

- Page 444 and 445:

!"# $""%&! !'! $""%& !'! $""%&(

- Page 446 and 447:

#!$ % ##/ #"(#/"#"//'; • /#4/

- Page 448 and 449:

&# ## " ' ( # "/ # 4' "# #(#

- Page 450 and 451:

$##("'# ,# (""''&# ! # ,#)#'!$&1!!

- Page 452 and 453:

!A;3 ,## /!?;"/( 0 $ #" "& 7>

- Page 454 and 455:

+' #4 ( # # 1 # #'# # (" / #2"

- Page 456 and 457:

!9>; '##(& ""#"'"##(&"# $'$%B?A$%B

- Page 458 and 459:

'# $%B?A $%BB>H# /!9C;''##'#$%B

- Page 460 and 461:

-./ # $ 0

- Page 462 and 463:

# 3" $$ CB%$ " 4

- Page 464 and 465:

$$ ":$ $ $&$$ %$ 0 $ %$

- Page 466 and 467:

$ $ #3"6 $ 5"$ ": $ 2

- Page 468 and 469:

#$$ -# /# " $ 4- 4 " $$ /

- Page 470 and 471:

$3 $ $ • ) , * / #

- Page 472 and 473:

! ! ! !" !

- Page 474 and 475:

@@!"/ # !!@!@*"!+!!, "! ! A "!!

- Page 476 and 477:

= ( 7 ⋅8 ) − 7 ⋅8 [ 7

- Page 478 and 479: # , " (") +++/0" , +, + ! 1 1

- Page 480 and 481: % # -# .# ( (( #$ ( $ ((

- Page 482 and 483: " "# % (+ +$ ( ( ( )*

- Page 484 and 485: '( # ( & (- #((( # ( ( (

- Page 486 and 487: + $ ( ( + %$ + 8

- Page 488: (8

- Page 491 and 492: # %%%*% * 5 3 6. &78

- Page 493 and 494: , & ' "# ' *" ' ' & *

- Page 495 and 496: (%/) $ "*"& % %'% '# 5 ' %&7%

- Page 497 and 498: % # & & % ' 57 ' ' 57%M&*8

- Page 499 and 500: *3 -%%' ' JBK:%9C o #3%&-%%' %&J0

- Page 501 and 502: 0 B ' * ' *&%&* & % & % ' ! "

- Page 503 and 504: ')+( ! """ " " ! %" ,

- Page 505 and 506: ""% % ' . . (

- Page 507 and 508: -91)" 32#,000' !!! ' ) * *0"

- Page 510 and 511: "2+++ "1 =E>E=EEE1 =E>E1 , " C =9

- Page 512 and 513: W -=14" "

- Page 514 and 515: -=218%""1" -=918%""1"

- Page 516 and 517: !" #

- Page 518 and 519: +%) # ( +%$%,# $$ "$" B" "$ ) $

- Page 520 and 521: $#' $.' $"$" "#' # "$ $ ('#'"#". .

- Page 522 and 523: '7M "99 '" ##"- $G#'"#$# - $7

- Page 524 and 525: -%# ## :0*0 2 " " / # #

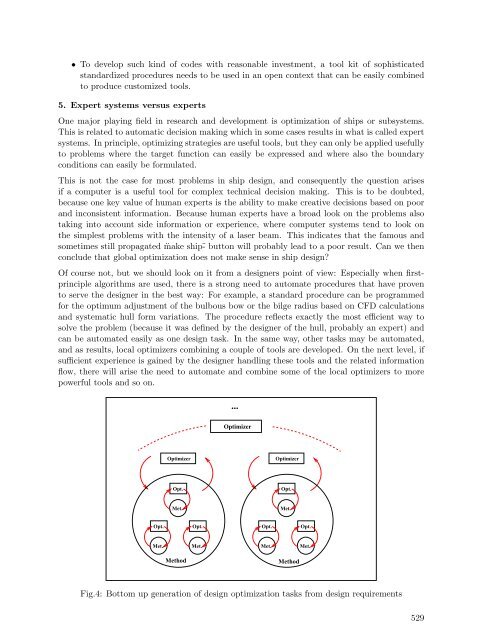

- Page 526 and 527: 2. Early design versus detailed des

- Page 530 and 531: This shows that the development of

- Page 532 and 533: Fig.6: Simultaneous engineering dur

- Page 534 and 535: ! !"#$ #%& ' # "

- Page 536 and 537: &$#$ ?+* # ) ) ) $ # ()

- Page 538 and 539: 2 -( $ $ < # $ )$*)$$+

- Page 540 and 541: 1500T Roll press jobshop Stock Cutt

- Page 542 and 543: ! ! "

- Page 544 and 545: 0 *$ !$$!$ $ $ $ #$ ! 4 $$& !

- Page 546 and 547: !' 0 $4#9$$(:#*$7 4 #!#$

- Page 548 and 549: 0 &$ !9=)( #!!#$*$!$$!$ $# 2!0 !&#

- Page 550: COMPIT'04 !"# #$$% &