You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Example<br />

case<br />

study<br />

Energy efficient <strong>META</strong> warehousing solution<br />

<strong>META</strong> mobile racking system + modern-look cantilever rack<br />

Customer:<br />

Hartl is a manufacturer of<br />

rock-crushing and screening<br />

systems. Hartl's highly diversified<br />

product portfolio includes<br />

track-mounted mobile impactors,<br />

jaw crushers, vertical mills and<br />

screening systems and is distributed<br />

through a widespread dealer<br />

network that covers more than 40<br />

countries.<br />

In 2003, its Powercrusher PC 1375<br />

I won the Red Dot Award "best of<br />

the best". In 2008, the company<br />

had 110 employees and a sales<br />

volume of 60 million Euro.<br />

Hartl applies the "lean manufacturing"<br />

principle in production, i.e.<br />

the Powercrusher is made only to<br />

customer order. They ensure high<br />

availability through extremely short<br />

lead times. This is due to perfect<br />

processes and the high availability<br />

of individual components.<br />

Mission statement:<br />

The Hartl plant is built on the site of an old gravel pit and has an<br />

extraordinary appearance, with clear lines, large surfaces and lightflooded<br />

rooms – so they needed a modern warehouse.<br />

Energy efficiency: the buildings The buildings have low-energy<br />

underfloor heating, very good noise insulation, natural lighting and<br />

environment-friendly ventilation systems.<br />

The new warehouse had to provide optimal support for internal material<br />

flows, to allow flexibility of production to meet customers' desired<br />

delivery dates.<br />

Solution:<br />

In just 4 weeks, <strong>META</strong> installed a <strong>META</strong> MULTIBLOC ® mobile racking<br />

system, with a <strong>META</strong> MULTIPAL ® pallet racking structure and a <strong>META</strong><br />

MULTISTRONG ® cantilever rack.<br />

The mobile racking system brings a 50% saving on space and a<br />

110% increase in storage capacity compared with stationary systems.<br />

Nevertheless, it still allows access to each individual storage position. The<br />

long distances that a stacker truck driver has to cover in a conventional<br />

warehouse have been considerably reduced through the use of a mobile<br />

racking system.<br />

The mobile racking system can store 21 pallets per bay on a total of<br />

seven levels, with a load capacity of one ton per pallet and is used<br />

mainly for storing cast parts, gearboxes and roller bearings.<br />

Pallet Racking<br />

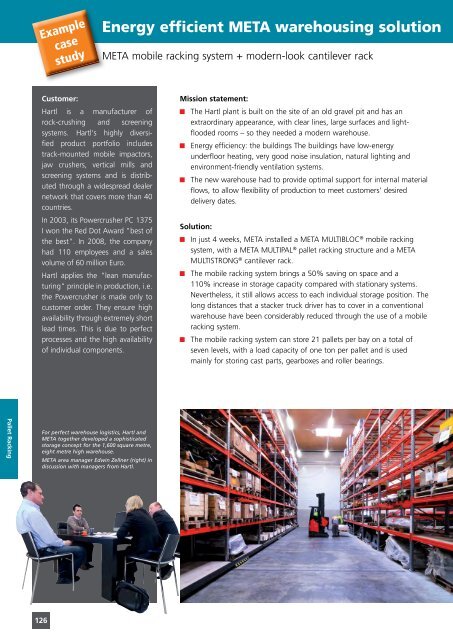

For perfect warehouse logistics, Hartl and<br />

<strong>META</strong> together developed a sophisticated<br />

storage concept for the 1,600 square metre,<br />

eight metre high warehouse.<br />

<strong>META</strong> area manager Edwin Zellner (right) in<br />

discussion with managers from Hartl.<br />

126