P216, P218 P220, P224 Performer Series - Cummins Onan

P216, P218 P220, P224 Performer Series - Cummins Onan

P216, P218 P220, P224 Performer Series - Cummins Onan

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Commutator Inspection: If commutator is dirty or discolored,<br />

clean with number 00 to 000 commutator<br />

paper. Blow grit out of armature after cleaning.<br />

If commutator is scored, rough, or worn, turn it down in a<br />

lathe.<br />

Field Coil: Use an ohmmeter to check for continuity<br />

between brushes. If there is no continuity, the field coil is<br />

open and must be replaced. With field coil mounted in<br />

the frame, check for continuity between the field coil and<br />

frame. Replace frame assembly if there is continuity.<br />

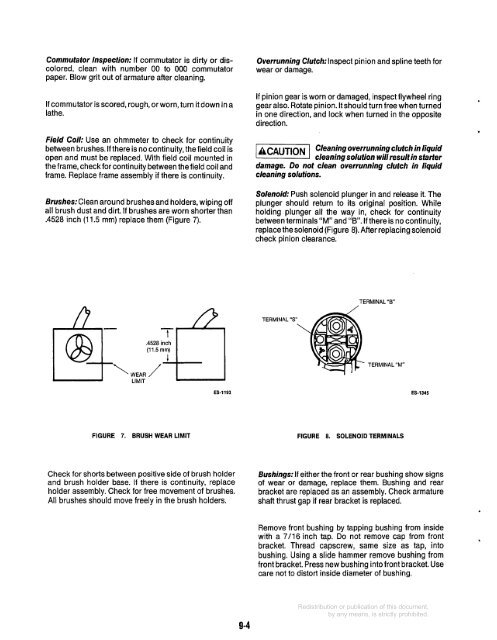

Brushes:Clean around brushes and holders, wiping off<br />

all brush dust and dirt. If brushes are worn shorter than<br />

.4528 inch (1 1.5 mm) replace them (Figure 7).<br />

Overrunning Clutch: Inspect pinion and spline teeth for<br />

wear or damage.<br />

If pinion gear is worn or damaged, inspect flywheel ring<br />

gear also. Rotate pinion. It should turn free when turned<br />

in one direction, and lock when turned in the opposite<br />

direction.<br />

-1 Cleaning overrunning clutch in liquid<br />

cleaning solution will result in starter<br />

damage. Do not clean overrunning clutch in liquid<br />

cleaning solutions.<br />

Solenoid: Push solenoid plunger in and release it. The<br />

plunger should return to its original position. While<br />

holding plunger all the way in, check for continuity<br />

between terminals “M” and “B’. If there is no continuity,<br />

replace the solenoid (Figure 8). After replacing solenoid<br />

check pinion clearance.<br />

TERMINAL “ B<br />

,4528 inch<br />

(11.5 mm)<br />

WEAR /<br />

LIMIT<br />

ES-1193<br />

ES-1345<br />

FIGURE 7. BRUSH WEAR LIMIT FIGURE 8. SOLENOID TERMINALS<br />

Check for shorts between positive side of brush holder<br />

and brush holder base. If there is continuity, replace<br />

holder assembly. Check for free movement of brushes.<br />

All brushes should move freely in the brush holders.<br />

Bushings:If either the front or rear bushing show signs<br />

of wear or damage, replace them. Bushing and rear<br />

bracket are replaced as an assembly. Check armature<br />

shaft thrust gap if rear bracket is replaced.<br />

Remove front bushing by tapping bushing from inside<br />

with a 7/16 inch tap. Do not remove cap from front<br />

bracket. Thread capscrew, same size as tap, into<br />

bushing. Using a slide hammer remove bushing from<br />

front bracket. Press new bushing into front bracket. Use<br />

care not to distort inside diameter of bushing.<br />

9-4