P216, P218 P220, P224 Performer Series - Cummins Onan

P216, P218 P220, P224 Performer Series - Cummins Onan

P216, P218 P220, P224 Performer Series - Cummins Onan

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Tappet Adjustment<br />

The engine is equipped with adjustable valve tappets.<br />

The valve tappet clearance should be checked and<br />

adjusted as specified in the Periodic Maintenance<br />

Schedule (located in the Operator's Manual). Adjust the<br />

valve clearance only when engine is at ambient temperature.<br />

Proceed as follows:<br />

1. Remove ignition key to prevent accidental starting.<br />

2. Remove all parts necessary to gain access to valve<br />

tappets.<br />

3. Remove spark plugs to ease the task of turning the<br />

engine over by hand.<br />

4. Place a socket wrench on the flywheel capscrew<br />

and rotate the crankshaft in a clockwise direction<br />

until the left intake valve (viewed from flywheel end)<br />

opens and closes. Continue turning the crankshaft<br />

until theTC markon the flywheel is lined up with the<br />

TC mark on the gear cover. This should place the<br />

left piston (#I) at the top of its compression stroke.<br />

Verify that the left intake and exhaust valves are<br />

closed and there is no pressure on the valve lifters.<br />

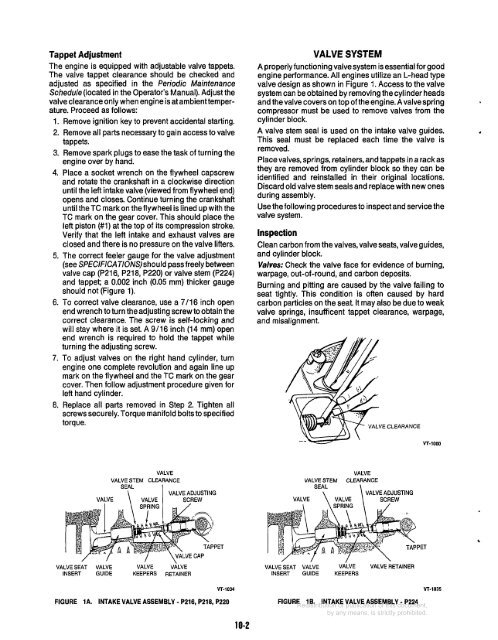

5. The correct feeler gauge for the valve adjustment<br />

(see SPE ClFlCATI0NS)should pass freely between<br />

valve cap (<strong>P216</strong>, <strong>P218</strong>, <strong>P220</strong>) or valve stem (<strong>P224</strong>)<br />

and tappet; a 0.002 inch (0.05 mm) thicker gauge<br />

should not (Figure 1).<br />

6. To correct valve clearance, use a 7/16 inch open<br />

end wrench to turn theadjusting screw toobtain the<br />

correct clearance. The screw is self-locking and<br />

will stay where it is set. A 9/16 inch (14 mm) open<br />

end wrench is required to hold the tappet while<br />

turning the adjusting screw.<br />

7. To adjust valves on the right hand cylinder, turn<br />

engine one complete revolution and again line up<br />

mark on the flywheel and the TC mark on the gear<br />

cover. Then follow adjustment procedure given for<br />

left hand cylinder.<br />

8. Replace all parts removed in Step 2. Tighten all<br />

screws securely. Torque manifold bolts to specified<br />

torque.<br />

VALVE SYSTEM<br />

A properly functioning valvesystem is essential for good<br />

engine performance. All engines utilize an L-head type<br />

valve design as shown in Figure 1. Access to the valve<br />

system can be obtained by removing the cylinder heads<br />

and thevalve coverson topoftheengine.Avalvespring<br />

compressor must be used to remove valves from the<br />

cy1 inder block.<br />

A valve stem seal is used on the intake valve guides.<br />

This seal must be replaced each time the valve is<br />

removed.<br />

Place valves, springs, retainers, and tappets in a rack as<br />

they are removed from cylinder block so they can be<br />

identified and reinstalled in their original locations.<br />

Discard old valve stem seals and replace with new ones<br />

during assembly.<br />

Use the following procedures to inspect and service the<br />

valve system.<br />

Inspection<br />

Clean carbon from thevalves, valve seats, valve guides,<br />

and cylinder block.<br />

Valves: Check the valve face for evidence of burning,<br />

warpage, out-of-round, and carbon deposits.<br />

Burning and pitting are caused by the valve failing to<br />

seat tightly. This condition is often caused by hard<br />

carbon particles on the seat It may also be due to weak<br />

valve springs, insufficent tappet clearance, warpage,<br />

and misalignment.<br />

VALVE<br />

VALVE STEM CLEARANCE<br />

SEAL<br />

I VALVE ADJUSTING<br />

VALVE \ VALVE SCREW<br />

VALVE<br />

VALVE STEM CLEARANCE<br />

SEAL<br />

\ \ VALVE ADJUSTING<br />

PET<br />

c<br />

VALVE SEAT VALVE VALVE VALVE<br />

INSERT GUIDE KEEPERS RETAINER<br />

VALVE SEAT VALVE VALVE VALVE RETAINER<br />

INSERT GUIDE KEEPERS<br />

FIGURE 1A.<br />

VT-1034<br />

INTAKE VALVE ASSEMBLY - <strong>P216</strong>, <strong>P218</strong>, <strong>P220</strong><br />

FIGURE 1B. INTAKE VALVE ASSEMBLY - <strong>P224</strong><br />

WIT-1035<br />

10-2