TM 3-4240-334-20&P

TM 3-4240-334-20&P

TM 3-4240-334-20&P

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

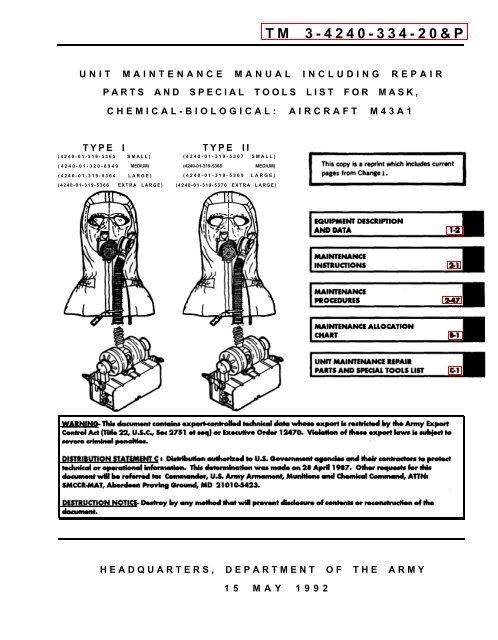

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

UNIT MAINTENANCE MANUAL INCLUDING REPAIR<br />

PARTS AND SPECIAL TOOLS LIST FOR MASK,<br />

CHEMICAL-BIOLOGICAL: AIRCRAFT M43A1<br />

TYPE I<br />

TYPE II<br />

(<strong>4240</strong>-01-319-5365 SMALL) (<strong>4240</strong>-01-319-5367 SMALL)<br />

(<strong>4240</strong>-01-320-8949 MEDIUM) (<strong>4240</strong>-01-319-5368 MEDIUM)<br />

(<strong>4240</strong>-01-319-5364 LARGE) (<strong>4240</strong>-01-319-5369 LARGE)<br />

(<strong>4240</strong>-01-319-5366 EXTRA LARGE) (<strong>4240</strong>-01-319-5370 EXTRA LARGE)<br />

HEADQUARTERS, DEPAR<strong>TM</strong>ENT OF THE ARMY<br />

15 MAY 1992

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

C1<br />

C HANGE<br />

No. 1<br />

HEADQUARTERS<br />

DEPAR<strong>TM</strong>ENT OF THE ARMY<br />

Washington, DC 15 June 1992<br />

UNIT MAINTENANCE MANUAL INCLUDING REPAIR<br />

PARTS AND SPECIAL TOOLS LIST FOR<br />

MASK, CHEMICAL-BIOLOGICAL: AIRCRAFT, M43A1<br />

1. The purpose of this change is to add the authentication page<br />

to the manual.<br />

2. New material is indicated by a vertical bar in the margin of<br />

the page.<br />

3. Remove old pages and insert new pages as indicated below.<br />

Remove Page<br />

None<br />

Insert Page<br />

Authentication Page<br />

(in front of back cover)<br />

4. File this sheet after the title page for reference purposes.<br />

MILTON H. HAMILTON<br />

Administrative Assistant to the<br />

Secretary of the Army<br />

01567<br />

GORDON R. SULLIVAN<br />

General, United States Army<br />

Chief of Staff<br />

To be distributed in accordance with DA Form 12-28-E,<br />

Requirements for <strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P.<br />

(Block 0694), Uint Maintenance,

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

WARNING<br />

Wear a protective mask and clothing in accordance with local SOP when replacing canisters exposed to toxic<br />

agents.<br />

If metal banding straps are used to secure packaging, exercise extreme care when removing them. The edges<br />

of metal binding straps are sharp, and they can injure eyes or cut skin.<br />

Canisters may be changed only in a nontoxic atmosphere.<br />

Inspect canister and canister disconnect threads for dirt or other material that could prevent an airtight seal.<br />

When decontaminating a mask that has been exposed to toxic agents, wear a protective mask and clothing in<br />

accordance with SOP.<br />

As a safety precaution, pilots needing prescription lenses shall go for a checkout ride in the helicopter when they<br />

receive their new masks or a prescription is changed. This is to assure that their vision is adequate to fly.<br />

If the green Light Emitting Diode (LED) on the blower lights and remains lit for more than 5 minutes, change the<br />

battery. Battery output voltage is too low.<br />

Lithium-sulfur dioxide (Li-SO2) batteries which are used in this equipment contain pressurized sulfur dioxide<br />

(SO2) gas. The gas is toxic, and the battery MUST NOT be abused in any way which may cause the battery to<br />

rupture.<br />

A hissing sound from the battery or the smell of vinegar or rotten eggs indicates a leaking battery. If a leaking<br />

battery is detected, move battery to well-ventilated storage area and contact Defense Reutilization and Marketing<br />

Office (DRMO) for disposal.<br />

FIRST AID<br />

For first aid information, refer to FM 21-11.<br />

HEALTH/ENVIRONMENTAL HAZARD<br />

Fitter canisters use ASC Whetlerite Carbon which contains Chromium VI. Chromium VI is a known carcinogen if<br />

inhaled or swallowed. Damaged or unusable canisters are classified as hazardous waste:<br />

DO NOT throw away damaged or unusable canisters as ordinary trash.<br />

DO turn in damaged or unusuable canisters to your hazardous waste management office or Defense<br />

Reutilization and Marketing Office (DRMO).<br />

Canisters are completely safe to handle and use if they are not damaged in such away that carbon leaks from<br />

them. In unlikely event that carbon should leak, use protection such as a dust respirator to cover nose and<br />

mouth and put carbon in container such as self-sealing plastic bag; turn into hazardous waste management<br />

office or DRMO.<br />

Disposal of hazardous waste is restricted by the Resource Conservation and Recovery Act as amended<br />

(42 U.S.C.A. sec 6901 et seq). Violation of these laws is subject to severe criminal penalties.<br />

LITHIUM-SULFUR DIOXIDE BATTERIES.<br />

according to TB 43-0130 and local SOP.<br />

Do not attempt to decontaminate batteries. Dispose of batteries<br />

a (b blank)

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

TECHNICAL MANUAL<br />

No. 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Headquarters<br />

Department of the Army<br />

Washington, DC, 15 May 1992<br />

UNIT MAINTENANCE MANUAL<br />

INCLUDING REPAIR PARTS AND SPECIAL TOOLS LIST<br />

FOR<br />

MASK, CHEMICAL-BIOLOGICAL: AIRCRAFT M43A1<br />

TYPE I<br />

TYPE II<br />

(<strong>4240</strong>-01-319-5365 SMALL) (<strong>4240</strong>-01-319-5367 SMALL)<br />

(<strong>4240</strong>-01-320-8949 MEDIUM) (<strong>4240</strong>-01-319-5368 MEDIUM)<br />

(<strong>4240</strong>-01-319-5364 LARGE) (<strong>4240</strong>-01-319-5369 LARGE)<br />

(<strong>4240</strong>-01-319-5366 EXTRA LARGE) (<strong>4240</strong>-01-319-5370 EXTRA LARGE)<br />

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS<br />

You can help improve this manual. If you find any mistakes or know of<br />

away to improve the procedures, please let us know. Mail your letter,<br />

DA Form 2028 (Recommended Changes to Publications and Blank<br />

Forms), or DA Form 2028-2 located in the back of this manual directly<br />

to Commander, U.S. Army Armament, Munitions and Chemical<br />

Command, ATTN: SMCCR-MAT, Aberdeen Proving Ground,<br />

MD 21010-5423. A reply will be furnished to you.<br />

WARNING - This document contains export-controlled technical data whose export is restricted<br />

by the Army Export Control Act (Tile 22, U.S.C., Sec 2751 et seq) or Executive Order 12470.<br />

Violation of these export laws is subject to severe criminal penalties.<br />

DISTRIBUTlON STATEMENT C: Distribution authorized to U.S. Government agencies and their<br />

contractors to protect technical or operational information. This determination was made on<br />

29 April 1987. Other requests for this document will be referred to: Commander, U.S. Army<br />

Armament, Munitions and Chemical Command, ATTN: SMCCR-MAT Aberdeen Proving Ground,<br />

MD 21010-5423.<br />

DESTRUCTION NOTICE - Destroy by any method that will prevent disclosure of contents or<br />

reconstruction of the document.<br />

TABLE OF CONTENTS<br />

Page<br />

CHAPTER 1<br />

Section I<br />

Section II<br />

Section Ill<br />

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1<br />

General Information . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1<br />

Equipment Description and Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2<br />

Principles of Operation . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3<br />

i

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

TABLE OF CONTENTS (CONT)<br />

Page<br />

CHAPTER 2<br />

Section I<br />

Section II<br />

Section Ill<br />

Section IV<br />

Section V<br />

Section VI<br />

MAINTENANCE INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1<br />

Repair Parts, Special Tools (RPSTL), Test Measurement<br />

and Diagnostic Equipment (<strong>TM</strong>DE), and Support Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1<br />

Service Upon Receipt ... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1<br />

Equipment/User Fitting Instructions .... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7<br />

Preventive Maintenance Checks and Services (PMCS) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15<br />

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-38<br />

Maintenance Procedures . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-47<br />

Section VII<br />

Section Vlll<br />

APPENDIX A<br />

Preparation for Storage or Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Mask Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

REFERENCES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

2-71<br />

2-72<br />

A-1<br />

APPENDIX B<br />

Section I<br />

Section II<br />

Section Ill<br />

MAINTENANCE ALLOCATION CHART (MAC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1<br />

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1<br />

Maintenance Allocation Chart for M43A1 Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4<br />

Tool and Test Equipment Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5<br />

Page<br />

Illus/<br />

Figure<br />

APPENDIX C<br />

Section I<br />

Section II<br />

UNIT MAINTENANCE REPAIR PARTS AND SPECIAL<br />

TOOLS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1<br />

Introduction . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1<br />

Repair Parts List . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1<br />

Group 00<br />

Group 01<br />

Mask, Chemical-Biological Aircraft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1-1<br />

Mask Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-2-1<br />

C-1<br />

C-2<br />

ii<br />

0101 Facepiece Assembly . . . . . . . . . . . ... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-3-1<br />

010101 Inlet Valve Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-4-1<br />

010102 Outlet Valve Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-5-1<br />

C-3<br />

C-4<br />

C-5

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

TABLE OF CONTENTS (CONT)<br />

Group 02<br />

Group 03<br />

Page<br />

01010201 Valve Cover Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-6-1<br />

010103 Communications Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-7-1<br />

010104 Communications Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. C-8-1<br />

0102 Carrier, Mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9-1<br />

Blower Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-10-1<br />

Blower Assembly: Auxiliary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-11-1<br />

Illus/<br />

Figure<br />

C-6<br />

C-7<br />

C-8<br />

C-9<br />

C-10<br />

C-11<br />

Group 04<br />

Harness Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

C-12-1<br />

C-12<br />

Section III<br />

Special Tools List (Not applicable)<br />

Section IV<br />

Cross-Reference Indexes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

C-I-1<br />

APPENDIX D<br />

Section I<br />

Section II<br />

EXPENDABLE AND DURABLE ITEMS LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1<br />

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1<br />

Expendable and Durable Items List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2<br />

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .<br />

Index-1<br />

iii

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

M43A1 MASK<br />

1-0

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

CHAPTER 1<br />

INTRODUCTION<br />

Section I. GENERAL INFORMATION<br />

1-1. SCOPE.<br />

a. Type of Manual. This is a unit maintenance manual including repair parts and special tools list<br />

(RPSTL) for use with the M43A1.<br />

b. Equipment Name and Model Number. Mask, Chemical-Biological: Aircraft M43A1.<br />

c. Purpose of Equipment. To protect face, eyes, and respiratory system from field concentrations of<br />

Chemical-Biological (CB) agents and Riot Control (RC) agents.<br />

d. Special Limitations on Equipment. Does not protect against ammonia or carbon monoxide gases.<br />

Does not protect the user in an oxygen deficient environment.<br />

1-2. MAINTENANCE FORMS AND PROCEDURES.<br />

Department of the Army forms and procedures used for equipment maintenance will be those<br />

prescribed by DA PAM 738-750, The Army Maintenance Management Systems (TAMMS) as contained in<br />

Maintenance Management Update.<br />

1-3. DESTRUCTION OF ARMY MATERIEL TO PREVENT ENEMY USE.<br />

Refer to <strong>TM</strong> 43-0002-31, Destruction of Chemical Weapons and Defense Equipment to Prevent Enemy<br />

Use, for methods of destruction.<br />

1-4. PREPARATION FOR STORAGE OR SHIPMENT.<br />

For instructions concerning storage or shipment, refer to para 2-17.<br />

1-5. REPORTING EQUIPMENT IMPROVEMENT RECOMMENDATIONS (EIR).<br />

If your mask needs improvement, let us know. Send us an EIR, You, the user, are the only one who can<br />

tell us what you don’t like about your equipment. Let us know why you don’t like the design or performance. Put<br />

it on an SF 368 (Quality Deficiency Report). Mail it to Commander, U.S. Army Armament Munitions and Chemical<br />

Command, ATTN: AMSMC-QAD (R), Rock Island, IL 61299-6000. We will send you a reply.<br />

1-6. SAFETY, CARE, AND HANDLING.<br />

Caution must be used when handling contaminated masks and canisters. Decontamination procedures<br />

for the facepiece assembly and blower assemblies can be found in para 2-19. For decontamination of other<br />

components of the M43A1 mask, follow procedures in FM 3-5.<br />

Caution must also be used when using n-amyl acetate to check facepiece for leaks. It is flammable,<br />

could irritate the skin under prolonged exposure, and may be toxic if inhaled in quantity. For first aid information,<br />

see FM 21-11.<br />

1-1

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

1.7. CORROSION PREVENTION AND CONTROL (CPC).<br />

a. Corrosion Prevention and Control (CPC) of Army materiel is a continuing concern. It is important<br />

that any corrosion problems with this item be reported so that the problem can be corrected and improvements<br />

can be made to prevent the problem in future items.<br />

b. While corrosion is typically associated with rusting of metals, it can also include deterioration of other<br />

materials such as rubber and plastic. Unusual cracking, softening, swelling, or breaking of these materials may<br />

be a corrosion problem.<br />

c. If a corrosion problem is identified, it can be reported using Standard Form 368, Use of key words<br />

such as corrosion, rust, deterioration, or cracking will assure that the information is identified as a CPC problem.<br />

d. The Standard Form 368 should be submitted to:<br />

Commander<br />

U.S. Army Armament, Munitions and Chemical Command<br />

ATTN: AMSMC-QAD (R) Customer Feedback Center<br />

Rock Island, Illinois 61299-6000<br />

1-8. NOMENCLATURE CROSS-REFERENCE LIST.<br />

Common Name<br />

Nuclear Hood<br />

Canister Seal<br />

Voicemitter Gasket<br />

Hose Restraint Clip<br />

Lanyard Restraint Loop<br />

Waist Strap<br />

Snap Hook<br />

Canisters<br />

Battery Cap<br />

O-Ring<br />

Spring<br />

Official Nomenclature<br />

CB Mask Hood<br />

Non-metallic Seal<br />

Packing, Preformed<br />

Lanyard Retainer Assembly<br />

Non-Elastic Hose Loop Assembly<br />

Carrier, Webbing Strap<br />

Hook Assembly<br />

CB Mask Canister<br />

Battery Filter Cap<br />

Preformed Packing<br />

Helical Spring<br />

1-9. LIST OF ABBREVIATIONS.<br />

CB<br />

HDU<br />

IHADSS<br />

IPD<br />

LED<br />

RC<br />

SARVIP<br />

VDC<br />

Chemical and Biological<br />

Helmet Display Unit<br />

Integrated Helmet and Display Sighting System<br />

Interpupillary Distance<br />

Light Emitting Diode<br />

Riot Control<br />

Survival Armor Recovery Vest Insert and Pocket<br />

Voltage Direct Current<br />

Section II. EQUIPMENT DESCRIPTION AND DATA<br />

Paragraphs containing information on equipment characteristics, capabilities, and features;<br />

description of major components; equipment data; and differences between models can be found in Chapter 1<br />

of <strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-10, Operator’s Manual for the M43A1 Mask.<br />

1-2

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Section III. PRINCIPLES OF OPERATION<br />

The mask protects the face, eyes, and respiratory system of the user from chemically, biologically, and<br />

radiologically toxic environments. Positive air pressure is supplied to the facepiece by either the blower assembly,<br />

during normal operations, or by the auxiliary blower assembly, in emergency situations. The M43A1 Mask<br />

can also be used without a source of positive air pressure, if both blower systems should fail.<br />

The Mower assembly motor is powered by a 12-volt dc (vdc) battery. The LED illuminates when approximately<br />

20 minutes of blower operation remain. The LED can be tested by pressing the pushbutton switch. The<br />

knob turns the blower assembly on and off and adjusts the speed of the blower, thereby changing the amount of<br />

air being blown into the mask.<br />

The auxiliary blower assembly motor is powered by two 3-volt batteries operating in parallel. It can be<br />

operated by a sliding power switch. The auxiliary blower assembly is attached to either of the filter canisters, and<br />

the other canister inlet is plugged with a rubber cap.<br />

The incoming air is forced through two filter canisters, which remove contaminants from the air. The<br />

airflow is directed three ways by the inlet valve assembly: the majority of the incoming air is directed into the<br />

facepiece assembly for breathing; another path feeds the lens defog system which keeps the lenses free from<br />

condensation; and the third path feeds the cooling duct, which directs air under the hood for user comfort. Two<br />

knobs on the inlet valve assembly are used to adjust the amount of air directed toward either the lens defog<br />

system or the hood cooling duct. The outlet valve assembly can also be adjusted to allow differing amounts of<br />

air to exit from the mask; this determines the amount of positive pressure allowed to build up inside the mask.<br />

Extra protection from nuclear thermal flash is provided by the nuclear hood, which is worn over the<br />

helmet and facepiece assembly.<br />

1-3 (1-4 blank)

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

CHAPTER 2<br />

MAINTENANCE INSTRUCTIONS<br />

Section I. REPAIR PARTS, SPECIAL TOOLS (RPSTL), TEST MEASUREMENT AND DIAG-<br />

NOSTIC EQUIPMENT (<strong>TM</strong>DE), AND SUPPORT EQUIPMENT<br />

NOTE<br />

All maintenance procedures in this manual may be performed by operator under<br />

Unit Maintenance supervision.<br />

2-1. COMMON TOOLS AND EQUIPMENT.<br />

For authorized common tools and equipment, refer to the Modified Table of Organization and Equipment<br />

(MTOE) applicable to your unit. Common tools contained in Electronic Equipment Tool Kit, TK105G, are used for<br />

unit maintenance.<br />

2-2. SPECIAL TOOLS, <strong>TM</strong>DE, AND SUPPORT EQUIPMENT.<br />

Refer to Appendix C for Repair Parts and Special Tools List (RPSTL) and Appendix B Maintenance<br />

Allocation Chart (MAC) for <strong>TM</strong>DE and Support Equipment.<br />

2-3. REPAIR PARTS.<br />

Repair parts are listed and illustrated in Appendix C of this manual.<br />

Section II. SERVICE UPON RECEIPT<br />

2-4. GENERAL.<br />

This section contains instructions, procedures, or services to be performed upon receipt of a new or<br />

overhauled mask. These services include unpacking and checking the mask.<br />

2-1

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

2-5. SERVICE UPON RECEIPT OF MATERIEL.<br />

This task covers:<br />

Unpacking and Checking Unpacked Equipment.<br />

INITIAL SETUP<br />

Materials/Parts<br />

Battery (Item 2, App B,<br />

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-10)<br />

UNPACKING<br />

WARNING<br />

If metal banding straps are used to secure packaging, exercise extreme care<br />

when removing them. The edges of metal binding straps are sharp and can<br />

injure eyes or cut skin.<br />

1. Plywood Container.<br />

NOTE<br />

Retain box, lid, and internal packaging for extended storage or reshipment.<br />

(a) Cut and remove banding straps (1).<br />

(b) Pry lid (2) off box.<br />

2. Large Inner Box.<br />

(a) Remove large inner box (3) from plywood container.<br />

(b) Cut tape (4) securing inner box lid (5).<br />

(c) Remove inner box lid (5).<br />

(d) Remove carrier (6) from inner box (3) and plastic bag.<br />

(e) Remove cardboard section divider (7) from inner box (3).<br />

(f) Remove facepiece assembly carrier (8).<br />

(g) Remove nuclear hood (9).<br />

2-2

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

NOTE<br />

IPD staples are not shipped with the mask. The proper IPD staple (Item 20,<br />

App D), if required, will be furnished and installed in the facepiece assembly by<br />

Unit Maintenance during initial mask fitting.<br />

(h)<br />

(i)<br />

(j)<br />

Remove mask holder insert (10).<br />

Remove lens cushions (11).<br />

Remove facepiece assembly abrasive cover (12).<br />

(k)<br />

Remove facepiece assembly (13), hose assembly (14), and canister quick disconnect (15). Remove<br />

and discard plastic cover from facepiece assembly.<br />

(l)<br />

(m)<br />

Remove faceform (16) from facepiece assembly (13).<br />

Remove plastic bag and plastic cap from microphone cable on facepiece assembly (13).<br />

NOTE<br />

Keep faceform for future facepiece assembly storage. Insert faceform in facepiece<br />

assembly if mask will be stored for 30 days or longer.<br />

(n)<br />

Remove two cans (17) containing canisters.<br />

NOTE<br />

If mask is to be stored for 30 days or longer before being issued to user, do not<br />

open cans; proceed to step p.<br />

(o) If canisters are to be installed, remove them from cans (17) and discard cans. Remove canister<br />

covers if present.<br />

(p) Permanently mark date can was opened on canister In Accordance With (IAW) unit SOP.<br />

2-3

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

2-5. SERVICE UPON RECEIPT OF MATERIEL (CONT).<br />

(q)<br />

(r)<br />

Make sure a flat washer (19) is present in each threaded port in canister disconnect before installing<br />

canisters, to prevent air leakage.<br />

Install canisters (18) by screwing clockwise into canister disconnect (20).<br />

3. Small Inner Box.<br />

Lift small inner box (21) out of plywood container (22), lay it flat, and lift off lid (23).<br />

NOTE<br />

The harness assembly and auxiliary carrier are contained in separate plastic<br />

bags.<br />

(a)<br />

(b)<br />

(c)<br />

Remove two sealed plastic bags (24), auxiliary blower assembly (25), and blower assembly (26) from<br />

small inner box (21).<br />

Open battery door (27). Insert new battery (28). Close and latch battery door as described in<br />

Operator’s Manual <strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-10.<br />

Take harness assembly and auxiliary blower assembly carrier out of plastic bag (24) and discard<br />

bag.<br />

2-4

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

CHECKING UNPACKED EQUIPMENT<br />

1. Inspect the equipment for damage incurred during shipment. If the equipment has been damaged,<br />

report the damage on SF 364, Report of Discrepancy (ROD).<br />

2. Check equipment against packing slip for completeness of shipment. Report all discrepancies in<br />

accordance with the instructions of DA PAM 738-750.<br />

3. Inspect the equipment for modifications. Make note of modifications on appropriate equipment records.<br />

4. Stow equipment in carrier as described in Operator’s Manual, <strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-10.<br />

2-5

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

2-6. INDIVIDUAL MASK IDENTIFICATION.<br />

This task covers:<br />

Mask Carrier and Facepiece Assembly Identification.<br />

INITIAL SETUP<br />

Materials/Parts<br />

Ink, Marking Stencil (Item 14, App D)<br />

MASK CARRIER IDENTIFICATION<br />

NOTE<br />

Do not make permanent identification markings on the blower assembly or<br />

mask carrier (AR 700-84).<br />

1. Obtain a removable tag to fit the carrier window pouch.<br />

2. Mark the tag with the user’s name or code number. Additional fitting information or blower assembly<br />

identification may also be included.<br />

NOTE<br />

Each unit may derive its own code. Do not include any information that may<br />

identify the parent organization. Avoid using codes similar to those of neighboring<br />

units.<br />

3. Place the completed identification tag in the mask carrier window pouch.<br />

FACEPIECE ASSEMBLY IDENTIFICATION<br />

Mark the sewn-in identification tag on the hood with the user’s name and serial number; use marking<br />

stencil ink.<br />

2-6

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Section III.<br />

EQUIPMENT/USER FlTTING INSTRUCTIONS<br />

2-7. FACEPIECE ASSEMBLY ADJUS<strong>TM</strong>ENT.<br />

This task covers:<br />

Facepiece Assembly Adjustment.<br />

INITIAL SETUP<br />

Tools<br />

Tool Kit, Electronic Equipment TK 105G (App B)<br />

Materials/Parts<br />

Staple Kit (Item 20, App D)<br />

Isopropyl Flubbing Alcohol (Item 15, App D)<br />

Cloth (Item 8, App D)<br />

Equipment CondltIon<br />

Hood over front of facepiece assembly.<br />

Suspension harness to rear of facepiece assembly.<br />

Soldier seated with glasses and headgear removed.<br />

Faceform removed from facepiece assembly.<br />

One canister removed from canister disconnect.<br />

Personnel Required<br />

Unit level M43A1 technician<br />

Soldier (operator)<br />

FACEPIECE ASSEMBLY ADJUS<strong>TM</strong>ENT<br />

WARNING<br />

Make sure the soldier is cleanshaven. An unshaven face could degrade the<br />

protection afforded by the facepiece assembly.<br />

1. Loosen ail straps (1).<br />

NOTE<br />

The primary objectives in fitting the soldier are visual acuity and comfort.<br />

2. Have soldier hold suspension harness (2) using both hands.<br />

NOTE<br />

When donning facepiece assembly, make sure donning tab is not folded under<br />

suspension harness.<br />

3. Have soldier place chin in chin cup (3), and<br />

pull suspension harness (2) over head while<br />

brushing hair back.<br />

4. Make sure donning tab (4) is centered on<br />

back of head and straps are not hanging<br />

over or cutting into ears.<br />

2-7

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

2-7. FACEPIECE ASSEMBLY ADJUS<strong>TM</strong>ENT (CONT).<br />

NOTE<br />

Do not pull donning tab too low on back of head. Discomfort will result if the tab<br />

is pulled too low.<br />

5. As the facepiece assembly is being donned make sure:<br />

(a) Suspension crown (5) is centered on top of head.<br />

(b) Straps are not over ears.<br />

(c) Ears are between temple and cheek straps.<br />

(d) Straps are not cutting into ears.<br />

(e) Donning tab (4) is not folded up under suspension crown.<br />

6. Tighten chin straps (6) by pulling on tabs.<br />

NOTE<br />

Use short jerks instead of long pulls to tighten straps.<br />

Do not tighten temple straps (7) at this time.<br />

7. Have soldier position facepiece assembly for optimum comfort.<br />

8. Check the following areas to make sure facepiece assembly fits properly:<br />

(a) Check that side edge (9) is no closer than 1/2 inch to ears.<br />

(b) Check that temple (7) and chin (6) straps do not cut into soldier’s ears.<br />

(c) Check that straps are flat against head, not twisted, and are in a straight line with tabs (8).<br />

2-8

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

(d) Check that facepiece assembly does not dig into the chin area of the wearer.<br />

(e) Check that facepiece assembly does not contact bridge of nose to cause discomfort.<br />

(f) Check that forehead area of the facepiece assembly is not so tight that it causes discomfort or so<br />

loose that it causes buckling in the temple area.<br />

9. Gently pull hood back over soldier’s head and into normal wearing position.<br />

NOTE<br />

Make sure facepiece assembly does not press so tightly that soldier’s eyes are<br />

partly closed.<br />

10. Check that soldier’s pupils are within the center one-third area (vertical) of the eye lens (10).<br />

NOTE<br />

If facepiece assembly fails to meet above fitting criteria, readjust straps or try<br />

another size facepiece assembly.<br />

11. Pinch bridge of nose or spread lenses apart until soldier indicates a comfortable fit and optimum vision.<br />

Optimum vision check includes peripheral vision, interference around bridge of nose, and vertical vision.<br />

If comfort or vision is improved when pinching or spreading the lenses an IPD staple may be required, as<br />

detailed in step 12.<br />

2-9

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

2-7. FACEPIECE ASSEMBLY ADJUS<strong>TM</strong>ENT (CONT).<br />

CAUTION<br />

Use care when installing IPD staples. Staples can scratch eye lens material.<br />

12. Select and install IPD staple, if required, as follows:<br />

(a)<br />

Obtain test button (11) from plastic bag.<br />

NOTE<br />

Staple size is located on top of staple and behind keyway.<br />

(b)<br />

(c)<br />

(d)<br />

(e)<br />

(f)<br />

(g)<br />

(h)<br />

(i)<br />

(j)<br />

(k)<<br />

Obtain staple number 61 (12), or appropriate size, if soldier knows his staple size, from plastic bag.<br />

Insert test button (11) into keyway of staple (12) from the top (numbered side of staple).<br />

Using test button (11), position staple (12) over IPD staple posts (13) located on facepiece<br />

assembly (14).<br />

On facepiece assembly (14), pinch bridge of nose or spread lenses apart, as required, to aline holes<br />

in staple (12) with IPD staple posts (13).<br />

Using test button (11) install staple (12) on IPD staple posts (13).<br />

Check staple fit for comfort and optimal vision. If staple fit is comfortable and vision is optimal,<br />

proceed to step l; otherwise, perform steps h thru k.<br />

Using test button (11) remove staple (12) from IPD staple posts (13).<br />

Remove test button (11 ) from staple (12).<br />

If staple fit is too tight over bridge of nose, obtain next larger size staple (12) from plastic bag. If<br />

staple fit is too loose, obtain next smaller size staple from plastic bag.<br />

Repeat steps d thru g as required until staple fit is comfortable and vision is optimal.<br />

2-10

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

(l) Remove test button (11) from staple (12).<br />

(m) Remove facepiece assembly.<br />

NOTE<br />

A retaining ring (part of staple kit) maybe used if a retainer clip is lost or<br />

damaged, or if facial features of soldier cause distortion in facepiece that would<br />

prevent locking of retainer clip on IPD staple post.<br />

(n) Install one retainer clip (15) on IPD staple post (13) as follows:<br />

(1)<br />

(2)<br />

(3)<br />

Position slotted hole of retainer clip (15) on top of IPD staple post (13) with vertical piece of clip<br />

pointing upward and away from lens.<br />

Grasp vertical piece of retainer clip (15) and pull away from facepiece assembly (14), approximately<br />

1/16-inch, until groove in IPD staple post (13) is seated in slot of retainer clip.<br />

Rotate retainer clip (15) towards bridge of nose until hole in clip snaps over button on<br />

staple (12).<br />

(o) Repeat step (n) to install other retainer clip (15).<br />

(p) Obtain filler button (16) from plastic bag.<br />

(q) Position filler button (16) over top of keyway in staple (12) and press button into keyway.<br />

13. Repeat steps 1 thru 7.<br />

2-11

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

2-7. FACEPIECE ASSEMBLY ADJUS<strong>TM</strong>ENT<br />

(CONT).<br />

14. Adjust temple strap (7).<br />

CAUTION<br />

If soldier feels discomfort around the eyes, eye lens cushions may be installed.<br />

If facepiece eye lens cushions are not needed, proceed to step 16.<br />

15.<br />

If necessary for comfort, remove facepiece and install eye lens cushions as follows:<br />

(a) Wipe inside of facepiece using alcohol and clean, lint-free cloth before installing eye lens cushions.<br />

(b) Peel protective paper off adhesive on eye lens cushions and press cushions in place inside of<br />

facepiece assembly.<br />

(c) Repeat steps 1 thru 7.<br />

16.<br />

17.<br />

18.<br />

19.<br />

20.<br />

Adjust temple strap (7).<br />

Gently pull hood back over soldier’s head.<br />

Check that flat washer (17) is present, an reinstall canister (18) into canister disconnect (19).<br />

Record proper IPD staple size for future reference acording to unit SOP.<br />

Issue remainder of mask assembly to soldier.<br />

WARNING<br />

Verify the fit of the helmet while wearing the mask to prevent extreme discomfort<br />

during flight.<br />

As a safety precaution, pilots needing prescription lenses shall go for a checkout<br />

ride in the helicopter when they receive their new mask or a prescription is<br />

changed. This is to assure that their vision is adequate to fly.<br />

2-12

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

2-8. MASK ASSEMBLY FUNCTIONAL TEST.<br />

This task covers:<br />

Testing.<br />

INITIAL SET-UP<br />

Materials/Parts<br />

Equipment Condition<br />

n-Amyl Acetate (Banana Oil) (Item 18, App D) The facepiece is adjusted to the soldier (para 2-7).<br />

Applicator (Item 1, App D)<br />

The lens defogging control and outlet valve flow<br />

GIoves, Chemical (Item 9, App D)<br />

control are set to allow maximum airflow<br />

(<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-10, para 2-8c).<br />

Personnel Required<br />

The hood cooling duct control is closed<br />

ALSE technician<br />

(<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-10, para 2-8c).<br />

Soldier (operator)<br />

WARNING<br />

Do NOT touch your skin (or the operator's) with n-amyl acetate (banana oil). It<br />

could irritate the skin. Wear gloves if an application could wet your fingers.<br />

Do NOT smoke around n-amyl acetate (banana oil). Keep n-amyl acetate away<br />

from open flame. It can catch fire.<br />

Do NOT test facepieces in an enclosed or poorly ventilated area. Test outdoors<br />

or in a well aired room. n-Amyl acetate (banana oil) may be toxic if inhaled in<br />

quantity.<br />

CAUTION<br />

Do not touch facepiece with n-amyl acetate (banana oil). It is a solvent and<br />

could weaken the facepiece.<br />

1. Have soldier don facepiece and turn on blower before opening the bottle of n-amyl acetate (banana oil).<br />

NOTE<br />

If operator smells n-amyl acetate just before masking, test results will be<br />

inaccurate.<br />

2. Dip applicator in n-amyl acetate.<br />

NOTE<br />

Instruct soldier to breathe deeply through nose only.<br />

3. Move applicator approximately 1 or 2 inches from facepiece.<br />

2-13

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

2-8.<br />

4.<br />

5.<br />

6.<br />

MASK ASSEMBLY FUNCTIONAL TEST (CONT).<br />

While operator is looking straight ahead, move applicator around outlet valve (1), voicemitter (2), inlet<br />

valve (3), and lenses.<br />

Move applicator along the length of the hose (4), around the canister disconnect (5), canisters (6), and<br />

the blower assembly (7).<br />

If soldier can smell n-amyl acetate, replace canisters and battery and retest.<br />

NOTE<br />

You should wait at least 30 minutes before retests.<br />

7.<br />

8.<br />

9.<br />

If soldier smells n-amyl acetate, perform procedures in table 2-3 and retest.<br />

If soldier can still smell n-amyl acetate, replace mask.<br />

If soldier cannot smell n-amyl acetate (banana oil), have him remove facepiece and smell the applicator<br />

to be sure his sense of smell is not impaired.<br />

NOTE<br />

If the soldier’s sense of smell is impaired, the facepiece must be tested in a CS<br />

(irritant) chamber or using a smoke tube (Item 21, App D) and an aspirator bulb<br />

(Item 3, App D) which produces an irritating acid smoke. Read and follow directions<br />

on the kit. The smoke tube test should be conducted in still air in an area<br />

that can be ventilated.<br />

2-14

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Section IV. PREVENTIVE MAINTENANCE CHECKS AND SERVICES (PMCS)<br />

2-9. GENERAL<br />

NOTE<br />

In time of combat, the semiannual PMCS becomes weekly.<br />

a. General. The PMCS Table has been provided so you can keep your equipment in good operating<br />

condition and ready for its primary mission. PMCS procedures in this section are to be performed by a unit<br />

maintenance technician or by the user, under unit maintenance supervision.<br />

b. Warnings and Cautions. Always observe the warnings and cautions appearing in your PMCS table.<br />

Warnings and cautions appear before the applicable procedures. You must observe all warnings and cautions<br />

to prevent serious injury to yourself or others and to prevent damage to your equipment.<br />

2-10. INTRODUCTION TO PMCS PROCEDURES.<br />

a. Table Entries. The following paragraphs describe the information presented in each column of the<br />

PMCS table.<br />

(1)<br />

(2)<br />

(3)<br />

(4)<br />

(5)<br />

Item Number Column. Numbers in this column are for reference. When completing DA Form<br />

2404 (Equipment Inspection and Maintenance Worksheet), include the item number for the<br />

check/service indicating a fault. Item numbers also appear in the order that you must do checks<br />

and services for the intervals listed.<br />

Interval Column. This column tells you when you must do the procedure in the procedure<br />

column.<br />

Item to Check/Service Column. This column identifies the item to be checked or serviced.<br />

Procedure Column. This column gives the procedure you must do to check or service the item<br />

listed in the item to Check/Service column to know if the equipment is ready or available for its<br />

intended mission or for operation. You must do the procedure at the time stated in the interval<br />

column.<br />

Not Fully Mission Capable If: Column. Information in this column tells you what faults will keep<br />

your equipment from being capable of performing its primary mission. If you make check and<br />

service procedures that show faults listed in this column, do not operate the equipment. Follow<br />

standard operating procedures for maintaining the equipment or reporting equipment failure.<br />

b. Other Tabie Entries. Be sure to observe all special information and notes that appear in your table.<br />

2-15

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Table 2-1. PREVENTIVE MAINTENANCE CHECKS AND SERVICES FOR M43A1<br />

Item<br />

No.<br />

Interval<br />

Item to<br />

Check/Service<br />

Procedure<br />

Not Fully Mission<br />

Capable If:<br />

1<br />

Semi-<br />

Annual<br />

FACEPIECE<br />

ASSEMBLY<br />

NOTE<br />

Canister disconnect must<br />

be separated from blower<br />

assembly before performing<br />

PMCS. Refer to operating<br />

procedures, Operators<br />

Manual, <strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-10.<br />

a.<br />

b.<br />

c.<br />

Visually inspect inside and<br />

outside surfaces for dirt,<br />

mud, and greasy or oily substances.<br />

Check faceblank (1) for holes,<br />

tears, splits, nicks, or dry rot.<br />

Check rubber next to lenses<br />

(2), inlet valve assembly (3),<br />

outlet valve assembly (4),<br />

microphone outside backing<br />

plate (5), hood cooling duct<br />

(6), and drink tube passthrough<br />

assembly (7) to be<br />

sure these components will<br />

not pull away from faceblank<br />

(1).<br />

Dirt or grease is on sealing<br />

surfaces. Dirt, mud, or greasy<br />

substances interfere with<br />

normal operation.<br />

Faceblank has holes, tears, splits,<br />

nicks, or dry rot which will allow<br />

air to enter facepiece assembly.<br />

Lenses, inlet valve assembly,<br />

outlet valve assembly, microphone<br />

outside backing plate,<br />

hood cooling duct, or drink<br />

tube pass-through assembly<br />

pull away from faceblank.<br />

2-16

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Item<br />

No.<br />

Interval<br />

Item to<br />

Check/Service<br />

Procedure<br />

Not Fully Mission<br />

Capable If:<br />

d.<br />

Check hood assembly (8) and<br />

inner skirt (9) for chafed or worn<br />

areas, cuts, tears, or separation<br />

of seams, and check hood for<br />

separation from faceblank (1).<br />

Check for areas above neck<br />

elastic where rubber coating<br />

is worn away or areas below<br />

neck elastic, larger than a<br />

dime, that are worn away.<br />

Hood assembly has areas above<br />

neck elastic where rubber coating<br />

is worn away, or areas below<br />

neck elastic larger than a dime<br />

that are worn away. Hood<br />

assembly and inner skirt has<br />

cuts, tears, or separation of<br />

seams, or has pulled away<br />

from faceblank.<br />

e.<br />

Check neck closure (10) for<br />

chafed or worn areas, cuts,<br />

tears, separation of seams, or<br />

stretched elastic.<br />

Neck closure is chafed, torn, cut,<br />

separated at seams, or elastic is<br />

stretched.<br />

2<br />

Semi-<br />

Annual<br />

SUSPENSION<br />

HARNESS<br />

a.<br />

Check suspension harness.<br />

Make sure it stretches. Firmly,<br />

hold faceblank (1) with one<br />

hand. With the other hand,<br />

stretch each strap (2) 1-1/2<br />

inches from facepiece<br />

assembly.<br />

Straps do not stretch, or suspension<br />

harness will not hold facepiece<br />

assembly firmly against<br />

face.<br />

b.<br />

Check straps (2) for cuts, tears,<br />

missing metal clips (3), or deterioration<br />

such as mildewing<br />

or fraying.<br />

Straps are cut, torn, frayed, have<br />

missing parts, or have deteriorated.<br />

c.<br />

Check for missing, bent, or<br />

broken clip-buckles (4).<br />

Clip-buckle assemblies are<br />

missing, bent, or broken.<br />

2-17

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Table 2-1. PREVENTIVE MAINTENANCE CHECKS AND SERVICES FOR M43A1 (CONT)<br />

Item<br />

No.<br />

Interval<br />

Item to<br />

Check/Service<br />

Procedure<br />

Not Fully Mission<br />

Capable If:<br />

3<br />

Semi-<br />

Annual<br />

INLET VALVE<br />

ASSEMBLY<br />

a.<br />

Check inlet valve body (1) for<br />

cracks, dents, missing parts,<br />

or loose faceblank fit. Check<br />

that inlet valve cannot be<br />

rotated in faceblank.<br />

Inlet valve body is cracked,<br />

dented, or has parts missing.<br />

Inlet valve body can be rotated<br />

in faceblank.<br />

b.<br />

Check that actuator shaft assemblies<br />

(2) are free to move,<br />

and set screws (3) are present<br />

and adjusted properly.<br />

Actuator shaft assemblies bind<br />

or stick. Set screws are missing<br />

or maladjusted.<br />

c.<br />

Remove air deflector (4) inside<br />

faceblank (5) by squeezing<br />

edges of air deflector and<br />

pulling upward until deflector<br />

snaps out of groove.<br />

d.<br />

Check that inlet valve disk (6)<br />

and retaining ring (7) are<br />

present.<br />

Disk inlet valve or retaining ring<br />

is missing.<br />

e.<br />

Check that 90° ell branch (8)<br />

and defogging tubes (9) are<br />

not damaged, kinked, or<br />

detached.<br />

Fitting is broken, cracked, or<br />

detached from inlet valve assembly.<br />

Defogging tubes are<br />

kinked, cracked or detached<br />

from fitting or lens.<br />

2-18

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Item<br />

No.<br />

Interval<br />

Item to<br />

Check/Service<br />

Procedure<br />

Not Fully Mission<br />

Capable If:<br />

f. Check air deflector (4) for<br />

cracks, deformation, or pieces<br />

broken off.<br />

Air deflector is cracked, deformed,<br />

or has pieces broken off.<br />

g.<br />

Aline notch on air deflector (4)<br />

with 90° ell branch (8) and<br />

snap air deflector into groove<br />

around inlet valve assembly on<br />

inside of facepiece assembly<br />

by squeezing edges of air<br />

deflector.<br />

2-19

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Table 2-1. PREVENTIVE MAINTENANCE CHECKS AND SERVICES FOR M43A1 (CONT)<br />

Item<br />

No.<br />

Interval<br />

Item to<br />

Check/Service<br />

Procedure<br />

Not Fully Mission<br />

Capable If:<br />

4<br />

Semi-<br />

Annual<br />

OUTLET VALVE<br />

ASSEMBLY AND<br />

OUTLET VALVE<br />

COVER<br />

a.<br />

Lift outlet valve cover (1) by<br />

pulling tab on bottom of cover<br />

out and up.<br />

WARNING<br />

Do not use facepiece assembly<br />

if valve disk (2) is missing<br />

or damaged. The facepiece<br />

assembly will leak.<br />

b.<br />

c.<br />

d.<br />

e.<br />

Check that outlet valve disk (2)<br />

is present and is not curled or<br />

distorted. Rotate outlet valve<br />

disk to make sure it is not<br />

sticking.<br />

WARNING<br />

Do not use paper to remove<br />

dirt or moisture from outlet<br />

valve cover or outlet valve<br />

disk. Paper may break up<br />

and lodge in outlet valve<br />

causing valve to leak.<br />

Check outlet valve seat (3) for<br />

dirt.<br />

Check outlet valve disk (2) for<br />

nicks, tears, or rips. Wipe off<br />

any moisture from valve disk<br />

with a soft, clean cloth (Item 8,<br />

App D). Smooth disk with your<br />

finger so that it lies flat on outlet<br />

valve seat.<br />

Check outlet valve cover (1) for<br />

breaks, cracks, and missing<br />

hinge pin (4) or retaining ring<br />

(5).<br />

Valve disk is missing, distorted,<br />

or sticking.<br />

Outlet valve seat is dirty.<br />

Outlet valve disk is nicked, torn,<br />

or ripped; cannot be cleaned,<br />

or will not seat properly.<br />

Outlet cover is broken or<br />

cracked. Hinge pin or retaining<br />

ring is missing.<br />

2-20

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Item<br />

No.<br />

Interval<br />

Item to<br />

Not Fully Mission<br />

Check/Service Procedure Capable If:<br />

5<br />

Semi-<br />

Annual<br />

VOICEMITTER a.<br />

Check retaining ring (1) on<br />

voicemitter (2) for corrosion,<br />

cracks, or nicks. Check<br />

retaining ring for looseness.<br />

Retaining ring is corroded,<br />

cracked, nicked or loose.<br />

b.<br />

Check voicemitter (2) for dents,<br />

cracks, or punctures. Make<br />

sure voicemitter (2) is not<br />

missing. Make sure the four<br />

pins (3) in the center of<br />

voicemitter (2) are facing<br />

outward. Close outlet valve<br />

cover (4).<br />

Voicemitter is dented, cracked,<br />

punctured, missing, or installed<br />

backwards.<br />

2-21

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Table 2-1. PREVENTIVE MAINTENANCE CHECKS AND SERVICES FOR M43A1 (CONT)<br />

Item<br />

No.<br />

Interval<br />

Item to<br />

Check/Service<br />

Procedure<br />

Not Fully Mission<br />

Capable If:<br />

6<br />

Semi-<br />

Annual<br />

LENSES<br />

a.<br />

Check lenses (1) for cracks,<br />

cuts, scratches, or stains that<br />

affect vision.<br />

Lenses are cracked, cut,<br />

scratched, or have stains that<br />

affect vision.<br />

b.<br />

Check that mounting pins (2)<br />

are straight and mounted<br />

securely in faceblank (3).<br />

Mounting pins are bent or loose<br />

in faceblank.<br />

NOTE<br />

If IPD staple is missing,<br />

bent, broken, or needs to<br />

be up-sized or down-sized,<br />

see para 2-7 (12).<br />

c.<br />

If lens cushions (4) were<br />

installed, make sure they are<br />

securely attached without<br />

having edges folded up.<br />

2-22

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Item<br />

No.<br />

Interval<br />

Item to<br />

Check/Service<br />

Procedure<br />

Not Fully Mission<br />

Capable If:<br />

7<br />

Semi-<br />

Annual<br />

DRINKING<br />

SYSTEM<br />

a.<br />

Check that internal (1) and<br />

external (2) drink tubes are<br />

present. Look for cracks or cuts<br />

in internal and external drink<br />

tubes.<br />

Internal or external drink tube is<br />

missing, cracked, or cut.<br />

b.<br />

Check movement of internal (1)<br />

and external (2) drink tubes.<br />

Internal or external drink tube<br />

does not move.<br />

c.<br />

Check that internal drink tube<br />

(1) is present and is not caught<br />

behind microphone (3) or pin<br />

protector (4).<br />

Internal drink tube is caught<br />

behind microphone or pin<br />

protector.<br />

d.<br />

Check that quick-disconnect<br />

coupling half (5) is not crushed<br />

dented, corroded, or separated<br />

from external drink tube (2).<br />

Return quick-disconnect half (5)<br />

to pocket.<br />

Quick-disconnect coupling half<br />

crushed, dented, corroded, or<br />

separated from external drink<br />

tube.<br />

2-23

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Table 2-1. PREVENTIVE MAINTENANCE CHECKS AND SERVICES FOR M43A1 (CONT)<br />

Item<br />

No.<br />

Interval<br />

Item to<br />

Check/Service<br />

Procedure<br />

Not Fully Mission<br />

Capable If:<br />

8 Semi-<br />

Annual<br />

MICROPHONE<br />

a.<br />

Check microphone (1) for<br />

cracked or broken housing.<br />

Microphone housing is cracked<br />

or broken.<br />

b.<br />

Check microphone adapter (2).<br />

Look for loose screws (3) or<br />

cracked or broken housing or<br />

tangs (4) and pin protector (5).<br />

Screws are loose or missing.<br />

Housing or pin protector is<br />

cracked or broken.<br />

c.<br />

Check microphone cable (6) for<br />

broken connectors, bare wires,<br />

or cut wires.<br />

Connectors are broken, wires are<br />

bare, or wires are cut.<br />

2-24

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Item<br />

No.<br />

Interval<br />

Item to<br />

Check/Service<br />

Procedure<br />

Not Fully Mission<br />

Capable If:<br />

9<br />

Semi-<br />

Annual<br />

HOSE<br />

a.<br />

Unscrew canisters (1) counterclockwise<br />

from canister disconnect<br />

(2). Check hose (3) for<br />

tears, cuts, or holes, and that it<br />

is not sticky or soft.<br />

Hose has tears, cuts, holes or it<br />

has sticky or soft spots.<br />

b.<br />

Check that clamp (4) on each<br />

end of hose (3) is secure.<br />

Clamps are loose or missing.<br />

c.<br />

Check that canister disconnect<br />

(2) is not loose in hose, bent,<br />

cracked, or broken; and that<br />

threads are clean and<br />

serviceable.<br />

Canister disconnect is loose in<br />

hose, bent, cracked, or broken;<br />

or has threads that are<br />

unserviceable.<br />

d.<br />

Remove flat washers (5) and<br />

make certain they are not torn,<br />

cut, or distorted.<br />

Flat washers are missing, torn,<br />

cut, or distorted.<br />

e.<br />

Reinstall a flat washer in each<br />

side of canister disconnect.<br />

2-25

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Table 2-1. PREVENTIVE MAINTENANCE CHECKS AND SERVICES FOR M43A1 (CONT)<br />

Item<br />

No.<br />

Interval<br />

Item to<br />

Check/Service<br />

Procedure<br />

Not Fully Mission<br />

Capable If:<br />

10<br />

Semi-<br />

Annual<br />

CANISTERS<br />

WARNING<br />

Filter canisters use ASC Whetlerite Carbon which contains<br />

Chromium Vl, a known carcinogen. The canisters<br />

are safe to handle if they are not damaged in such a way<br />

that would permit the carbon to leak out. Damaged or<br />

unused canisters for turn-in are classified as hazardous<br />

waste and must be turned into your hazardous waste<br />

management office or Defense Reutilization Marketing<br />

Office (DRMO) for disposal.<br />

a.<br />

b.<br />

c.<br />

Check canisters (1) for dented<br />

or deformed body, damaged<br />

threads, breaks, cracks, dirt in<br />

openings, moisture or water<br />

stains.<br />

Shake canisters (1) and listen<br />

for loose particles.<br />

Check expiration date of canisters<br />

(1) and canister replacement<br />

interval. Reinstall serviceable<br />

canisters. Screw a canister<br />

clockwise into each side<br />

of canister disconnect (1) until<br />

handtight.<br />

NOTE<br />

Refer to Canister Replacement<br />

Criteria, Operator's<br />

Manual, <strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-10.<br />

Either canister is wet, crushed,<br />

split, cracked, clogged with<br />

dirt, or has water stains.<br />

Canister has loose particles that<br />

rattle or fall out when shaken.<br />

Canister replacement criteria is<br />

exceeded.<br />

2-26

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Item<br />

No.<br />

lnterval<br />

Item to<br />

Check/Service<br />

Procedure<br />

Not Fully Mission<br />

Capable If:<br />

11<br />

Semi-<br />

Annual<br />

BLOWER<br />

ASSEMBLY<br />

a.<br />

Check air distribution tubes (1)<br />

for cracks, breaks, and<br />

alinement.<br />

Air distribution tubes are cracked<br />

broken, or bent.<br />

b.<br />

Check that wiper seals (2) are<br />

not cut, torn, or missing.<br />

Either wiper seal is cut, torn, or<br />

missing.<br />

c.<br />

Ensure that both snap hooks<br />

(3) are present.<br />

Snap hooks are missing.<br />

d.<br />

Check that blower assembly<br />

release D-ring (4) and latch pin<br />

(5) work properly.<br />

Blower release latch pin does<br />

not retract.<br />

e.<br />

Check that knob (6), pushbutton<br />

(7), and LED (8) are<br />

present and not broken.<br />

Knob, pushbutton, or LED is<br />

missing or broken.<br />

CAUTION<br />

Do not attempt to tighten or<br />

adjust screw; damage to<br />

blower assembly may<br />

result.<br />

f.<br />

Check screw (9) for red antitamper<br />

seal.<br />

Red anti-tamper seal is cracked,<br />

chipped or broken, indicating<br />

possible screw rotation.<br />

2-27

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Table 2-1. PREVENTIVE MAINTENANCE CHECKS AND SERVICES FOR M43A1 (CONT)<br />

Item<br />

No.<br />

Interval<br />

Item to<br />

Check/Service<br />

Procedure<br />

Not Fully Mission<br />

Capable If:<br />

g.<br />

h.<br />

i.<br />

j.<br />

k.<br />

Check mounting rails (10) for<br />

damage.<br />

Check guide pin cup (11) for<br />

dirt and debris or loose or<br />

missing screws (12).<br />

Check electrical connector<br />

outer shroud (13) and inner<br />

shroud (14) for damage.<br />

Check electrical connector pins<br />

(15) for damage.<br />

Check adapter cover adapter<br />

plate (16) for cracks, breaks,<br />

or distortion.<br />

Rail has broken areas longer than<br />

1 inch and wider than 1/8 inch.<br />

Guide pin cup clogged with dirt<br />

or debris or loose or missing<br />

screws.<br />

Shroud damage will interfere with<br />

mating of electrical connector.<br />

Pins are bent, broken or missing.<br />

Adapter cover/adapter plate is<br />

cracked, broken, or distorted.<br />

2-28

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Item<br />

No.<br />

Interval<br />

Item to<br />

Check/Service<br />

Procedure<br />

Not Fully Mission<br />

Capable If:<br />

l.<br />

m.<br />

Check that gasket (17) between<br />

cover/adapter plate (16) and air<br />

distribution tube (1) is not<br />

damaged or missing.<br />

NOTE<br />

If anti-tamper seal reveals<br />

possible screw rotation,<br />

return blower assembly to<br />

Depot Maintenance.<br />

Check case (18) for cracks or<br />

damage.<br />

Gasket is damaged or missing.<br />

Cracks or separation in blower<br />

assembly housing material or<br />

holes are present where material<br />

has been broken away.<br />

12<br />

Semi-<br />

Annual<br />

BATTERIES<br />

WARNING<br />

Lithium-sulfur dioxide<br />

(Li-SO2) batteries which are<br />

used in this equipment<br />

contain pressurized sulfur<br />

dioxide (SO2) gas. The gas<br />

is toxic, and the battery<br />

MUST NOT be abused in<br />

any way which may cause<br />

the battery to rupture.<br />

A hissing sound from the<br />

battery or the smell of vinegar<br />

or rotten eggs indicates<br />

a leaking battery. If a leaking<br />

battery is detected,<br />

move battery to a well ventilated<br />

storage area and<br />

contact Defense Reutilization<br />

and Marketing Office<br />

for disposal.<br />

CAUTION<br />

Remove batteries if blower is<br />

to be stored 30 days or more.<br />

2-29

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Table 2-1. PREVENTIVE MAINTENANCE CHECKS AND SERVICES FOR M43A1 (CONT)<br />

Item<br />

No.<br />

Interval<br />

Item to<br />

Check/Service<br />

Procedure<br />

Not Fully Mission<br />

Capable If:<br />

NOTE<br />

Replace bad batteries. Be<br />

sure battery is new and has<br />

only been used for brief<br />

periods while checking<br />

blower assembly.<br />

a.<br />

b.<br />

c.<br />

d.<br />

e.<br />

f.<br />

g.<br />

h.<br />

Check that battery in blower<br />

assembly is charged by turning<br />

on blower assembly knob (1)<br />

and observing LED (2).<br />

Check LED (2) condition by<br />

pressing pushbutton (3). Turn<br />

off blower assembly knob (1) at<br />

end of check.<br />

Open battery door (4) by<br />

moving latch (5), and remove<br />

battery (6) from blower assembly<br />

by pulling battery removal<br />

strap (7). Remove spare battery<br />

from carrier. Check each battery<br />

for leaks, cracks, breaks,<br />

bulging, or swelling in its case.<br />

Check battery connector pins<br />

(8) for damage.<br />

Check blower assembly battery<br />

connector mounting plate (9)<br />

for damage.<br />

Check blower assembly battery<br />

connector pins (10) for damage.<br />

Check battery removal strap<br />

(7) for frayed or torn material.<br />

Install spare battery from carrier<br />

into blower assembly. Refer to<br />

operating procedures, Operators<br />

Manual <strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-10.<br />

Battery is discharged enough<br />

to cause the LED to light and<br />

remain lit for more than 5<br />

minutes.<br />

LED does not light.<br />

Material is leaking from battery,<br />

or battery case is cracked,<br />

broken, bulging, or swelling.<br />

Pins are bent, loose, broken, or<br />

missing.<br />

Mounting plate is loose or<br />

broken.<br />

Pins are bent, loose, broken, or<br />

missing.<br />

Battery removal strap is excessively<br />

frayed or torn so that the<br />

battery cannot easily be moved.<br />

Battery is discharged enough<br />

to cause the LED to light and<br />

remain lit for more than 5<br />

minutes.<br />

2-30

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Interval<br />

Item to<br />

Check/Service<br />

Procedure<br />

Not Fully Mission<br />

Capable If:<br />

i. Remove spare battery from<br />

blower assembly and install<br />

primary battery. Refer to<br />

operating procedures, Opertors<br />

Manual <strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-10.<br />

Blower does not run properly or<br />

LED lights and remains lit for<br />

more than 5 minutes.<br />

13<br />

Semi-<br />

Annual<br />

HARNESS<br />

ASSEMBLY<br />

a. Check harness assembly (1)<br />

for cut or frayed webbing, and<br />

for missing D-rings or buckles.<br />

Harness is cut or frayed, or clips<br />

or buckles are missing.<br />

b. Check that lanyard (2) and<br />

lanyard loops (3) are present<br />

and not cut, frayed, or torn.<br />

Lanyard or lanyard loops are<br />

cut, frayed, or torn.<br />

2-31

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Table 2-1. PREVENTIVE MAINTENANCE CHECKS AND SERVICES FOR M43A1 (CONT)<br />

Item<br />

No.<br />

Interval<br />

Item to<br />

Check/Service<br />

Procedure<br />

Not Fully Mission<br />

Capable If:<br />

14<br />

Semi-<br />

Annual<br />

AUXILIARY<br />

BLOWER<br />

ASSEMBLY<br />

a.<br />

b.<br />

Check for presence of lanyard<br />

assembly (1).<br />

Check lanyard assembly (1) for<br />

cut or frayed cord.<br />

Lanyard assembly is missing.<br />

Cord is cut or frayed.<br />

c.<br />

Check lanyard assembly (1) for<br />

presence and condition of<br />

canister plug (2).<br />

Canister plug is missing or has<br />

cuts or tears.<br />

d.<br />

Check canister connector (3)<br />

for cracks or breaks.<br />

Canister connector is cracked or<br />

broken.<br />

e.<br />

Check that canister seal (4)<br />

not cut, torn, or missing.<br />

is<br />

Canister seal is cut, torn, or<br />

missing.<br />

f.<br />

Check case (5) for missing<br />

parts.<br />

Case has missing parts.<br />

g.<br />

Check that power switch (6)<br />

and canister connector switch<br />

(7) are present and not broken.<br />

Power switch or canister connector<br />

switch is missing or broken.<br />

2-32

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Item<br />

No.<br />

Interval<br />

Item to<br />

Check/Service<br />

Procedure<br />

Not Fully Mission<br />

Capable If:<br />

WARNING<br />

Lithium-sulfur dioxide<br />

(Li-SO2) batteries that are<br />

used in this equipment<br />

contain pressurized sulfur<br />

dioxide (SO2) gas. The gas<br />

is toxic, and the batteries<br />

MUST NOT be abused in<br />

any way which may cause<br />

the batteries to rupture.<br />

A hissing sound from the<br />

battery or the smell of vinegar<br />

or rotten eggs indicates<br />

a leaking battery. If a leaking<br />

battery is detected,<br />

move battery to a well ventilated<br />

storage area and<br />

contact Defense Reutilization<br />

and Marketing Office<br />

for disposal.<br />

NOTE<br />

Replace bad batteries. Be<br />

sure battery is new and has<br />

only been used for brief<br />

periods while checking<br />

auxiliary blower assembly.<br />

2-33

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Table 2-1. PREVENTIVE MAINTENANCE CHECKS AND SERVICES FOR M43A1 (CONT)<br />

Interval<br />

Item to<br />

Check/Service<br />

Procedure<br />

Not Fully Mission<br />

Capable If:<br />

h.<br />

k.<br />

l.<br />

m.<br />

Remove both battery caps (8)<br />

and check that batteries (9),<br />

O-rings (10), and springs (11)<br />

are present.<br />

Check batteries (9) for leaks,<br />

cracks, breaks, bulging, or<br />

swelling.<br />

Install spare batteries (9) with<br />

negative terminal (button end)<br />

faceing down in case.<br />

Install battery caps (8) with<br />

springs (11) and O-rings (10)<br />

over batteries (9) and tighten<br />

handtight.<br />

Operate power switch and<br />

check that auxiliary blower<br />

motor operates properly.<br />

Reinstall original batteries (9)<br />

with negative terminal (button<br />

end) facing down in case.<br />

Either battery, O-ring, or spring<br />

is not present.<br />

Batteries are leaking, cracked,<br />

broken, bulging, or swelling.<br />

Auxiliary blower motor does not<br />

operate.<br />

2-34

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Item<br />

No.<br />

Interval<br />

Item to<br />

Check/Service<br />

Procedure<br />

Not Fully Mission<br />

Capable If:<br />

15<br />

Semi-<br />

Annual<br />

AUXILIARY<br />

BLOWER<br />

CARRIER<br />

a.<br />

Visually inspect inside and<br />

outside surface of auxiliary<br />

carrier (1) for dirt, mud, grease<br />

or oily surfaces, sharp edges,<br />

and torn straps.<br />

Dirt or grease is on surface,<br />

straps are torn or missing, or<br />

there are sharp edges that could<br />

cut or tear.<br />

b.<br />

Make sure nothing other than<br />

auxiliary blower assembly is<br />

inside of carrier.<br />

Unauthorized items are carried<br />

inside or attached to outside of<br />

carrier.<br />

16<br />

Semi-<br />

Annual<br />

NUCLEAR<br />

HOOD<br />

a.<br />

Visually inspect inside and<br />

outside surfaces for dirt, mud,<br />

and greasy or oily substances.<br />

Dirt or grease is on surfaces.<br />

b.<br />

Check for chafed or worn areas<br />

cuts, tears, or separation of<br />

seams.<br />

CB mask hood has areas larger<br />

than a dime that are worn away,<br />

or has cuts, tears, or separation<br />

of seams.<br />

c.<br />

Check bungi cords (1). Make<br />

sure they stretch. Make sure<br />

they have not become detached<br />

from the hood material.<br />

Bungi cords do not stretch<br />

enough to ensure a snug fit<br />

outside facepiece. Bungi cords<br />

have come detached from<br />

material.<br />

2-35

<strong>TM</strong> 3-<strong>4240</strong>-<strong>334</strong>-20&P<br />

Table 2-1. PREVENTIVE MAINTENANCE CHECKS AND SERVICES FOR M43A1 (CONT)<br />

Item<br />

No.<br />

Interval<br />

Item to<br />

Check/Service<br />

Procedure<br />

Not Fully Mission<br />

Capable If:<br />

17<br />

Semi-<br />

Annual<br />

FACEPIECE<br />

CARRIER<br />

Empty facepiece carrier (1) and<br />

check for dirt, sharp edges, torn<br />

straps, or missing hardware.<br />

Make sure facepiece assembly<br />

(2) and faceform (3) are<br />

present, and no unauthorized<br />

material is inside or on<br />

carrier (1).<br />

Straps are torn or hardware is<br />

missing. There are sharp edges<br />

inside carrier that could damage<br />

mask.<br />

NOTE<br />

Insert faceform in facepiece<br />

assembly if mask is to be<br />

stored for 30 days or<br />

longer.<br />

2-36