What really does cause induction contamination? - TAT - The ...

What really does cause induction contamination? - TAT - The ...

What really does cause induction contamination? - TAT - The ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

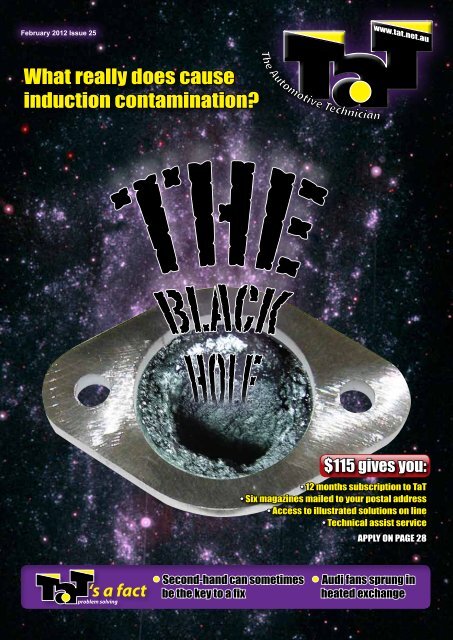

February 2012 Issue 25<br />

www.tat.net.au<br />

<strong>What</strong> <strong>really</strong> <strong>does</strong> <strong>cause</strong><br />

<strong>induction</strong> <strong>contamination</strong>?<br />

$115 gives you:<br />

• 12 months subscription to TaT<br />

• Six magazines mailed to your postal address<br />

• Access to illustrated solutions on line<br />

• Technical assist service<br />

APPLY ON PAGE 28<br />

‘s a fact<br />

problem solving<br />

• Second-hand can sometimes<br />

be the key to a fix<br />

• Audi fans sprung in<br />

heated exchange

Now Available! - an OEM generic scan<br />

tool for DIESEL, PETROL & HYBRID<br />

Electrical Vehicles!<br />

OEM Generic Automotive Scan Tool<br />

Hottest new scan tool<br />

on the market today!<br />

www.gscan.com.au<br />

Trucks, Cars, Hybrids,<br />

4WD’s, Gasoline, Diesel<br />

& Electrical models<br />

call (02) 9905 8055<br />

for your nearest Distributor

You are no doubt familiar<br />

with the phrase ‘keep it<br />

simple, stupid’?<br />

It is commonly called the KISS<br />

principle, an acronym coined<br />

by a guy called Johnson,<br />

a senior engineer at the<br />

Lockheed aeroplane plant.<br />

<strong>The</strong> story goes that Johnson<br />

gave a team of design<br />

engineers a handful of tools,<br />

with the challenge that the jet<br />

aircraft they were designing<br />

must be repairable by an<br />

average mechanic in the field<br />

under combat conditions with<br />

only these tools.<br />

I’ve often wondered why the<br />

word ‘stupid’ was added,<br />

but apparently it refers to<br />

the relationship between the<br />

way things break and the<br />

sophistication available to fix<br />

them.<br />

Johnson’s KISS principle is<br />

obviously unknown to the car<br />

design industry.<br />

with Ken Newton<br />

It seems to be a race between<br />

sophisticated technology, and<br />

the sophisticated tools needed<br />

to fix it.<br />

Which brings me to the point.<br />

<strong>The</strong> vehicle world has become<br />

so complex that the skills and<br />

tools of the mechanic who was<br />

once able to fix anything and<br />

everything are now more likely<br />

to be found in a museum than<br />

in a workshop.<br />

I once knew an old mechanic<br />

who showed me his main<br />

diagnostic tool. It was huge<br />

screwdriver, the old fashioned<br />

type where the metal shaft<br />

extended through to the top of<br />

the wooden handle. He would<br />

start an engine and used the<br />

screwdriver like a stethoscope,<br />

placing it on top of or against<br />

various parts of the engine.<br />

He cupped his hand around<br />

the handle and pressed his ear<br />

against his hand. He claimed<br />

he could hear the innards of<br />

the engine and the sounds and<br />

vibrations he picked up would<br />

tell him where the problem<br />

was.<br />

So working on the premise that<br />

no single human being can<br />

possibly know enough to be<br />

able to fix any problem in any<br />

make of vehicle, one can only<br />

conclude that technicians and<br />

mechanics today need a lot of<br />

help.<br />

<strong>The</strong>re’s plenty of it around,<br />

including TaT.<br />

But there is a real danger of<br />

being swamped by too much<br />

information. More information,<br />

you might think, should be<br />

useful, but only if you can<br />

interpret it.<br />

Our own TaT specialists are<br />

often heard to say ‘Google it’.<br />

It’s amazing what you will find<br />

on the internet. But beware, a<br />

lot of it is rubbish.<br />

Beware of social media too. It’s<br />

not so much the accuracy of<br />

the information you will find on<br />

Google or on social media. It’s<br />

about wasting time.<br />

A recent survey of companies<br />

and their workers revealed<br />

that all workers are already<br />

overloaded, with a majority<br />

claiming they can’t make sense<br />

of the data they already have.<br />

And it’s getting worse.<br />

<strong>The</strong> deluge of data is expected<br />

to grow by 40 times in the next<br />

seven years or so.<br />

So here’s my contribution to<br />

your New Year’s resolution list.<br />

Concentrate on a handful of<br />

known and trusted sources<br />

of information. Of course I<br />

will nominate TaT at the top<br />

of the list, but it could contain<br />

data and wiring diagram<br />

providers like Autodata and<br />

Boyce, networks like Bosch,<br />

or perhaps some friendly<br />

wholesaler reps.<br />

But keep it simple. That’s what<br />

we aim to do at TaT.<br />

Simple, straight forward<br />

information from people just<br />

like you who work on the<br />

workshop floor every day. Trust<br />

me, it’s one network you can<br />

trust.<br />

<strong>The</strong> TaT team<br />

Contents<br />

Publisher<br />

<strong>The</strong> Automotive Technician Pty Ltd<br />

ABN 27 121 589 802<br />

72 Holtermann Street<br />

CROWS NEST NSW 2065<br />

tat@tat.net.au<br />

Ph 1300 828 000<br />

Fax 1300 828 100<br />

Editor in chief<br />

Ken Newton<br />

knewton@tat.net.au<br />

0438 569 517<br />

Fax 1300 828 100<br />

Editorial and online<br />

assistant<br />

Tony Wragg<br />

twragg@tat.net.au<br />

Technical editor<br />

Jeff Smit<br />

jsmit@tat.net.au<br />

1300 828 000<br />

Technical research<br />

Deyan Barrie<br />

dbarrie@tat.net.au<br />

02 9476 6277<br />

Technical advisers<br />

Jack Stepanian<br />

Nick Murphy<br />

nmurphy@tat.net.au<br />

Wayne Broady<br />

www.broadyauto.com.au<br />

Gil Sher<br />

gil@bigpond.com<br />

Columnists<br />

Julian Hentze – Georgia USA<br />

Hayley Windsor – Australia<br />

Reader<br />

Bron Robinson<br />

Advertising inquiries<br />

Jeff Smit<br />

jsmit@tat.net.au<br />

02 9966 8600<br />

Graphic design<br />

Russell Jones<br />

Russell Jones Graphic Design<br />

07 5532 2840 0411 817 012<br />

rjdesign2@optusnet.com.au<br />

Printing<br />

McPherson’s Printing Group<br />

5-7 Dunlop Rd<br />

Mulgrave VIC 3170<br />

www.mcphersonsprinting.com.au<br />

Affiliated associations<br />

VASA secretary@vasa.org.au<br />

AAAA member info@aaaa.com.au<br />

Capricorn Society Alliance Supplier<br />

•TaT Assist •TaT Chat •TaT Train<br />

•TaT’s a fact •Tips for TaT • TaT Biz<br />

are all registered trade names of<br />

<strong>The</strong> Automotive Technician Pty Ltd.<br />

<strong>The</strong> Automotive Technician Pty Ltd<br />

publishes technical advice and<br />

actual case studies for the<br />

purpose of educating technicians.<br />

<strong>The</strong>se advices are given in good<br />

faith, and are based on actual<br />

workshop repairs. No guarantee is<br />

given, nor any liability accepted in<br />

respect to any published advice.<br />

<strong>The</strong> Automotive Technician Pty Ltd<br />

is not responsible for the accuracy<br />

of any information contained in<br />

material submitted by third parties<br />

and published in this magazine and<br />

accepts no liability in relation to<br />

such materials or their content.<br />

Newsworthy articles or comments<br />

are welcomed, and should be<br />

submitted to the editor in chief.<br />

All material appearing in <strong>The</strong><br />

Automotive Technician is copyright.<br />

Reproduction in whole or in part is<br />

illegal without prior written consent<br />

from the editor in chief.<br />

All advertisers agree to indemnify<br />

the publisher for all damages or<br />

liabilities arising from their published<br />

or unpublished material.<br />

Induction <strong>contamination</strong>……………4 – 7<br />

You get what you pay for………………7<br />

Regular a/c service saves plenty…………9<br />

A car full of ideas………………………9<br />

Throwing some light on the lights………10<br />

Good vibrations for accessory unit drive…11<br />

Strike a light on a weird problem………14<br />

Top Tools – ignition analyser……………15<br />

Tat’s a facts………………………16 – 17<br />

Murphy’s Law – a diagnostic path………18<br />

Mitsubishi plug-in SUV…………………19<br />

Don’t ignore the pollen filter…………21<br />

Street Cred with Hayley Windsor………22<br />

Oil and water just don’t mix……………23<br />

A/c and communication……………24 – 25<br />

V8 racer stays cool on the track………26<br />

Letter from America……………………26<br />

<strong>The</strong> quick and the dead………………28<br />

When all else fails, try cleaning it………28<br />

TaT’s interesting………………………30<br />

Geoff Mutton’s business tips…………30<br />

<strong>The</strong> Automotive Technician is a member of the<br />

Circulations Audit Board.<br />

Audit period, 1st April to 30th September 2011.<br />

Average net distribution 9,974.<br />

<strong>The</strong> Automotive Technician 3

Induction is the stage of the<br />

working cycle of an engine<br />

in which the fuel and air is<br />

drawn into the cylinders.<br />

Contamination means to<br />

make impure by exposure<br />

to or addition of a polluting<br />

substance.<br />

Induction <strong>contamination</strong> means<br />

any change from the original state<br />

of the complete intake system, fuel<br />

or air, of a vehicle. <strong>The</strong> air intake<br />

system includes the air filter box, air filter,<br />

air intake hoses, throttle body or butterfly<br />

unit, inlet manifold, engine valves and even<br />

the cylinder bores.<br />

<strong>The</strong> incidence of vehicles losing power<br />

and performance be<strong>cause</strong> of some form of<br />

<strong>induction</strong> restriction is increasing greatly.<br />

TaT sees evidence of this problem through<br />

the increasing numbers of TaT assist<br />

requests. Some of the pictures showing<br />

serious build-up of carbon have come<br />

from TaT workshops and others from our<br />

subscribers.<br />

It raises the<br />

question – what’s<br />

changed?<br />

And what do the aftermarket workshops<br />

need to know? Is there a need for some<br />

education of the motoring public? Can the<br />

<strong>contamination</strong> trend be slowed or reversed<br />

through some preventative measures?<br />

Many things are blamed for the build-up of<br />

carbon in inlet manifolds – poor fuel quality,<br />

poor or incorrect engine oil, engine design<br />

and even driving styles.<br />

Sometimes technology generates new<br />

problems. Is the build-up of carbon in the<br />

intake system one of them?<br />

Take the inlet manifold, for example. Once,<br />

there was a carburetor sitting on top of<br />

the engine. Fuel was delivered above the<br />

throttle plates, which were awash in petrol,<br />

one of the world’s great solvents.<br />

So carbon could not build up be<strong>cause</strong> of<br />

the washing action of swirling, fuel laden<br />

air.<br />

It’s fairly common now to find vehicles<br />

with very dirty inlet manifolds and throttle<br />

bodies bad enough<br />

to <strong>cause</strong> some<br />

<strong>The</strong> Automotive Technician 4<br />

<strong>The</strong> next<br />

plague…<br />

INDUCTION<br />

CONTAMINATION<br />

by Jeff Smit<br />

components to stick and fail. Customers<br />

complain of a loss of power or poor fuel<br />

economy.<br />

Vehicles began suffering from <strong>induction</strong><br />

<strong>contamination</strong> with the introduction of the<br />

first electronic fuel injection (EFI) systems.<br />

While these systems bring many benefits,<br />

including improved performance, fuel<br />

economy and lower emission output, they<br />

are subject to intake and throttle bore<br />

<strong>contamination</strong> problems. Once fuel was<br />

stopped from passing through the throttle<br />

bore, contaminants began to build up.<br />

Eventually, those carbon deposits must be<br />

removed to restore engine performance.<br />

Strict environmental controls, Euro 4<br />

emissions standards, and consumer<br />

demands for better fuel economy and<br />

performance forced design engineers to<br />

develop direct injection systems for both<br />

petrol and diesel engines. <strong>The</strong>se systems<br />

took the introduction of the fuel away from<br />

the inlet manifold altogether.<br />

So yet again the introduction of new and<br />

supposedly better systems has by their<br />

very design <strong>cause</strong>d a spin-off problem.<br />

<strong>The</strong>re appears to be no single reason for<br />

a build-up of contaminants in the intake<br />

systems, and it seems some makes and<br />

models suffer more than others.<br />

Source of<br />

<strong>contamination</strong><br />

Carbon build-up around the throttle body,<br />

throttle bore and inlet manifold restricts<br />

the airflow into the engine cylinders.<br />

Such an obstruction will result in a poor<br />

idle, a stalling condition and a drop in<br />

performance and fuel economy. <strong>The</strong><br />

most common source of<br />

these deposits is from the<br />

combustion and crankcase<br />

gases.<br />

<strong>The</strong> combination of the<br />

gases from the positive<br />

crankcase ventilation (PCV)<br />

system and from the exhaust<br />

gas recirculation (EGR) system<br />

will, in most cases, <strong>cause</strong> the<br />

intake <strong>contamination</strong>, more so when<br />

the PCV and the EGR points are<br />

positioned near the throttle<br />

plate. <strong>The</strong> EGR gases mix<br />

with the gases from the PCV<br />

system to form the gummy or<br />

waxy residue.<br />

<strong>The</strong> piston strokes and the<br />

negative to positive pressure<br />

pulsations direct the gases<br />

towards the throttle body,<br />

where they are baked on due<br />

to the intense heat. Foreign and<br />

domestic vehicles suffer equally.<br />

Engine PCV system<br />

<strong>The</strong> vapours that end up in an engine’s<br />

crankcase contain moisture as well as<br />

combustion by-products and unburned<br />

fuel vapours. <strong>The</strong> crankcase is sealed to<br />

prevent the escape of these gases into<br />

the atmosphere, but the vapours must<br />

be removed to prevent oil <strong>contamination</strong><br />

that leads to sludge formation. <strong>The</strong> PCV<br />

system siphons these vapours from the<br />

crankcase and routes them into the intake<br />

manifold so they can be reburned in the<br />

engine.<br />

<strong>The</strong> main component in the PCV system is<br />

the PCV valve, which is usually located in<br />

the valve cover. A hose connects the PCV<br />

valve to the intake manifold.<br />

<strong>The</strong> PCV valve is spring-loaded with a<br />

specific orifice size designed to restrict the<br />

amount of air siphoned from the crankcase<br />

into the intake manifold. This is necessary<br />

be<strong>cause</strong> air drawn through the valve from<br />

the crankcase has a leaning effect on the<br />

fuel mixture, much the same as a vacuum<br />

leak. So airflow through the valve must<br />

be controlled within certain limits. At idle,<br />

air flow is reduced be<strong>cause</strong> little blow-by<br />

is produced. When the engine is cruising<br />

and vacuum is high, airflow through the<br />

PCV valve is at a maximum to purge the<br />

vapours from the crankcase.<br />

EGR system<br />

A chemistry lesson on NOx first.<br />

<strong>The</strong> ‘x’ in NOx stands for the various<br />

oxides of nitrogen that are created. Among<br />

them are: NO (nitric oxide), a colorless,<br />

poisonous gas; NO 2<br />

(nitrogen dioxide)<br />

which is a reddish brown, toxic gas; and<br />

N 2<br />

O (nitrous oxide) which is commonly<br />

known as laughing gas.<br />

Environmental imperatives will demand<br />

continuing control of nitrogen oxide<br />

emissions. Most of the carbon monoxide<br />

and almost 50 per cent of the nitrogen<br />

oxides and hydrocarbons come from<br />

burning petrol and diesel fuels in cars and<br />

trucks. Nitrogen oxides are only created at<br />

very high temperatures and pressures, as<br />

found in automotive engines.<br />

Basic EGR operation<br />

NOx forms under high pressures and<br />

temperatures found in the combustion<br />

chamber, so it can be controlled by

educing the compression or the<br />

temperature in the combustion chamber.<br />

Emission control engineers chose the<br />

latter. Temperature is controlled by<br />

introducing a metered amount of inert gas<br />

into the cylinder to partially quench the fire.<br />

<strong>The</strong> result is that the fire in the combustion<br />

chamber is less intense. EGR exhaust<br />

gas occupies space that would otherwise<br />

contain air. With EGR, the fire is more like<br />

a smoldering pile of leaves than a blast<br />

furnace. Exhaust gas was chosen be<strong>cause</strong><br />

it is free and plentiful. EGR reduces the<br />

formation of NOx up to 60 per cent. <strong>The</strong><br />

cat usually cleans up much of the rest.<br />

<strong>The</strong> EGR valve would normally open<br />

during light throttle and warm engine<br />

cruising and channel the exhaust gases<br />

back into the engine’s inlet air. It <strong>does</strong>n’t<br />

take much. EGR accounts for less than<br />

10 per cent of the total air/fuel mixture but<br />

even this small amount of non-flammable<br />

stuff is enough to quench the flame<br />

somewhat.<br />

<strong>The</strong>re are a number of EGR system<br />

types:<br />

• Ported<br />

(late 1960s to present)<br />

• Positive backpressure<br />

(1970s to present)<br />

• Negative backpressure<br />

(1970s to present)<br />

• Pulse-width modulated<br />

(early 1980s to present)<br />

• Digital–electronic<br />

(late 1980 to early 1990s)<br />

• Linear–electronic<br />

(early 1990s to present)<br />

It’s the later model types that are linked<br />

with the direct injection systems which<br />

concern technicians today.<br />

Symptoms of EGR<br />

malfunction<br />

<strong>The</strong> EGR system is often misdiagnosed<br />

or blamed for problems that may not be<br />

its fault, including hard starting, stalling<br />

and hesitation during warm-up, rough<br />

idle, missing, spark knock, backfiring and<br />

loss of power. Sure, the EGR system can<br />

<strong>cause</strong> these symptoms, but so can other<br />

components and systems. Don’t jump to<br />

any conclusions until you have checked<br />

the basics. One common reason is carbon<br />

build-up in the intake system.<br />

It appears that with the introduction<br />

of the Euro 4 emission standards, the<br />

EGR system may be operating in many<br />

more situations than in previous models,<br />

sometimes at idle.<br />

<strong>The</strong> build-up of <strong>contamination</strong> in the intake<br />

system can be <strong>cause</strong>d by a number of<br />

possible factors. First, the engine needs<br />

to be in good working order so that the<br />

PCV gases are as low as possible and as<br />

clean as possible. This is<br />

where correct and regular<br />

servicing, as well as quality<br />

and correct engine and drive<br />

train oils, are very important.<br />

It is TaT’s belief that many<br />

technicians would claim that the<br />

servicing schedule for the modern<br />

vehicle is too stretched out.<br />

Car makers have been promoting<br />

low cost service, but this has had<br />

the effect of teaching vehicle<br />

owners that they can get away<br />

with one service a year or even<br />

worse, every 18 months. This<br />

puts the engine under high stress,<br />

causing excessive build-up of PCV<br />

gases.<br />

<strong>The</strong>n we add the EGR to the<br />

equation. <strong>The</strong> EGR valve is now<br />

operating more frequently and even at idle,<br />

this high heat coupled with the excessive<br />

PCV gases entering the intake system<br />

triggers the process of carbon build-up.<br />

At first it <strong>does</strong>n’t <strong>cause</strong> too many problems.<br />

But as time goes on, with stretched out<br />

servicing and a quick oil and filter change,<br />

the build-up continues. Eventually, the<br />

build-up <strong>cause</strong>s more issues with poor<br />

performance and fuel economy which in<br />

turn <strong>cause</strong> more PCV gases. Eventually<br />

the EGR valve won’t seat correctly and<br />

allows EGR gases to enter the throttle<br />

body at idle and compound the problem.<br />

Some of the worst cases we have seen<br />

have been on common rail diesel vehicles.<br />

A lot has been said about the quality of<br />

diesel fuel, and perhaps this is a small<br />

contributor to the problem. <strong>The</strong>re have<br />

been issues with vehicles losing power<br />

and becoming barely driveable. <strong>The</strong> top<br />

part of the inlet manifold is found to be<br />

choked with carbon. In some cases the<br />

inlet manifolds have had to be replaced<br />

be<strong>cause</strong> of the extent of the <strong>contamination</strong><br />

and damage to the manifolds.<br />

<strong>The</strong>re have been stories that some<br />

technicians have even blocked off the EGR<br />

system and fitted oil traps in the PCV lines.<br />

TaT has heard that manufacturers are<br />

working on software upgrades to try and<br />

minimise the problem, but this may not be<br />

enough.<br />

<strong>The</strong>re are many good products available<br />

which can help clean and maintain the inlet<br />

manifold.<br />

<strong>The</strong> BG product for both petrol and diesel<br />

engines is one that we know works very<br />

well, and there are no doubt others.<br />

It’s a problem which will need some<br />

customer education so that the clearning<br />

and servicing of the throttle body and inlet<br />

manifold are included as an important<br />

part of every service. You owe it to your<br />

customers to let them know about this<br />

issue so that you can at least ensure<br />

continued top performance of later model<br />

vehicles.<br />

TaT invites<br />

technicians<br />

to share their<br />

knowledge of this<br />

problem be<strong>cause</strong> the industry<br />

is only now seeing the early stages of<br />

<strong>contamination</strong>.<br />

Please send your photos and your<br />

remedies.<br />

TaT will continue to cover this important<br />

subject. In the meantime, the TaT field<br />

specialists were invited to share their<br />

experiences.<br />

Anthony Tydd:<br />

From what I have seen it’s the turbo<br />

diesels that have the biggest problem,<br />

probably due to the engine trying to<br />

recirculate soot back into the inlet.<br />

<strong>The</strong> Mercedes Vitos and the VW soot up<br />

big time in the inlet. I have seen them so<br />

bad I have tried to scrape the carbon out<br />

so the engine could breathe.<br />

I am surprised manufacturers have not<br />

played more with water injection at the<br />

throttle body to cool the charge and clean<br />

the inlet shiny new.<br />

Ask any mechanic who has done a Ford<br />

head gasket and you will find that the<br />

cylinder that has been getting water into it<br />

will have a shiny piston top and polished<br />

like an exhaust valve.<br />

<strong>The</strong> diesel engine may not be as<br />

accommodating to my idea as the petrol<br />

engine.<br />

A lot of turbo engines seem to seep oil past<br />

the turbo bush and back into the inlet tract<br />

which is another compounding problem for<br />

inlet <strong>contamination</strong>.<br />

I believe the biggest <strong>cause</strong> of carbon<br />

build-up would be the use of low grade oils<br />

or too long an interval between services.<br />

Either of these would <strong>cause</strong> carbon buildup<br />

and feedback into the inlet via EGRs<br />

and rocker cover breather (the baffles<br />

inside to separate oil from blow-by gas).<br />

I have seen rocker cover breathers block<br />

up due to lack of oil changes. <strong>The</strong> vent<br />

galleries close up and become venturi-like,<br />

increasing the air speed and dragging oil<br />

into the inlet.<br />

<strong>The</strong> Automotive Technician 5

In one such case, a dealership quoted on<br />

a new engine be<strong>cause</strong> of oil usage. <strong>The</strong><br />

customer wanted a second opinion and we<br />

cleaned out the rocker covers and it was all<br />

fixed with no more oil usage.<br />

<strong>The</strong> early Daihatsus had a breather<br />

hose from the rocker cover to the intake<br />

manifold. It had a restrictor in it. When<br />

it got blocked, a new vacuum hose was<br />

usually fitted, ignoring the restrictor and of<br />

course it started sucking oil while driving.<br />

Most of the Saab diesels would have<br />

logged a fault code before 110,000<br />

kilometres due to the EGR being blocked.<br />

<strong>The</strong>y are easy to unblock and free up if<br />

seized and my take on it is that the diesels<br />

are made for long driving, not for putting<br />

around town like Miss Daisy. Turbos hate<br />

this too. People who have no intention of<br />

using the turbo, shouldn’t buy one. People<br />

buy diesels be<strong>cause</strong> they can get seven<br />

litres per 100 kilometres but they putt<br />

around their suburbs and rarely give the<br />

engine a chance to breathe. This is why a<br />

lot of them have blocked particulate filters<br />

as well.<br />

Jason Smith:<br />

Petrol engines<br />

I have been cleaning throttle bodies for<br />

more than 20 years expecially in the<br />

early days when no one else would do it.<br />

If the car had a rough or low idle, many<br />

mechanics would wrongly adjust the<br />

throttle plate stop screw to bring the idle<br />

up. This then created a problem. After<br />

cleaning the very dirty throttle body, the<br />

car would idle far too fast. A base idle reset<br />

had to be done to make the car right again.<br />

I have always used a toothbrush and the<br />

appropriate cleaning solution and found<br />

this did the job quite well. A large workshop<br />

I once worked in reported a saving in<br />

the amount of throttle body cleaner they<br />

were using after adopting my toothbrush<br />

techique for all the mechanics.<br />

Cleaning throttle bodies has now become<br />

a crucial part of servicing late model<br />

vehicles.<br />

A 120 series 2006 Prado which had always<br />

been dealer serviced was brought to me<br />

for a major service. <strong>The</strong> throttle body was<br />

extremely dirty. Having said that, I admit it<br />

is not an easy throttle body to check and<br />

clean.<br />

After cleaning the throttle bodies on these<br />

cars, the engine idles all over the place. A<br />

tip – either perform a relearn with the scan<br />

tool or take the car for a long road test.<br />

Even after this, the car will still need a day<br />

or two for the idle to settle down.<br />

Dedicated throttle body and intake cleaning<br />

and decarbon machines are available now.<br />

<strong>The</strong>se can clean the throttle body, butterfly<br />

face and behind the butterfly face.<br />

<strong>The</strong>y can also do the inlet runners, the<br />

backs of the valves and some claim the<br />

oxygen sensor as well.<br />

I am getting excellent results from one<br />

of these machines, especially with BAs,<br />

BFs and Territories which are a little off at<br />

idle. Perform the upper engine clean and<br />

decarbon, replace the plugs and they purr<br />

like kittens. It’s also another way to make<br />

a dollar.<br />

More tips – It is a good idea to replace<br />

the spark plugs after performing the upper<br />

engine clean and decarbon and not before.<br />

Sometimes, when performing the clean, a<br />

fault code can be logged in the ECU, so it<br />

will need to be cleared.<br />

Diesel engines<br />

Complaints about late models with very<br />

dirty inlet manifolds are increasing. <strong>The</strong>re<br />

are rumours that manufacturers might have<br />

to rethink their EGR strategy, so stay tuned<br />

for this. But I don’t know how they will get<br />

around this to comply with strict emission<br />

specs.<br />

Maurice Donovan:<br />

Many people blame the EGR for the<br />

carbon build-up. This is justifiable be<strong>cause</strong><br />

the EGR is recycling exhaust gas back into<br />

the <strong>induction</strong> system. <strong>The</strong>re is a general<br />

opinion that unburnt fuel gas is the biggest<br />

<strong>cause</strong> of the build-up inside the intake<br />

system.<br />

*<br />

Tougher driving,<br />

quieter braking...<br />

Bendix 4WD brake pads now come<br />

with STEALTH Advanced Technology,<br />

delivering smoother and<br />

quieter operation.<br />

Bendix engineers have used high tech laser and dynamometer equipment to<br />

study the surface contact between each individual brake pad and rotor, and<br />

identified the optimum contact surface area. <strong>The</strong> result is STEALTH Advanced<br />

Technology. <strong>The</strong>se new 4WD pads deliver whisper quiet braking, silky smooth<br />

operation and noticeably less dust.<br />

This revolutionary innovation means:<br />

» Whisper quiet braking<br />

» Noise and vibration virtually eliminated<br />

» Silky smooth operation<br />

» Unrivalled stopping performance<br />

» Noticeably less dust<br />

» Long wearing<br />

FOR MORE INFORMATION<br />

Freecall the Bendix Brake Advice Centre on 1800 819 666<br />

(8am-5pm Monday to Friday EST) or +61 3 5327 0211 from overseas.<br />

Or visit bendix.com.au or bendix.co.nz<br />

Bendix is a trademark of Honeywell International Inc.<br />

*Not applicable to all part numbers.<br />

LEADING<br />

TECHNOLOGY<br />

BEST<br />

RANGE<br />

WIDEST<br />

COVERAGE<br />

OF CARS<br />

Put your foot down with confidence<br />

<strong>The</strong> Automotive Technician 6

I still believe if a fuel is poor quality or if<br />

the mixture is over rich <strong>cause</strong>d by leaking<br />

injectors, more of this unburnt fuel will be<br />

left in the intake system and <strong>cause</strong> sludge.<br />

However, I am starting to think that<br />

crankcase oil caught up in the breather and<br />

entering the intake system may be a bigger<br />

issue then we realise. Some years back I<br />

was involved with the import and servicing<br />

of the Toyota Surfs 2 litre and 1KZ engines.<br />

<strong>The</strong>y had a major problem with oil entering<br />

the intake system.<br />

At the time I put it down to bad design<br />

in the engine breathing system. I had<br />

modified the breather, fitting steel wool<br />

inside, and when that did not work I<br />

redesigned the inside of the rocker cover<br />

with bigger chambers and more baffles and<br />

even this did not work. I also had turbos<br />

rebuilt to ensure that they were not the<br />

culprit.<br />

No matter what I tried I could not solve this<br />

problem. <strong>The</strong> Toyota Estima with the layon-the-side<br />

3CT engine is even worse.<br />

I have this unproven theory that when the<br />

turbo is on boost it would pressurise the<br />

engine through the breather. When the<br />

turbo comes off boost, the pressure being<br />

released from the turbo creates a vacuum<br />

and draws the oil up into the intake system.<br />

I have in the past blocked off EGR systems<br />

in Surfs due to running factors, but this<br />

has not stopped the build-up forming in the<br />

intake system. <strong>The</strong> issue of poor quality<br />

fuel being the <strong>cause</strong> is another argument<br />

and possibly has some truth, but I have<br />

witnessed badly sludged build-up in the<br />

diesel intake systems on used engines that<br />

are straight out of Japan. I have been told<br />

that Japan has a better quality of fuel than<br />

ours.<br />

With the advent of common rail direct<br />

injection, it would seem that the intake<br />

build-up has escalated to plague<br />

proportions.<br />

I admit I have been<br />

blaming the poor fuel<br />

and the EGR. But after<br />

my experience with<br />

a Hilux I am starting<br />

to think back to all my<br />

past experiences and I<br />

continue to question the<br />

main <strong>cause</strong> of this sludge.<br />

I do not know why common<br />

rail systems appear to have a<br />

much bigger issue and this is another<br />

issue I would like to investigate.<br />

Many people blame everything to do with<br />

diesel sludge as a fuel issue and I know<br />

this is not always the case. It’s a problem<br />

we all need to understand.<br />

It is not enough to have the best product on<br />

the market to clean this sludge out of the<br />

<strong>induction</strong> system. <strong>The</strong> fact is, there should<br />

never be this much sludge in the first place.<br />

I realise petrol engines also have problems<br />

and I am comfortable with the fact that our<br />

fuel quality has a lot to do with this as well<br />

as other factors. Generally speaking, petrol<br />

engines, if serviced regularly and with the<br />

right fuel treatments and the necessary<br />

<strong>induction</strong> servicing, will keep most petrol<br />

engine intake systems under control.<br />

I have been using the BG products for<br />

both the petrol and diesel engines for<br />

some time and have found<br />

them to be very good. Most<br />

customers comment<br />

on how well their<br />

vehicles are running<br />

after the <strong>induction</strong><br />

system has been<br />

cleaned. It’s not<br />

hard to understand<br />

that the engine can<br />

then breathe properly<br />

again.<br />

TaT and its specialist<br />

workshops are highlighting this<br />

growing problem in the hope that some<br />

answers might emerge, either from fellow<br />

workshop technicians or from engine<br />

specialists.<br />

In the meantime, working on the principle<br />

that shared knowledge is worthwhile, TaT<br />

invites technicians to send in their photos<br />

and ideas about <strong>contamination</strong> build-up in<br />

engines. Only by sharing examples and<br />

techniques will we ever find the truth.<br />

YOU<br />

SAID<br />

IT!<br />

You get what<br />

you pay for<br />

This fuel filter was removed<br />

from a customer’s Jackaroo.<br />

Once out of the car, I did the<br />

normal procedure and drained<br />

it, and then I noticed a jingling<br />

noise coming from inside the<br />

filter like something was loose. <br />

My curiosity was aroused, so in<br />

an idle moment I cut it open and<br />

flopping around inside was the<br />

inside end cap which had come<br />

away from the glue that bonds<br />

it. <strong>The</strong>refore, the fuel filter was<br />

not working at all. When I see<br />

things like this, it justifies my<br />

decision to always use premium<br />

quality parts. <br />

Jason Smith <br />

JDS Automotive <br />

MOOROOLBARK VIC<br />

(<strong>The</strong> real question this little<br />

story raises is: would a supplier<br />

of a cheap filter, used in a late<br />

model vehicle, come to the<br />

party when serious damage<br />

is <strong>cause</strong>d to the engine<br />

be<strong>cause</strong> of <strong>contamination</strong>.<br />

In our view, it’s possible for a<br />

high performance engine to<br />

be destroyed if particles in the<br />

fuel were not captured by an<br />

effective filter. Why would you<br />

use cheap and nasty parts<br />

which can often come back and<br />

bite the person who installed<br />

them. Money is no longer an<br />

excuse in these situations. Ed) <br />

<strong>The</strong> Automotive Technician 7

At last, an<br />

air conditioning<br />

cleaning service<br />

supported by<br />

science.<br />

Air conditioning service programs have often been synonymous with<br />

gimmicky science and questionable effectiveness. <strong>The</strong> Rid Odor Pro service<br />

is supported by independent testing and the reassurance that thousands of<br />

workshops, hire car fleets, emergency services, taxis and even airlines use<br />

Rid Odor Pro worldwide, as their air conditioning service product of choice.<br />

• FIVE MINUTE service (cars)<br />

• $60.00 + GST service cost to motorist<br />

• No quibble, twelve month effectiveness guarantee<br />

• Free reception area point of sale & mirror hangers<br />

• Available in both ‘New Car’ and Leather scents<br />

• Free applicator tool for new customers before<br />

December 31st 2011 (conditions apply)<br />

View the Rid Odor Pro demonstration video at:<br />

http://www.ridodor.com/videos.php<br />

• Permanently destroys tobacco, food and<br />

beverage, body and dampness odours.<br />

• Full point of sale promotional support for<br />

participating service centres.<br />

Streptococcus pyogenes<br />

Ulocadium chartarum<br />

Aspergillus niger<br />

Penicillum purporogenum<br />

Staphylococcus aureus<br />

MRSA<br />

Trichophyton metagrophytes<br />

100% kill<br />

100% kill<br />

100% kill<br />

100% kill<br />

100% kill<br />

99% kill<br />

99% kill<br />

Authorised and exclusive Australian distributors of:<br />

Essential Service Programs<br />

Ph: 02 9911 4096<br />

Email: enquiries@espro.com.au<br />

www.espro.com.au<br />

<strong>The</strong> Automotive Technician 8

Regular a/c service saves plenty<br />

Vehicle air conditioning<br />

specialists have been advising<br />

their customers for years that<br />

a minimum annual service on air<br />

conditioning systems will save money<br />

in the end.<br />

Now, one of the world’s leading suppliers<br />

in the field of thermal management, Behr<br />

Hella, has delivered proof that commercial<br />

vehicle air conditioning units, serviced at<br />

least every six months, will save money.<br />

<strong>The</strong> company’s thermal experts<br />

say regular servicing reduces the<br />

fuel consumption <strong>cause</strong>d by the air<br />

conditioning system.<br />

Air conditioning units which are not<br />

serviced properly are veritable gas<br />

guzzlers. Behr Hella research has<br />

revealed that a commercial vehicle air<br />

conditioning unit consumes around 0.6<br />

litres more fuel per 100 kilometres when<br />

not serviced regularly.<br />

A commercial vehicle that travels 125,000<br />

kilometres each year and uses the air<br />

conditioning unit 60 per cent of the time<br />

on average, will consume up to 450 litres<br />

more fuel each year.<br />

Fuel saving aside, regular servicing will<br />

also prevent high repair costs.<br />

For example, the oil circulating with the<br />

refrigerant lubricates the air conditioning<br />

compressor. Every year, up to 10 per cent<br />

of this refrigerant escapes through natural<br />

evaporation, which can <strong>cause</strong> compressor<br />

failure due to lack of lubrication. <strong>The</strong><br />

evaporator can become the <strong>cause</strong> of many<br />

problems given that it is a significant part<br />

of the air-conditioning unit.<br />

Condensation forms in its fins and over<br />

time bacteria, fungi and micro-organisms<br />

accumulate. This can endanger the health<br />

of the driver and passengers so the<br />

evaporator must be disinfected regularly.<br />

Behr Hella 1800 061 729 <br />

custservice@ha.hella.com<br />

A car full of ideas<br />

<strong>The</strong> German auto manufacturing giant, Schaeffler Group,<br />

has developed a car full of ideas called the Schaeffler<br />

Hybrid.<br />

<strong>The</strong> vehicle is part of a project that enables a practical comparison<br />

of the options available for e-mobility (mobile and wireless<br />

communication).<br />

Various driving conditions can be switched on and off in the<br />

Schaeffler Hybrid. <strong>The</strong>se options range from using a combustion<br />

engine, operation as a parallel hybrid or serial hybrid to operation<br />

using the electric motor only.<br />

<strong>The</strong> combustion engine can power the vehicle and be coupled<br />

for use as a range extender. An automated manual transmission<br />

increases the options available.<br />

<strong>The</strong> transmission incorporates clutch products specially matched<br />

to the requirements of hybrid vehicles from the Schaeffler brand<br />

LuK. <strong>The</strong> energy store, which is a 16 kWh lithium-ion battery<br />

(400 V, 400 A), is charged by means of energy recovery, the range<br />

extender and also via an external power supply (plug-in hybrid).<br />

<strong>The</strong> unit comprises a liquid-cooled 50 kW and 95 Nm electric<br />

motor. ‘eWheel Drive’ is the name that has been given to the<br />

wheel hub motors. Motors mounted in the Schaeffler Hybrid have<br />

an output of around 50 kW each and torque of around 530 Nm.<br />

Accordingly, these wheel hub motors form a compact unit that<br />

integrates wheel bearing, drive and brake.<br />

An important advantage of these drive units is the fact that they<br />

can be integrated into an existing vehicle platform without any<br />

major changes to the vehicle architecture.<br />

<strong>The</strong> eWheel Drive features an appealing torque development as<br />

well as a remarkably low noise level.<br />

<strong>The</strong> Automotive Technician 9

YOU<br />

SAID<br />

IT!<br />

Throwing some light<br />

on the lights<br />

corrosion on the pins where<br />

the controller plugs onto the<br />

headlight.<br />

<strong>The</strong> controller pushes up onto<br />

the headlight and the seal isn’t<br />

good enough. Bumper removal<br />

is required.<br />

This car came in with one<br />

headlight out.<br />

Anthony Tydd<br />

Briggs Automotive<br />

BENDIGO VIC<br />

It was fitted with the Xenon<br />

type globe, which cost a mint.<br />

<strong>The</strong> hardest bit to figure<br />

out with most vehicles that<br />

incorporate the Xenon<br />

headlight is whether it’s the<br />

$200 globe or the even more<br />

expensive igniter.<br />

If the fuse is blown for the<br />

relevant headlight it will most<br />

likely be water damage in<br />

the controller, which <strong>cause</strong>s<br />

(Thanks Anthony. And here’s<br />

another story. A trade customer<br />

came to me with a globe in<br />

his hot little hand and asked<br />

if I had one. He had no clue<br />

what he was holding. It was an<br />

HID globe worth a couple of<br />

hundred bucks. He asked if I<br />

could test it. <strong>The</strong> answer was<br />

‘no, bring me the car’.<br />

Guess what – he gets a new<br />

globe from Honda, and it<br />

<strong>does</strong>n’t work.<br />

He brings the car back to<br />

me and bleats that he is<br />

now in trouble be<strong>cause</strong> he<br />

underquoted the job for<br />

insurance and would be out of<br />

pocket if I charged him a lot to<br />

fix it.<br />

We grabbed the old globe<br />

and put it into the good<br />

headlight and it worked. Next<br />

we checked the fuses and<br />

replaced a blown fuse in the<br />

offending headlight. It blew<br />

again. To prove it was the<br />

controller we removed the<br />

other headlight assembly and<br />

swapped the modules over<br />

and sure enough the other side<br />

blew the fuse. <strong>The</strong> customer,<br />

armed with the bad news,<br />

ordered a new module and<br />

we fitted it as required. Deyan<br />

Barrie)<br />

<strong>The</strong> Automotive Technician 10

Good vibrations for accessory unit drive<br />

<strong>The</strong> engine combustion cycle<br />

accelerates and decelerates the<br />

rotary motion of the crankshaft. This<br />

rotational imbalance is transferred to the<br />

front end accessory unit drive.<br />

1.<br />

and improve the service life of belt drive<br />

components and fuel consumption.<br />

For a long time, the rigid belt pulley (pic 2)<br />

was the standard pulley used on an alternator.<br />

With a design pre-dating V-ribbed pulleys with<br />

3. 5.<br />

recommends replacement at a service interval.<br />

A decoupler (pic 3) is an alternator belt pulley<br />

that powers the alternator by means of a<br />

soft torsion spring. It absorbs the rotational<br />

imbalance, thus preventing torque fluctuations.<br />

Sample assembly drive indicating vibrations <strong>cause</strong>d<br />

by the use of a conventional rigid belt pulley on an<br />

alternator.<br />

As a result, the belt is subjected to strong<br />

vibrations (pic 1) causing unpleasant juddering<br />

noises. Increased torque fluctuations and<br />

extreme forces can occur on the alternator in<br />

particular.<br />

Two key pieces of technology have been tested<br />

with the aim of combating these negative<br />

effects on the assembly drive – overrunning<br />

alternator pulley and decoupler. <strong>The</strong>se<br />

components will enhance driving comfort<br />

2.<br />

Rigid belt pulley<br />

Decoupler<br />

(1) Ball bearing (2) Clutch (3) Friction bearing<br />

(4) Torsion spring (5) Outer ring with moulded race<br />

(6) Cover<br />

one groove, the rigid belt pulleys have been<br />

developed further so that they can be used with<br />

modern V-ribbed belts with multiple grooves.<br />

<strong>The</strong> sole function of the rigid belt pulley is to<br />

drive the alternator by means of the looped<br />

belt. <strong>The</strong> belt needs to be replaced only in<br />

the event of damage, corrosion or significant<br />

wear and tear, unless the vehicle manufacturer<br />

4.<br />

Overrunning alternator pulley<br />

(1) Serrated inner ring (2) Radial support bearing<br />

(3) Overrunning clutch unit (4) Seals (5) Outer ring<br />

with moulded race (6) Cover<br />

Special tools for fitting and removing different<br />

overrunning alternator pulleys.<br />

<strong>The</strong> dynamic forces on the component bearing<br />

points within the assembly drive decrease,<br />

while the belt tensioner and the V-ribbed belt<br />

are protected against damage.<br />

An overrunning alternator pulley (pic 4,5)<br />

features an overrunning clutch unit. This<br />

enables the alternator to be decoupled from the<br />

rotational imbalance on the crankshaft and the<br />

effects of the alternator’s moment of inertia on<br />

the assembly drive and the belt vibrations are<br />

significantly reduced as a result.<br />

<strong>The</strong> force within the assembly drive is reduced,<br />

and the tensioner, pulleys and belts are<br />

subjected to smaller loads and have a longer<br />

service life.<br />

Schaeffler provided valuable assistance in the<br />

preparation of this article.To order your copy<br />

of the INA technical movie comparing Overrun<br />

Alternator Pulley (OAP), Overrun Alternator<br />

Decoupler (OAD) and solid pulleys, please<br />

contact:<br />

02 8977 1038 INA-AS.au@Schaeffler.com<br />

<strong>The</strong> Automotive Technician 11

PERFORMANCE INNOVATION<br />

DEVELOPED EXCLUSIVELY<br />

BY, WITH AND FOR EXPERTS<br />

Introducing our new range of Castrol Professional<br />

engine oils, now micro filtered to some of<br />

the world’s leading new car manufacturer<br />

requirements when filling new vehicle engines<br />

for the first time. When supported by the strong<br />

and powerful Castrol brand, this latest Castrol<br />

Professional product innovation has been proven<br />

through customer research to be an advantage<br />

your customers value.<br />

<strong>The</strong> Automotive Technician 12

Please contact your local Castrol Account<br />

Manager or Regional Manager to hear more<br />

about these exciting Castrol Professional<br />

innovations and the host of additional service<br />

programmes developed exclusively for you and<br />

your Professional Workshop.<br />

Castrol Regional Managers<br />

QLD Bob Scholz 07 3850 9311<br />

NSW Gary Macbeth 02 9795 4822<br />

VIC/SA/TAS David Mellington 03 9268 4294<br />

WA David Gibson 08 9268 9196<br />

<strong>The</strong> Automotive Technician 13

YOU<br />

SAID<br />

IT!<br />

Strike a light – what<br />

a weird problem<br />

<strong>The</strong> tail light fuse<br />

A Toyota Corolla, an ex hire<br />

car, had a dodgy headlight<br />

switch.<br />

It was a 8/2007 Toyota<br />

Corolla ZRE152 with a<br />

2ZR-FE engine and 82,000<br />

kilometres on the clock.<br />

<strong>The</strong> customer complained<br />

that the dash lights didn’t<br />

work sometimes.<br />

I found the park and tail lights<br />

were not working either when<br />

the dash lights failed. When<br />

this happened, sometimes<br />

if the switch was left on for<br />

a few minutes, the park lights<br />

would eventually start working<br />

and sometimes stop working.<br />

It was a weird problem.<br />

Other lights checked OK<br />

as did the fuses under the<br />

bonnet. <strong>The</strong> fuse box is inside<br />

the car just under the glove<br />

box.<br />

I found no power to the<br />

tail light fuse with the park<br />

lights switched on and park<br />

lights not working. When they<br />

started working, the fuse then<br />

had power. Performed basic<br />

wiring checks and then moved<br />

to the headlight switch.<br />

Removed the steering<br />

column shroud to expose the<br />

headlight switch wiring and<br />

connector.<br />

Later I pulled the rear cover<br />

off the old headlight switch<br />

and found the park light<br />

switch contacts and pin<br />

junction appeared to be the<br />

problem.<br />

<strong>The</strong> action of unplugging<br />

and reconnecting the wiring<br />

harness at the back of the<br />

headlight switch made the<br />

lights start working most of<br />

the time. <strong>The</strong> slight movement<br />

of the pin inside the light<br />

switch was just enough for<br />

the circuit to work.<br />

In case anyone is wondering–<br />

Inside the fuse box<br />

<strong>The</strong> headlight switch wires<br />

were given a good tug and<br />

they seemed OK. <strong>The</strong> power<br />

and earths were OK. <strong>The</strong><br />

problem was so unpredictable<br />

and intermittent.<br />

Instant Credit with hundreds of Top Name Suppliers | One Consolidated<br />

Monthly Statement | Reward points with every purchase | FREE Online<br />

Service Data | Social Events ...and more<br />

Established in 1975 as a buying co-operative for the automotive service and repair industry in Australia,<br />

Capricorn Society Limited has grown to represent over 14,000 members in three countries, that collectively<br />

purchased over AU $900 million in products and services from a network of over 2,200 preferred suppliers<br />

accross three countries. With member benefits such as our own travel agency, our own insurance alternative<br />

and many great financial services, shouldn’t you be a member too ? To find out more, please visit our<br />

website at www.capricorn.coop<br />

<strong>The</strong> Automotive Technician 14<br />

if YOU run<br />

a business<br />

in the<br />

Automotive<br />

Industry...<br />

...then you<br />

NEED to<br />

know about<br />

Capricorn.....<br />

Capricorn Society Limited - Registered under the Corporations Act 2001 ACN 008 347<br />

When I disconnected and<br />

reconnected the wiring<br />

harness to the headlight<br />

switch, the park lights would<br />

start to work most of the time.<br />

<strong>The</strong> wiring connector and pins<br />

were also checked but the<br />

problem didn’t appear to be<br />

in the wiring. It seemed to be<br />

the headlight switch. I tapped<br />

the headlight switch and still<br />

no luck.<br />

After using a test light I<br />

was able to confirm that the<br />

headlight switch internal<br />

contacts were the problem<br />

and that explained why it was<br />

so intermittent.<br />

To replace the headlight<br />

switch, the driver’s airbag,<br />

steering wheel and clock<br />

spring must be removed, so<br />

follow all precautions when<br />

working with airbags.<br />

<strong>The</strong> suspect headlight switch<br />

was replaced, all parts refitted<br />

and the system tested.<br />

Everything, including the park<br />

lights were working fine.<br />

Time taken was approximately<br />

two hours.<br />

Inspecting the<br />

old switch<br />

<strong>The</strong> switch location<br />

yes, you probably could<br />

clean the contacts and better<br />

secure the pin junction, but<br />

I would always recommend<br />

replacing the switch to avoid<br />

any possibility of lights failure<br />

at night.<br />

Jason Smith<br />

JDS Automotive<br />

MOOROOLBARK VIC

with Jeff Smit Multisystem<br />

Ignition Analyser<br />

W<br />

orkshops are<br />

constantly on the<br />

lookout for equipment or<br />

tools that make the job<br />

of diagnosing problem<br />

vehicles easier and more<br />

accurate.<br />

A good one to start the year<br />

is the TA500 Multisystem<br />

Ignition Analyser.<br />

<strong>The</strong> very first day of working<br />

with this great little tester, in<br />

came a vehicle with a miss.<br />

A quick removal of the<br />

covers over the coil-onplugs<br />

and we were able to<br />

test each cylinder’s ignition<br />

performance within a couple<br />

of minutes.<br />

It immediately showed that<br />

number three cylinder was the<br />

offender.<br />

A quick check of the inputs<br />

to the coil-on-plug and the<br />

diagnosis was done. <strong>The</strong><br />

workshop has since used it<br />

in a number of situations and<br />

found it to be very effective in<br />

every case.<br />

<strong>The</strong> TA500’s unique and<br />

proprietary technology allows<br />

workshops to perform quick<br />

and reliable diagnostics of<br />

non-starts, misfires, fouled up<br />

or damaged spark plugs, or<br />

spark plug wires by comparing<br />

digital read-outs of the spark<br />

plug voltage and spark burn<br />

Spark plug wire, testing position<br />

time between cylinders on<br />

engines using coil-on-plug,<br />

coil-near-plug, conventional<br />

distributor/ignition coil,<br />

DIS (distributorless) or<br />

waste spark and magneto<br />

technologies.<br />

It’s so simple to use. <strong>The</strong><br />

TA500 requires no special<br />

adapters or cables and is<br />

equipped with a large digital<br />

display that shows spark plug<br />

voltage, spark burn time,<br />

RPM, as well as minimum<br />

and maximum readings in real<br />

time.<br />

<strong>The</strong> user handbook is very<br />

well laid out with complete<br />

operating instructions – that<br />

in itself is a bit rare these<br />

days. <strong>The</strong> user manual<br />

also includes a section on<br />

diagnosing problems using<br />

spark burn time and spark<br />

KV readings. This includes<br />

common <strong>cause</strong>s for long and<br />

short burn times and common<br />

<strong>cause</strong>s for high and low KV<br />

readings.<br />

It’s certainly pleasing to see<br />

a user manual that makes<br />

sense, and that educates the<br />

reader at the same time.<br />

Rest assured that this<br />

little diagnostic gem was<br />

purchased by this workshop<br />

and is now one of the most<br />

used diagnostic tools for<br />

checking vehicles that are not<br />

running well.<br />

Coil-on-plug, dead<br />

cylinder, no spark<br />

Coil-on-plug, testing position<br />

Coil-on-plug, good cylinder<br />

Spark plug wire, good cylinder<br />

Specifications:<br />

• Measures spark plug voltage<br />

from 0 to 50,000 volts<br />

• Measures spark burn time from<br />

0 to 10 milliseconds<br />

• Special antenna sensor allows<br />

quick testing of coil-on-plug and<br />

coil-near-plug modules, and<br />

easy hook-up to spark plug and<br />

ignition coil wires<br />

• No ground wire connections<br />

required enables fast<br />

troubleshooting<br />

• Multiple diagnostic<br />

applications are described in<br />

a comprehensive handbook<br />

included with the tester<br />

Tachometer function:<br />

• For 1 to 12 cylinders and<br />

suitable for 2 and 4 cycle<br />

engines with special<br />

distributorless ignition system<br />

mode<br />

• Measures from 200 to 20,000<br />

RPM on a 4.5 digit LCD display<br />

• Advanced microcontroller<br />

technology gives 0.5 per cent<br />

accuracy<br />

• Works on coil-on-plug, coilnear-plug,<br />

DIS (distributorless<br />

or waste spark), conventional,<br />

magneto and other spark<br />

ignition system<br />

Simple and easy to use<br />

• Ignition analyser: Place the<br />

antenna’s capacitive sensor<br />

on top of the coil-on-plug<br />

module, or over a spark plug<br />

or ignition coil wire. Spark peak<br />

voltage and spark burn time are<br />

displayed<br />

• Tachometer: Set the number<br />

of cycles and type of ignition<br />

system, and then place the<br />

capacitive sensor either on a<br />

coil-on-plug module or spark<br />

plug wire, and RPM is displayed<br />

• Selectable display functions:<br />

<strong>The</strong> display can be set to show<br />

all three (RPM, spark burn<br />

time and spark plug voltage)<br />

measurements simultaneously,<br />

or one of the selected<br />

measurements with real time<br />

maximum and minimum<br />

readings<br />

• Spark capture mode: Maximum<br />

and minimum captures the<br />

spark peak voltage and spark<br />

burn time for testing of ignition<br />

systems for no-start conditions<br />

diagnosis<br />

Information:<br />

Dayle Thomas 0466 909 653<br />

www.olct.co<br />

<strong>The</strong> Automotive Technician 15

‘s a fact<br />

problem solving<br />

FORBA03414<br />

FORD BA<br />

2003<br />

6 Cylinders<br />

Customer Complaint<br />

Losing accessories.<br />

Problem Summary<br />

When the key is turned to start position and released, the key<br />

<strong>does</strong> not spring back to the full ignition and accessory position.<br />

Diagnostic Sequence<br />

Checked the operation of the ignition switch and key.<br />

<strong>The</strong> key felt very rough and would not come back to accessories.<br />

<strong>The</strong> fault was isolated to the ignition switch electrics internally<br />

collapsing.<br />

Fault Description<br />

<strong>The</strong> electrical part of the switch will not come out, only the<br />

barrel and key assembly.<br />

Through Ford, the part is only available by purchasing the<br />

complete steering column assembly.<br />

Fault Solution<br />

A second hand part was located.<br />

<strong>The</strong> original barrel and key assembly was fitted to the<br />

replacement column and refitted to the vehicle.<br />

No programming was required be<strong>cause</strong> of the use of the original<br />

barrel and key assembly.<br />

Recommended Time<br />

Labour time was 3 hours, taking into account research time,<br />

location of parts and actual time spent fixing the problem.<br />

tips for<br />

ideas division<br />

When acquiring a second-hand column make sure it is identical<br />

to the original be<strong>cause</strong> there is a difference between models.<br />

It is the barrel and key housing that varies and the barrels will not<br />

interchange.<br />

Correct position<br />

column unlocked<br />

Make sure the second-hand unit is not in the steering locked<br />

position without the barrel and key, be<strong>cause</strong> this becomes<br />

impossible to unlatch unless you release the pin.<br />

Check TaT’s a fact FORBA04414<br />

<strong>The</strong> Automotive Technician 16

‘s a fact<br />

problem solving<br />

AUDA401114<br />

AUDI A4 1.8T<br />

2001<br />

4 Cylinders<br />

Customer Complaint<br />

Vehicle was overheating.<br />

Problem Summary<br />

Scan tool code relating to coolant<br />

temperature sensor was incorrect.<br />

A new sensor had recently been<br />

fitted.<br />

Diagnostic Sequence<br />

<strong>The</strong> system operation was<br />

checked. <strong>The</strong> engine temperature<br />

climbed beyond the required<br />

levels for fans to cut in. <strong>The</strong>re<br />

was no action from the engine<br />

fans on high or low speeds.<br />

Tested the circuits and found the<br />

signal was going to the control<br />

module (as indicated in pic 3) but<br />

still no fans.<br />

<strong>The</strong> engine fan control module is<br />

located on the fan shroud behind<br />

the radiator on the inner top<br />

passenger side.<br />

Checked both fan motor circuits,<br />

in and out, and had no continuity.<br />

Found both fans internally open<br />

circuited.<br />

Fault Description<br />

<strong>The</strong> fan assembly is located<br />

between the engine and the<br />

radiator.<br />

6<br />

7<br />

To access the fans and<br />

remove the complete<br />

assembly, the front end<br />

has to be disassembled<br />

including the front<br />

bar and headlights so<br />

that the radiator and<br />

condenser section can<br />

be pulled forward.<br />

When the fans and<br />

shroud assembly were<br />

finally removed and<br />

pulled apart they were<br />

found to be totally<br />

worn out. <strong>The</strong>y were<br />

so bad that both of<br />

the commutators were<br />

cut clean by the brush<br />

spring arms.<br />

As can be seen in these<br />

images, the brushes<br />

had broken up, allowing<br />

the springs to contact<br />

the segments and work<br />

as the brush until they<br />

cut right through to the<br />

insulating bakelite.<br />

Fault Solution<br />

A new engine dual fan and<br />

housing assembly was indentified<br />

and supplied. <strong>The</strong> control box had<br />

to be swapped over, the assembly<br />

was refitted and the front end<br />

reassembled. Functions tested<br />

and all were OK.<br />

Recommended Time<br />

Labour time was 8.5 hours,<br />

taking into account research time,<br />

location of parts and actual time<br />

spent fixing the problem.<br />

7<br />

6<br />

<strong>The</strong> Automotive Technician 17

Murphy’s<br />

Law<br />

by Nick Murphy<br />

This is a story of a late model Nissan<br />

Maxima V6 that had a fellow technician<br />

a bit perplexed.<br />

<strong>The</strong> technician had been told that the car had<br />

not started after being switched off the night<br />

before. One would first assume that everything<br />

mechanically had to be OK, if it was switched off<br />

after driving well. <strong>The</strong> vehicle had to be towed to<br />

a TaT workshop for diagnosis.<br />

Was the information received correct? <strong>The</strong><br />

info could be second-hand and could lead a<br />

technician down the wrong path.<br />

Our advice is to listen and then ask basic<br />

questions. In this case, did the car start and run<br />

OK the last time it was driven? Did the car not<br />

start after it was switched off? Did it have enough<br />

fuel and was the driver using the regular key?<br />

<strong>The</strong> answers – the car started and ran normally<br />

until this fault and there was no second key.<br />

A simple deduction could be that the car wouldn’t<br />

have a mechanical fault if it ran normally right<br />

up to switch off. Sometimes drivers might not<br />

know if their vehicles were not running properly<br />

so information like ‘it was running fine yesterday’<br />

may not be accurate.<br />

<strong>The</strong> scan tool showed code P0340, indicating<br />

that one of the cam shaft sensors had a fault and<br />

there was no other indication of anything that<br />

might stop the car from starting.<br />

It was at this point more questions had to<br />

be asked of the original repairer, such as,<br />

had anyone previously checked codes or<br />

disconnected anything prior to us receiving the<br />

vehicle. Yes, they said, the front and rear cam<br />

sensors had been unplugged to do some tests<br />

and there were no codes prior to that.<br />

So the basics, like fuel, injector trigger, spark<br />

and compression were checked. <strong>The</strong> rear spark<br />

plugs are very hard to get to on a V6 Maxima<br />

so only the front three cylinders were tested<br />

for compression and all came back with good<br />

results.<br />

<strong>The</strong>re was fuel pressure and one lot of injector<br />

pulse only for every cylinder when first cranked<br />

over. This occurred every time. <strong>The</strong>re was no<br />

spark or coil trigger at any of the coil-on-plugs,<br />

yet no crank or cam positioning sensor codes<br />

were recorded.<br />

At this point a piece of notepad paper was<br />

spotted on the passenger’s side floor. It was<br />

a road service note on which was scribbled<br />

(P0011) and (P0021). Back to the original repair<br />

for more grilling.<br />

It turned out that the road service was called to<br />

the car before it was towed to the first repairer.<br />

<strong>The</strong>y had used their scan tool, extracted the<br />

codes and cleared them hoping the vehicle<br />

would start, then left the note with the two<br />

numbers, but kept the owner in the dark.<br />

A very crooked diagnostic path<br />

It was at this point the technicians started looking<br />

at the problem from scratch rather than relying<br />

on previous information or expecting that others<br />

had properly checked the basics.<br />

<strong>The</strong> job was to diagnose the problem, give an<br />

accurate report and get the vehicle running<br />

if possible. <strong>The</strong> coolant system level and the<br />

engine oil were checked. <strong>The</strong> oil was down<br />

about 1.5 litres.<br />

<strong>The</strong> importance of the level of oil in this specific<br />

engine and its predisposition to not run if the<br />

oil was low was known to the technicians on<br />

the job. <strong>The</strong> correct type and quantity of oil was<br />

added, but still no go.<br />

<strong>The</strong> blue sig is crank, red is good cam sig<br />

and green is faulty cam sig<br />

Not wishing to guess a solution right then,<br />

the next step was to go for the serious stuff.<br />

<strong>The</strong> code logged was related to cam phasing<br />

issues so why not start there. Scan tool live<br />

data showed an irregularity in the cam phase<br />

percentages. <strong>The</strong> oscilloscope showed the cam<br />

and crank signal patterns were spot on with<br />

good voltage levels and the signal was pulled to<br />

ground. So what was wrong with this car?<br />

One tip when testing components is to increase<br />

the time base on the oscilloscope. It’s like looking<br />

through a bigger window, and the view is more<br />

extensive. Looking at the crank and both cam<br />

signals at the same time, the problems became<br />

more evident. <strong>The</strong> rear bank camshaft was not<br />

in line.<br />

Variable cam shaft timing can be a bit tricky.<br />

<strong>The</strong>re is a lot that can go wrong and it’s not<br />

unusual for the mechanism to seize or lock up.<br />

Poor oil or lack of oil changes are killers in this<br />

area.<br />

In this case, the rear camshaft timing was<br />

misaligned by more than 45 per cent of its basic<br />

idle speed or crank position. <strong>The</strong> back cam<br />

sprocket, which is a two-piece sprocket, had<br />

slipped, so the alignment of the three sensors,<br />

crank and two cams was incorrect. We believe<br />

this was be<strong>cause</strong> the lack of oil to the top of the<br />

motor <strong>cause</strong>d the rear camshaft to start to grab<br />

or seize causing the two-piece sprocket to slip,<br />

similar to some harmonic balancers.<br />

Crank and cam misalignment can be the <strong>cause</strong><br />

of a number of trouble codes in some vehicles.<br />

<strong>The</strong> ECU is programmed to pick up a signal and<br />

work out if it’s within specs and react accordingly.<br />

If a camshaft is out of alignment, some makes of<br />

ECUs won’t have a code criterion for it, so it may<br />

not log a code for the crank or cam sensor. <strong>The</strong><br />

German makes are generally pretty accurate<br />

when it comes to identifying cam misalignment.<br />

You may see common code explanations such<br />

as ‘no correlation between crank and cam, crank<br />

and cam shaft out of time, cam shaft out of<br />

specification or cam shaft not returning to TDC’.<br />

Common faults with misalignment are<br />

sometimes created by an incorrectly fitted timing<br />

belt or variable camshaft mechanism sticking.<br />

<strong>The</strong> quickest way to determine if there is a fault<br />

is by looking at the data on your scan tool. Some<br />

manufacturers have a lot of data involving the<br />

cam timing, such as actual timing compared to<br />

desired timing.<br />

Looking at data can tell you within seconds what<br />

the valve timing is doing. At idle, the cam shaft<br />

will not have moved much. If, for example, the<br />