caution - Toro

caution - Toro

caution - Toro

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Cutting Deck Motor<br />

Removal<br />

1. Park machine on a level surface, lower cutting deck,<br />

stop engine, engage parking brake and remove key<br />

from the ignition switch.<br />

2. Read the General Pre<strong>caution</strong>s for Removing and<br />

Installing Hydraulic System Components at the beginning<br />

of this section.<br />

3. To prevent contamination of hydraulic system during<br />

motor removal, thoroughly clean exterior of motor and<br />

fittings.<br />

5. Remove caps or plugs from fittings and hoses. Connect<br />

hydraulic hoses to deck motor.<br />

6. After assembly is completed, verify that hydraulic<br />

hoses and fittings are not contacted by moving components<br />

through full range of deck movement.<br />

4<br />

1<br />

5<br />

4. Disconnect hydraulic lines from deck motor. Put<br />

caps or plugs on fittings and hoses to prevent contamination.<br />

Label hydraulic lines for proper installation.<br />

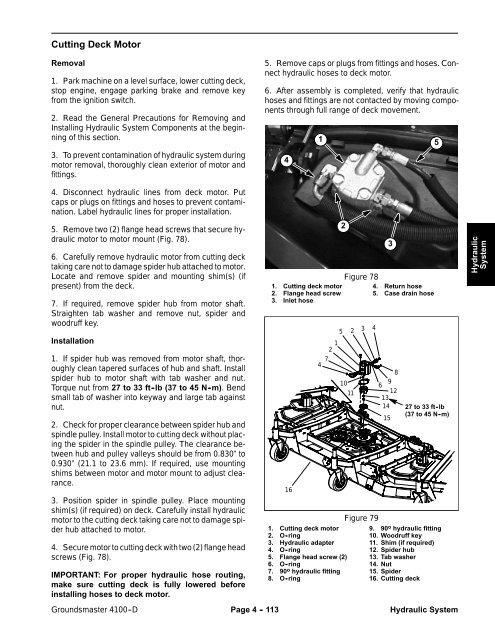

5. Remove two (2) flange head screws that secure hydraulic<br />

motor to motor mount (Fig. 78).<br />

6. Carefully remove hydraulic motor from cutting deck<br />

taking care not to damage spider hub attached to motor.<br />

Locate and remove spider and mounting shim(s) (if<br />

present) from the deck.<br />

7. If required, remove spider hub from motor shaft.<br />

Straighten tab washer and remove nut, spider and<br />

woodruff key.<br />

Installation<br />

1. If spider hub was removed from motor shaft, thoroughly<br />

clean tapered surfaces of hub and shaft. Install<br />

spider hub to motor shaft with tab washer and nut.<br />

Torque nut from 27 to 33 ft -lb (37 to 45 N -m). Bend<br />

small tab of washer into keyway and large tab against<br />

nut.<br />

2. Check for proper clearance between spider hub and<br />

spindle pulley. Install motor to cutting deck without placing<br />

the spider in the spindle pulley. The clearance between<br />

hub and pulley valleys should be from 0.830” to<br />

0.930” (21.1 to 23.6 mm). If required, use mounting<br />

shims between motor and motor mount to adjust clearance.<br />

3. Position spider in spindle pulley. Place mounting<br />

shim(s) (if required) on deck. Carefully install hydraulic<br />

motor to the cutting deck taking care not to damage spider<br />

hub attached to motor.<br />

4. Secure motor to cutting deck with two (2) flange head<br />

screws (Fig. 78).<br />

IMPORTANT: For proper hydraulic hose routing,<br />

make sure cutting deck is fully lowered before<br />

installing hoses to deck motor.<br />

Groundsmaster 4100--D<br />

Page 4 - 113<br />

1. Cutting deck motor<br />

2. Flange head screw<br />

3. Inlet hose<br />

16<br />

7<br />

4<br />

1<br />

2<br />

2<br />

10<br />

1. Cutting deck motor<br />

2. O -ring<br />

3. Hydraulic adapter<br />

4. O -ring<br />

5. Flange head screw (2)<br />

6. O -ring<br />

7. 90 o hydraulic fitting<br />

8. O -ring<br />

Figure 78<br />

5 2<br />

11<br />

3<br />

3<br />

4. Return hose<br />

5. Case drain hose<br />

4<br />

8<br />

9<br />

6<br />

12<br />

13<br />

14<br />

15<br />

27 to 33 ft -lb<br />

(37to45N-m)<br />

Figure 79<br />

9. 90 o hydraulic fitting<br />

10. Woodruff key<br />

11. Shim (if required)<br />

12. Spider hub<br />

13. Tab washer<br />

14. Nut<br />

15. Spider<br />

16. Cutting deck<br />

Hydraulic System<br />

Hydraulic<br />

System