caution - Toro

caution - Toro

caution - Toro

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3. Slowly lower engine into the machine.<br />

4. Align engine to the engine supports and hydraulic<br />

pump input shaft. Secure engine to engine supports with<br />

cap screws, rebound washers and flange nuts.<br />

5. Secure hydraulic pump assembly to engine (see<br />

Pump Assembly Installation in the Service and Repairs<br />

section of Chapter 4 -- Hydraulic System).<br />

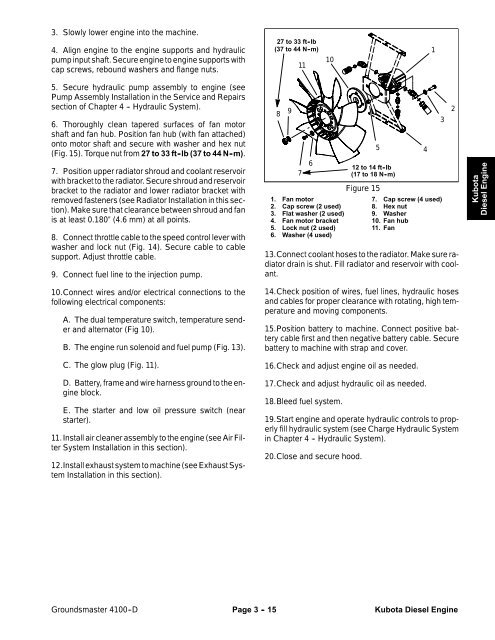

6. Thoroughly clean tapered surfaces of fan motor<br />

shaft and fan hub. Position fan hub (with fan attached)<br />

onto motor shaft and secure with washer and hex nut<br />

(Fig. 15). Torque nut from 27 to 33 ft -lb (37 to 44 N -m).<br />

7. Position upper radiator shroud and coolant reservoir<br />

with bracket to the radiator. Secure shroud and reservoir<br />

bracket to the radiator and lower radiator bracket with<br />

removed fasteners (see Radiator Installation in this section).<br />

Make sure that clearance between shroud and fan<br />

is at least 0.180” (4.6 mm) at all points.<br />

8. Connect throttle cable to the speed control lever with<br />

washer and lock nut (Fig. 14). Secure cable to cable<br />

support. Adjust throttle cable.<br />

9. Connect fuel line to the injection pump.<br />

10.Connect wires and/or electrical connections to the<br />

following electrical components:<br />

A. The dual temperature switch, temperature sender<br />

and alternator (Fig 10).<br />

B. The engine run solenoid and fuel pump (Fig. 13).<br />

C. The glow plug (Fig. 11).<br />

D. Battery, frame and wire harness ground to the engine<br />

block.<br />

E. The starter and low oil pressure switch (near<br />

starter).<br />

11.Install air cleaner assembly to the engine (see Air Filter<br />

System Installation in this section).<br />

12.Install exhaust system to machine (see Exhaust System<br />

Installation in this section).<br />

27 to 33 ft -lb<br />

(37to44N-m)<br />

10<br />

11<br />

8 9<br />

7<br />

6<br />

1. Fan motor<br />

2. Cap screw (2 used)<br />

3. Flat washer (2 used)<br />

4. Fan motor bracket<br />

5. Lock nut (2 used)<br />

6. Washer (4 used)<br />

12 to 14 ft -lb<br />

(17to18N-m)<br />

Figure 15<br />

5 4<br />

1<br />

7. Cap screw (4 used)<br />

8. Hex nut<br />

9. Washer<br />

10. Fan hub<br />

11. Fan<br />

13.Connect coolant hoses to the radiator. Make sure radiator<br />

drain is shut. Fill radiator and reservoir with coolant.<br />

14.Check position of wires, fuel lines, hydraulic hoses<br />

and cables for proper clearance with rotating, high temperature<br />

and moving components.<br />

15.Position battery to machine. Connect positive battery<br />

cable first and then negative battery cable. Secure<br />

battery to machine with strap and cover.<br />

16.Check and adjust engine oil as needed.<br />

17.Check and adjust hydraulic oil as needed.<br />

18.Bleed fuel system.<br />

19.Start engine and operate hydraulic controls to properly<br />

fill hydraulic system (see Charge Hydraulic System<br />

in Chapter 4 -- Hydraulic System).<br />

20.Close and secure hood.<br />

3<br />

2<br />

Kubota<br />

Diesel Engine<br />

Groundsmaster 4100--D Page 3 - 15 Kubota Diesel Engine