PercuFIX us.qxp - Small Bone Innovations

PercuFIX us.qxp - Small Bone Innovations

PercuFIX us.qxp - Small Bone Innovations

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

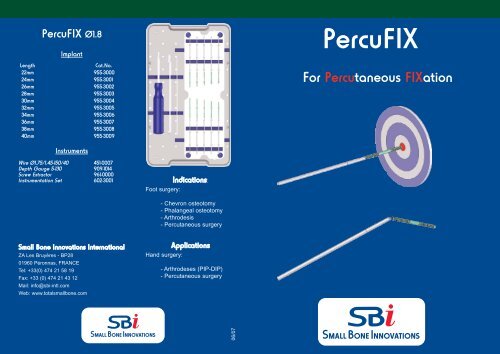

<strong>PercuFIX</strong> Ø1.8<br />

Implant<br />

Length<br />

Cat.No.<br />

22mm 955-3000<br />

24mm 955-3001<br />

26mm 955-3002<br />

28mm 955-3003<br />

30mm 955-3004<br />

32mm 955-3005<br />

34mm 955-3006<br />

36mm 955-3007<br />

38mm 955-3008<br />

40mm 955-3009<br />

<strong>PercuFIX</strong><br />

For Percutaneo<strong>us</strong> FIXation<br />

Instruments<br />

Wire Ø1.75/1.45-150/40 451-0007<br />

Depth Gauge 5-130 909-1014<br />

Screw Extractor 961-0000<br />

Instrumentation Set 602-3001<br />

Indications:<br />

Foot surgery:<br />

- Chevron osteotomy<br />

- Phalangeal osteotomy<br />

- Arthrodesis<br />

- Percutaneo<strong>us</strong> surgery<br />

<strong>Small</strong> <strong>Bone</strong> <strong>Innovations</strong> International<br />

ZA Les Bruyères - BP28<br />

01960 Péronnas, FRANCE<br />

Tel: +33(0) 474 21 58 19<br />

Fax: +33 (0) 474 21 43 12<br />

Mail: info@sbi-intl.com<br />

Web: www.totalsmallbone.com<br />

Applications<br />

Hand surgery:<br />

- Arthrodeses (PIP-DIP)<br />

- Percutaneo<strong>us</strong> surgery<br />

06/07

<strong>PercuFIX</strong> Standard Surgical Technique<br />

<strong>PercuFIX</strong> Surgical Technique for Arthrodesis<br />

1)<br />

2)<br />

A) Direct method<br />

A1) A2)<br />

1) Drill over the two step wires (451-0007)<br />

through both fragments.<br />

3) 4)<br />

2) Measure the screw length with the<br />

direct-reading depth gauge inserted over<br />

the first wire.<br />

A1)Decorticate articular surfaces.<br />

Determine screw length.<br />

A3)<br />

A3) Check for correct positioning and<br />

compression.<br />

A2) Insert <strong>PercuFIX</strong> screw.<br />

A4)<br />

B) To and For method<br />

A4) Break off the shank ONLY if position<br />

and compression are fully satisfactory.<br />

B1) B2)<br />

3) Remove the first wire (the second wire<br />

is left in place to maintain the synthesis of<br />

bone fragments). Drive in the first screw,<br />

taking care to maintain axial alignment.<br />

Advance the screw until the break-off<br />

groove has been reached (color change<br />

point).<br />

5) 6)<br />

4) Measure the second screw length in the<br />

same way.<br />

B1) Decorticate articular surfaces.<br />

Determine screw length.<br />

B3)<br />

B<br />

A<br />

B3) Hold part A to drive the shank (B) into<br />

the distal fragment.<br />

Hold part B and complete retrograde<br />

insertion by reverse screwing.<br />

B2) Perforate the distal bone fragment with<br />

the wire (451-0007).<br />

B4)<br />

B4) Accurately position the two bone<br />

fragments. Drive the screw into the proximal<br />

fragment until the break-off groove reaches<br />

the cortex of the distal fragment.<br />

Check for correct positioning (cf. A3).<br />

Break off shank (cf. A4).<br />

C) Removal<br />

5) Remove the second wire (while the first<br />

screw maintains the synthesis of bone<br />

fragments), and insert the second screw<br />

as previo<strong>us</strong>ly described.<br />

6) Assess fixation before breaking off the<br />

shanks. If fixation is not fully satisfactory,<br />

remove the screws and repeat the<br />

procedure.<br />

C1) C1) Use a small gouge to prepare the entry site for the<br />

screw extractor (961-0000)<br />

-Position the screw extractor in line with the axis of the<br />

screw. If necessary, <strong>us</strong>e image intensification to check for<br />

proper alignment<br />

-Turn counterclockwise so that the extractor engages the<br />

counter threads of the screw over 3 mm and then drives the<br />

screw backward.<br />

WARNING : Disengage the screw from the extractor by<br />

rotating CLOCKWISE : the screw m<strong>us</strong>t be removed prior to<br />

cleaning the instrument.