Downloadable PDF file - Trilogiq

Downloadable PDF file - Trilogiq

Downloadable PDF file - Trilogiq

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

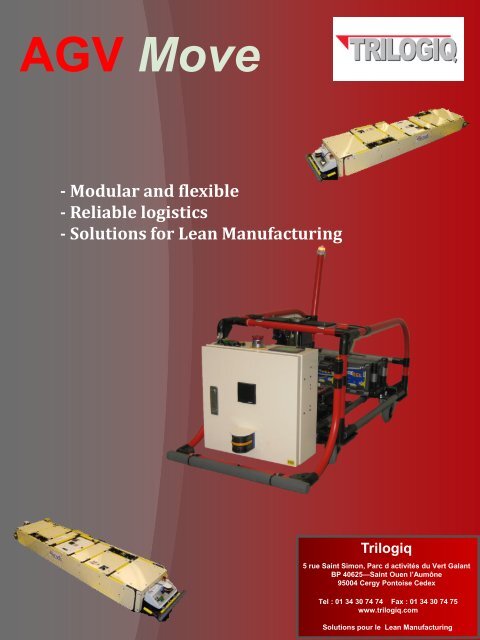

AGV Move<br />

- Modular and flexible<br />

- Reliable logistics<br />

- Solutions for Lean Manufacturing<br />

<strong>Trilogiq</strong><br />

5 rue Saint Simon, Parc d activités du Vert Galant<br />

BP 40625—Saint Ouen l’Aumône<br />

95004 Cergy Pontoise Cedex<br />

Tel : 01 34 30 74 74 Fax : 01 34 30 74 75<br />

www.trilogiq.com<br />

Solutions pour le Lean Manufacturing

AGV Move<br />

Every company experiences problems related to its internal transport.<br />

Whether it is a simple delivery path from point A to point B or the most complex grid<br />

system, the “Lean” philosophy (elimination of the mudas) can apply.<br />

The principles of the AGV (Driverless vehicle, smaller more frequent loads) are a critical<br />

part in the reduction of the cost of transport.<br />

The AGV is used in factories and workshops<br />

to provide logistics support and supply parts<br />

to the assembly lines.<br />

The AGV is also used as a flexible assembly<br />

line by providing transport and conveying<br />

the production tooling.<br />

The AGV Move is constructed using a Lean-<br />

Tek® structure, custom built according to<br />

your needs.<br />

The flexibility of Move<br />

The flexibility of the <strong>Trilogiq</strong> range are ideal for<br />

custom design of your Move for your application.<br />

Move is designed for 3 principal functions:<br />

Easy: Single speed on single path<br />

Standard: 3 speeds on basic multiple path<br />

Professional: Fully programmable<br />

Advantages<br />

- Simplicity of implementation<br />

- Reliable transport<br />

- Easy Maintenance<br />

- Easy to Program via touch screen or PC<br />

- Multiple Functions<br />

- Modular Structure LeanTek®<br />

- Automatic indexing (pop up hook).

AGV Move

AGV Move

AGV Move<br />

Product range<br />

3 Types :<br />

AGV Type 1 “Simple” AGV Type 2 “Standard” AGV Type 3 “Professionnal”<br />

- Automatic Stop<br />

- Manual Restarting<br />

- Single fixed speed<br />

- Automatic Stop<br />

- Manual Restarting<br />

- 3 preset speeds<br />

- Management of simple Paths<br />

Capacity of 64 programs managing:<br />

- Multiple Speeds<br />

- The complexity of the course<br />

- The automatic stop<br />

- The automatic indexing carriages<br />

- Obstacle Sensor patterns and<br />

parameters<br />

- Management of junctions (to turn<br />

right/left)<br />

- Shifting of speed (from 3 to 50<br />

m/min) between tags<br />

- Automatic Change of zones of the<br />

programmable obstacle sensor of<br />

obstacle<br />

- Melody on / off<br />

- Raising and lowering of the<br />

indexing device (pop up hook)<br />

- Change of programmed paths<br />

- Start/stop by remote control<br />

- Loading/unloading<br />

The optimal capacity of the MOVE is reached in towing mode, the carrying mode has a load capacity<br />

of 65% compared to the towing mode.<br />

AGV Type 1 / 2 / 3 Towing Carrying<br />

Réf : 400 Kg 400 Kg 250 Kg<br />

Réf : 750 Kg 750 Kg 400 Kg<br />

Réf : 1 000 Kg 1 000 Kg 650 Kg

AGV Move<br />

Standard elements<br />

This unit is driven<br />

by two individual<br />

brushless motors.<br />

MOVE control box with<br />

Data and PBS Ports<br />

Light signal informing<br />

status of the MOVE<br />

PX-22<br />

Fixed area photoelectric<br />

personnel and obstacle<br />

detector<br />

Contact with the bump<br />

trip stops the MOVE<br />

unit<br />

Several types of obstacle detectors<br />

PX 22 : Stops MOVE if<br />

an obstacle is detected<br />

within a radius of<br />

1 meter<br />

Optional Elements<br />

PBS : Detector has 15<br />

Different programmable<br />

patterns, with a sweep<br />

of 180°<br />

S300 : Infra-red, fully<br />

programmable optical<br />

sensor scanning a<br />

270°field<br />

8 bit communication unit<br />

for interfacing the MOVE<br />

with an adjacent machine<br />

Remote control: For remote<br />

starting of the AGV.<br />

Touch screen panel for<br />

parameter adjustment of<br />

the MOVE Type 1 &<br />

Type 2 units.<br />

Additional sensing for<br />

the side of the vehicle.<br />

Stops the MOVE if whisker<br />

meets an obstacle