A publication of the James F. Lincoln Arc Welding Foundation

A publication of the James F. Lincoln Arc Welding Foundation

A publication of the James F. Lincoln Arc Welding Foundation

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

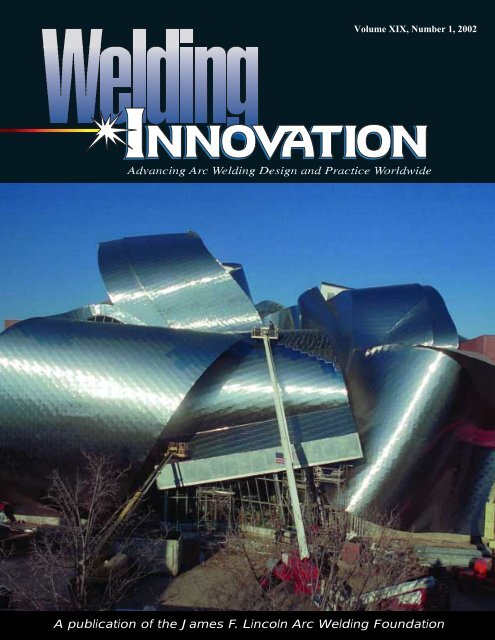

Volume XIX, Number 1, 2002<br />

A <strong>publication</strong> <strong>of</strong> <strong>the</strong> <strong>James</strong> F. <strong>Lincoln</strong> <strong>Arc</strong> <strong>Welding</strong> <strong>Foundation</strong>

Continuing <strong>the</strong> Tradition…<br />

It was with humility that I recently accepted<br />

Duane Miller’s <strong>of</strong>fer to assist in <strong>the</strong> editing <strong>of</strong><br />

<strong>Welding</strong> Innovation. This was true because I did<br />

not think it would be possible for me to fill <strong>the</strong><br />

position left vacant by my predecessor Scott<br />

Funderburk. He covered <strong>Welding</strong> Innovation<br />

for several years as assistant editor, and he<br />

mentored well under Duane’s watchful eye. I<br />

would expect that Scott will be sorely missed<br />

here in <strong>the</strong> application engineering department<br />

and by our readership. We all wish him <strong>the</strong> very<br />

best in his new assignment.<br />

As is certainly <strong>the</strong> case with <strong>the</strong> roles <strong>of</strong> most<br />

pr<strong>of</strong>essionals employed in industry today, we are<br />

required to wear many hats, and my primary<br />

position as senior application engineer has<br />

dovetailed nicely with my additional responsibility<br />

to <strong>Welding</strong> Innovation. The irony <strong>of</strong> this is that<br />

nearly twenty years ago, I was asked to assist<br />

<strong>the</strong> former editor, Richard Sabo, by suggesting a<br />

name for this <strong>publication</strong>. We finally settled on<br />

The <strong>Welding</strong> Innovation Quarterly, and that<br />

name became synonymous with high-quality,<br />

creative design engineering concepts coupled<br />

with fundamentally strong welding principles. If<br />

you needed answers to tough problems, <strong>the</strong>n in<br />

return we were prepared as a group to provide<br />

high quality information. In principle, it is our<br />

objective to continue <strong>the</strong> rich tradition <strong>of</strong><br />

<strong>Welding</strong> Innovation, and I would like to suggest<br />

that <strong>the</strong> articles in this issue <strong>of</strong> <strong>the</strong> magazine<br />

reflect our commitment to that objective.<br />

Pr<strong>of</strong>essor Henry Petroski’s contribution to this<br />

issue, “The Fall <strong>of</strong> Skyscrapers,” provides an<br />

analysis <strong>of</strong> <strong>the</strong> collapse <strong>of</strong> <strong>the</strong> World Trade<br />

Center towers resulting from <strong>the</strong> September 11<br />

terrorist attack. In addition, Pr<strong>of</strong>essor Petroski<br />

provides us with ideas regarding future design<br />

considerations, and <strong>the</strong> practicality <strong>of</strong> future<br />

skyscraper construction. In contrast, contributing<br />

writer Carla Rautenberg provides an article that<br />

presents Frank Gehry’s free-form design <strong>of</strong> <strong>the</strong><br />

Peter B. Lewis Building at <strong>the</strong> Wea<strong>the</strong>rhead<br />

School <strong>of</strong> Management located on <strong>the</strong> Case<br />

Western Reserve University campus. The compelling<br />

design <strong>of</strong> <strong>the</strong> newly constructed Gehry<br />

design is a clear break from <strong>the</strong> historical<br />

constraints <strong>of</strong> rectangular designed structures.<br />

We are confident that this issue <strong>of</strong> <strong>Welding</strong><br />

Innovation will be thought-provoking, and we<br />

encourage your innovative input for future issues.<br />

I especially urge you to consider sharing with our<br />

readers <strong>the</strong> value <strong>of</strong> your own experience, in <strong>the</strong><br />

form <strong>of</strong> a submission to <strong>the</strong> “Lessons Learned in<br />

<strong>the</strong> Field” column initiated by our senior design<br />

consultant, Omer W. Blodgett. See page 18 for<br />

ano<strong>the</strong>r <strong>of</strong> Omer’s timeless and valuable engineering<br />

lessons.<br />

Jeff Nadzam<br />

Assistant Editor<br />

Australia and New Zealand<br />

Raymond K. Ryan<br />

Phone: 61-2-4862-3839<br />

Fax: 61-2-4862-3840<br />

INTERNATIONAL SECRETARIES<br />

Croatia<br />

Pr<strong>of</strong>. Dr. Slobodan Kralj<br />

Phone: 385-1-61-68-222<br />

Fax: 385-1-61-56-940<br />

Russia<br />

Dr. Vladimir P. Yatsenko<br />

Phone: 077-095-737-62-83<br />

Fax: 077-093-737-62-87

Cover: With a shimmering stainless steel<br />

skin concealing its intricate welded structure,<br />

<strong>the</strong> ro<strong>of</strong> <strong>of</strong> <strong>the</strong> almost-completed Peter B.<br />

Lewis Building at Case Western Reserve<br />

University definitely makes an architectural<br />

statement. See story on page 20.<br />

Omer W. Blodgett, Sc.D., P.E.<br />

Design Consultant<br />

Volume XIX<br />

Number 1, 2002<br />

Editor<br />

Duane K. Miller,<br />

Sc.D., P.E.<br />

Assistant Editor<br />

Jeff R. Nadzam<br />

The <strong>James</strong> F. <strong>Lincoln</strong><br />

<strong>Arc</strong> <strong>Welding</strong> <strong>Foundation</strong><br />

The views and opinions<br />

expressed in <strong>Welding</strong><br />

Innovation do not necessarily<br />

represent those <strong>of</strong><br />

The <strong>James</strong> F. <strong>Lincoln</strong> <strong>Arc</strong><br />

<strong>Welding</strong> <strong>Foundation</strong> or The<br />

<strong>Lincoln</strong> Electric Company.<br />

The serviceability <strong>of</strong> a<br />

product or structure utilizing<br />

<strong>the</strong> type <strong>of</strong> information<br />

presented herein is, and<br />

must be, <strong>the</strong> sole responsibility<br />

<strong>of</strong> <strong>the</strong> builder/user.<br />

Many variables beyond <strong>the</strong><br />

control <strong>of</strong> The <strong>James</strong> F.<br />

<strong>Lincoln</strong> <strong>Arc</strong> <strong>Welding</strong><br />

<strong>Foundation</strong> or The <strong>Lincoln</strong><br />

Electric Company affect <strong>the</strong><br />

results obtained in applying<br />

this type <strong>of</strong> information.<br />

These variables include,<br />

but are not limited to, welding<br />

procedure, plate chemistry<br />

and temperature,<br />

weldment design, fabrication<br />

methods, and service<br />

requirements.<br />

Features<br />

2 Orthotropic Design Meets Cold Wea<strong>the</strong>r Challenges<br />

This overview <strong>of</strong> orthotropic steel deck bridges discusses a number<br />

<strong>of</strong> examples that have been built in Norway, Russia, Sweden and Ukraine.<br />

12 The Fall <strong>of</strong> Skyscrapers<br />

In an article reprinted from American Scientist, Duke University Pr<strong>of</strong>essor<br />

Henry Petroski considers some ramifications <strong>of</strong> <strong>the</strong> collapse <strong>of</strong> <strong>the</strong> World Trade<br />

Center towers on <strong>the</strong> future skylines <strong>of</strong> <strong>the</strong> world’s cities.<br />

20 Gleaming “Waterfall” Refreshes Urban Campus<br />

The work <strong>of</strong> architect Frank Gehry inspires controversy and excitement<br />

as <strong>the</strong> new home <strong>of</strong> Case Western Reserve University’s Wea<strong>the</strong>rhead School<br />

nears completion in Cleveland, Ohio.<br />

Departments<br />

7 Design File: Designing Fillet Welds for Skewed T-Joints, Part 1<br />

11 Opportunities: <strong>Lincoln</strong> Electric Technical Programs<br />

17 Opportunities: <strong>Lincoln</strong> Electric Pr<strong>of</strong>essional Programs<br />

18 Lessons Learned in <strong>the</strong> Field: Consider <strong>the</strong> Transfer <strong>of</strong> Stress<br />

through Members<br />

Visit us online at www.<strong>Welding</strong>Innovation.com<br />

THE JAMES F. LINCOLN ARC WELDING FOUNDATION<br />

Dr. Donald N. Zwiep, Chairman<br />

Orange City, Iowa<br />

John Twyble, Trustee<br />

Mosman, NSW, Australia<br />

Duane K. Miller, Sc.D., P.E.<br />

Executive Director & Trustee<br />

Roy L. Morrow<br />

President<br />

<strong>Welding</strong> Innovation Vol. XIX, No. 1, 2002<br />

1

Orthotropic Design Meets Cold Wea<strong>the</strong>r Challenges<br />

An Overview <strong>of</strong> Orthotropic Steel Deck Bridges in Cold Regions<br />

By Alfred R. Mangus, P.E.<br />

Transportation Engineer, Civil<br />

California Dept. <strong>of</strong> Transportation (CALTRANS)<br />

Sacramento, California<br />

Introduction<br />

Initially developed by German engineers<br />

following World War II, orthotropic<br />

bridge design was a creative response<br />

to material shortages during <strong>the</strong> postwar<br />

period. Lightweight orthotropic steel<br />

bridge decks not only <strong>of</strong>fered excellent<br />

structural characteristics, but were also<br />

economical to build (Troitsky 1987).<br />

Moreover, <strong>the</strong>y could be built in cold<br />

climates at any time <strong>of</strong> <strong>the</strong> year.<br />

Engineers from around <strong>the</strong> world utilize<br />

this practical and economic system for<br />

all types <strong>of</strong> bridges. While concrete<br />

must be at or above 5 degrees Celsius<br />

to properly cure, it is physically possible<br />

to encapsulate and heat <strong>the</strong> concrete<br />

construction process; admittedly, this<br />

adds to construction costs (Mangus<br />

1988), (Mangus 1991).<br />

Orthotropic steel deck bridges have<br />

proven to be durable in cold regions.<br />

The orthotropic steel deck integrates<br />

<strong>the</strong> driving surface as part <strong>of</strong> <strong>the</strong><br />

superstructure, and has <strong>the</strong> lowest<br />

total mass <strong>of</strong> any practicable system.<br />

In Europe, where <strong>the</strong> advantages <strong>of</strong><br />

orthotropic design have been<br />

embraced with enthusiasm, <strong>the</strong>re are<br />

more than 1,000 orthotropic steel deck<br />

bridges. In all <strong>of</strong> North America, <strong>the</strong>re<br />

are fewer than 100 bridges <strong>of</strong><br />

orthotropic design.<br />

This article will give an overview <strong>of</strong><br />

imaginative steel deck bridges currently<br />

in operation in Norway, Russia,<br />

Sweden, and Ukraine. The examples<br />

Figure 1. Rib designs.<br />

cover a matrix <strong>of</strong> rib types, superstructure<br />

types and various bridge types.<br />

Russia has developed a mass manufactured<br />

panelized orthotropic deck<br />

system and has devised special<br />

launching methods for cold regions.<br />

Russian engineers prefer <strong>the</strong> open rib<br />

design and have industrialized this<br />

system, while most o<strong>the</strong>r engineers<br />

prefer <strong>the</strong> closed rib. Researchers, as<br />

well as <strong>the</strong> owners <strong>of</strong> orthotropic steel<br />

deck bridges, continue to monitor <strong>the</strong><br />

performance <strong>of</strong> various rib types<br />

(Figure 1).<br />

In Norway<br />

Nordhordland Floating Bridge<br />

The Nordhordland Bridge across <strong>the</strong><br />

Salhus fjord is Norway’s second floating<br />

bridge and <strong>the</strong> world’s largest floating<br />

bridge (Meaas, Lande, and Vindoy,<br />

1994). The bridge was opened for traffic<br />

in 1994. The total bridge length is<br />

1615 m and consists <strong>of</strong> a high level<br />

369 m long cable stayed bridge and a<br />

1246 m long floating bridge (Figure 2).<br />

The floating bridge consists <strong>of</strong> a steel<br />

box girder, which is supported on ten<br />

concrete pontoons and connected to<br />

abutments with transition elements in<br />

forged steel. The main elements are a<br />

high-level cable stayed bridge providing<br />

a ship channel and a floating<br />

bridge between <strong>the</strong> underwater rock<br />

Klauvaskallen and <strong>the</strong> o<strong>the</strong>r side <strong>of</strong><br />

<strong>the</strong> fjord. The cable stayed bridge provides<br />

a clear ship channel. A 350 m<br />

long ramp is required to transition from<br />

<strong>the</strong> higher bridge deck on <strong>the</strong> cable<br />

2 <strong>Welding</strong> Innovation Vol. XIX, No. 1, 2002<br />

Figure 2. Nordhordland Floating Bridge across Salhus fjord <strong>of</strong> Norway.

stayed bridge to <strong>the</strong> bridge deck 11 m<br />

above <strong>the</strong> waterline. The steel box<br />

girder <strong>of</strong> <strong>the</strong> floating bridge forms a<br />

circular arch with a radius <strong>of</strong> 1,700 m<br />

in <strong>the</strong> horizontal plane. The supporting<br />

pontoons are positioned with a center<br />

distance <strong>of</strong> 113 m and act as elastic<br />

supports for <strong>the</strong> girder, which is<br />

designed without internal hinges. The<br />

bridge follows <strong>the</strong> tidal variations by<br />

elastic deformations <strong>of</strong> <strong>the</strong> girder.<br />

The steel box girder is <strong>the</strong> main loadcarrying<br />

element <strong>of</strong> <strong>the</strong> bridge (Figure<br />

3). The octagon girder is 5.5 m high<br />

and 13 m wide. The free height below<br />

<strong>the</strong> girder down to <strong>the</strong> waterline is 5.5<br />

m and this allows for passage <strong>of</strong> small<br />

boats. The plate thickness varies from<br />

14 mm to 20 mm. The plate stiffeners<br />

are in <strong>the</strong> traditional trapezoidal shape<br />

and <strong>the</strong>y span in <strong>the</strong> longitudinal direction<br />

<strong>of</strong> <strong>the</strong> girder. The stiffeners are<br />

supported by cross-frames with center<br />

distance <strong>of</strong> maximum 4.5 m. At <strong>the</strong><br />

supports on <strong>the</strong> pontoons, bulkheads<br />

are used instead <strong>of</strong> cross-frames. This<br />

is done because <strong>the</strong> loads in <strong>the</strong>se<br />

sections are significantly larger than in<br />

<strong>the</strong> cross-frames. The plate thickness<br />

Figure 3. Nordhordland Floating<br />

Bridge.<br />

in <strong>the</strong> bulkheads varies from 8 mm to<br />

50 mm. The box girder is constructed<br />

in straight elements with lengths varying<br />

from 35 m to 42 m. The elements<br />

are welded toge<strong>the</strong>r with a skew angle<br />

<strong>of</strong> 1.2° to 1.3° to accommodate <strong>the</strong><br />

arch curvature in <strong>the</strong> horizontal plane.<br />

The cross section dimensions <strong>of</strong> <strong>the</strong><br />

octagonal box girder are constant for<br />

<strong>the</strong> length <strong>of</strong> <strong>the</strong> bridge.<br />

The stress level varies significantly<br />

over <strong>the</strong> length <strong>of</strong> <strong>the</strong> bridge. In <strong>the</strong><br />

areas with <strong>the</strong> highest stresses, steel<br />

with a yield strength <strong>of</strong> 540 MPa is<br />

used.<br />

Orthotropic bridge design<br />

was a creative response<br />

to material shortages<br />

during <strong>the</strong> postwar period<br />

In <strong>the</strong> remainder <strong>of</strong> <strong>the</strong> bridge (in <strong>the</strong><br />

cross-frames and bulkheads) normalized<br />

steel with yield strength <strong>of</strong> 355<br />

MPa is used. The total steel weight <strong>of</strong><br />

<strong>the</strong> box girder is 12,500 tons, <strong>of</strong> which<br />

approximately 3,000 tons are high<br />

strength steel. The elevated ramp is<br />

approximately 350 m long and has a<br />

grade <strong>of</strong> 5.7 percent (Figure 4). The<br />

elevated ramp is constructed with an<br />

orthotropic plate deck 12 mm thick<br />

and has 8 mm and 10 mm thick trapezoidal<br />

ribs 800 mm deep. T-shaped<br />

crossbeams support <strong>the</strong> ribs with a<br />

maximum center distance <strong>of</strong> 4.5 m.<br />

The main 1,200 mm deep box girders<br />

are located one at each edge <strong>of</strong> <strong>the</strong><br />

ramp in order to maximize <strong>the</strong> stiffness<br />

about a vertical axis. The steel weight<br />

<strong>of</strong> <strong>the</strong> ramp is 1,600 tons.<br />

Figure 4. Nordhordland Floating<br />

Bridge.<br />

Bybrua Bridge<br />

The Bybrua cable stayed bridge has a<br />

main span <strong>of</strong> 185 m. The 15.5 m wide<br />

roadway superstructure was fabricated<br />

in <strong>the</strong> shop in 9.0 m sections (Figure 5).<br />

There is a combined pedestrian plus<br />

bicycles area on each side <strong>of</strong> <strong>the</strong> three<br />

traffic lanes. The cross section <strong>of</strong> <strong>the</strong><br />

main span has a deck-plate 12 mm<br />

thick, but this increases to 16 and 20<br />

mm at <strong>the</strong> cable anchorage. The bottom<br />

plate varies between 8 mm and<br />

10 mm thickness, and <strong>the</strong> webs<br />

between 12 mm and 20 mm. At<br />

intervals <strong>of</strong> 3.0 m <strong>the</strong>re are frames<br />

supporting <strong>the</strong> longitudinal stiffening<br />

system. In <strong>the</strong> bridge deck this is<br />

made up <strong>of</strong> standard trapezoidal ribs<br />

Figure 5. Bybrua Bridge.<br />

<strong>Welding</strong> Innovation Vol. XIX, No. 1, 2002 3

from <strong>the</strong> German steel company<br />

Krupp, and in <strong>the</strong> bottom flange box<br />

section <strong>of</strong> bulb flats open ribs were utilized<br />

(Aune and Holand 1981). In <strong>the</strong><br />

longitudinal direction <strong>the</strong> deck was<br />

divided into six fabricated sections,<br />

two <strong>of</strong> which were welded to <strong>the</strong> web<br />

sections. The box bottom was fabricated<br />

as three sections. The total steel<br />

weight is about 1,100 tons. All elements<br />

prefabricated in <strong>the</strong> shop were<br />

welded, as were <strong>the</strong> field splices in <strong>the</strong><br />

deck, whereas “Huck” high tensile<br />

bolts were used in all o<strong>the</strong>r field joints.<br />

All field joints were calculated as friction<br />

connections. The whole steel<br />

structure is metallized with zinc and<br />

painted according to <strong>the</strong> specifications<br />

<strong>of</strong> <strong>the</strong> Norwegian Public Roads<br />

Administration. The superstructure<br />

received <strong>the</strong> maximum live load<br />

stresses during <strong>the</strong> erection <strong>of</strong> <strong>the</strong><br />

bridge. The wearing surface <strong>of</strong> <strong>the</strong><br />

bridge deck is <strong>the</strong> same as that developed<br />

by <strong>the</strong> Danish State Road<br />

Laboratories for <strong>the</strong> Lillebelt Bridge <strong>of</strong><br />

Denmark.<br />

Storda and Bomla Bridges<br />

The “Triangle Link” project connects<br />

three islands <strong>of</strong>f <strong>the</strong> Norwegian coast<br />

south <strong>of</strong> Belgen to <strong>the</strong> mainland with<br />

three bridges (Larson and Valen<br />

Researchers continue<br />

to monitor <strong>the</strong> performance<br />

<strong>of</strong> various rib types<br />

2000). The entire project was completed<br />

in April 2001. The two orthotropic<br />

steel deck suspension bridges are<br />

known as <strong>the</strong> Storda Bridge and <strong>the</strong><br />

Bomla Bridge. The Storda Bridge is<br />

1,076 m long, has a main span <strong>of</strong> 677<br />

m, with towers 97 m high and a vertical<br />

clearance <strong>of</strong> 18 m (Figure 6). The<br />

Bomla Bridge is 990 m long with a<br />

main span <strong>of</strong> 577 m and <strong>the</strong> tower<br />

height is 105 m. The roadway <strong>of</strong> both<br />

bridges is 9.7 m wide. Scanbridge AS<br />

<strong>of</strong> Norway fabricated <strong>the</strong> Bomla<br />

Bridge’s steel approach superstructure,<br />

which was launched out over <strong>the</strong><br />

tops <strong>of</strong> <strong>the</strong> columns from <strong>the</strong> shore.<br />

The steel components for <strong>the</strong> main<br />

span superstructure <strong>of</strong> <strong>the</strong> Storda<br />

Bridge were prefabricated in <strong>the</strong><br />

Ne<strong>the</strong>rlands (Figure 6) and <strong>the</strong> main<br />

span superstructure <strong>of</strong> <strong>the</strong> Bomla<br />

Bridge was prefabricated in Italy. The<br />

orthotropic ribs for <strong>the</strong> Storda Bridge<br />

were prefabricated in France. The<br />

orthotropic sections were transported<br />

to <strong>the</strong> site by barge, and were lifted<br />

into position by a crane.<br />

Figure 6. Storda Bridge.<br />

In Russia<br />

Russian engineers have standardized<br />

<strong>the</strong>ir orthotropic deck plates using<br />

open or flat plate ribs as shown in<br />

Figure 1. They have several launching<br />

solutions or standardized methods for<br />

pushing <strong>the</strong> superstructure across a<br />

river or gorge. There are a limited<br />

number <strong>of</strong> bridge case histories documented<br />

in English, but <strong>the</strong>y provide an<br />

overall view <strong>of</strong> Russian techniques<br />

(Blank, Popov, and Seliverstov 1999).<br />

In <strong>the</strong> city <strong>of</strong> Arkhangel, Russia, a vertical<br />

lift record span bridge <strong>of</strong> 120.45<br />

m was completed in 1990 (Stepanov<br />

1991). The Berezhkovsky twin parallel<br />

bridges are multi-cell box girder<br />

bridges consisting <strong>of</strong> three spans <strong>of</strong><br />

110 m + 144.5 m +110 m. Each bridge<br />

has four traffic lanes 3.75 m wide.<br />

These bridges were <strong>the</strong> first to be<br />

launched with inclined webs<br />

(Surovtsev, Pimenov, Seliverstov, and<br />

Iourkine 2000).<br />

Oka Bridge<br />

The four-lane orthotropic twin box<br />

girder bridge crossing <strong>the</strong> Oka River<br />

on <strong>the</strong> bypass freeway around <strong>the</strong> city<br />

<strong>of</strong> Gorki, Russia, was opened to traffic<br />

in 1991 (Figure 7). The 966 m long<br />

superstructure consists <strong>of</strong> 2 spans x<br />

84 m + 5 spans x 126 m + 2 spans x<br />

84 m (Design Institute Giprotransmost<br />

1991). This bridge is a single continuous<br />

superstructure with a fixed bearing<br />

420 m away from one <strong>of</strong> <strong>the</strong> abutments.<br />

The total bridge width (29.5 m<br />

including steel traffic barriers) provides<br />

two sidewalks 1.5 m wide each, four<br />

traffic lanes, four safety shoulders and<br />

a center median. The total weight <strong>of</strong><br />

steel for <strong>the</strong> superstructure is 10,635<br />

tons, or 373 kg/m2. The orthotropic<br />

steel superstructure comprises five<br />

basic elements (Figure 7). There are<br />

two main box girders assembled from<br />

two L-shaped sections for <strong>the</strong> bottom<br />

face and sides. The intermediate<br />

orthotropic plate sections were used<br />

for <strong>the</strong> top flange <strong>of</strong> <strong>the</strong> two box girders,<br />

as well as <strong>the</strong> majority <strong>of</strong> <strong>the</strong><br />

deck. The end sections <strong>of</strong> <strong>the</strong><br />

orthotropic plate were panelized with<br />

tapered ends, because only sidewalk<br />

loading is required. The transverse<br />

diaphragms are steel trusses between<br />

<strong>the</strong> box girders. The diaphragms<br />

required extra steel beams at <strong>the</strong> bottom<br />

flange <strong>of</strong> <strong>the</strong> box girder above <strong>the</strong><br />

bearings. The main box girder was<br />

shop fabricated in L-shaped sections<br />

that are 21 m long and 3.6 m deep.<br />

The intermediate orthotropic welded<br />

steel deck plate was shop fabricated in<br />

panelized sections 2.5 m wide and<br />

11.5 m long.<br />

The longitudinal ribs <strong>of</strong> <strong>the</strong> orthotropic<br />

deck and steel box girders are flat rib<br />

plates spaced at 0.35 m, and <strong>the</strong><br />

spacing <strong>of</strong> transverse ribs is 3.0 m for<br />

both components. The stiffening ribs <strong>of</strong><br />

<strong>the</strong> main girder are located on both<br />

sides <strong>of</strong> every web. The vertical split-T<br />

ribs <strong>of</strong> <strong>the</strong> box girders were aligned<br />

with <strong>the</strong> transverse ribs <strong>of</strong> <strong>the</strong> ribbed<br />

plate, thus creating <strong>the</strong> integral internal<br />

diaphragms. The longitudinal stiffening<br />

ribs are at a constant spacing<br />

4 <strong>Welding</strong> Innovation Vol. XIX, No. 1, 2002

Figure 7. Twin box girder bridge crossing <strong>the</strong> Oka River, Russia (split–section).<br />

along <strong>the</strong> bridge. Depending on <strong>the</strong><br />

web thickness, additional vertical stiffening<br />

ribs were required between <strong>the</strong><br />

diaphragms. The superstructure was<br />

erected using “continuous launching”<br />

from one bank <strong>of</strong> <strong>the</strong> Oka River. The<br />

shop-fabricated elements were added<br />

piece by piece to form a continuous<br />

structure at <strong>the</strong> “erection slip” area on<br />

this riverbank. The joints <strong>of</strong> <strong>the</strong> horizontal<br />

sections <strong>of</strong> <strong>the</strong> orthotropic deck<br />

and ribbed plates, as well as <strong>the</strong> joints<br />

<strong>of</strong> <strong>the</strong> web <strong>of</strong> <strong>the</strong> main girder, were<br />

automatically welded. The joints <strong>of</strong> <strong>the</strong><br />

longitudinal ribs <strong>of</strong> <strong>the</strong> ribbed plate<br />

were manually welded. All <strong>the</strong> remaining<br />

joints used high strength bolts.<br />

In Sweden<br />

High Coast Suspension Bridge<br />

The High Coast Suspension Bridge <strong>of</strong><br />

Sweden is almost <strong>the</strong> same size as<br />

San Francisco’s Golden Gate Bridge<br />

(Merging with Nature 1998). The main<br />

span is 1,210 m long with suspended<br />

abutment to abutment where expansion<br />

joints and hydraulic buffers are<br />

located. The 48 box girder sections<br />

were fabricated at a shipyard in<br />

Finland (Pedersen 1997). The standard<br />

section is 20 m long with two<br />

Figure 9. High Coast, Sweden<br />

components.<br />

sets <strong>of</strong> hangers each and weighs 320<br />

tons (Figure 9). The 20 m long panels<br />

for <strong>the</strong> deck, sides and bottom were<br />

fabricated with a maximum width <strong>of</strong> 10<br />

m. They were fabricated from steel<br />

plates, typically 9 to 14 mm thick,10 m<br />

long and 3 to 3.3 m wide. The ribs<br />

were 20 m long trapezoidal ribs with a<br />

plate thickness <strong>of</strong> 6 to 8 mm.<br />

The plates were placed on a plane<br />

and welded in <strong>the</strong> transverse and longitudinal<br />

direction and <strong>the</strong> trough stiffeners<br />

were fitted and welded<br />

longitudinally. Plates connecting <strong>the</strong><br />

panels and <strong>the</strong> diaphragms were welded<br />

between ribs. The 20 m long edge<br />

sections and units for <strong>the</strong> transverse<br />

diaphragm, or bulkhead, were prefabricated.<br />

The bottom and inclined sides<br />

were placed first. Each 4 m deep<br />

transverse diaphragm or bulkhead was<br />

fitted. The edge sections were installed<br />

and finally <strong>the</strong> two deck panels were<br />

placed on top, completing a 20 m long<br />

subsection. The 31 bridge girder sections<br />

for <strong>the</strong> main span were transported<br />

from <strong>the</strong> fabrication yard in Finland<br />

on <strong>the</strong> three barges in <strong>the</strong> same way<br />

as <strong>the</strong> sections for <strong>the</strong> side spans, and<br />

erected with a floating sheerleg crane,<br />

130 m boom, starting from mid-span<br />

and proceeding towards <strong>the</strong> towers<br />

(Edwards and Westergren 1999).<br />

In Ukraine<br />

South Bridge over <strong>the</strong> Dnipro River<br />

The 1992 signature span <strong>of</strong> <strong>the</strong> South<br />

Bridge over <strong>the</strong> Dnipro [Dnepr] River<br />

in Kyiv [Kiev], Ukraine is an unsymmetrical<br />

cable stayed bridge with a<br />

main span <strong>of</strong> 271 m (Korniyiv and.<br />

Fuks 1994). The main span side <strong>of</strong> <strong>the</strong><br />

H-tower is a continuous three-span<br />

steel box girder with orthotropic steel<br />

deck. The back-span superstructure on<br />

<strong>the</strong> opposite side <strong>of</strong> <strong>the</strong> H-tower is a<br />

segmental prestressed concrete box<br />

section. Concrete construction for <strong>the</strong><br />

shorter back span <strong>of</strong> 60 m was used<br />

as a counter-weight mass equal to <strong>the</strong><br />

longer orthotropic main span. The<br />

bridge carries a six-lane roadway, two<br />

rail tracks and four large-diameter<br />

water pipes (Figure 10). The total live<br />

Figure 8. High Coast, Sweden, section.<br />

side spans <strong>of</strong> 310 m and 280 m. The<br />

width <strong>of</strong> <strong>the</strong> roadway is 17.8 m, allowing<br />

for a possible future extension to 4<br />

lanes (Figure 8). The distance<br />

between <strong>the</strong> main cables is 20.8 m<br />

and <strong>the</strong>re are 20 m between <strong>the</strong> hangers.<br />

The girder is continuous through<br />

<strong>the</strong> towers extending 1,800 m from<br />

Figure 10. South Bridge (cable stayed) <strong>of</strong> Ukraine (split–section).<br />

<strong>Welding</strong> Innovation Vol. XIX, No. 1, 2002 5

load is about 246 kN/m. The threespan<br />

(80.5 m + 90 m + 271 m) continuous<br />

steel box girders are made <strong>of</strong><br />

low-alloy steel with a minimum yield<br />

strength <strong>of</strong> 390 MPa.<br />

The bridge was divided into segments<br />

that were shop-welded. Field splices<br />

were ei<strong>the</strong>r welded or joined by highstrength<br />

bolts. Bolting was used where<br />

automatic welding was impractical<br />

because <strong>of</strong> <strong>the</strong> short length <strong>of</strong> <strong>the</strong><br />

weld or difficult access. The cross section<br />

<strong>of</strong> <strong>the</strong> twin two-cell box girder<br />

bridge consists <strong>of</strong> six vertical webs,<br />

<strong>the</strong> upper deck plate and <strong>the</strong> lower<br />

box flanges. The narrow cell is for <strong>the</strong><br />

cable stayed bridge anchorage. In <strong>the</strong><br />

central portion <strong>of</strong> <strong>the</strong> cross section<br />

that carries <strong>the</strong> two hot water supply<br />

pipes, <strong>the</strong> lower flange was omitted to<br />

preclude <strong>the</strong> undesirable effects <strong>of</strong><br />

unequal heating inside a closed box.<br />

The bearings at <strong>the</strong> piers permit lateral<br />

displacement <strong>of</strong> <strong>the</strong> superstructure<br />

because <strong>of</strong> <strong>the</strong> 41.5 m bridge width.<br />

The orthotropic decks, bottom flanges<br />

<strong>of</strong> <strong>the</strong> boxes and <strong>the</strong> webs have open<br />

flat-bar stiffening ribs, a common feature<br />

in Ukrainian and Russian bridges.<br />

Longitudinal flat or open ribs were<br />

placed on <strong>the</strong> top face <strong>of</strong> <strong>the</strong><br />

orthotropic deck plate under <strong>the</strong> rail<br />

tracks, thus avoiding intersections <strong>of</strong><br />

longitudinal and transverse stiffeners.<br />

This facilitated fabrication, at <strong>the</strong> same<br />

time precluding stress concentrations<br />

at crossing welds that would be susceptible<br />

to fatigue under dynamic train<br />

loading. Longitudinal ribs under <strong>the</strong><br />

train tracks have a depth in excess <strong>of</strong><br />

<strong>the</strong> design requirements, which permitted<br />

longitudinal pr<strong>of</strong>ile adjustments<br />

<strong>of</strong> <strong>the</strong> tracks after erection <strong>of</strong> <strong>the</strong><br />

bridge superstructure. The steel girders<br />

were pre-assembled on <strong>the</strong> bank<br />

<strong>of</strong> <strong>the</strong> south and erected by launching.<br />

The twin two-cell box girders were<br />

equipped with a launching nose and<br />

stiffened with a temporary strut system<br />

(Rosignoli1999). Single erection rollers<br />

were used at <strong>the</strong> tops <strong>of</strong> supports and<br />

had a friction factor <strong>of</strong> less than 0.015.<br />

The erection <strong>of</strong> <strong>the</strong> 271 m main span<br />

was accomplished with two false work<br />

supports providing three equal spans<br />

<strong>of</strong> about 90 m. At <strong>the</strong> H-tower <strong>of</strong> <strong>the</strong><br />

cable stayed bridge, hinged conditions<br />

are provided by supports with limited<br />

rotational capability in <strong>the</strong> vertical and<br />

<strong>the</strong> horizontal planes. The torsional<br />

rigidity <strong>of</strong> <strong>the</strong> bridge is supplied by <strong>the</strong><br />

two planes <strong>of</strong> cable stays, plus <strong>the</strong><br />

stiffness <strong>of</strong> <strong>the</strong> closed box sections.<br />

Under one-sided loading <strong>of</strong> <strong>the</strong> bridge<br />

(three traffic lanes), <strong>the</strong> deck cross<br />

slope <strong>of</strong> 0.3% was measured in field<br />

tests, less than <strong>the</strong> calculated value <strong>of</strong><br />

0.35%. Eccentric hinged connections<br />

between <strong>the</strong> bottom flanges <strong>of</strong> <strong>the</strong><br />

stiffening girders and <strong>the</strong> H-tower were<br />

constructed, considerably reducing <strong>the</strong><br />

bending moments in <strong>the</strong> girders.<br />

Conclusion<br />

The foregoing examples illustrate a<br />

range <strong>of</strong> creative responses to <strong>the</strong><br />

challenge <strong>of</strong> designing and constructing<br />

orthotropic steel deck bridges in<br />

cold wea<strong>the</strong>r regions. The versatility,<br />

economy and structural integrity <strong>of</strong><br />

welded orthotropic design undoubtedly<br />

will continue to inspire bridge designers<br />

and structural engineers in <strong>the</strong><br />

21st century.<br />

Figure Credits<br />

Figure 1 from Ballio, G., Mazzolani, F. M. 1983,<br />

“Theory and Design <strong>of</strong> Steel Design Structures,”<br />

Chapman & Hall Ltd. courtesy <strong>of</strong> Dr. Mazzolani;<br />

Figures 2, 3, & 4 courtesy <strong>of</strong> Dr. Ing. A-<br />

Aas–Jakobsen, AS Structural Engineering<br />

Consultants, Oslo, Norway; Figure 5 adapted from<br />

Aune, Petter, and Holand, Ivar (1981); Figure 6<br />

courtesy <strong>of</strong> Mr. L. Adelaide <strong>of</strong> Pr<strong>of</strong>ilafroid, France;<br />

Figures 8 & 9 courtesy <strong>of</strong> Claus Pedersen <strong>of</strong><br />

Mondberg & Thorsen AS, Copenhagen, Denmark;<br />

Figures 7 & 10 courtesy <strong>of</strong> IABSE International<br />

Association <strong>of</strong> Bridge Structural Engineers.<br />

References<br />

Aune, P., Holand, I. (1981) Norwegian Bridge<br />

Building – A Volume Honoring Arne Selberg,<br />

Tapir, Norway<br />

Blank, S. A., Popov, O. A., Seliverstov, V. A., (1999)<br />

“Chapter 66 Design Practice in Russia,” Bridge<br />

Engineering Handbook, 1st ed., Chen, W.F.,<br />

and Duan, L. Editors, CRC Press, Boca Raton<br />

Florida<br />

Design Institute Giprotransmost, (1991) “The<br />

Bridge-Crossing over <strong>the</strong> River Oka on<br />

<strong>the</strong> Bypass Road near Gorki” Structural<br />

Engineering International, IABSE, Zurich,<br />

Switzerland, Vol. 1, Number 1, 14-15<br />

Edwards,Y. & Westergren P., (1999), “Polymer<br />

modified waterpro<strong>of</strong>ing and pavement system<br />

for <strong>the</strong> High Coast Sweden” NordicRoad &<br />

Transport Research No. 2, 28<br />

Korniyiv, M. H. and Fuks, G. B (1994) “The South<br />

Bridge, Kyiv, Ukraine” Structural Engineering<br />

International, IABSE, Zurich, Switzerland, Vol.<br />

4, Number 4, 223-225<br />

Larsen J., and Valen, A., (2000) “Comparison <strong>of</strong><br />

Aerial Spinning versus Locked-Coil Cables<br />

for Two Suspension Bridges (Norway),”<br />

Structural Engineering International, IABSE,<br />

10(3), 128-131<br />

Mangus, A., (1988) “Air Structure Protection <strong>of</strong><br />

Cold Wea<strong>the</strong>r Concrete,” Concrete<br />

International, American Concrete Institute,<br />

Detroit, MI, October 22-27<br />

Mangus, A., (1991) “Construction Activities Inside<br />

<strong>of</strong> Air Structures Protected From <strong>the</strong> <strong>Arc</strong>tic<br />

Environment,” International <strong>Arc</strong>tic Technology<br />

Conference, Society <strong>of</strong> Petroleum Engineers,<br />

Anchorage, AK, May 29-31<br />

Mangus, A, and Shawn, S., (1999) “Chapter 14<br />

Orthotropic Deck Bridges,” Bridge Engineering<br />

Handbook, 1st ed., Chen, W.F., and Duan, L.<br />

Editors, CRC Press, Boca Raton Florida<br />

Mangus, A., (2000) “Existing Movable Bridges<br />

Utilizing Orthotropic Bridge Decks,” 8th Heavy<br />

Movable Bridge Symposium Lake Buena Vista<br />

Florida, Heavy Movable Structures, P. O. Box<br />

398, Middletown, NJ<br />

Merging with Nature – Hoga Kusten [High Coast]<br />

(1998), Bridge Design & Engineering, 10, (1),<br />

50–56<br />

Meaas, P., Lande, E., Vindoy, V., (1994) “Design <strong>of</strong><br />

<strong>the</strong> Salhus Floating Bridge (Nordhordland<br />

Norway),” Strait Crossings 94, Balkema,<br />

Rotterdam ISBN 90-5410 388-4 3(3), 729-734<br />

Pedersen, C., (1997) The Hoga Kusten (High<br />

Coast) Bridge-suspension bridge with 1210 m<br />

main span –construction <strong>of</strong> <strong>the</strong> superstructure,<br />

Mondberg & Thorsen A/S Copenhagen,<br />

Denmark<br />

Rosignoli, M.,(1999) Launched Bridges –<br />

Prestressed Concrete Bridges built on <strong>the</strong><br />

ground and launched into <strong>the</strong>ir final position,<br />

ASCE Press, Reston, VA<br />

Stepanov, G. M., (1991), “Design <strong>of</strong> Movable<br />

Bridges,” Structural Engineering International,<br />

IABSE, Zurich, Switzerland, Volume 1,<br />

Number 1, 9-1<br />

Surovtsev, V., Pimenov, S., Seliverstov, V., &<br />

Iourkine, S, (2000) “Development <strong>of</strong> Structural<br />

Forms and Analysis <strong>of</strong> Steel Box Girders with<br />

inclined webs for operation and erection conditions”<br />

Giprotransmost J.S.Co, Pavla<br />

Kortchagina str. 2, 129278 Moscow, Russian<br />

Federation<br />

Troitsky, M. S., (1987) Orthotropic Bridges - Theory<br />

and Design, 2nd ed., The <strong>James</strong> F. <strong>Lincoln</strong> <strong>Arc</strong><br />

<strong>Welding</strong> <strong>Foundation</strong>, Cleveland, OH<br />

6 <strong>Welding</strong> Innovation Vol. XIX, No. 1, 2002

Design File<br />

Designing Fillet Welds for Skewed T-joints—Part 1<br />

Practical Ideas for <strong>the</strong> Design Pr<strong>of</strong>essional by Duane K. Miller, Sc.D., P.E.<br />

Introduction<br />

Detailing fillet welds for 90-degree T-joints is a fairly<br />

straightforward activity. Take <strong>the</strong> 90-degree T-joint and skew<br />

it—that is, rotate <strong>the</strong> upright member so as to create an<br />

acute and obtuse orientation, and <strong>the</strong> resultant geometry<br />

<strong>of</strong> <strong>the</strong> fillet welds becomes more complicated (see Figure<br />

1). The greater <strong>the</strong> degree <strong>of</strong> rotation, <strong>the</strong> greater <strong>the</strong> difference<br />

as compared to <strong>the</strong> 90-degree counterpart.<br />

A series <strong>of</strong> equations can be used to determine weld sizes<br />

for various angular orientations and required throat dimensions.<br />

Since <strong>the</strong> weld sizes on ei<strong>the</strong>r side <strong>of</strong> <strong>the</strong> joint are<br />

not necessarily required to be <strong>of</strong> <strong>the</strong> same size, <strong>the</strong>re are a<br />

variety <strong>of</strong> combinations that can be used to transfer <strong>the</strong><br />

loads across <strong>the</strong> joint. While <strong>the</strong>re are <strong>the</strong>oretical savings<br />

to be seen by optimizing <strong>the</strong> combinations <strong>of</strong> weld sizes,<br />

rarely do such efforts result in a change in fillet weld size <strong>of</strong><br />

even one standard size.<br />

Codes prescribe different methods <strong>of</strong> indicating <strong>the</strong><br />

required weld size. These are summarized herein.<br />

When acute angles become smaller, <strong>the</strong> difficulty <strong>of</strong><br />

achieving a quality weld in <strong>the</strong> root increases. The AWS<br />

D1.1 Structural <strong>Welding</strong> Code deals with this issue by<br />

requiring <strong>the</strong> consideration <strong>of</strong> a Z-loss factor.<br />

This edition <strong>of</strong> Design File addresses <strong>the</strong> situation where<br />

<strong>the</strong> end <strong>of</strong> <strong>the</strong> upright member in <strong>the</strong> skewed T-joint is parallel<br />

to <strong>the</strong> surface <strong>of</strong> <strong>the</strong> o<strong>the</strong>r member. A future Design<br />

File column will consider <strong>the</strong> situation in which <strong>the</strong> upright<br />

member has a square cut on <strong>the</strong> end, resulting in a gap on<br />

<strong>the</strong> obtuse side. Also to be addressed in <strong>the</strong> future are<br />

weld options o<strong>the</strong>r than fillet welds in skewed T-joints.<br />

LEG<br />

SIZE<br />

DIHEDRAL ANGLE<br />

0<br />

135 MAX<br />

ω 2<br />

ω 1<br />

ψ 2<br />

ω ψ 1<br />

1<br />

f 2<br />

ω 2<br />

b 2 b 1<br />

f 1<br />

t 2<br />

t 1<br />

b 2<br />

b 1<br />

Figure 1. Equal throat sizes (t 1 = t 2 ).<br />

DIHEDRAL<br />

ANGLE<br />

0<br />

60 MIN<br />

The Geometry<br />

Figure 1 provides a visual representation <strong>of</strong> <strong>the</strong> issue. For<br />

<strong>the</strong> 90-degree orientation, <strong>the</strong> weld throat is 70.7% <strong>of</strong> <strong>the</strong><br />

weld leg dimension. This relationship does not hold true for<br />

fillet welds in skewed joints. On <strong>the</strong> obtuse side, <strong>the</strong> weld<br />

throat is smaller than what would be expected for a fillet<br />

weld <strong>of</strong> a similar leg size in a 90-degree joint, and <strong>the</strong><br />

opposite is <strong>the</strong> case for <strong>the</strong> acute side. These factors must<br />

be considered when <strong>the</strong> fillet weld leg size is determined<br />

and specified.<br />

Careful examination <strong>of</strong> <strong>the</strong> fillet welds on <strong>the</strong> skewed joint<br />

raises this question: What is <strong>the</strong> size <strong>of</strong> <strong>the</strong> fillet weld in a<br />

skewed joint?<br />

LEG<br />

SIZE<br />

Figure 1 illustrates <strong>the</strong> fillet weld leg size for a skewed T-<br />

joint, and is designated by “ω.” This, however, is inconsistent<br />

with AWS Terms and Definitions (AWS A3.0-94) which<br />

defines a “fillet weld leg” as “The distance from <strong>the</strong> joint<br />

root to <strong>the</strong> toe <strong>of</strong> <strong>the</strong> fillet weld.” According to this definition,<br />

and as shown in Figure 1, <strong>the</strong> fillet weld leg is dimension<br />

“b.” The dimension that is labeled “ω” is <strong>the</strong> distance from a<br />

member to a parallel line extended from <strong>the</strong> bottom weld<br />

<strong>Welding</strong> Innovation Vol. XIX, No. 1, 2002 7

toe. While not technically correct according to AWS A3.0, it<br />

is <strong>the</strong> dimension and terminology used when fillet welds in<br />

skewed joints are discussed in <strong>the</strong> AWS D1.1 Structural<br />

<strong>Welding</strong> Code, as well as o<strong>the</strong>r AWS <strong>publication</strong>s (i.e., The<br />

<strong>Welding</strong> Handbook, ninth edition, volume 1). Such terminology<br />

will be used here.<br />

This raises an additional question: What would a weld<br />

inspector actually measure when dealing with a fillet weld<br />

in a skewed T-joint? Conventional fillet weld gauges could<br />

be used to measure <strong>the</strong> obtuse side’s fillet weld leg dimension<br />

“ω” as shown in Figure 1. Dimension “b” would be difficult<br />

to measure directly since <strong>the</strong> location <strong>of</strong> <strong>the</strong> weld root<br />

cannot be easily determined. Welds on <strong>the</strong> acute side are<br />

impossible to measure using conventional fillet weld<br />

gauges. The face dimension “f,” however, <strong>of</strong>fers an easy<br />

alternative: when this dimension is known for <strong>the</strong> weld size<br />

and <strong>the</strong> dihedral angle, <strong>the</strong> welder and inspector can easily<br />

determine what <strong>the</strong> actual size is by using a pair <strong>of</strong><br />

dividers. Alternately, a series <strong>of</strong> simple gauges <strong>of</strong> various<br />

widths could be made to directly compare <strong>the</strong> requirements<br />

to <strong>the</strong> actual weld size. Thus, dimension “f” may be important<br />

for controlling weld sizes in skewed T-joints.<br />

When sizing a fillet weld for 90-degree T-joints or skewed T-<br />

joints, <strong>the</strong> starting point is to determine <strong>the</strong> required throat<br />

size needed to resist <strong>the</strong> applied loads. From <strong>the</strong> throat<br />

dimension, <strong>the</strong> fillet weld leg size can be determined. Three<br />

options will be considered:<br />

Where <strong>the</strong> throat size is <strong>the</strong> same on ei<strong>the</strong>r side <strong>of</strong> <strong>the</strong><br />

joint (see Figure 1)<br />

To determine <strong>the</strong> required fillet weld size for a given throat,<br />

<strong>the</strong> following relationship can be used:<br />

ψ<br />

ω = 2 t sin<br />

(<br />

2<br />

) (1)<br />

The width <strong>of</strong> <strong>the</strong> face <strong>of</strong> <strong>the</strong> weld (“f”) can be found from<br />

this equation:<br />

(2)<br />

f = 2 t tan (<br />

ψ<br />

2 )<br />

Dimension “b,” that is, <strong>the</strong> ‘true’ fillet leg size, can be found<br />

from this relationship: t<br />

b =<br />

cos (<br />

ψ<br />

2 )<br />

(3)<br />

Finally, <strong>the</strong> cross-sectional area <strong>of</strong> <strong>the</strong> weld metal can be<br />

determined from <strong>the</strong> following:<br />

A = t 2 tan (<br />

ψ<br />

2 )<br />

(4)<br />

Where <strong>the</strong> leg size is <strong>the</strong> same on both sides<br />

(see Figure 2)<br />

If <strong>the</strong> designer decides to make both welds with <strong>the</strong> same<br />

leg size (as is illustrated in figure 2), <strong>the</strong> first required step<br />

is to determine <strong>the</strong> composite total dimension <strong>of</strong> <strong>the</strong> two<br />

8 <strong>Welding</strong> Innovation Vol. XIX, No. 1, 2002<br />

ω 2<br />

b<br />

ω 1<br />

b<br />

b<br />

t 2<br />

Figure 2. Equal fillet weld leg sizes (ω 1 = ω 2 ).<br />

throat sizes. This dimension “t T ” is <strong>the</strong>n inserted into <strong>the</strong> following<br />

equations to determine <strong>the</strong> two throats “t 1 ” and “t 2 .”<br />

ψ<br />

cos<br />

t 1<br />

= t T<br />

(<br />

1<br />

2 )<br />

ψ<br />

cos (<br />

1<br />

)<br />

ψ<br />

+ cos (<br />

2<br />

)<br />

2<br />

ψ<br />

cos<br />

t 2<br />

= t T<br />

(<br />

2<br />

2 )<br />

ψ<br />

cos (<br />

1<br />

)<br />

ψ<br />

+ cos (<br />

2<br />

)<br />

2<br />

Equations 1 – 4 can be used to find <strong>the</strong> corresponding fillet<br />

weld leg size, face dimension, “b” dimension, and crosssectional<br />

area. These calculations will be made using <strong>the</strong><br />

applicable throat dimension “t” determined from equations<br />

5 and 6, not <strong>the</strong> total throat dimension “t T ” used in equations<br />

5 and 6.<br />

Where a minimum quantity <strong>of</strong> weld metal is used<br />

(see Figure 3)<br />

Even a casual review <strong>of</strong> Figure 1 shows that, when fillet<br />

weld leg sizes are specified to be <strong>of</strong> <strong>the</strong> same size on<br />

ei<strong>the</strong>r side <strong>of</strong> <strong>the</strong> skewed T-joint, <strong>the</strong> use <strong>of</strong> weld metal is<br />

as efficient as could be. Minimum weld metal can be<br />

obtained by taking advantage <strong>of</strong> <strong>the</strong> more favorable condition<br />

that results on <strong>the</strong> acute side where a greater weld<br />

throat can be obtained for <strong>the</strong> same quantity <strong>of</strong> metal that<br />

would be placed on <strong>the</strong> obtuse side.<br />

To minimize <strong>the</strong> volume <strong>of</strong> weld metal used in <strong>the</strong> combination<br />

<strong>of</strong> <strong>the</strong> two welds, <strong>the</strong> following equations may be used<br />

once <strong>the</strong> total throat dimension “t T ” is known:<br />

t 1<br />

=<br />

t 2<br />

=<br />

1 + tan 2 (<br />

1 + tan 2 (<br />

t T<br />

ψ1<br />

)<br />

t T<br />

2<br />

ψ2<br />

)<br />

2<br />

t 1<br />

b<br />

2<br />

2<br />

(5)<br />

(6)<br />

(7)<br />

(8)

Although <strong>the</strong> preceding calculations are not particularly difficult,<br />

Table 1 has been provided to simplify <strong>the</strong> process.<br />

Columns A and B are used to determine fillet weld leg<br />

sizes and face widths for various dihedral angles. To obtain<br />

<strong>the</strong> required fillet weld size, <strong>the</strong> calculated throat is multiplied<br />

by <strong>the</strong> factor in Column A. Face widths can be found<br />

following <strong>the</strong> same procedure.<br />

t 2<br />

b 2<br />

b 1<br />

t 1<br />

If <strong>the</strong> same leg size is desired on ei<strong>the</strong>r side <strong>of</strong> <strong>the</strong> joint,<br />

columns C-E are used. In this case <strong>the</strong> total weld throat “t T ”<br />

is used, as opposed to what was done with columns<br />

A and B.<br />

For <strong>the</strong> minimum weld volume, columns F–H can be used.<br />

Again, <strong>the</strong> total weld throat “t T ” is used.<br />

As will be discussed below, for dihedral angles <strong>of</strong> 30–60<br />

degrees, <strong>the</strong> D1.1 Code requries <strong>the</strong> application <strong>of</strong> a Z-loss<br />

factor. Thus, <strong>the</strong> values in Table 1 that apply to dihedral angles<br />

where this applies are shown in blue numbers to remind <strong>the</strong><br />

user to incorporate this factor into <strong>the</strong> weld throat sizes.<br />

b 2<br />

b 1<br />

Figure 3. Minimum weld volume.<br />

Influence <strong>of</strong> Dihedral Angle<br />

AWS D1.1 Structural <strong>Welding</strong> Code–Steel provides for five<br />

groupings <strong>of</strong> skewed T-joints, depending on <strong>the</strong> range <strong>of</strong><br />

sizes <strong>of</strong> <strong>the</strong> dihedral angle: a) Obtuse angles greater than<br />

100 degrees, b) angles <strong>of</strong> 80–100 degrees, c) acute angles<br />

<strong>of</strong> 60–80 degrees, d) acute angles <strong>of</strong> 30–60 degrees, and<br />

e) acute angles <strong>of</strong> less than 30 degrees. Each is dealt with<br />

in a slightly different manner.<br />

Dihedral Angle<br />

Leg & Face Dimensions<br />

Multipy by t<br />

Table 1.<br />

Same Leg Size<br />

Multipy by t T<br />

Minimum Weld Volume<br />

Multipy by t T<br />

Ψ A B C D E F G H<br />

phi1 deg leg size face width throat leg size face width throat leg size face width<br />

30 0.517 0.536 0.788 0.408 0.422 0.933 0.483 0.536<br />

35 0.601 0.630 0.760 0.457 0.479 0.910 0.547 0.630<br />

40 0.684 0.728 0.733 0.501 0.533 0.883 0.604 0.728<br />

45 0.765 0.828 0.707 0.541 0.585 0.854 0.653 0.828<br />

50 0.845 0.932 0.682 0.576 0.635 0.822 0.694 0.932<br />

55 0.923 1.04 0.657 0.607 0.684 0.787 0.726 1.04<br />

60 1.00 1.15 0.634 0.634 0.731 0.750 0.750 1.15<br />

65 1.07 1.27 0.611 0.656 0.778 0.712 0.764 1.27<br />

70 1.15 1.40 0.588 0.674 0.823 0.671 0.770 1.40<br />

75 1.22 1.53 0.566 0.689 0.868 0.630 0.766 1.53<br />

80 1.29 1.68 0.544 0.699 0.912 0.587 0.755 1.68<br />

85 1.35 1.83 0.522 0.705 0.956 0.544 0.735 1.83<br />

90 1.41 2.00 0.500 0.707 0.999 0.500 0.707 2.00<br />

95 1.47 2.18 0.478 0.705 1.043 0.457 0.673 2.18<br />

100 1.53 2.38 0.456 0.699 1.087 0.414 0.633 2.38<br />

105 1.59 2.60 0.434 0.689 1.131 0.371 0.589 2.60<br />

110 1.64 2.85 0.412 0.675 1.175 0.329 0.540 2.85<br />

115 1.69 3.14 0.389 0.656 1.221 0.289 0.488 3.14<br />

120 1.73 3.46 0.366 0.634 1.267 0.250 0.434 3.46<br />

125 1.77 3.84 0.343 0.608 1.314 0.214 0.379 3.84<br />

130 1.81 4.28 0.318 0.577 1.363 0.179 0.324 4.28<br />

135 1.85 4.82 0.293 0.542 1.413 0.147 0.271 4.82<br />

140 1.88 5.48 0.267 0.502 1.465 0.117 0.221 5.48<br />

145 1.91 6.33 0.240 0.458 1.519 0.091 0.173 6.33<br />

150 1.93 7.44 0.212 0.409 1.576 0.067 0.130 7.44<br />

Blue numbers indicate that Z-loss factors must be considered.<br />

<strong>Welding</strong> Innovation Vol. XIX, No. 1, 2002 9

Obtuse angles greater than 100 degrees<br />

For this category, contract drawings should show <strong>the</strong><br />

required effective throat. Shop drawings are to show <strong>the</strong><br />

required leg dimension, calculated with equation 1, or by<br />

using columns C or D <strong>of</strong> Table 1 (AWS D1.1-2002, para<br />

2.2.5.2, 2.3.3.2).<br />

Angles <strong>of</strong> 80–100 degrees<br />

For this group, shop drawings are required to show <strong>the</strong><br />

fillet leg size (AWS D1.1-2002, para 2.2.5.2). While not<br />

specifically stated in <strong>the</strong> code, <strong>the</strong> assumption is that<br />

contract drawings also show this dimension.<br />

Angles <strong>of</strong> 60–80 degrees<br />

For this category, contract drawings should show <strong>the</strong><br />

required effective throat. Shop drawings are to show <strong>the</strong><br />

required leg dimension (AWS D1.1-2002, para 2.2.5.2,<br />

2.3.3.2)<br />

Angles <strong>of</strong> 30–60 degrees<br />

Contract drawings are to show <strong>the</strong> effective throat. Shop<br />

drawings are required to “show <strong>the</strong> required leg dimensions<br />

to satisfy <strong>the</strong> required effective throat, increased by <strong>the</strong> Z-<br />

loss allowance ... ” (AWS D1.1-2002, para 2.2.5.2, 2.3.3.3).<br />

The Z-loss factor is used to account for <strong>the</strong> likely incidence<br />

<strong>of</strong> poor quality welding in <strong>the</strong> root <strong>of</strong> a joint with a small<br />

included angle. The amount <strong>of</strong> poor quality weld in <strong>the</strong> root<br />

<strong>of</strong> <strong>the</strong> joint is a function <strong>of</strong> <strong>the</strong> dihedral angle, <strong>the</strong> welding<br />

process, and <strong>the</strong> position <strong>of</strong> welding. Table 2.2 <strong>of</strong> D1.1<br />

summarizes this data as contained below:<br />

Table 2. Z-loss dimension.<br />

60 o >Ψ > 45 o FCAW-S 1/8 3 FCAW-S 0 0<br />

FCAW-G 1/8 3 FCAW-G 0 0<br />

Position <strong>of</strong> <strong>Welding</strong> Position <strong>of</strong> <strong>Welding</strong><br />

V or OH<br />

H or F<br />

Dihedral Angle Ψ Process Z (in.) Z (mm) Process Z (in.) Z (mm)<br />

SMAW 1/8 3 SMAW 1/8 3<br />

GMAW N/A N/A GMAW 0 0<br />

45 o >Ψ > 30 o<br />

SMAW 1/4 6 SMAW 1/4 6<br />

FCAW-S 1/4 6 FCAW-S 1/8 3<br />

FCAW-G 3/8 10 FCAW-G 1/4 6<br />

GMAW N/A N/A GMAW 1/4 6<br />

Once <strong>the</strong> Z-loss dimension has been determined, it is added<br />

to <strong>the</strong> required throat dimension. Even though part <strong>of</strong> <strong>the</strong><br />

weld in <strong>the</strong> root is considered to be <strong>of</strong> such poor quality as<br />

to be incapable <strong>of</strong> transferring stress, <strong>the</strong> resultant weld will<br />

contain sufficient quality weld metal to permit <strong>the</strong> transfer <strong>of</strong><br />

imposed loads. Figure 4 illustrates this concept.<br />

The data in Table 1 that applies to dihedral angles <strong>of</strong><br />

30–60 degrees has been shown in blue numbers because<br />

<strong>the</strong>se values must be modified to account for <strong>the</strong> Z-loss<br />

factors. Such a modification has not been done for <strong>the</strong> data<br />

in <strong>the</strong> Table.<br />

Z<br />

Figure 4. Z-loss.<br />

Acute angles less than 30 degrees<br />

The D1.1 code says that welds in joints with dihedral<br />

angles <strong>of</strong> less than 30 degrees “shall not be considered as<br />

effective in transmitting applied forces …” and <strong>the</strong>n goes<br />

on to discuss a single exception related to tubular structures.<br />

In that exception, with qualification <strong>of</strong> <strong>the</strong> welding<br />

procedure specification, such welds may be used for transferring<br />

applied stresses. For plate (e.g., non-tubular) applications,<br />

such an option is not presented in <strong>the</strong> code.<br />

The practical application <strong>of</strong> this principle is that when welds<br />

are placed on <strong>the</strong> acute side, no capacity is assigned to<br />

<strong>the</strong> weld. Ra<strong>the</strong>r, <strong>the</strong> full load is assumed to be transferred<br />

with <strong>the</strong> weld on <strong>the</strong> obtuse side.<br />

Practical Considerations<br />

The most straightforward, and easiest, approach to determining<br />

<strong>the</strong> required weld size is to assume two welds with<br />

equal throat dimensions will be used, calculate <strong>the</strong><br />

required weld throat dimension, and <strong>the</strong>n calculate <strong>the</strong><br />

required fillet weld leg size, using ei<strong>the</strong>r equation 1 or Table<br />

1, columns A and B. Simple? Yes. Best? Let’s see.<br />

The optimizing method that uses equations 6 and 7 will<br />

result in reduced weld metal volumes. But, reduced how<br />

much? The significance increases with greater rotations<br />

from <strong>the</strong> 90-degree T-joint orientation. For angles <strong>of</strong> 80, 70,<br />

and 60 degrees, <strong>the</strong> differences in weld volume are<br />

approximately 3, 12 and 25%. However, note that <strong>the</strong>se differences<br />

are functions <strong>of</strong> <strong>the</strong> leg size squared. Accordingly,<br />

<strong>the</strong> change in leg size is approximately 1, 6, and 13%. In<br />

practical terms, for dihedral angles between 60 and 120<br />

degrees, <strong>the</strong>re will not be a standard fillet weld leg size<br />

until <strong>the</strong> welds become quite large. In <strong>the</strong> case <strong>of</strong> a 70-<br />

degree dihedral angle, for example, and assuming a 1/8 in.<br />

increment for standard sizing <strong>of</strong> fillet welds over 1 in. leg<br />

size, <strong>the</strong> leg size would need to be 2 in. before <strong>the</strong> optimized<br />

weld size would result in a smaller weld. For a 2 mm<br />

standard size, this would equal a 34 mm fillet.<br />

t<br />

ω<br />

ω<br />

ψ 1<br />

10 <strong>Welding</strong> Innovation Vol. XIX, No. 1, 2002

For angles less than 60 degrees, <strong>the</strong>re can be significant<br />

differences in weld volume. These are situations where <strong>the</strong><br />

Z-loss factor must be considered as well. Thus, for angles<br />

<strong>of</strong> 30–60 degrees, optimization <strong>of</strong> weld size makes sense,<br />

and <strong>the</strong> Z-loss factors can be considered at <strong>the</strong> same time.<br />

It must be recognized that o<strong>the</strong>r code provisions may fur<strong>the</strong>r<br />

affect <strong>the</strong>se results. For example, when optimized for<br />

minimum weld volume, welds on <strong>the</strong> obtuse side may be<br />

smaller than minimum fillet weld sizes as contained in Table<br />

5.8 <strong>of</strong> D1.1. The calculated sizes, if less than <strong>the</strong>se minimums,<br />

must be increased to comply with this requirement.<br />

There does not appear to be any intrinsic value in having<br />

welds on opposite sides <strong>of</strong> <strong>the</strong> skewed T-joint be <strong>of</strong> <strong>the</strong><br />

same size. If this approach is used, <strong>the</strong> resultant weld volumes<br />

will fall somewhere between <strong>the</strong> results for <strong>the</strong> same<br />

sized throat and <strong>the</strong> optimized sizes.<br />

After <strong>the</strong> welds are detailed, <strong>the</strong> joint must be welded.<br />

Practical considerations apply here too. It must be recognized<br />

that <strong>the</strong> ratio <strong>of</strong> <strong>the</strong> face width “f” to <strong>the</strong> throat dimension<br />

“t” constitutes <strong>the</strong> equivalent <strong>of</strong> a width-to-depth ratio<br />

for <strong>the</strong> root pass. On <strong>the</strong> obtuse side, this ratio is large,<br />

exceeding 1:6 for dihedral angle <strong>of</strong> 106 degrees or more. It<br />

is very difficult to get a single weld bead to “wash” out this<br />

wide without electrode manipulation (weaving). On <strong>the</strong><br />

acute side, <strong>the</strong> ratio is less than 1:2 for angles <strong>of</strong> 62<br />

degrees. This can lead to width-to-depth ratio cracking.<br />

Recommendations<br />

When determining fillet weld details for skewed T-joints with<br />

dihedral angles from 60–120 degrees, it rarely matters<br />

which method <strong>of</strong> proportioning <strong>of</strong> weld sizes is used. Using<br />

equal throat dimensions is a straightforward method, similar<br />

to what is typically done for fillet welds on ei<strong>the</strong>r side <strong>of</strong> a<br />

90-degree T-joint. Unless <strong>the</strong> weld size is large, optimizing it<br />

will probably not result in a smaller specified weld size.<br />

For fillet welds on skewed T-joints with dihedral angles from<br />

30–60 degrees, <strong>the</strong> Z-loss factor must be considered.<br />

Based on <strong>the</strong> specific dihedral angle, <strong>the</strong> welding process,<br />

and <strong>the</strong> position <strong>of</strong> welding, <strong>the</strong> Z-loss factor can be determined,<br />

and this dimension added to <strong>the</strong> required weld<br />

throat dimension.<br />

It is important to consider how <strong>the</strong>se dimensions should be<br />

communicated between <strong>the</strong> designer, fabricator, welder and<br />

inspector. The face dimension is a practical means <strong>of</strong> verifying<br />

that <strong>the</strong> proper weld size has been achieved.<br />

Opportunities<br />

<strong>Lincoln</strong> Electric Technical Programs<br />

<strong>Welding</strong> Technology Workshop<br />

June 10-14, 2002<br />

July 29 – August 2, 2002<br />

The purpose <strong>of</strong> this program is to<br />

introduce or enhance knowledge <strong>of</strong><br />

current thinking in arc welding safety,<br />

<strong>the</strong>ory, processes, and practices. The<br />

course is designed primarily for welding<br />

instructors, supervisors and pr<strong>of</strong>essional<br />

welders. Fee: $395.<br />

<strong>Welding</strong> <strong>of</strong> Aluminum Alloys,<br />

Theory and Practice<br />

October 15-18, 2002<br />

Designed for engineers, technologists,<br />

technicians and welders who are<br />

already familiar with basic welding<br />

processes, this technical training<br />

program provides equal amounts <strong>of</strong><br />

classroom time and hands-on welding.<br />

Fee: $595.<br />

Space is limited, so register early to avoid disappointment. For full details, see<br />

www.lincolnelectric.com/knowledge/training/seminars/<br />

Or call 216/383-2240, or write to Registrar, Pr<strong>of</strong>essional Programs, The <strong>Lincoln</strong> Electric<br />

Company, 22801 St. Clair Avenue, Cleveland, OH 44117-1199.<br />

<strong>Welding</strong> Innovation Vol. XIX, No. 1, 2002 11

The Fall <strong>of</strong> Skyscrapers<br />

By Henry Petroski<br />

A.S. Vesic Pr<strong>of</strong>essor <strong>of</strong> Civil Engineering<br />

and Pr<strong>of</strong>essor <strong>of</strong> History<br />

Duke University<br />

Durham, North Carolina<br />

Editor’s Note: This article first<br />

appeared in American Scientist,<br />

Volume 90, January-February 2002.<br />

It is reprinted here with permission.<br />

Copyright, Henry Petroski, 2002.<br />

The article is reprinted as written earlier<br />

this year. In <strong>the</strong> ensuing months,<br />

many investigations have been performed,<br />

and <strong>the</strong> level <strong>of</strong> understanding<br />

<strong>of</strong> some <strong>of</strong> <strong>the</strong> technical aspects <strong>of</strong><br />

<strong>the</strong> World Trade Center collapse have<br />

increased. The results <strong>of</strong> <strong>the</strong> FEMA<br />

investigation discussed in this article<br />

are now available at www.house.gov/<br />

science/hot/wtc/wtcreport.htm<br />

The terrorist attacks <strong>of</strong> September 11,<br />

2001, did more than bring down <strong>the</strong><br />

World Trade Center towers. The collapse<br />

<strong>of</strong> those New York City megastructures,<br />

once <strong>the</strong> fifth and sixth<br />

tallest buildings in <strong>the</strong> world, signaled<br />

<strong>the</strong> beginning <strong>of</strong> a new era in <strong>the</strong> planning,<br />

design, construction and use <strong>of</strong><br />

skyscrapers . For <strong>the</strong> foreseeable<br />

future, at least in <strong>the</strong> West, <strong>the</strong>re are<br />

not likely to be any new super-tall<br />

buildings proposed, and only those<br />

currently under construction will be<br />

added to <strong>the</strong> skylines <strong>of</strong> <strong>the</strong> great<br />

cities <strong>of</strong> <strong>the</strong> world. Even <strong>the</strong> continued<br />

occupancy <strong>of</strong> signature skyscrapers<br />

may come under scrutiny by <strong>the</strong>ir<br />

prime tenants.<br />

Since two hijacked airplanes loaded<br />

with jet fuel were crashed within about<br />

15 minutes <strong>of</strong> each o<strong>the</strong>r into <strong>the</strong> two<br />

most prominent and symbolic structures<br />

<strong>of</strong> lower Manhattan, <strong>the</strong> once<br />

reassuringly low numbers generated<br />

by probabilistic risk assessment seem<br />

irrelevant. What happened in New York<br />

ceased being a hypo<strong>the</strong>tical, incredible<br />

or ignorable scenario. From now on,<br />

12 <strong>Welding</strong> Innovation Vol. XIX, No. 1, 2002<br />

Figure 1. With <strong>the</strong> collapse <strong>of</strong> <strong>the</strong> World Trade Center towers, <strong>the</strong> fate <strong>of</strong> future<br />

skyscraper projects has come into question.<br />

structural engineers must be prepared<br />

to answer harder questions about how<br />

skyscrapers will stand up to <strong>the</strong> impact<br />

<strong>of</strong> jumbo jets and, perhaps more<br />

important, how <strong>the</strong>y will fare in <strong>the</strong><br />

ensuing conflagration. <strong>Arc</strong>hitects will<br />

likely have to respond more to questions<br />

about stairwells and evacuation<br />

routes than to those about facades<br />

and spires. Because <strong>of</strong> <strong>the</strong> nature <strong>of</strong><br />

skyscrapers, nei<strong>the</strong>r engineers nor<br />

architects will be able to find answers<br />

that will satisfy everyone.<br />

Inclination, Not Economy<br />

Although <strong>the</strong> idea <strong>of</strong> <strong>the</strong> skyscraper is<br />

modern, <strong>the</strong> inclination to build upward<br />

is not. The Great Pyramids, with <strong>the</strong>ir<br />

broad bases, reached heights unapproached<br />

for <strong>the</strong> next four millennia.<br />

But even <strong>the</strong> great Gothic ca<strong>the</strong>drals,<br />

crafted <strong>of</strong> bulky stone into an aes<strong>the</strong>tic<br />

<strong>of</strong> lightness and slenderness, are<br />

dwarfed by <strong>the</strong> steel and reinforced<br />

concrete structures <strong>of</strong> <strong>the</strong> 20th century.<br />

It was modern building materials<br />

that made <strong>the</strong> true skyscraper structurally<br />

possible, but it was <strong>the</strong> mechanical<br />

device <strong>of</strong> <strong>the</strong> elevator that made<br />

<strong>the</strong> skyscraper truly practical.<br />

Ironically, it is also <strong>the</strong> elevator that<br />

has had so much to do with limiting<br />

<strong>the</strong> height <strong>of</strong> most tall buildings to<br />

about 70 or 80 stories. Above that,<br />

elevator shafts occupy more than 25<br />

percent <strong>of</strong> <strong>the</strong> volume <strong>of</strong> a tall building,<br />

and so <strong>the</strong> economics <strong>of</strong> renting out<br />

space argues against investing in<br />

greater height.<br />

The World Trade Center towers were<br />

110 stories tall, but even with an elaborate<br />

system <strong>of</strong> local and express elevators,<br />

<strong>the</strong> associated sky lobbies and<br />

utilities located in <strong>the</strong> core still<br />

removed almost 30 percent <strong>of</strong> <strong>the</strong> towers’<br />

floor area from <strong>the</strong> rentable space<br />

category. By all planning estimates,

<strong>the</strong> World Trade Center towers should<br />

have been viewed as a poor investment<br />

and so might not have been<br />