VAV Controllers LVC-LowVelocity - TROX

VAV Controllers LVC-LowVelocity - TROX

VAV Controllers LVC-LowVelocity - TROX

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Order details<br />

Specification text<br />

Circular <strong>VAV</strong> circular controllers of type <strong>LVC</strong>-<strong>LowVelocity</strong> for<br />

low velocities in variable air flow systems, suitable for supply<br />

or extract air, available in 4 nominal sizes.<br />

Measurement and control of low volume flow rates based on<br />

a new measurement principle. Plastic nozzle with damper<br />

blade for measuring the differential pressure, or effective<br />

pressure, upstream and downstream of the damper blade.<br />

The relation between differential pressure and damper<br />

blade position is stored in the <strong>TROX</strong> Compact controller<br />

such that a high control accuracy is achieved even in case<br />

of unfavourable upstream flow conditions.<br />

Special characteristics<br />

– Optimised for low air velocities of 0.6 to 6 m/s<br />

– High control accuracy even in case of unfavourable<br />

upstream flow conditions<br />

– Easy flow rate setting without additional equipment<br />

– Factory setting and aerodynamic function testing of every<br />

individual unit on a special test rig<br />

Selection based on nominal size determination. The<br />

customer can easily set volume flows Vmin and V max on the<br />

potentiometers with percentage scales during installation or<br />

commissioning. No supply voltage is required for this. A<br />

transparent protective cover prevents inadvertent resetting<br />

and provides general safety. The control damper blade is set<br />

to 45° ex factory, which allows ventilation air flow without<br />

control.<br />

Differential pressure range 30 to 600 Pa.<br />

The averaging differential pressure sensor is resistant to<br />

dust and pollution.<br />

Air leakage when the damper blade is closed complies<br />

with EN 1751, class 3. The position of the damper blade is<br />

indicated on the outside by the damper blade shaft end.<br />

Variable flow rate control with factory mounted electronic<br />

Compact controller to switch an external control signal;<br />

actual value signal can be integrated into BMS.<br />

24 V AC/DC supply voltage<br />

Electrical connections with screw terminals. Double terminal<br />

for looping the 24 V supply voltage, i.e. for the simple<br />

connection of voltage transmission to the next controller.<br />

Wire clamping bracket fixed to the casing.<br />

Voltage range for control and actual value signal<br />

0 to 10 V DC. Possible override controls with external<br />

switches using potential-free contacts: OPEN, CLOSED,<br />

Vmin and V max .<br />

Clearly visible external indicator light for signalling the<br />

functions:<br />

Set, not set and power failure.<br />

Materials<br />

Casing made of galvanised sheet steel. Nozzle, damper<br />

blade, and plain bearings made of ABS plastic, UL 94, flame<br />

retardant (V0). Damper blade seal made of TPV plastic.<br />

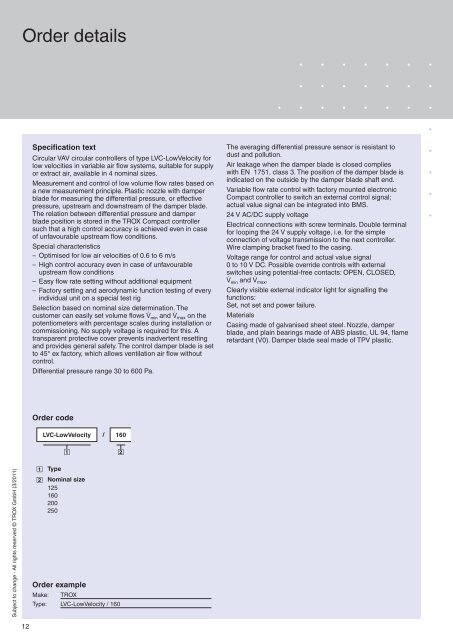

Order code<br />

<strong>LVC</strong>-<strong>LowVelocity</strong><br />

/<br />

160<br />

Subject to change · All rights reserved © <strong>TROX</strong> GmbH (3/2011)<br />

ype<br />

Nominal size<br />

125<br />

160<br />

200<br />

250<br />

Order example<br />

Make: <strong>TROX</strong><br />

Type: <strong>LVC</strong>-<strong>LowVelocity</strong> / 160<br />

12