Series TY-B - Tyco Fire Products

Series TY-B - Tyco Fire Products

Series TY-B - Tyco Fire Products

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

TFP151_EN Page 55 of 8<br />

K<br />

K<br />

40<br />

2.8<br />

1/2”<br />

1/2"<br />

NPT<br />

NPT<br />

80<br />

1/2” 5.6<br />

NPT 1/2"<br />

NPT<br />

115<br />

3/4”<br />

NPT 8.0<br />

3/4"<br />

NPT<br />

115<br />

1/2”<br />

NPT<br />

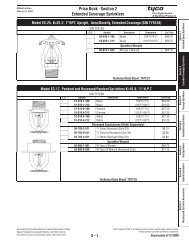

SPRINKLER SPRINKLER FINISH FINISH<br />

<strong>TY</strong>PE NATURAL NATURAL CHROME-PLA-<br />

WHITE WHITE LEAD<br />

<strong>TY</strong>PE<br />

LEAD COATED<br />

BRASS BRASS TEDPLATEDPOLYESTER<br />

COATED<br />

WAX<br />

WAX COATED<br />

COATED<br />

PENDENT PENDENT (<strong>TY</strong>1251) (<strong>TY</strong>1251) and<br />

and<br />

12,1 bar<br />

175<br />

(175<br />

PSI<br />

psi)<br />

(12,1 BAR)<br />

N/A<br />

UPRIGHT (<strong>TY</strong>1151)<br />

N/A<br />

UPRIGHT (<strong>TY</strong>1151)<br />

PENDENT (<strong>TY</strong>3251) and<br />

PENDENT (<strong>TY</strong>3251)<br />

17,2 bar (250 psi)<br />

12,1 bar (175 psi)<br />

UPRIGHT (<strong>TY</strong>3151)<br />

and<br />

250 ORPSI (17,2 BAR)<br />

175 PSI (12,1 BAR)<br />

RECESSED UPRIGHT PENDENT (<strong>TY</strong>3151)<br />

12,1 bar (175<br />

OR<br />

psi)<br />

(SEE<br />

175<br />

NOTE<br />

PSI<br />

1)<br />

N/A<br />

(<strong>TY</strong>3251)<br />

(12,1 BAR)<br />

RECESSED PENDENT<br />

PENDENT (<strong>TY</strong>4251) (<strong>TY</strong>3251)<br />

N/A<br />

and<br />

(SEE NOTE 1) 12,1 bar (175 psi)<br />

UPRIGHT (<strong>TY</strong>4151)<br />

PENDENT (<strong>TY</strong>4251)<br />

RECESSED PENDENT<br />

and<br />

(<strong>TY</strong>4251)<br />

UPRIGHT (<strong>TY</strong>4151)<br />

12,1 bar (175 psi) 175 PSI (12,1 BAR) N/A<br />

PENDENT (<strong>TY</strong>4951)<br />

RECESSED and PENDENT<br />

UPRIGHT (<strong>TY</strong>4851) (<strong>TY</strong>4251)<br />

12,1 bar (175 psi)<br />

175 PSI (12,1 BAR)<br />

N/A<br />

WAX OVER<br />

LEAD COATED<br />

NOTE:<br />

8.0<br />

PENDENT (<strong>TY</strong>4951)<br />

1. The 1/2" maximum working and pressure of 17,2 bar (250 psi) only applies to the Listing 175 by PSI Underwriters (12,1 BAR) Laboratories, Inc. (UL); the Listing by<br />

Underwriters NPT Laboratories, UPRIGHT Inc. (<strong>TY</strong>4851) for use in Canada (C-UL); and, the Approval by the City of New York.<br />

NOTE:<br />

1. The maximum working pressure of 250 psi<br />

TABLE<br />

(17,2 bar)<br />

B, MAXIMUM<br />

only applies<br />

WORKING<br />

to the ListingPRESSURE<br />

by Underwriters Laboratories, Inc. (UL); the Listing by<br />

Underwriters Laboratories, Inc. for use in Canada (C-UL); and, the Approval by the City of New York.<br />

TABLE B, MAXIMUM WORKING PRESSURE<br />

Technical Data<br />

Approvals<br />

Data<br />

UL and C-UL Listed.<br />

FM, Approvals LPCB, VdS, and NYC Approved.<br />

(Refer UL and to C-UL Table Listed. A for complete approval<br />

information FM, LPCB, including VdS, andcorrosion NYC Approved. resistant<br />

status.)<br />

(Refer to Table A for complete approval<br />

information including corrosion<br />

Maximum resistant Working status.) Pressure<br />

Refer Maximum to Table Working B. Pressure<br />

Discharge Refer to Table Coefficient B.<br />

40,3 Discharge l/min.bar 0,5 Coefficient<br />

(2.8 usgpm/psi 0,5 )<br />

80,6 K = l/min.bar 2.8 GPM/psi 0,5 (5.6 1/2 usgpm/psi (40,3 LPM/bar 0,5 ) 1/2 )<br />

115,2 K = 5.6 l/min.bar GPM/psi 0,5 (8.0 1/2 usgpm/psi (80,6 LPM/bar 0,5 )<br />

1/2 )<br />

K = 8.0 GPM/psi 1/2 (115,2 LPM/bar 1/2 )<br />

Temperature Ratings<br />

Refer Temperature to Table A Ratings<br />

Refer to Table A.<br />

Finish<br />

Sprinkler: FinishesRefer to Table A.<br />

Recessed Sprinkler: Escutcheon: Refer to Table White Coated, A.<br />

Chrome Recessed Plated, Escutcheon: Brass PlatedWhite Coated,<br />

Chrome Plated, or Brass Plated.<br />

Physical Characteristics<br />

Frame............................................................Bronze<br />

Physical Characteristics<br />

Button.............................................Brass/Copper<br />

Frame . . . . . . . . . . . . . Bronze<br />

Button . . . . . . . . . Brass/Copper<br />

Sealing<br />

Sealing<br />

Assembly..................................................<br />

Assembly . . . . . . . . . .<br />

................................ . . . . . Beryllium Beryllium Nickel Nickel w/Teflon† w/Teflon*<br />

Bulb..................................................................Glass<br />

. . . . . . . . . . . . . . . Compression Screw.................................... . . . . . Bronze Brass<br />

Deflector....................................................Copper<br />

. . . . . . . . . . . Bushing (K40)............................................Bronze<br />

(K=2.8) . . . . . . . *Registered trademark of DuPont.<br />

Operation<br />

The glass Bulb contains a fluid which<br />

The expands glass bulb when contains exposed a fluid to that heat. expands When<br />

when the rated exposed temperature to heat. When is reached, the rated temperature<br />

fluid expands is reached, sufficiently the fluid to expands shattersuffi-<br />

the<br />

the<br />

ciently glass to Bulb, shatter allowing the glass the bulb, sprinkler activating to<br />

the activate sprinkler and and water allowing to flow. water to flow.<br />

Design Criteria<br />

Criteria<br />

The <strong>Series</strong> <strong>TY</strong>-B Pendent and Upright Sprinklers<br />

The<br />

are<br />

<strong>Series</strong><br />

intended<br />

<strong>TY</strong>-B<br />

for<br />

Pendent<br />

fire protection<br />

and Upright<br />

systems<br />

Sprinklers are intended for fire protection<br />

systems<br />

designed in accordance<br />

designed<br />

with<br />

in accordance<br />

the standard<br />

installation with the standard rules recognized installationby rules the recognizedListing<br />

by the or applicable Approval agency Listing(e.g.<br />

or<br />

applicable<br />

UL Approval Listing is agency based on (e.g., the requirements UL Listing of is<br />

NFPA based 13, on and the FM requirements Approval is based of NFPA on the<br />

requirements 13, and FMof Approval FM’s Loss isPrevention based Data the<br />

Sheets). requirements Only the ofStyle FM’s10 Loss or 40 Prevention Recessed<br />

Escutcheon, Data Sheets). as applicable, Only the is Style to be 10 used or 40 for<br />

recessed<br />

Recessed<br />

pendent<br />

Escutcheon,<br />

installations.<br />

as applicable,<br />

is to be used for recessed pendent<br />

installations.<br />

Installation<br />

The <strong>Series</strong> <strong>TY</strong>-B Sprinklers must be installed in<br />

accordance with the following instructions:<br />

NOTES<br />

Do not install any bulb type sprinkler if the<br />

bulb is cracked or there is a loss of liquid from<br />

the bulb. With the sprinkler held horizontally,<br />

a small air bubble should be present. The diameter<br />

of the air bubble is approximately 1,5<br />

mm (1/16”) for the 57°C (135°F) to 2,5 mm<br />

(3/32”) for the 182°C (360°F) temperature ratings.<br />

A leak tight 1/2” NPT sprinkler joint should be<br />

obtained with a torque of 10 to 19 Nm (7 to<br />

14 ft.lbs.). A maximum of 29 Nm (21 ft. lbs.)<br />

of torque may be used to install sprinklers<br />

with 1/2 NPT connections. A leak tight 3/4”<br />

NPT sprinkler joint should be obtained with<br />

a torque of 13 to 37 Nm (10 to 20 ft.lbs.). A<br />

maximum of 41 Nm (30 ft.lbs.) of torque is to<br />

be used to install sprinklers with 3/4 NPT connections.<br />

Higher levels of torque may distort<br />

the sprinkler inlet and cause leakage or impairment<br />

of the sprinkler.<br />

Do not attempt to make-up for insufficient<br />

adjustment in the escutcheon plate by underor<br />

over-tightening the sprinkler. Readjust the<br />

position of the sprinkler fitting to suit.<br />

† DuPont Registered Trademark