Handbook of Sludge Pumping, contents - Flygt

Handbook of Sludge Pumping, contents - Flygt

Handbook of Sludge Pumping, contents - Flygt

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

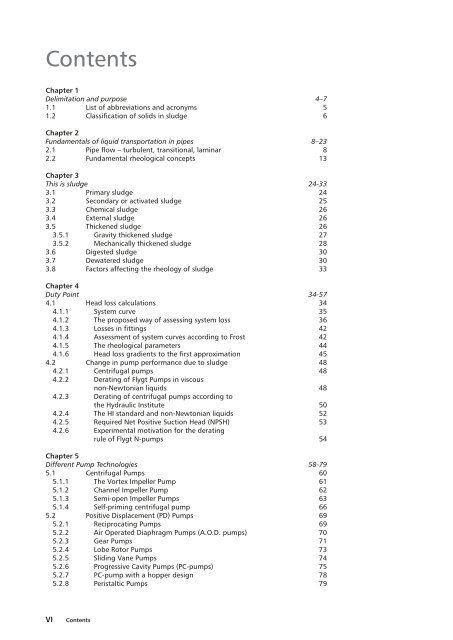

Contents<br />

Chapter 1<br />

Delimitation and purpose 4–7<br />

1.1 List <strong>of</strong> abbreviations and acronyms 5<br />

1.2 Classification <strong>of</strong> solids in sludge 6<br />

Chapter 2<br />

Fundamentals <strong>of</strong> liquid transportation in pipes 8–23<br />

2.1 Pipe flow – turbulent, transitional, laminar 8<br />

2.2 Fundamental rheological concepts 13<br />

Chapter 3<br />

This is sludge 24-33<br />

3.1 Primary sludge 24<br />

3.2 Secondary or activated sludge 25<br />

3.3 Chemical sludge 26<br />

3.4 External sludge 26<br />

3.5 Thickened sludge 26<br />

3.5.1 Gravity thickened sludge 27<br />

3.5.2 Mechanically thickened sludge 28<br />

3.6 Digested sludge 30<br />

3.7 Dewatered sludge 30<br />

3.8 Factors affecting the rheology <strong>of</strong> sludge 33<br />

Chapter 4<br />

Duty Point 34-57<br />

4.1 Head loss calculations 34<br />

4.1.1 System curve 35<br />

4.1.2 The proposed way <strong>of</strong> assessing system loss 36<br />

4.1.3 Losses in fittings 42<br />

4.1.4 Assessment <strong>of</strong> system curves according to Frost 42<br />

4.1.5 The rheological parameters 44<br />

4.1.6 Head loss gradients to the first approximation 45<br />

4.2 Change in pump performance due to sludge 48<br />

4.2.1 Centrifugal pumps 48<br />

4.2.2 Derating <strong>of</strong> <strong>Flygt</strong> Pumps in viscous<br />

non-Newtonian liquids 48<br />

4.2.3 Derating <strong>of</strong> centrifugal pumps according to<br />

the Hydraulic Institute 50<br />

4.2.4 The HI standard and non-Newtonian liquids 52<br />

4.2.5 Required Net Positive Suction Head (NPSH) 53<br />

4.2.6 Experimental motivation for the derating<br />

rule <strong>of</strong> <strong>Flygt</strong> N-pumps 54<br />

Chapter 5<br />

Different Pump Technologies 58-79<br />

5.1 Centrifugal Pumps 60<br />

5.1.1 The Vortex Impeller Pump 61<br />

5.1.2 Channel Impeller Pump 62<br />

5.1.3 Semi-open Impeller Pumps 63<br />

5.1.4 Self-priming centrifugal pump 66<br />

5.2 Positive Displacement (PD) Pumps 69<br />

5.2.1 Reciprocating Pumps 69<br />

5.2.2 Air Operated Diaphragm Pumps (A.O.D. pumps) 70<br />

5.2.3 Gear Pumps 71<br />

5.2.4 Lobe Rotor Pumps 73<br />

5.2.5 Sliding Vane Pumps 74<br />

5.2.6 Progressive Cavity Pumps (PC-pumps) 75<br />

5.2.7 PC-pump with a hopper design 78<br />

5.2.8 Peristaltic Pumps 79<br />

VI Contents

Chapter 6<br />

<strong>Sludge</strong> pump applications, easy, difficult or hard? 80-109<br />

6.1 The right pump for the right application 81<br />

6.1.1 Different ways <strong>of</strong> installing an N-pump 82<br />

6.2 Head loss, system design and pump characteristics 83<br />

6.2.1 Factors influencing head loss 83<br />

6.2.2 General system design recommendations 85<br />

6.2.3 General recommendations if a centrifugal<br />

pump is used for sludge pumping 87<br />

6.2.4 General recommendations if a PC-pump is<br />

used for sludge pumping 88<br />

6.3 Removal <strong>of</strong> primary sludge 89<br />

6.4 External/imported sludge transportation 91<br />

6.5 Return activated sludge (RAS) pumping 93<br />

6.6 Waste activated sludge (WAS) removal 95<br />

6.7 Transportation <strong>of</strong> gravity thickened sludge 97<br />

6.8 Transportation <strong>of</strong> mechanically thickened sludge 99<br />

6.9 Digester recirculation 101<br />

6.10 Digester withdrawal 103<br />

6.11 Feeding sludge to a dewatering unit 104<br />

6.12 Dewatered sludge transportation 106<br />

6.13 Which pump for what application? 107<br />

Chapter 7<br />

Some real life applications 110-125<br />

7.1 Overview 110<br />

7.2 Digester recirculation in Rättvik WWTP, Sweden 110<br />

7.2.1 Analysis <strong>of</strong> specific pump selection 112<br />

7.2.2 Analysis <strong>of</strong> the piping system and associated pressure head loss 112<br />

7.2.3 Analysis <strong>of</strong> the duty point 114<br />

7.3 Feeding <strong>of</strong> a digester in Apeldoorn WWTP, the Netherlands 116<br />

7.4 Emptying sludge hoppers with centrifugal pumps in<br />

SNJ WWTP, Norway 119<br />

7.5 Transportation <strong>of</strong> mechanically thickened sludge<br />

in Bekkelaget WWTP, Norway 121<br />

7.6 Digester recirculation at Naburn WWTP, Yorkshire, UK 123<br />

Appendix A<br />

Basic pumping theory 126-149<br />

A1 Affinity laws 126<br />

A2 Capacity 127<br />

A3 Pump Head 128<br />

A4 Power and efficiency 129<br />

A5 Specific speed related to pump type 130<br />

A6 Net Positive Suction Head or NPSH 132<br />

A7 Inlet vortexes 134<br />

A8 Performance curves for centrifugal pumps 134<br />

A9 Viscosity 137<br />

A10 System curves 138<br />

A11 Serial and parallel pumping 143<br />

A12 Speed control 144<br />

A13 Positive Displacement Pumps 147<br />

Appendix B<br />

Questions to ask regarding sludge applications, PC-pump and N-pump 150-151<br />

Bibliography 152-153<br />

Index 154-159<br />

Contents<br />

VII