Maltings in England - English Heritage

Maltings in England - English Heritage

Maltings in England - English Heritage

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

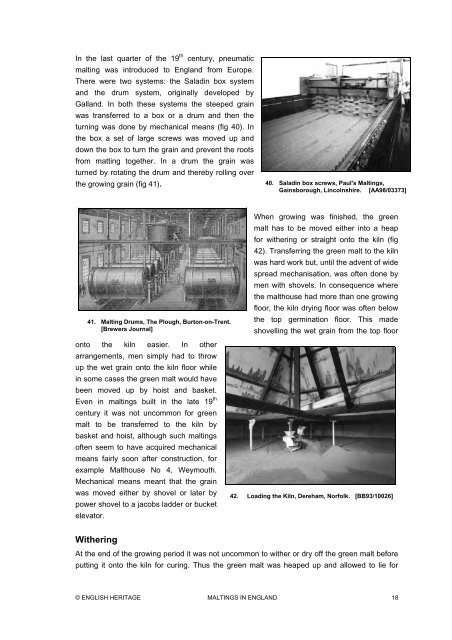

In the last quarter of the 19 th century, pneumatic<br />

malt<strong>in</strong>g was <strong>in</strong>troduced to <strong>England</strong> from Europe.<br />

There were two systems: the Salad<strong>in</strong> box system<br />

and the drum system, orig<strong>in</strong>ally developed by<br />

Galland. In both these systems the steeped gra<strong>in</strong><br />

was transferred to a box or a drum and then the<br />

turn<strong>in</strong>g was done by mechanical means (fig 40). In<br />

the box a set of large screws was moved up and<br />

down the box to turn the gra<strong>in</strong> and prevent the roots<br />

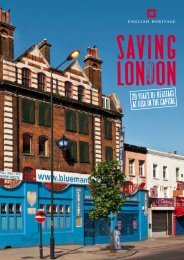

from matt<strong>in</strong>g together. In a drum the gra<strong>in</strong> was<br />

turned by rotat<strong>in</strong>g the drum and thereby roll<strong>in</strong>g over<br />

the grow<strong>in</strong>g gra<strong>in</strong> (fig 41).<br />

40. Salad<strong>in</strong> box screws, Paul's <strong>Malt<strong>in</strong>gs</strong>,<br />

Ga<strong>in</strong>sborough, L<strong>in</strong>colnshire. [AA98/03373]<br />

41. Malt<strong>in</strong>g Drums, The Plough, Burton-on-Trent.<br />

[Brewers Journal]<br />

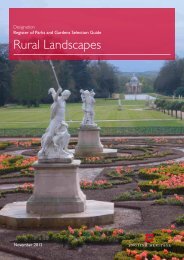

When grow<strong>in</strong>g was f<strong>in</strong>ished, the green<br />

malt has to be moved either <strong>in</strong>to a heap<br />

for wither<strong>in</strong>g or straight onto the kiln (fig<br />

42). Transferr<strong>in</strong>g the green malt to the kiln<br />

was hard work but, until the advent of wide<br />

spread mechanisation, was often done by<br />

men with shovels. In consequence where<br />

the malthouse had more than one grow<strong>in</strong>g<br />

floor, the kiln dry<strong>in</strong>g floor was often below<br />

the top germ<strong>in</strong>ation floor. This made<br />

shovell<strong>in</strong>g the wet gra<strong>in</strong> from the top floor<br />

onto the kiln easier. In other<br />

arrangements, men simply had to throw<br />

up the wet gra<strong>in</strong> onto the kiln floor while<br />

<strong>in</strong> some cases the green malt would have<br />

been moved up by hoist and basket.<br />

Even <strong>in</strong> malt<strong>in</strong>gs built <strong>in</strong> the late 19 th<br />

century it was not uncommon for green<br />

malt to be transferred to the kiln by<br />

basket and hoist, although such malt<strong>in</strong>gs<br />

often seem to have acquired mechanical<br />

means fairly soon after construction, for<br />

example Malthouse No 4, Weymouth.<br />

Mechanical means meant that the gra<strong>in</strong><br />

was moved either by shovel or later by<br />

power shovel to a jacobs ladder or bucket<br />

elevator.<br />

42. Load<strong>in</strong>g the Kiln, Dereham, Norfolk. [BB93/10026]<br />

Wither<strong>in</strong>g<br />

At the end of the grow<strong>in</strong>g period it was not uncommon to wither or dry off the green malt before<br />

putt<strong>in</strong>g it onto the kiln for cur<strong>in</strong>g. Thus the green malt was heaped up and allowed to lie for<br />

© ENGLISH HERITAGE MALTINGS IN ENGLAND 18