Maltings in England - English Heritage

Maltings in England - English Heritage

Maltings in England - English Heritage

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

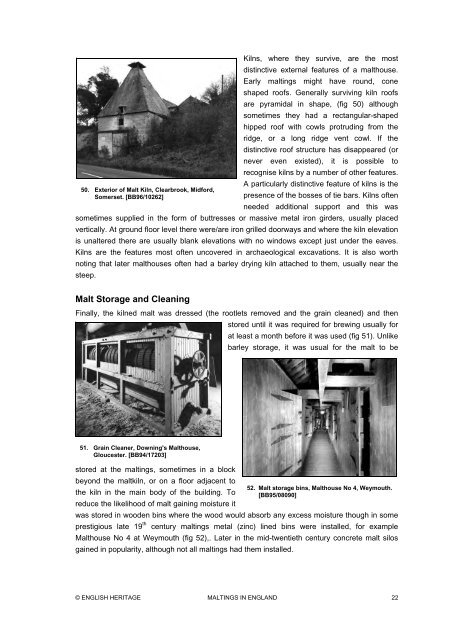

Kilns, where they survive, are the most<br />

dist<strong>in</strong>ctive external features of a malthouse.<br />

Early malt<strong>in</strong>gs might have round, cone<br />

shaped roofs. Generally surviv<strong>in</strong>g kiln roofs<br />

are pyramidal <strong>in</strong> shape, (fig 50) although<br />

sometimes they had a rectangular-shaped<br />

hipped roof with cowls protrud<strong>in</strong>g from the<br />

ridge, or a long ridge vent cowl. If the<br />

dist<strong>in</strong>ctive roof structure has disappeared (or<br />

never even existed), it is possible to<br />

recognise kilns by a number of other features.<br />

A particularly dist<strong>in</strong>ctive feature of kilns is the<br />

50. Exterior of Malt Kiln, Clearbrook, Midford,<br />

Somerset. [BB96/10262]<br />

presence of the bosses of tie bars. Kilns often<br />

needed additional support and this was<br />

sometimes supplied <strong>in</strong> the form of buttresses or massive metal iron girders, usually placed<br />

vertically. At ground floor level there were/are iron grilled doorways and where the kiln elevation<br />

is unaltered there are usually blank elevations with no w<strong>in</strong>dows except just under the eaves.<br />

Kilns are the features most often uncovered <strong>in</strong> archaeological excavations. It is also worth<br />

not<strong>in</strong>g that later malthouses often had a barley dry<strong>in</strong>g kiln attached to them, usually near the<br />

steep.<br />

Malt Storage and Clean<strong>in</strong>g<br />

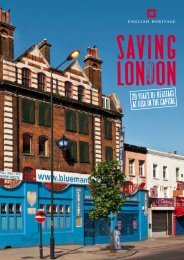

F<strong>in</strong>ally, the kilned malt was dressed (the rootlets removed and the gra<strong>in</strong> cleaned) and then<br />

stored until it was required for brew<strong>in</strong>g usually for<br />

at least a month before it was used (fig 51). Unlike<br />

barley storage, it was usual for the malt to be<br />

51. Gra<strong>in</strong> Cleaner, Down<strong>in</strong>g's Malthouse,<br />

Gloucester. [BB94/17203]<br />

stored at the malt<strong>in</strong>gs, sometimes <strong>in</strong> a block<br />

beyond the maltkiln, or on a floor adjacent to<br />

the kiln <strong>in</strong> the ma<strong>in</strong> body of the build<strong>in</strong>g. To<br />

reduce the likelihood of malt ga<strong>in</strong><strong>in</strong>g moisture it<br />

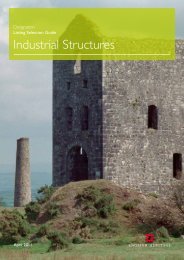

52. Malt storage b<strong>in</strong>s, Malthouse No 4, Weymouth.<br />

[BB95/08090]<br />

was stored <strong>in</strong> wooden b<strong>in</strong>s where the wood would absorb any excess moisture though <strong>in</strong> some<br />

prestigious late 19 th century malt<strong>in</strong>gs metal (z<strong>in</strong>c) l<strong>in</strong>ed b<strong>in</strong>s were <strong>in</strong>stalled, for example<br />

Malthouse No 4 at Weymouth (fig 52),. Later <strong>in</strong> the mid-twentieth century concrete malt silos<br />

ga<strong>in</strong>ed <strong>in</strong> popularity, although not all malt<strong>in</strong>gs had them <strong>in</strong>stalled.<br />

© ENGLISH HERITAGE MALTINGS IN ENGLAND 22