Journal of the Minnesota Precision Manufacturing Association

Journal of the Minnesota Precision Manufacturing Association

Journal of the Minnesota Precision Manufacturing Association

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

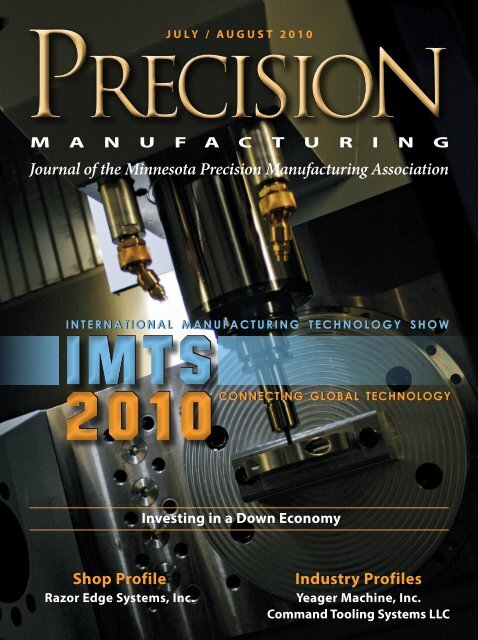

J u l y / A u g u s t 2 0 1 0<br />

M A N U F A C T U R I N G<br />

<strong>Journal</strong> <strong>of</strong> <strong>the</strong> <strong>Minnesota</strong> <strong>Precision</strong> <strong>Manufacturing</strong> <strong>Association</strong><br />

IMTS<br />

2O1O<br />

I n t e r n a t i o n a l M a n u f a c t u r i n g T e c h n o l o g y S h o w<br />

Connecting global technology<br />

Investing in a Down Economy<br />

Shop Pr<strong>of</strong>ile<br />

Razor Edge Systems, Inc.<br />

Industry Pr<strong>of</strong>iles<br />

Yeager Machine, Inc.<br />

Command Tooling Systems LLC

<strong>the</strong> all new 2010<br />

St-30<br />

turning Center<br />

The all-new, 2010 ST-30 turning center is <strong>the</strong> culmination<br />

<strong>of</strong> 15 years <strong>of</strong> continuous development, and it <strong>of</strong>fers <strong>the</strong> most<br />

performance for <strong>the</strong> money – <strong>the</strong> best value – <strong>of</strong> any turning<br />

center on <strong>the</strong> market today.<br />

more rigidity.<br />

more tools.<br />

more power . . . more value.<br />

r e l e a s e d f o r a c t i v e d u t y : 0 1 . 0 1 . 1 0<br />

Visit us at IMTS<br />

Booth S-8119<br />

Haas Factory Outlet | A Division <strong>of</strong> Productivity Inc | 763.742.1263 | www.haasproductivity.com<br />

2 | PRECISION MANUFACTURING July | August 2010<br />

Specifications subject to change without notice. Not responsible for typographical errors. Machines shown with optional equipment.

IMTS 2O1O<br />

<strong>Minnesota</strong> <strong>Precision</strong> <strong>Manufacturing</strong> <strong>Association</strong><br />

quick guide<br />

S - South Building Hall A (Booths 8000-8999) N - North Building Hall B (Booths 6000-7999)<br />

E - Lakeside Center East Hall D (Booths 3000-4999) W- West Building Hall F (Booths 2000-2999)<br />

Distributor Builder tyPE bldg/Booth #<br />

Agility Machine Tool, Inc. Chevalier Machinery Milling & Grinding S-8586<br />

AKARI / SEIKI Milling S-8255<br />

ARES SEIKI Milling S-8255<br />

HONOR SEIKI Turning S-8255<br />

VTEC Vision Wide Milling S-8255<br />

YCM Milling, Turning & EDM S-8129<br />

Hwacheon Milling & Turning S-8738<br />

NEXTURN Swiss Turning S-8646<br />

All Tech<br />

Machinery & Supply Chmer EDM EDM E-4328<br />

Jinn Fa Cyber CNC Turning S-8483<br />

YASDA <strong>Precision</strong> Milling S-9163<br />

Concept Machine<br />

Tool Sales, Inc. Kern Micro Machining S-8460<br />

Kitamura Milling S-9148<br />

Mitsubishi EDM E-4920<br />

Miyano Turning S-9419<br />

Samung (Dynamic Int’l) Milling & Turning S-8450<br />

Toyoda Milling & Grinding S-8336<br />

Tsugami Swiss Turning S-9410<br />

Ellison Technologies DMG Milling & Turning S-8900<br />

Ellison Technologies Automation Robotic Machine Load/Unload S-8900<br />

KIRA America Milling & Turning TBD<br />

Mori Seiki Milling & Turning S-8900<br />

SNK America Milling S-8936<br />

United Grinding Technolgoies Grinding N-6800<br />

Hales Machine Tool, Inc. Yamazen/Bro<strong>the</strong>r Milling, Drilling/Tapping S-8548<br />

Doosan Milling & Turning S-8100<br />

Eurotech Elite Turning S-9482<br />

FPT Milling S-8670<br />

Hankook Turning S-8021<br />

Hanwha Swiss Turning S-8686<br />

Milltronics Milling & Turning S-8327<br />

Yamazen / Mitsubishi Milling S-8548<br />

OKK / Dynamic Int’l Milling S-8359<br />

SIP Milling S-9476<br />

Starragheckert Milling S-9476<br />

UNISIG / Entrust Gun Drills S-9159<br />

United Grinding / Walter / EWAG Grinding N-6800<br />

Willemin-Macodel SA Milling S-9352<br />

Hegman Machine Tool, Inc. Chiron Milling W-1600<br />

Hardinge Group Milling, Turning & Grinding S-8348<br />

Hydromat Milling & Turning S-8353<br />

Maier USA Swiss Turning S-8460<br />

Okuma Milling, Turning & Grinding S-8500<br />

Techni Waterjet Waterjet Cutting N-6256<br />

Trumpf Fabrication N-6223

IMTS 2O1O<br />

<strong>Minnesota</strong> <strong>Precision</strong> <strong>Manufacturing</strong> <strong>Association</strong><br />

quick guide<br />

S - South Building Hall A (Booths 8000-8999) N - North Building Hall B (Booths 6000-7999)<br />

E - Lakeside Center East Hall D (Booths 3000-4999) W- West Building Hall F (Booths 2000-2999)<br />

Distributor Builder tyPE bldg/Booth #<br />

Machine Tool Supply Corp. Feeler by Methods Milling & Turning S-9119<br />

FIDIA Milling S-9447<br />

Fryer Milling & Turning S-8719<br />

Ganesh Turning S-9379<br />

HARIG Products Grinding N-6730<br />

HE&M Saw Fabrication N-6948<br />

Index / Traub Turning S-8136<br />

Kiwa Japan Milling S-9119<br />

Microlution Milling S-8048<br />

SNK Nigata Milling S-8936<br />

Porta North America Milling S-9282<br />

Romi Turning TBD<br />

SNK Prodigy Turning S-8936<br />

Takamaz Turning S-9424<br />

Tru-Tech Systems Grinding N-6730<br />

Weldon Solutions Grinding N-7422<br />

Productivity Inc ANCA Grinding N-7414<br />

Behringer-Eisele Fabrication N-6859<br />

Citizen Swiss Turning S-9419<br />

FANUC Robodrill Milling S-9119<br />

FANUC Robotics Automation S-8919, S-9119<br />

Haas Automation, Inc. Milling & Turning S-8119<br />

Hermle Milling S8136<br />

Hyundai-Kia Turning S-8948<br />

Makino Milling, EDM S-8700<br />

Matsuura Milling S-9119<br />

Muratec Turning S-8574<br />

Nakamura-Tome Turning S-9119<br />

Okamoto Grinding TBD<br />

Omax Fabrication & Waterjet Cutting N-6228<br />

Shigiya Grinding N-6668<br />

USACH Grinding N-6938<br />

Stone Machinery, Inc. Chevalier Grinding S-8586<br />

HydMech Saws Fabrication N-6656<br />

Hurco Milling & Turning S-8319<br />

Johnford Milling & Turning S-8536<br />

Nomura Turning S-9266<br />

Southwest Industries Milling & Turning S-8032<br />

YouJi Turning S-8536<br />

ZPS Turning S-8640<br />

T. Bryce & Associates Inc. Current EDM EDM E-4626, S-9119<br />

Exeron EDM S-9119<br />

Fanuc Wire EDM S-8919, S-9119<br />

SmalTec EDM E-4340<br />

www.mpma.com

TABLE | OF CONTENTS<br />

July | August 2010<br />

8<br />

w w w . p m - m n . c o m<br />

Cover photo courtesy <strong>of</strong> Hegman Machine Tool, Inc. and Chiron. Photograph taken by Severyn Skoug with<br />

<strong>Minnesota</strong> <strong>Precision</strong> <strong>Manufacturing</strong> <strong>Association</strong>.<br />

18 Shop Pr<strong>of</strong>ile: Razor Edge Systems, Inc.<br />

A Sharper Approach From Stone Machinery<br />

Departments<br />

6 President’s Letter<br />

Features<br />

25 Industry Pr<strong>of</strong>ile: Yeager Machine, Inc.<br />

What You Need, When You Need It<br />

32 Investing in a Down Economy<br />

Companies Making Significant Investments<br />

by Melissa DeBilzan<br />

36 Industry Pr<strong>of</strong>ile: Command Tooling Systems LLC<br />

The New Command<br />

25 36<br />

18 32<br />

17 Who’s Who<br />

20 Made in MN<br />

23 Ask <strong>the</strong> Lawyer<br />

30 <strong>Manufacturing</strong> Matters<br />

34 <strong>Manufacturing</strong> Marvels<br />

39 MPMA Calendar<br />

40 MPMA Highlights<br />

42 Manufacturers’<br />

Marketplace<br />

45 MPMA Member Directory<br />

49 Advertisers’ Index<br />

July | August 2010 PRECISION MANUFACTURING | 5

PRESIDENT’S | LETTER<br />

Building a Base<br />

MAINTAINING MANUFACTURING<br />

by Mike Gramse<br />

In my last letter I wrote about leaving<br />

on a trip to Sou<strong>the</strong>ast Asia and <strong>the</strong><br />

appreciation I have for my staff who<br />

would allow me to be out <strong>of</strong> <strong>the</strong> country<br />

for 3 weeks. Now, obviously, we are back<br />

from Asia so I thought I would share<br />

some observations with you.<br />

None <strong>of</strong> <strong>the</strong> places we went to,<br />

including Bangkok; Singapore; Vung<br />

Tau, Vietnam; Taiwan; Okinawa,<br />

Japan; and Hong Kong, Shanghai, and<br />

Beijing, China were anything like I had<br />

remembered. We only saw a small part <strong>of</strong><br />

each city and for only one day each, but<br />

I was amazed at how westernized <strong>the</strong>y<br />

have all become, even Vietnam.<br />

To me <strong>the</strong>y all looked like any o<strong>the</strong>r<br />

big city in <strong>the</strong> United States. They have<br />

wide, four lane highways, tall buildings<br />

and landscaped boulevards, along with<br />

Kentucky Fried Chickens and 7-Elevens<br />

everywhere. Everyone dresses like us or<br />

better and an unbelievable number have<br />

cell phones.<br />

It appears to me that much <strong>of</strong> <strong>the</strong> old<br />

culture is gone. Their local tours took us<br />

to areas that have replicated or preserved<br />

<strong>the</strong>ir culture, in a fashion similar to that<br />

<strong>of</strong> our pioneer villages. The old stuff<br />

seems to be all gone except for a few<br />

isolated pockets.<br />

I was surprised to talk with <strong>the</strong> local<br />

people; <strong>the</strong>y all seem to be pretty pleased<br />

with <strong>the</strong>ir lifestyles and <strong>the</strong>ir governments,<br />

even in Vietnam. Thailand is bracing for<br />

demonstrations and hundreds <strong>of</strong> police<br />

<strong>of</strong>ficers and soldiers are getting prepared.<br />

That said, I don’t understand how<br />

<strong>the</strong>ir economies work. A $40,000 car in<br />

Vietnam cost $20,000 in <strong>the</strong> United States<br />

and a $30,000 Dodge van in <strong>the</strong> United<br />

States cost $60,000 in China. I don’t know<br />

how <strong>the</strong>re can be so many cars when <strong>the</strong><br />

average income ranges from $100 to $200<br />

per month.<br />

We had spent several days in Beijing<br />

10 years ago, and today you wouldn’t have<br />

known it was <strong>the</strong> same city. The old areas<br />

They all are building<br />

a manufacturing<br />

base and we will<br />

need to maintain<br />

ours in order to not<br />

be passed by.<br />

and a billion bicycles all have disappeared<br />

and have been replaced by four-to-six<br />

lane roads, subways, and shopping areas<br />

with designer products or replicas <strong>the</strong>re<br />

<strong>of</strong>. The Olympic Village buildings are<br />

amazing. It seems impossible to complete<br />

so much change in just 10 years.<br />

But what really surprises me is that<br />

<strong>the</strong> economies are growing in all <strong>of</strong> <strong>the</strong>se<br />

countries. Their standards <strong>of</strong> living are<br />

improving and <strong>the</strong>y all seem pretty happy.<br />

They certainly haven’t caught up to us, but<br />

<strong>the</strong>y are getting closer. If Beijing could<br />

rebuild itself in 10 years, how far behind<br />

are <strong>the</strong>y really?<br />

Our country seems to have been pretty<br />

stagnant, or maybe even retracted in <strong>the</strong><br />

past 10 years but, obviously, we are setting<br />

<strong>the</strong> standard and it’s going to take a lot <strong>of</strong><br />

something to maintain our position.<br />

They all are building a manufacturing<br />

base and we will need to maintain ours in<br />

order to not be passed by.<br />

Preserve <strong>the</strong> Programs. GET ENGAGED.<br />

By <strong>the</strong> way, my staff did a great job<br />

while I was gone; I had no reason to<br />

worry. PM<br />

Mike Gramse is president<br />

<strong>of</strong> MRG Tool & Die Corp. in<br />

Faribault, Minn. He can be<br />

reached at<br />

mgramse@toolanddie.net.<br />

www.pm-mn.com<br />

Supporting <strong>Minnesota</strong> in becoming<br />

<strong>the</strong> world leader in precision contract<br />

manufacturing and related technologies.<br />

EDITOR | PUBLICATIONS MANAGER<br />

Amy Slettum<br />

SALES MANAGER<br />

Tim Crolley<br />

Designer | Art Director<br />

Severyn Skoug<br />

<strong>Minnesota</strong> <strong>Precision</strong><br />

<strong>Manufacturing</strong> <strong>Association</strong><br />

5353 Wayzata Blvd., Suite 207<br />

Minneapolis, MN 55416<br />

952.564.3041<br />

www.mpma.com<br />

MPMA Officers<br />

President<br />

Mike Gramse, MRG Tool & Die Corp.<br />

Vice President<br />

Bob Miller, Kendeco Tool Crib<br />

Treasurer<br />

Paul Huot, Huot <strong>Manufacturing</strong> Company<br />

Secretary<br />

Kim Arrigoni, Haberman Machine, Inc.<br />

EXECUTIVE DIRECTOR<br />

Jaime Nolan, CAE<br />

associate DIRECTOR<br />

Luann Bartley<br />

Editorial Committee<br />

Chair, Editor-in-Chief<br />

Brenda Kyle<br />

blk@sppa.com<br />

Michelle Gates<br />

mgates@bpkz.com<br />

Denny Nybo<br />

dennynybo@comcast.net<br />

Bill Remes<br />

billr@ameristarmfg.com<br />

Chuck Remillard<br />

chuckr@kurt.com<br />

Ted Roberts<br />

troberts@robertsautomatic.com<br />

Andrew Skoog<br />

apskoog@gmail.com<br />

Fred Zimmerman<br />

zimco@visi.com<br />

For editorial, advertising or<br />

membership information:<br />

Voice: 952.564.3041<br />

Fax: 952.252.8096<br />

<strong>Precision</strong> <strong>Manufacturing</strong> (ISSN 0273-7523),<br />

is published six times per year by IntrinXec<br />

Management Inc., 5353 Wayzata Blvd., Suite<br />

207, Minneapolis, MN 55416. <strong>Precision</strong><br />

<strong>Manufacturing</strong> is <strong>the</strong> only authorized regular<br />

publication <strong>of</strong> <strong>the</strong> <strong>Minnesota</strong> <strong>Precision</strong><br />

<strong>Manufacturing</strong> <strong>Association</strong> (MPMA). Opinions<br />

and conclusions expressed in <strong>the</strong> magazine<br />

are those <strong>of</strong> <strong>the</strong> individual writer and do<br />

not necessarily reflect <strong>the</strong> <strong>of</strong>ficial position<br />

<strong>of</strong> <strong>the</strong> MPMA or its <strong>of</strong>ficers. Advertising<br />

rates provided on request. Correspondence<br />

regarding <strong>the</strong> magazine, including industry<br />

news releases, photographs and press releases<br />

relating to precision manufacturing should be<br />

sent to <strong>Precision</strong> <strong>Manufacturing</strong>, Amy Slettum,<br />

c/o IntrinXec Management, Inc., 5353 Wayzata<br />

Blvd., Suite 207, Minneapolis, MN 55416.<br />

Electronic correspondence, including attached<br />

files in Word or plain text formats, may be sent<br />

to amy@mpma.com. Unsolicited materials will<br />

not be returned. POSTMASTER: Send address<br />

changes to: <strong>Precision</strong> <strong>Manufacturing</strong>, c/o<br />

IntrinXec Management, Inc., 5353 Wayzata<br />

Blvd., Suite 207, Minneapolis, MN 55416.<br />

Copyright ©2010 <strong>Minnesota</strong> <strong>Precision</strong><br />

<strong>Manufacturing</strong> <strong>Association</strong>.<br />

6 | PRECISION MANUFACTURING July | August 2010

The FEDERATED Insurance Companies<br />

Home Office: 121 East Park Square • Owatonna, <strong>Minnesota</strong> 55060<br />

Phone: (507) 455-5200 • www.federatedinsurance.com<br />

®

IMTS<br />

2O1O<br />

I n t e r n a t i o n a l M a n u f a c t u r i n g T e c h n o l o g y S h o w<br />

by B Kyle<br />

Connecting global technology<br />

The largest and longest running<br />

manufacturing technology trade<br />

show in <strong>the</strong> United States is held<br />

every o<strong>the</strong>r year at McCormick<br />

Place in Chicago, Ill.<br />

The International <strong>Manufacturing</strong><br />

Technology Show (IMTS) 2010 will<br />

run September 13 - 18. IMTS is ranked<br />

among <strong>the</strong> largest tradeshows in<br />

<strong>the</strong> world. Recognized as one <strong>of</strong><br />

<strong>the</strong> world’s preeminent stages for<br />

introducing and selling manufacturing<br />

equipment and technology, IMTS<br />

attracts more than 92,000 visitors<br />

from every level <strong>of</strong> industry and more<br />

than 116 countries. IMTS is owned<br />

and managed by <strong>the</strong> <strong>Association</strong> for<br />

<strong>Manufacturing</strong> Technology (AMT).<br />

In preparation for this issue, we spoke<br />

with Doug Woods, president <strong>of</strong> AMT.<br />

PM: Doug, thanks for talking with us.<br />

On behalf <strong>of</strong> our readers who may<br />

be considering his or her first trip to<br />

Chicago, “Why IMTS?”<br />

DW: IMTS is <strong>the</strong> opportunity to elevate<br />

your thinking, optimize your business,<br />

find inspiration. This is <strong>the</strong> premier<br />

event for manufacturing technology.<br />

IMTS has a hard earned reputation as a<br />

business generator, providing you with<br />

<strong>the</strong> highest concentration <strong>of</strong> buyers and<br />

decision makers in <strong>the</strong> manufacturing<br />

technology industry.<br />

You can see and compare technologies<br />

from around <strong>the</strong> world. You get answers<br />

that you need to stay competitive. It’s all<br />

in one place, under one ro<strong>of</strong>, at one time.<br />

PM: What is <strong>the</strong> history <strong>of</strong> IMTS?<br />

DW: IMTS’s first exposition was in 1927,<br />

held in <strong>the</strong> Cleveland Auditorium. The<br />

show occupied 63,000 square feet and<br />

attendance was just over 12,000. The<br />

show had a total <strong>of</strong> 428 machines on<br />

display, and required more power than<br />

any single industry exposition ever held,<br />

anywhere before.<br />

Despite history intervening in <strong>the</strong><br />

1940s, IMTS was re-established and<br />

moved to Chicago right after World War<br />

II. Today IMTS occupies over 1.2 million<br />

square feet <strong>of</strong> exhibit space, with over<br />

92,000 attendees.<br />

IMTS initially was developed as<br />

a vehicle for major manufacturers to<br />

get toge<strong>the</strong>r and share technology, to<br />

demonstrate <strong>the</strong> latest in technology<br />

advancements. And it has come a long<br />

way since <strong>the</strong>n. The focus at early shows<br />

was on machine tools and accessories.<br />

Today, <strong>the</strong> focus is on manufacturing<br />

technologies: All <strong>of</strong> <strong>the</strong> things that<br />

would go into machining centers,<br />

multi-tasking machines, workholding<br />

alternatives, manufacturing processes,<br />

including water jets, plasma and laser<br />

systems, quality systems, s<strong>of</strong>tware<br />

controls technology, gear manufacturing,<br />

cleaning systems, and more.<br />

IMTS really is a diverse<br />

manufacturing technology event where<br />

you have an opportunity to learn about<br />

any aspect <strong>of</strong> manufacturing that would<br />

be important to your business.<br />

PM: We already are looking forward to a<br />

very busy IMTS. What is new this year?<br />

DW: This year we are very proud to<br />

introduce <strong>the</strong> new Industry and<br />

Technology Conference, which will<br />

take place during IMTS. The conference<br />

opens on Monday, September 13, with<br />

<strong>the</strong> first-ever Industry Inspiration Day. A<br />

luncheon keynote program will conclude<br />

with a roundtable panel discussion<br />

among experts representing <strong>the</strong><br />

aerospace, medical device, automotive<br />

and energy sectors.<br />

Industry and<br />

Technology Conference<br />

Monday, September 13, 2010<br />

Location: Industry and Technology<br />

Conference area <strong>of</strong> <strong>the</strong> West Building<br />

Time: 12:00 – 3:00 pm<br />

Panel Members<br />

Aerospace Sector: Allan McArtor,<br />

chairman <strong>of</strong> Airbus Americas<br />

Medical Device Sector: Rene van<br />

de Zande, president and CEO <strong>of</strong> <strong>the</strong><br />

Emergo Group<br />

Automotive Sector: Jim Tetrealt,<br />

vice president <strong>of</strong> North American<br />

<strong>Manufacturing</strong> for Ford Motor<br />

Company<br />

Energy Sector: Denise Bode,<br />

nationally recognized policy expert<br />

and CEO <strong>of</strong> <strong>the</strong> American Wind<br />

Energy <strong>Association</strong> (AWEA)<br />

More information on <strong>the</strong> conference<br />

can be found at<br />

www.imts.com/conference.<br />

8 | PRECISION MANUFACTURING July | August 2010

PM: What do you expect from IMTS<br />

2010 attendance compared to 2008?<br />

DW: Good question. Truly, we expect this<br />

year’s attendance to be quite close to 2008<br />

numbers. There is a lot <strong>of</strong> pent-up demand<br />

in <strong>the</strong> marketplace, and we should see that<br />

reflected in show numbers.<br />

Across most industries, tradeshows<br />

are <strong>of</strong>f by 20-30 percent. For us, as <strong>of</strong><br />

May, we already are very close to 2008<br />

exhibitor numbers. This is substantially<br />

less participation change than <strong>the</strong><br />

industry norm, and we are very pleased.<br />

Considering how difficult <strong>the</strong> 2009<br />

recession was on our industry, we see this<br />

to be recognition that, as we recover, we<br />

need to promote technology, continue to<br />

collaborate and seek out opportunities<br />

wherever possible.<br />

PM: What’s new in <strong>the</strong> Emerging<br />

Technology Center this year?<br />

DW: I always find <strong>the</strong> Emerging Technology<br />

Center (ETC) to be especially interesting.<br />

This area was conceived in 2006. Its<br />

purpose is to provide both exhibitors and<br />

attendees a glimpse <strong>of</strong> where <strong>the</strong> industry<br />

is going regarding newest technology.<br />

Essentially, what you see at <strong>the</strong> ETC will be<br />

on <strong>the</strong> IMTS floor one or two shows into<br />

<strong>the</strong> future.<br />

Featured this year in <strong>the</strong> ETC are<br />

MTConnect and Cloud Computing.<br />

MTConnect was introduced at <strong>the</strong> 2008<br />

show, and was well received. This show<br />

will demo some enhanced applications,<br />

actual methodologies for utilizing, and<br />

interactive opportunities for users to<br />

figure out how to use<br />

<strong>the</strong> data provided.<br />

O<strong>the</strong>r cells will<br />

feature nanotechnology,<br />

microtechnology,<br />

additive and freeform<br />

technologies.<br />

PM: What’s a “must see”<br />

on your show schedule?<br />

DW: I definitely will be<br />

checking out Lockheed<br />

Martin’s F35 Lightning<br />

fighter aircraft.<br />

This fifth generation<br />

fighter combines stealth<br />

with high speed, has a<br />

lot <strong>of</strong> sensor technology<br />

and networks built in.<br />

This is <strong>the</strong> epitome<br />

<strong>of</strong> true advanced<br />

manufacturing<br />

technology in a single<br />

system fighter jet.<br />

(Refer to page 14 for<br />

additional information<br />

on <strong>the</strong> F35 Lightning<br />

fighter aircraft.)<br />

I also plan to take<br />

a look at <strong>the</strong> Tesla<br />

Roadster, a high<br />

performance electric<br />

sports car. And an<br />

engine from Boeing’s<br />

new commercial aircraft,<br />

<strong>the</strong> 787 Dreamliner, will<br />

be on display as well.<br />

w w w . i m t s . c o m<br />

Monday, September 13 -<br />

Saturday, September 18, 2010<br />

IMTS ATTRACTIONS<br />

Some fun and exciting activities that will be<br />

happening during IMTS 2010!<br />

EMERGING TECHNOLOGY CENTER<br />

The Emerging Technology Center (ETC) will<br />

be showcasing leading edge manufacturing<br />

technologies in 3D. Experts will be providing<br />

hands-on experiences in ways that must be<br />

seen to be believed. The ETC technologies<br />

highlighted this year include:<br />

• Additive <strong>Manufacturing</strong><br />

• Cloud Computing<br />

• MTConnect<br />

• Nanotechnology<br />

• Micro-<strong>Manufacturing</strong><br />

• Location: North Building Lobby, Booth N-650<br />

IMTS 2010 SHOW PAVILIONS<br />

Whatever your interest you’ll find a pavilion for it.<br />

You can compare machines capabilities, prices,<br />

services, everything you need to know from elite<br />

builders around <strong>the</strong> world right at IMTS.<br />

South Building<br />

Metal Cutting<br />

North Building<br />

Abrasive Machining/Sawing/Finishing<br />

Alternative <strong>Manufacturing</strong> Processes<br />

Gear Generation<br />

Metal Forming & Fabricating/Lasers<br />

East Building (Lakeside Center)<br />

EDM<br />

Machine Components/Cleaning/Environmental<br />

Quality Assurance<br />

Controls and CAD-CAM<br />

West Building<br />

Tooling and Workholding Systems<br />

NIMS Student Summit at IMTS<br />

South Building, Room S105<br />

Hours are 9:00 a.m. until 1:00 p.m. daily<br />

The NIMS Student Summit will combine<br />

an interactive Career Development Center<br />

(CDC) with a dynamic self-guided tour<br />

<strong>of</strong> <strong>the</strong> technology and manufacturing<br />

exhibition. The Student Summit aims to stir<br />

up interest and excitement toward careers<br />

in precision manufacturing among young<br />

people through close contact with industry<br />

pr<strong>of</strong>essionals, interactive demonstrations<br />

and real life examples.

cover | IMTS 2010<br />

distributors in our region<br />

Productivity Inc • Plymouth, Minn.<br />

Andy Archer and Pete Nelson, sales managers<br />

www.productivity.com<br />

Productivity Inc. is a solutions-based provider in Plymouth,<br />

Minn, representing a wide range <strong>of</strong> manufacturing solutions.<br />

<strong>Manufacturing</strong> definitely looks to be having a better year, so<br />

we expect to see a lot <strong>of</strong> activity at IMTS. We anticipate seeing <strong>the</strong><br />

most interesting developments in specific areas.<br />

The first development is in <strong>the</strong> 5-axis machining solutions.<br />

Traditionally regarded as advanced technology, best suited to<br />

<strong>the</strong> aerospace and automotive industry, 5-axis machining now<br />

is being applied to a wide variety <strong>of</strong> manufacturing applications,<br />

including medical and <strong>the</strong> mold and die sector. One <strong>of</strong> <strong>the</strong> biggest<br />

advantages <strong>of</strong> this technology, particularly in a slower economy,<br />

is smaller lot sizes and quicker turnaround time in addition to<br />

better overall accuracy and reduced work in process. The result<br />

can produce a significant competitive advantage.<br />

Second would be <strong>the</strong> multi-tasking machines. Some <strong>of</strong> <strong>the</strong><br />

new multi-tasking technologies that will be shown by Nakamura<br />

include 3 turret—twin spindle machines capable <strong>of</strong> having three<br />

tools in <strong>the</strong> cut simultaneously to drastically reduce cycle times<br />

and increase throughput.<br />

Ano<strong>the</strong>r new technology that will be shown includes<br />

machines with a B-axis head and full 5-axis machining capability.<br />

They <strong>of</strong>fer solutions to many typical production challenges:<br />

multiple setups, tolerance stack-up, large in-process inventory<br />

and longer cycle times.<br />

Ano<strong>the</strong>r technology worth exploring at IMTS is <strong>the</strong> nanoor<br />

micro-machining technology. As applications grow in<br />

complexity and shrink in size, <strong>the</strong> future is about miniature,<br />

micron, and sub-micron parts production. The world definitely<br />

is getting smaller, and we anticipate seeing some very interesting<br />

demos in this area. Within our product line in particular, we<br />

have seen some new advances in Swiss turning technology<br />

with Citizen. Citizen has introduced a couple <strong>of</strong> new models,<br />

particularly <strong>the</strong> A-Series machines. These machines are <strong>the</strong><br />

fastest CNC machines in <strong>the</strong> world with rapid rates at 1,576<br />

IPM, easy to use and very cost competitive.<br />

The field <strong>of</strong> robotics continues to develop rapidly, particularly<br />

in <strong>the</strong> area <strong>of</strong> vision guidance. Robotic vision is used for part<br />

identification and navigation, and applications generally deal with<br />

finding a part and orienting it for robotic handling or inspection.<br />

Productivity’s Robotics Division is happy to introduce <strong>the</strong> latest<br />

in vision technologies at <strong>the</strong> Fanuc booth.<br />

There are many new advances in <strong>the</strong> world <strong>of</strong> waterjet cutting.<br />

Omax will be displaying <strong>the</strong>ir new Maxiem line <strong>of</strong> cost effective<br />

machines as well as bevel cutting and 4th axis.<br />

You also don’t want to miss <strong>the</strong> tooling and accessories at IMTS.<br />

They are mostly in <strong>the</strong> West Hall and will afford great opportunities<br />

to find specific tooling solutions to your most demanding needs.<br />

Productivity works with a wide variety <strong>of</strong> tooling and accessories<br />

companies and our staff will be at those booths.<br />

Hales Machine Tool, Inc. • Plymouth, Minn.<br />

Tim Hales, vice president<br />

www.halesmachinetool.com<br />

Hales Machine Tool, Inc., in Plymouth, Minn., is <strong>the</strong> number<br />

one distributor in <strong>the</strong> country for major machine tool<br />

manufacturers.<br />

There is a lot to see at IMTS this year. Most OEMs are<br />

introducing machines that can do more in one work envelope.<br />

Combining multiple technologies on a single machine makes<br />

<strong>the</strong> process more complex, but <strong>the</strong> advantages can be worth <strong>the</strong><br />

effort. Among o<strong>the</strong>r benefits, we’re talking improved component<br />

quality, greater flexibility, and drastically increased throughput<br />

and daily invoicing.<br />

Doosan: Coming to you from Seoul, Korea, Doosan is now <strong>the</strong><br />

third largest machine tool builder in <strong>the</strong> world, and <strong>the</strong>ir booth<br />

will have some really incredible demos at this show. They will<br />

have 12 turning centers, many with multiple axis, and eight<br />

machining centers on display. Their newest and biggest is a VTL,<br />

60” swing with a 50” table. It is a RAM style with tool changer<br />

and live tooling.<br />

Doosan also has a new model in <strong>the</strong> MX Series, which is a<br />

multi-tasking machine. It features an articulating milling head<br />

on <strong>the</strong> upper slide and standard style turret with live tooling<br />

on <strong>the</strong> lower slide and has two opposing spindles with identical<br />

specifications. This is not unique to Doosan, but is a new model<br />

for <strong>the</strong>m.<br />

Yamazen: Yamazen is an importer <strong>of</strong> multiple product lines. One<br />

<strong>of</strong> <strong>the</strong>ir most well-known lines is Bro<strong>the</strong>r. Bro<strong>the</strong>r always has<br />

been known for extremely fast, high-speed drill tap machines.<br />

Their latest series <strong>of</strong> product takes it to ano<strong>the</strong>r level <strong>of</strong> rigidity and<br />

speed, and now will be considered a VMC ra<strong>the</strong>r than just a drill<br />

tap machine. They will be displaying five new models in <strong>the</strong> booth.<br />

Yamazen also imports Mitsubishi and <strong>the</strong>y’ve got a new<br />

machine, <strong>the</strong> V1, with super high precision for manufacturing<br />

extremely high tolerance parts. One <strong>of</strong> <strong>the</strong> target markets <strong>of</strong> this<br />

machine is <strong>the</strong> medical industry. The machine comes in multiple<br />

configurations, and I expect to see a 5-axis model at <strong>the</strong> show.<br />

Mitsubishi also builds bridge type mills. We will see a bridge mill<br />

with attachment changers.<br />

Milltronics: An American machine tool builder in Waconia,<br />

Minn., Milltronics has come out with some really unique<br />

machines in <strong>the</strong> last few months. Their new machines, <strong>the</strong> TT24<br />

and TT40, are VMCs, with an in-line pallet changing system and<br />

two pallets <strong>of</strong> ei<strong>the</strong>r 24x24 or 40x40. Through programming,<br />

<strong>the</strong>se machines have <strong>the</strong> capability to sync those two pallets and<br />

make <strong>the</strong> 24x24 into a 24x48 travel, or a 40x40 into a 40x80.<br />

Milltronics is <strong>the</strong> only builder in <strong>the</strong> world with this capability.<br />

They will have a TT24 with full synchronization in <strong>the</strong>ir booth.<br />

Everyone has to stop and see that demo.<br />

Also, don’t miss <strong>the</strong> tooling pavilion. Kurt <strong>Manufacturing</strong><br />

Company Inc., in particular, is showing <strong>of</strong>f many productivity<br />

enhancement products, including <strong>the</strong> NEMI flat table vacuum<br />

pod workholding systems. One <strong>of</strong> <strong>the</strong> many workholding<br />

innovations that Kurt will be showing, may be <strong>the</strong> item that pays<br />

for your visit to IMTS.<br />

10 | PRECISION MANUFACTURING July | August 2010

JOIN MPMA AT IMTS 2010<br />

Hegman Machine Tool, Inc. • Maple Grove, Minn.<br />

Terry Gren, sales manager - machining division<br />

www.hegmanmachine.com<br />

Hegman Machine Tool, Inc. (HMT) is an upper Midwest leader<br />

in providing products, services and support to manufacturers<br />

committed to performance and pr<strong>of</strong>itability.<br />

We anticipate that this will be an exciting show. With <strong>the</strong><br />

introduction over <strong>the</strong> last 2 years <strong>of</strong> really amazing and innovative<br />

technologies to help American manufacturers compete, and as <strong>the</strong><br />

global economy continues its trend toward recovery, manufacturing in<br />

<strong>the</strong> United States is going to continue to show marked improvements.<br />

The pressure <strong>of</strong> global competition is forcing all <strong>of</strong> us to examine our<br />

efficiencies and processes. This could be <strong>the</strong> most important IMTS we<br />

have ever attended.<br />

Please visit with us this year at IMTS and be sure to stop and explore<br />

<strong>the</strong> future at <strong>the</strong> following world-class machine tool manufacturers:<br />

Okuma: The debut <strong>of</strong> <strong>the</strong> Genos M460 VMC as well as <strong>the</strong> MA-4000H<br />

HMC, both featuring <strong>the</strong> innovative Okuma Thinc Control, will be two<br />

<strong>of</strong> Okuma’s featured highlights.<br />

Additionally, <strong>the</strong> newly designed LB-EX Series <strong>of</strong> multi-tasking<br />

turning centers utilizes VTL technology second to none in <strong>the</strong> industry.<br />

The new MULTUS B750 NP for very large, complex components,<br />

requiring multiple operations on a single setup will be featured.<br />

Hardinge: Hardinge will display with <strong>the</strong>ir new T-Series turning centers<br />

and <strong>the</strong> Super-<strong>Precision</strong> T-Series turning center. The T-Series machine<br />

is ideal for 2-axis, high precision machining or complex multi-tasking<br />

operations that require delicate part handling or single setup, quite<br />

possibly <strong>the</strong> most accurate production turning center on <strong>the</strong> market.<br />

Chiron: Chiron will have a machine on display in <strong>the</strong> Big Kaiser Tooling<br />

booth. Chiron has some <strong>of</strong> <strong>the</strong> most innovative 5-axis processes for<br />

complex components, developed as stand alone machines or full<br />

turnkey solutions. Multiple spindles, automation, complexity, tight<br />

tolerances, funky materials—welcome to Chiron’s world.<br />

Maier USA: A subsidiary <strong>of</strong> Maier Machine Tools in Germany, Maier<br />

is known for its modular systems at a great price. Its series <strong>of</strong> Swiss<br />

turning machines starts at <strong>the</strong> basic yet precise Series B, 5-axis machine<br />

all <strong>the</strong> way up to its Series F4, a 16-axis machine that allows for<br />

simultaneous working with four tools.<br />

Hydromat: If you are running large part volumes, you already know<br />

about Hydromat. This year you should pay particular attention to <strong>the</strong><br />

AT 6-100 Advanced Technology Productivity Center, best described<br />

as four high speed (up to 60,000 RPM ), mini VTLs, all cutting<br />

simultaneously in one package, producing parts fast, complete and<br />

totally deburred.<br />

Trumpf: Trumpf will be displaying two new products at IMTS. The<br />

first is <strong>the</strong> TruBend 7036 All Electric Press Brake, which <strong>of</strong>fers a 40 ton<br />

x 40” bend width, featuring a lightweight carbon fiber backguage and<br />

RAM control <strong>of</strong> .00008 in. repeatability.<br />

The second is <strong>the</strong> TruLaser 1030. This is Trumpf technology at an<br />

incredible price for this 120” x 60” x 3” TruCoax Laser for .5” mild steel.<br />

Techni Waterjet: Next generation technology is on display at this<br />

innovative leader in <strong>the</strong> waterjet industry. The Quantum ESP is<br />

an electric servo pump that can save companies 30,000 kilowatt<br />

hours and 240,000 gallons <strong>of</strong> water a year. The PAC55 is <strong>the</strong> only<br />

functioning 5-axis cutting waterjet head in <strong>the</strong> industry.<br />

CHOOSE FROM 2-DAY OR 3-DAY PACKAGES<br />

Join MPMA for <strong>the</strong> 28th edition <strong>of</strong> IMTS, <strong>the</strong><br />

premier manufacturing technology show in<br />

North America. More than 1,500 exhibiting<br />

companies will occupy 1.2 million net square<br />

feet <strong>of</strong> exhibit space at <strong>the</strong> McCormick Place<br />

complex in Chicago, Ill. <strong>Manufacturing</strong> industry<br />

pr<strong>of</strong>essionals from <strong>the</strong> United States and over<br />

119 countries attend IMTS. See more than<br />

15,000 new machine tools, controls, computers,<br />

s<strong>of</strong>tware, components, systems and processes<br />

that can improve your efficiency. You will gain<br />

valuable ideas and insights from over 1,500 <strong>of</strong><br />

<strong>the</strong> world’s leading equipment producers.<br />

COMPLETE PACKAGE INCLUDES:<br />

Two- and three-day packages available.<br />

Packages include:<br />

• Round-trip airfare from Minneapolis to<br />

Chicago.<br />

• Transportation from Midway Airport to<br />

Hyatt Regency on arrival date.<br />

• Transportation from McCormick Place to<br />

Midway Airport on departure date.<br />

• One- or two-night stay at <strong>the</strong> Hyatt<br />

Regency on Wacker Drive (single or double<br />

occupancy available).<br />

• IMTS show admission and free shuttle<br />

service from hotel to show and back<br />

throughout <strong>the</strong> day.<br />

• IMTS pre-planning information packets<br />

featuring show layout and directory.<br />

• Evening member reception at Hyatt<br />

Regency on Tuesday, September 14, 2010 -<br />

sponsored by EPICOR.<br />

PACKAGE A – 2-DAY PACKAGE<br />

Itinerary: Tuesday, September 14, 2010<br />

Depart MSP 8:45 a.m.<br />

Arrive MDW: 10:10 a.m.<br />

Wednesday, September 15, 2010<br />

Depart MDW 5:30 p.m.<br />

Arrive MSP 7:10 p.m.<br />

Cost: Double Occupancy $545 per person<br />

Single Occupancy $650 per person<br />

PACKAGE B – 3-DAY PACKAGE<br />

Itinerary: Tuesday, September 14, 2010<br />

Depart MSP 8:45 a.m.<br />

Arrive MDW: 10:10 a.m.<br />

Thursday, September 16, 2010<br />

Depart MDW 5:30 p.m.<br />

Arrive MSP 7:10 p.m.<br />

Cost: Double Occupancy $675 per person<br />

Single Occupancy $895 per person<br />

July | August 2010 PRECISION MANUFACTURING | 11

cover | IMTS 2010<br />

distributors in our region<br />

Agility Machine Tool, Inc.<br />

Blaine, Minn.<br />

Brian Holcomb, president<br />

www.agilitymachine.com<br />

Established in 1996, Agility Machine<br />

Tool’s specialty is in personalized service<br />

and flexible solutions for our customers.<br />

We are seeing <strong>the</strong> smaller job shops<br />

expanding into multi-axis, multioperational<br />

machines. For <strong>the</strong>se shops to<br />

be competitive, <strong>the</strong>y know <strong>the</strong>y need to<br />

have more complete parts coming <strong>of</strong>f <strong>the</strong><br />

machine in one setup. This includes la<strong>the</strong>s<br />

with live tooling and sub spindles, Swiss<br />

turning machines with multiple axes, and<br />

vertical and horizontal machining centers<br />

with 4- and 5-axis design. The challenge is<br />

that <strong>the</strong>se machines do more but <strong>the</strong>y also<br />

require more highly skilled operators.<br />

One Agility customer is a great<br />

example <strong>of</strong> <strong>the</strong> trend. This customer had<br />

a family <strong>of</strong> parts with repeat orders every<br />

month. Agility worked with <strong>the</strong>m to<br />

analyze production time requirements.<br />

The solution was a 6-pallet horizontal with<br />

120 tools. All <strong>the</strong> fixtures and tools were<br />

in <strong>the</strong> machine at all times. Their setup<br />

time was reduced to zero. The capability<br />

<strong>of</strong> running all <strong>the</strong> parts simultaneously<br />

was a huge cost and time savings.<br />

My advice for <strong>the</strong> new person at IMTS:<br />

Everyone will be sending out advertising—<br />

read it. Then plan your route so you are<br />

sure to visit <strong>the</strong> booths <strong>of</strong> highest priority<br />

first. And, <strong>of</strong> course, be sure to find us at<br />

our various booths.<br />

<strong>Manufacturing</strong> is not dead in America.<br />

Keep <strong>the</strong> faith. We’ve been through this<br />

before; this was a bad one but <strong>the</strong> survivors<br />

should be seeing business improve.<br />

YCM: CNC milling and turning along<br />

with wire EDM’s.<br />

CNC Systems: HMC’s, drill tap machines,<br />

bridge mills, VTL’s.<br />

Nexturn: CNC Swiss turning.<br />

Hwacheon: CNC la<strong>the</strong>s, 5-axis milling.<br />

All Tech Machinery & Supply<br />

Maple Grove, Minn.<br />

Jeff Johnson, president<br />

www.atms.us.com<br />

All Tech Machinery & Supply specializes<br />

in niche areas that create <strong>the</strong> very best<br />

value to <strong>the</strong> manufacturing solution.<br />

All Tech deals with <strong>the</strong> pinnacle<br />

machines—<strong>the</strong> finest quality. With <strong>the</strong><br />

right equipment, we can compete. But it<br />

does take commitment at all levels <strong>of</strong> a<br />

company and <strong>the</strong> suppliers. We currently<br />

are working on a mold making automation<br />

project using robots, which will make<br />

our customer price competitive with its<br />

Chinese competitors. Bottom line: China<br />

will not beat us. There is plenty <strong>of</strong> work to<br />

do, but we can compete!<br />

Right now, computers in this industry<br />

are under-utilized. This has to change, and<br />

I believe it will. Those who don’t embrace<br />

<strong>the</strong> change will find it more difficult to<br />

compete. What will help drive this is <strong>the</strong><br />

new s<strong>of</strong>tware coming out: manufacturing<br />

and CAM s<strong>of</strong>tware. We need to advance<br />

our processes and I anticipate seeing a lot<br />

<strong>of</strong> that at IMTS this year.<br />

Solid S<strong>of</strong>tware has partnered with<br />

CAM s<strong>of</strong>tware companies to allow<br />

for multiple programs to be generated<br />

automatically from solids. Same for die<br />

manufacturing when Solid S<strong>of</strong>tware<br />

partners with Cam Tool. We anticipate its<br />

entrance into <strong>the</strong> industry sometime in<br />

late 2010, 2011.<br />

Yasda: Capabilities include cutting carbide<br />

on a machining center—primarily die<br />

manufacturing. Hard milling, such as,<br />

carbide, glass, and 65 Rockwell steel, all are<br />

no problem for us. We are capable <strong>of</strong> <strong>the</strong><br />

most demanding tolerances and processes.<br />

Jinn Fa Cyber CNC<br />

Chmer EDM<br />

Creative Evolutions<br />

NTC<br />

Concept Machine Tool Sales, Inc.<br />

Minneapolis, Minn.<br />

Craig Conlan, president/CEO<br />

www.conceptmachine.com<br />

Concept Machine Tool Sales, Inc.<br />

exclusively represents a variety <strong>of</strong> <strong>the</strong><br />

finest machine tool manufacturers<br />

throughout <strong>the</strong> world and has kept<br />

abreast <strong>of</strong> technological change by<br />

representing <strong>the</strong> most sophisticated and<br />

advanced machines available today.<br />

Since <strong>the</strong> company’s inception in<br />

1974, our highly qualified team has been<br />

committed to providing <strong>the</strong> highest level<br />

<strong>of</strong> customer satisfaction, applications,<br />

and service support to <strong>the</strong> manufacturing<br />

community. Our goal is to help you<br />

achieve outstanding results from your<br />

manufacturing process.<br />

Concept Machine Tool brings toge<strong>the</strong>r<br />

a dedicated and winning combination<br />

<strong>of</strong> machines, people, facilities and<br />

processes. Our experienced personnel and<br />

comprehensive facilities enable Concept<br />

Machine Tool to complete machine tool<br />

orders from <strong>the</strong> time <strong>the</strong> equipment is<br />

ordered, to delivery and installation on<br />

your shop floor and followed up with after<br />

<strong>the</strong> sale service and support. Concept<br />

has grown to a position <strong>of</strong> leadership<br />

among machine tool distributorships. The<br />

company’s beliefs and values have been <strong>the</strong><br />

cornerstones on which it was built.<br />

We know what it takes to keep you<br />

pr<strong>of</strong>itable.<br />

Our Machine Tool Division is a full<br />

service department <strong>of</strong>fering quality<br />

products such as CNC vertical and<br />

horizontal machining centers, wire EDM,<br />

sinkers, grinders, Swiss la<strong>the</strong>s, turning,<br />

grinding, boring, milling, drilling and<br />

tapping, CNC turning, and special<br />

purpose machining systems.<br />

Our line card is extensive. We invite<br />

you to visit <strong>the</strong> booths <strong>of</strong> our machine tool<br />

lines to meet our team. Enjoy <strong>the</strong> show!<br />

12 | PRECISION MANUFACTURING July | August 2010

cover | IMTS 2010<br />

Ellison Technologies<br />

Plymouth, Minn.<br />

Craig St John, president<br />

www.ellisontechnologies.com<br />

Ellison Technologies provides CNC<br />

machine tools, turnkey solutions, robotic<br />

automations and application-specific<br />

accessories to large scale manufacturers<br />

and job shops in <strong>Minnesota</strong>, North &<br />

South Dakota and western Wisconsin.<br />

Ellison recently celebrated our 50th<br />

year <strong>of</strong> providing CNC machine tool<br />

solutions to U.S. manufacturing. Our goal<br />

is keeping U.S. manufacturers globally<br />

competitive. We want manufacturing and<br />

related jobs to remain in <strong>the</strong> United States.<br />

By delivering solutions that enable our<br />

customers to produce parts at “<strong>the</strong> lowest<br />

cost per part,” we can keep <strong>the</strong> work here.<br />

Our primary products are la<strong>the</strong>s and<br />

machining centers made by Mori Seiki. We<br />

also handle Studer, Blohm, and Magerle<br />

CNC grinders and Kira machining centers.<br />

Ellison Technologies is also <strong>the</strong> largest<br />

integrator <strong>of</strong> Fanuc robots for machine<br />

tool load and unload applications. We<br />

see automation as a growing and very<br />

necessary trend in our industry.<br />

One <strong>of</strong> <strong>the</strong> biggest news items <strong>of</strong> <strong>the</strong><br />

year is that Mori Seiki is now <strong>the</strong> importer<br />

and support organization for DMG, <strong>the</strong><br />

world’s largest machine tool builder. The<br />

combination <strong>of</strong> Mori Seiki’s and DMG’s<br />

innovative products creates an impressive<br />

array <strong>of</strong> high-tech machine tool solutions.<br />

We encourage all visitors to IMTS to<br />

stop by <strong>the</strong> DMG/Mori Seiki booth. It<br />

will be hard to miss as it will be <strong>the</strong> largest<br />

booth at <strong>the</strong> show.<br />

I also encourage IMTS attendees to<br />

spend time visiting tooling and accessory<br />

booths while at <strong>the</strong> show. Looking at all<br />

<strong>the</strong> high-tech machine tools is fun and<br />

interesting, but one also can pick up ideas<br />

and low cost solutions in <strong>the</strong> tooling<br />

booths that can be quickly implemented<br />

and have quick paybacks.<br />

Machine Tool Supply Corp.<br />

Eagan, Minn.<br />

Todd Kerin, president<br />

www.machtool.com<br />

Machine Tool Supply Corp. is a 60 yearold<br />

regional distributor, with a full line <strong>of</strong><br />

machine tools, cutting tools, workholding<br />

products and engineered solutions.<br />

Production manufacturers and<br />

job shops are looking for <strong>the</strong> best way<br />

to compete globally. Automation and<br />

technology will drive our growth in<br />

manufacturing moving forward. We<br />

anticipate that companies are going<br />

to focus on investing in production<br />

capabilities that allow <strong>the</strong>m to be more<br />

cost effective, reduce labor, give <strong>the</strong>m<br />

competitive edge, reduce setup, reduce<br />

handling, run unattended, etc.<br />

Methods Machine Tool Group<br />

Feeler: These all-new machines feature<br />

extensive design and engineering by<br />

Methods Machine Tools, <strong>the</strong> leader in<br />

application expertise, service and support.<br />

FFG/Feeler is one <strong>of</strong> <strong>the</strong> world’s largest<br />

machine tool builders. Their booth display<br />

<strong>of</strong> machines is a must-see for IMTS 2010.<br />

Kiwa: High quality, Japanese built<br />

horizontal machining center product<br />

line that <strong>of</strong>fers unique capabilities in<br />

expandable pallets and tool capacity. They<br />

uniquely <strong>of</strong>fer <strong>the</strong> ability to field retr<strong>of</strong>it,<br />

expand, add pallet stations and add<br />

additional tooling stations.<br />

Microlution: This is an innovative<br />

Chicago-based builder focused on micromanufacturing.<br />

Their equipment is very<br />

desirable to <strong>the</strong> medical market and<br />

anyone making high precision small parts.<br />

Offers 3-axis and 5-axis micromachining,<br />

with compact footprints and significantly<br />

reduced energy consumption compared to<br />

<strong>the</strong> machine tools used to machine small<br />

parts today.<br />

Index-Traub: Their reputation for<br />

innovation in multi-tasking, multi-spindle,<br />

high production type machines is well<br />

known. It is a very high quality Germanbuilt<br />

machine. It is definitely worth your<br />

time to visit this exciting booth.<br />

Takamaz: A high quality, Japanese<br />

machine tool builder focusing on multitasking,<br />

integrated automation and part<br />

load/unload type capabilities.<br />

Quality & Service Machine<br />

Tool Company<br />

Minneapolis, Minn.<br />

Bill Lidfors, owner/president<br />

www.qandsmachinetool.com<br />

Quality & Service Machine Tool Company<br />

is an industrial distributor in business for<br />

over 40 years. We are focused on cutting<br />

tools, cutting fluids and applications<br />

to help our customers improve <strong>the</strong>ir<br />

tooling and tool performance.<br />

For an industrial distributor, IMTS is<br />

a great opportunity to see advances in all<br />

facets <strong>of</strong> machining.<br />

In choosing a machine with capability<br />

for <strong>the</strong> desired job (whe<strong>the</strong>r it is heavy<br />

duty milling or high speed aluminum<br />

machining), toolholding, workholding<br />

and cutting tools with design, material,<br />

and coating for <strong>the</strong> application all affect<br />

<strong>the</strong> performance <strong>of</strong> <strong>the</strong> o<strong>the</strong>r. So, when<br />

deciding what to see at IMTS, think about<br />

operations to improve, <strong>the</strong> machine being<br />

used, and <strong>the</strong> return on investment in each<br />

<strong>of</strong> <strong>the</strong>se areas. Cutting tools <strong>of</strong>ten show<br />

a significant increase in performance by<br />

utilizing new technology.<br />

Ano<strong>the</strong>r area to consider is using<br />

a coolant that can perform in high<br />

pressure applications without foaming<br />

and will allow <strong>the</strong> tools to run faster and<br />

longer while holding size and finish.<br />

At IMTS many machines running<br />

ChipBLASTER high-pressure units will<br />

show <strong>the</strong> effectiveness <strong>of</strong> QualiChem<br />

coolant at 1,000 psi.<br />

Inventory management also can<br />

affect <strong>the</strong> total cost <strong>of</strong> manufacturing<br />

and is more than simply a method to reorder<br />

tooling. AutoCrib has dispensing<br />

equipment and unique “demand-based<br />

ordering” s<strong>of</strong>tware proven to reduce<br />

inventory while still maintaining<br />

required levels <strong>of</strong> stock. It gives you<br />

<strong>the</strong> ability to automate routine re-order<br />

functions and collect job cost data on<br />

<strong>the</strong> tooling being dispensed.<br />

July | August 2010 PRECISION MANUFACTURING | 13

cover | IMTS 2010<br />

distributors in our region<br />

Stone Machinery, Inc.<br />

Saint Paul, Minn.<br />

Tom Drazkowski, owner/president<br />

www.stonemachinery.com<br />

Stone Machinery, Inc. is a niche<br />

machinery supplier/distributor with a<br />

broad CNC product line. We focus on<br />

products that fit a particular niche for<br />

our customers, focusing on automation,<br />

part complexity and output.<br />

Stone Machinery is <strong>the</strong> longest running<br />

distributor in <strong>Minnesota</strong>. We work with <strong>the</strong><br />

very short-run manufacturers as well as <strong>the</strong><br />

very high production customers.<br />

For <strong>the</strong> short-run manufacturers we<br />

represent Hurco and Southwest Industries.<br />

Hurco: The hottest new product in<br />

machine controls is Hurco’s new WinMax<br />

8. The control s<strong>of</strong>tware accesses <strong>the</strong><br />

Internet for <strong>of</strong>f-site monitoring capability.<br />

Hurco also provides controls that are ready<br />

to run 5-axis standard on all machines.<br />

A definite must-see at <strong>the</strong> Hurco booth.<br />

The SR machines have a tilt head, allowing<br />

shorter tool capability. Hurco la<strong>the</strong>s are<br />

now 8-axis capable.<br />

Southwest Industries: The ProtoTrak line<br />

is a toolroom equipment line, known for<br />

its easy to program machinery.<br />

For <strong>the</strong> large production equipment,<br />

we represent Absolute Machine Tools,<br />

Chevalier, and ZPS.<br />

Absolute Machine Tools: Absolute<br />

will have 14 machines on-site, all large<br />

envelope machines and all worth seeing.<br />

Worthy <strong>of</strong> special mention are:<br />

▶▶<br />

Johnford: Manufacturer <strong>of</strong> very large<br />

machines. Last year we installed <strong>the</strong><br />

largest la<strong>the</strong> ever sold in Midwest, a 30’<br />

machine, producing long cylinders.<br />

▶▶<br />

YouJi: Will have a 2000 mm VTL on<br />

display, and a 1500 mm HMC.<br />

▶▶<br />

Tong Tai: They have begun branding<br />

<strong>the</strong>ir own machines, known as <strong>the</strong><br />

Hitachi-Seiki supplier/builder.<br />

ZPS: This European manufacturer will<br />

display 6 and 8 spindle CNC multispindle<br />

machines.<br />

Chevalier: Known for its production<br />

grinding, Stone installed two automated<br />

CNC Chevalier grinding machines<br />

into Kurt <strong>Manufacturing</strong>’s new facility.<br />

The robot-loaded machines feature full<br />

interactive gaging and an auto clamp, three<br />

zone pallet system.<br />

T. Bryce & Associates Inc.<br />

Plymouth, Minn.<br />

Terry Bryce, owner/president<br />

www.tbryce.com<br />

Electrical discharge machining is a small<br />

slice <strong>of</strong> <strong>the</strong> pie in <strong>the</strong> machine tool<br />

business but it’s critical in toolmaking<br />

and many o<strong>the</strong>r types <strong>of</strong> high precision,<br />

unusual problem-solving projects.<br />

EDM is a machining method<br />

primarily used for hard metals or those<br />

that would be very difficult to machine<br />

with traditional techniques. EDM can<br />

cut intricate contours or cavities in <strong>the</strong>se<br />

materials—its precision is extraordinary.<br />

Fanuc: This year Fanuc’s wire EDMs<br />

are a little bigger and faster in terms <strong>of</strong><br />

automatic threading, cutting and ease<br />

<strong>of</strong> operation. The main feature <strong>of</strong> our<br />

equipment, overall, is reliability. Because<br />

I’ve been doing this for over 30 years now,<br />

I know that reliability is critical—in any<br />

machine, really. You can’t afford to have<br />

back-up machinery anymore. The price<br />

competitiveness factor no longer will<br />

permit that paradigm.<br />

Current EDM: We also handle Current<br />

small hole drilling machines. These<br />

machines can drill holes to less than<br />

a diameter <strong>of</strong> a human hair and up to<br />

3/8” diameter in hardened or carbide<br />

materials. Current is sophisticated,<br />

accurate and reliable.<br />

This year at IMTS, learning more<br />

about cloud computing is at <strong>the</strong> top <strong>of</strong><br />

my list. Cloud computing simply means<br />

using remote, large Internet server farms<br />

to host and manage <strong>the</strong> programs that<br />

are assessed on site simply through, say, a<br />

manufacturing dashboard. MTConnect,<br />

for example, can be connected to <strong>the</strong><br />

cloud where detailed analytics could<br />

be run simply from a browser. This is<br />

very exciting and has <strong>the</strong> potential to<br />

revolutionize manufacturing. PM<br />

Lockheed Martin F-35 Lightning<br />

II Joint Strike Fighter to be<br />

Showcased at IMTS<br />

Lockheed Martin has agreed to exhibit<br />

a full-scale model <strong>of</strong> its F-35 Lightning<br />

II Joint Strike Fighter during IMTS.<br />

The F-35 Lightning II is a 5th<br />

generation fighter, combining<br />

advanced stealth with fighter<br />

speed and agility, fully fused sensor<br />

information, network-enabled<br />

operations, advanced sustainment,<br />

and lower operational and support<br />

costs. Lockheed Martin is developing<br />

<strong>the</strong> F-35 with its principal industrial<br />

partners, Northrop Grumman<br />

and BAE Systems. Two separate,<br />

interchangeable F-35 engines are<br />

under development: <strong>the</strong> Pratt &<br />

Whitney F135 and <strong>the</strong> GE Rolls-Royce<br />

Fighter Engine Team F136.<br />

“While <strong>the</strong> manufacturing technology<br />

featured at IMTS stands alone as a<br />

must-see, what’s really exciting is<br />

seeing <strong>the</strong> end result from some <strong>of</strong><br />

those machines,” says John Krisko,<br />

IMTS director -exhibitions. “Everyone<br />

at <strong>the</strong> show will have <strong>the</strong> opportunity<br />

to learn about <strong>the</strong> plane’s construction<br />

and <strong>the</strong> manufacturing technology<br />

behind it. We are thrilled to have this<br />

amazing example <strong>of</strong> an end product<br />

featured at IMTS.” GIE Media was<br />

instrumental in working with IMTS to<br />

secure <strong>the</strong> fighter for exhibit.<br />

The F-35 is intended to be <strong>the</strong> world’s<br />

premiere strike aircraft through 2040.<br />

The United States intends to buy a<br />

total <strong>of</strong> 2,443 aircraft with a total <strong>of</strong><br />

more than 4,000 F-35s forecast to<br />

be built for <strong>the</strong> United States and<br />

foreign customers combined. The F-35<br />

program’s overall value is estimated<br />

at $323 billion, making it <strong>the</strong> largest<br />

defense program ever.<br />

The F35 will be on display in <strong>the</strong> front<br />

<strong>of</strong> McCormick Place’s West Building in<br />

Booth W-100.<br />

Source: www.imts.com<br />

14 | PRECISION MANUFACTURING July | August 2010

Now is <strong>the</strong> time to take your shot!<br />

There has never been a better time to start or relocate your business in Nor<strong>the</strong>astern <strong>Minnesota</strong>.<br />

Be a player in <strong>the</strong> unprecedented economic expansion poised on our horizon.<br />

It’s time to see beyond our great golf and northwoods charm, and take a serious look at<br />

<strong>the</strong> opportunities at hand:<br />

1. Unprecedented growth<br />

2. Innovation<br />

3. Home to world-class global companies<br />

4. Quality <strong>of</strong> place<br />

5. Millions available for financing<br />

Contact our Business Development Team today and find out how Iron Range Resources<br />

can assist you with financing, site selection and incentive packages that are way above par.<br />

877-829-3936<br />

ironrangeresources.net<br />

Your vision. Our backing.<br />

16 | PRECISION MANUFACTURING July | August 2010

who’s | who<br />

Doug Mulder, CAB Construction<br />

PRESERVING THE FUTURE OF MANUFACTURING<br />

by Rachel England<br />

“I measure my success by <strong>the</strong> successes <strong>of</strong><br />

those around me; those I have both learned<br />

from and taught.”<br />

- Doug Mulder<br />

Doug Mulder, production manager at<br />

CAB Construction.<br />

The future, while terrifying and<br />

seemingly distant at times, is actually as<br />

close as tomorrow. What can you do today<br />

to ensure <strong>the</strong> future <strong>of</strong> manufacturing?<br />

Doug Mulder, production manager at<br />

CAB Construction in Mankato, Minn., is<br />

leading <strong>the</strong> charge to get manufacturers<br />

more engaged.<br />

Learning and sharing his knowledge<br />

with o<strong>the</strong>rs keeps Mulder passionate<br />

about manufacturing. “I learn something<br />

new about myself, o<strong>the</strong>rs and <strong>the</strong><br />

business every day,” said Mulder. “I<br />

get <strong>the</strong> ultimate satisfaction from<br />

helping o<strong>the</strong>rs understand and grow<br />

both personally and pr<strong>of</strong>essionally.”<br />

His passion for knowledge drove him<br />

to get involved with Mankato area<br />

schools to increase <strong>the</strong> awareness <strong>of</strong><br />

manufacturing. “I measure my success<br />

by <strong>the</strong> successes <strong>of</strong> those around me;<br />

those I have both learned from and<br />

taught,” continued Mulder.<br />

Building Connections<br />

Mulder works with o<strong>the</strong>r<br />

manufacturers in <strong>the</strong> area to build<br />

stronger connections with <strong>the</strong> local<br />

schools and <strong>the</strong>ir administrative staff.<br />

The group has arranged tours <strong>of</strong> two<br />

area metal fabricators for <strong>the</strong> Mankato<br />

Area Public School’s counselors and<br />

administrators. The next tour Mulder<br />

envisions would include <strong>the</strong> schools,<br />

students, and <strong>the</strong>ir parents to tour<br />

manufacturing facilities.<br />

He also would like to start a program<br />

to <strong>of</strong>fer high school teachers summer<br />

employment in area manufacturing<br />

facilities. He views this as ano<strong>the</strong>r<br />

opportunity to show educators <strong>the</strong><br />

endless job possibilities within <strong>the</strong><br />

manufacturing industry. “We’d like to<br />

hire math teachers to see <strong>the</strong> inventory,<br />

estimating and accounting side <strong>of</strong> <strong>the</strong><br />

business; english teachers to see <strong>the</strong><br />

reading and writing involved in <strong>the</strong><br />

technical documents that come in; and<br />

science teachers to see how heat and<br />

stress impact metal. <strong>Manufacturing</strong><br />

encompasses every aspect <strong>of</strong> education,”<br />

Mulder said.<br />

Mulder knows first-hand <strong>the</strong> different<br />

roles individuals take at a manufacturing<br />

company. He began working in <strong>the</strong><br />

industry 30 years ago as an assembler,<br />

building skid loaders and articulated<br />

tractors. “My current position [at CAB<br />

Construction] began when I applied<br />

for a night shift supervisor position and<br />

was awarded <strong>the</strong> production manager<br />

position. I began working in January<br />

2008, so I’ve been with <strong>the</strong> company for 2<br />

years,” explained Mulder.<br />

Adapting to Change<br />

For 26 years, CAB Construction<br />

has been a family-owned business<br />

that changes and adapts to <strong>the</strong> needs<br />

<strong>of</strong> its clients. Originally started as a<br />

millwright service, <strong>the</strong>y added a metal<br />

fabrication division after an opportunity<br />

to fabricate parts for installation on <strong>the</strong><br />

job site presented itself. “CAB expanded<br />

several times from a 2-car garage to a<br />

new shop in Madison Lake, which was<br />

expanded in 2 years. CAB relocated to<br />

a 75,000-square-foot facility located in<br />

Mankato, where it has been since 2006,”<br />

said Mulder. CAB’s broad range <strong>of</strong><br />

services allows <strong>the</strong> company to fulfill a<br />

wide range <strong>of</strong> customer needs with high<br />

quality products.<br />

Engaging <strong>the</strong> Region 9 Chapter<br />

Mulder’s next step toward a<br />

stronger future for manufacturing is<br />

his involvement with MPMA’s Region<br />

9 Chapter. He worked with MPMA<br />

Executive Director Jaime Nolan to<br />

establish a plan that would allow<br />

companies from nine counties in<br />

Southwest <strong>Minnesota</strong> to join <strong>the</strong> MPMA<br />

and participate in workforce development<br />

initiatives specific to <strong>the</strong> area. “There are<br />

hundreds <strong>of</strong> shops across <strong>the</strong> state that<br />

don’t have a voice,” explained Mulder.<br />

“Formalizing will help <strong>the</strong>m have a voice<br />

and give <strong>the</strong>m a better shot <strong>of</strong> staying open<br />

when <strong>the</strong> economy takes a hard turn.”<br />

The future <strong>of</strong> manufacturing lies in <strong>the</strong><br />

actions <strong>of</strong> today. “It’s about engagement<br />

and getting a voice out, and making sure<br />

<strong>the</strong> funds can come in and are used for<br />

manufacturing,” said Mulder. PM<br />

Rachel England<br />

is a contributing<br />

writer for <strong>Minnesota</strong><br />

<strong>Precision</strong> <strong>Manufacturing</strong><br />

<strong>Association</strong>. She can be<br />

reached at<br />

rachel@mpma.com.<br />

July | August 2010 PRECISION MANUFACTURING | 17

shop | pr<strong>of</strong>ile<br />

Razor Edge Systems, Inc.<br />

A Sharper Approach from Stone Machinery<br />

Joe Juranitch, also known as Ragnar,<br />

uses a Hurco to make some <strong>of</strong> his Vikings<br />

weaponry. He also uses it to cut down <strong>the</strong><br />

manufacturing time needed to make his<br />

company’s sharpening equipment.<br />

Before he was Ragnar, <strong>the</strong> <strong>Minnesota</strong><br />

Vikings mascot, Joe Juranitch, set <strong>the</strong><br />

world record for shaving his beard with<br />

an axe (8 minutes and 43 seconds).<br />

He even sharpened it himself. A true<br />

Viking, indeed.<br />

At <strong>the</strong> time, he was trying to gain<br />

publicity for his company, not <strong>the</strong><br />

<strong>Minnesota</strong> Vikings. Shaving his beard<br />

with an axe was one way to demonstrate<br />

his company’s expertise at maintaining an<br />

extremely sharp edge.<br />

Juranitch is co-owner <strong>of</strong> Razor Edge<br />

Systems, Inc., a company in Ely, Minn.,<br />

that makes sharpening equipment for a<br />

variety <strong>of</strong> industries. His parents started<br />

<strong>the</strong> company more than 50 years ago out<br />

<strong>of</strong> <strong>the</strong>ir garage. Today it employs about<br />

20 people, including Jurantich and his<br />

three sisters.<br />

When Juranitch was selected to<br />

become Ragnar in 1994, he fit <strong>the</strong> role<br />

perfectly. He even made and sharpened<br />

his own Vikings weaponry. But he never<br />

quit his day job. When he isn’t greeting<br />

fans in a fur coat and boots, Juranitch<br />

is at his shop, working to develop and<br />

patent sharpening tools that maintain <strong>the</strong><br />

sharpest edges possible. His <strong>of</strong>fice is full<br />

<strong>of</strong> little inventions that have been made,<br />

scrapped and re-done.<br />

The Moustrap® Steel is one <strong>of</strong> his<br />

company’s best known products. It has<br />

been used for years in meatpacking and<br />

poultry processing plants to restore and<br />

maintain sharp edges. It even has been<br />

featured on <strong>the</strong> show “Modern Marvels.”<br />

“When I was a kid, I remember plant<br />

managers telling my dad <strong>the</strong>re was no way<br />