Journal of the Minnesota Precision Manufacturing Association

Journal of the Minnesota Precision Manufacturing Association

Journal of the Minnesota Precision Manufacturing Association

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

“Don’t assume what works for your neighbor will work for you.<br />

Do some investigation. Look for <strong>the</strong> best fit. Find out how o<strong>the</strong>r<br />

companies like yours were supported and treated before, during<br />

and after <strong>the</strong> sale.”<br />

- Tom Drazkowski, owner, Stone Machinery<br />

“I think one <strong>of</strong> <strong>the</strong> biggest challenges<br />

facing manufacturers today is that <strong>the</strong>ir<br />

employees need a broader skill set,”<br />

Drazkowski said. “We’re helping <strong>the</strong>m<br />

with that by providing free training. We<br />

work with <strong>the</strong>m on <strong>the</strong> machine side,<br />

<strong>the</strong> workholding side, <strong>the</strong> tooling side,<br />

<strong>the</strong> programming side and <strong>the</strong> part<br />

measurement side. We help <strong>the</strong>m through<br />

<strong>the</strong> entire process.”<br />

Lifetime Service<br />

Service is ano<strong>the</strong>r key aspect <strong>of</strong> Stone<br />

Machinery. Three full-time technicians<br />

with service trucks are dedicated to<br />

machine diagnosis, repair and testing,<br />

resulting in prompt service throughout<br />

<strong>the</strong> life <strong>of</strong> <strong>the</strong> machine.<br />

For companies like Razor Edge<br />

Systems, training, service and support<br />

are as important as <strong>the</strong> machine itself.<br />

“Our machinists are able to get on<br />

<strong>the</strong> phone and ask questions <strong>of</strong> Stone<br />

Machinery anytime,” Juranitch said.<br />

“I have zero complaints about <strong>the</strong> way<br />

we’ve been treated.”<br />

With a little more time on his hands,<br />

Juranitch is turning his focus to <strong>the</strong><br />

scissors and to edges in <strong>the</strong> medical field,<br />

studying how to maintain <strong>the</strong> sharpest<br />

edges possible—and determining which<br />

machines are best for <strong>the</strong> job.<br />

Like Razor Edge Systems, many<br />

manufacturers will be in <strong>the</strong> market for<br />

ano<strong>the</strong>r machine again soon. To all <strong>of</strong><br />

<strong>the</strong>m, Drazkowski <strong>of</strong>fers this advice:<br />

“Don’t assume what works for your<br />

neighbor will work for you. Do some<br />

investigation. Look for <strong>the</strong> best fit. Find<br />

out how o<strong>the</strong>r companies like yours were<br />

supported and treated before, during and<br />

after <strong>the</strong> sale.” PM<br />

For more information about Stone Machinery,<br />

visit www.stonemachinery.com or contact<br />

Tom Drazkowski at info@stonemachinery.com<br />

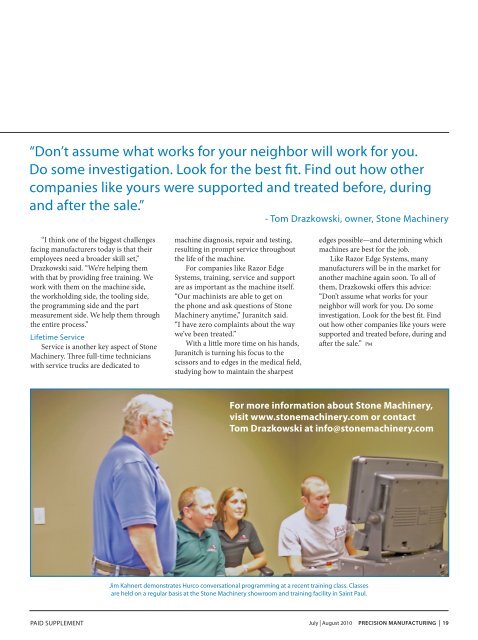

Jim Kahnert demonstrates Hurco conversational programming at a recent training class. Classes<br />

are held on a regular basis at <strong>the</strong> Stone Machinery showroom and training facility in Saint Paul.<br />

PAID SUPPLEMENT<br />

July | August 2010 PRECISION MANUFACTURING | 19