Journal of the Minnesota Precision Manufacturing Association

Journal of the Minnesota Precision Manufacturing Association

Journal of the Minnesota Precision Manufacturing Association

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

cover | IMTS 2010<br />

distributors in our region<br />

Stone Machinery, Inc.<br />

Saint Paul, Minn.<br />

Tom Drazkowski, owner/president<br />

www.stonemachinery.com<br />

Stone Machinery, Inc. is a niche<br />

machinery supplier/distributor with a<br />

broad CNC product line. We focus on<br />

products that fit a particular niche for<br />

our customers, focusing on automation,<br />

part complexity and output.<br />

Stone Machinery is <strong>the</strong> longest running<br />

distributor in <strong>Minnesota</strong>. We work with <strong>the</strong><br />

very short-run manufacturers as well as <strong>the</strong><br />

very high production customers.<br />

For <strong>the</strong> short-run manufacturers we<br />

represent Hurco and Southwest Industries.<br />

Hurco: The hottest new product in<br />

machine controls is Hurco’s new WinMax<br />

8. The control s<strong>of</strong>tware accesses <strong>the</strong><br />

Internet for <strong>of</strong>f-site monitoring capability.<br />

Hurco also provides controls that are ready<br />

to run 5-axis standard on all machines.<br />

A definite must-see at <strong>the</strong> Hurco booth.<br />

The SR machines have a tilt head, allowing<br />

shorter tool capability. Hurco la<strong>the</strong>s are<br />

now 8-axis capable.<br />

Southwest Industries: The ProtoTrak line<br />

is a toolroom equipment line, known for<br />

its easy to program machinery.<br />

For <strong>the</strong> large production equipment,<br />

we represent Absolute Machine Tools,<br />

Chevalier, and ZPS.<br />

Absolute Machine Tools: Absolute<br />

will have 14 machines on-site, all large<br />

envelope machines and all worth seeing.<br />

Worthy <strong>of</strong> special mention are:<br />

▶▶<br />

Johnford: Manufacturer <strong>of</strong> very large<br />

machines. Last year we installed <strong>the</strong><br />

largest la<strong>the</strong> ever sold in Midwest, a 30’<br />

machine, producing long cylinders.<br />

▶▶<br />

YouJi: Will have a 2000 mm VTL on<br />

display, and a 1500 mm HMC.<br />

▶▶<br />

Tong Tai: They have begun branding<br />

<strong>the</strong>ir own machines, known as <strong>the</strong><br />

Hitachi-Seiki supplier/builder.<br />

ZPS: This European manufacturer will<br />

display 6 and 8 spindle CNC multispindle<br />

machines.<br />

Chevalier: Known for its production<br />

grinding, Stone installed two automated<br />

CNC Chevalier grinding machines<br />

into Kurt <strong>Manufacturing</strong>’s new facility.<br />

The robot-loaded machines feature full<br />

interactive gaging and an auto clamp, three<br />

zone pallet system.<br />

T. Bryce & Associates Inc.<br />

Plymouth, Minn.<br />

Terry Bryce, owner/president<br />

www.tbryce.com<br />

Electrical discharge machining is a small<br />

slice <strong>of</strong> <strong>the</strong> pie in <strong>the</strong> machine tool<br />

business but it’s critical in toolmaking<br />

and many o<strong>the</strong>r types <strong>of</strong> high precision,<br />

unusual problem-solving projects.<br />

EDM is a machining method<br />

primarily used for hard metals or those<br />

that would be very difficult to machine<br />

with traditional techniques. EDM can<br />

cut intricate contours or cavities in <strong>the</strong>se<br />

materials—its precision is extraordinary.<br />

Fanuc: This year Fanuc’s wire EDMs<br />

are a little bigger and faster in terms <strong>of</strong><br />

automatic threading, cutting and ease<br />

<strong>of</strong> operation. The main feature <strong>of</strong> our<br />

equipment, overall, is reliability. Because<br />

I’ve been doing this for over 30 years now,<br />

I know that reliability is critical—in any<br />

machine, really. You can’t afford to have<br />

back-up machinery anymore. The price<br />

competitiveness factor no longer will<br />

permit that paradigm.<br />

Current EDM: We also handle Current<br />

small hole drilling machines. These<br />

machines can drill holes to less than<br />

a diameter <strong>of</strong> a human hair and up to<br />

3/8” diameter in hardened or carbide<br />

materials. Current is sophisticated,<br />

accurate and reliable.<br />

This year at IMTS, learning more<br />

about cloud computing is at <strong>the</strong> top <strong>of</strong><br />

my list. Cloud computing simply means<br />

using remote, large Internet server farms<br />

to host and manage <strong>the</strong> programs that<br />

are assessed on site simply through, say, a<br />

manufacturing dashboard. MTConnect,<br />

for example, can be connected to <strong>the</strong><br />

cloud where detailed analytics could<br />

be run simply from a browser. This is<br />

very exciting and has <strong>the</strong> potential to<br />

revolutionize manufacturing. PM<br />

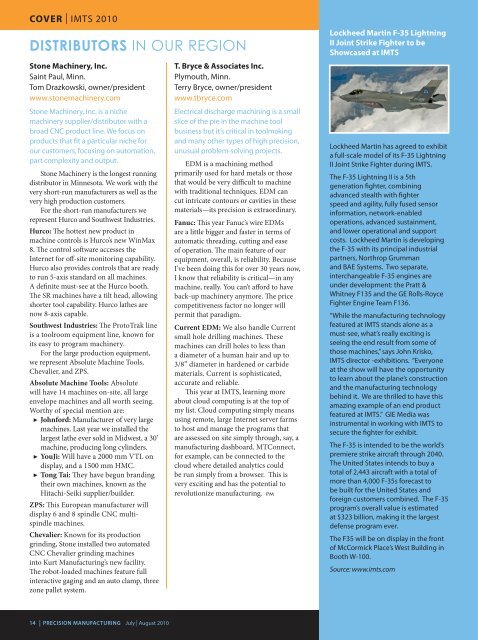

Lockheed Martin F-35 Lightning<br />

II Joint Strike Fighter to be<br />

Showcased at IMTS<br />

Lockheed Martin has agreed to exhibit<br />

a full-scale model <strong>of</strong> its F-35 Lightning<br />

II Joint Strike Fighter during IMTS.<br />

The F-35 Lightning II is a 5th<br />

generation fighter, combining<br />

advanced stealth with fighter<br />

speed and agility, fully fused sensor<br />

information, network-enabled<br />

operations, advanced sustainment,<br />

and lower operational and support<br />

costs. Lockheed Martin is developing<br />

<strong>the</strong> F-35 with its principal industrial<br />

partners, Northrop Grumman<br />

and BAE Systems. Two separate,<br />

interchangeable F-35 engines are<br />

under development: <strong>the</strong> Pratt &<br />

Whitney F135 and <strong>the</strong> GE Rolls-Royce<br />

Fighter Engine Team F136.<br />

“While <strong>the</strong> manufacturing technology<br />

featured at IMTS stands alone as a<br />

must-see, what’s really exciting is<br />

seeing <strong>the</strong> end result from some <strong>of</strong><br />

those machines,” says John Krisko,<br />

IMTS director -exhibitions. “Everyone<br />

at <strong>the</strong> show will have <strong>the</strong> opportunity<br />

to learn about <strong>the</strong> plane’s construction<br />

and <strong>the</strong> manufacturing technology<br />

behind it. We are thrilled to have this<br />

amazing example <strong>of</strong> an end product<br />

featured at IMTS.” GIE Media was<br />

instrumental in working with IMTS to<br />

secure <strong>the</strong> fighter for exhibit.<br />

The F-35 is intended to be <strong>the</strong> world’s<br />

premiere strike aircraft through 2040.<br />

The United States intends to buy a<br />

total <strong>of</strong> 2,443 aircraft with a total <strong>of</strong><br />

more than 4,000 F-35s forecast to<br />

be built for <strong>the</strong> United States and<br />

foreign customers combined. The F-35<br />

program’s overall value is estimated<br />

at $323 billion, making it <strong>the</strong> largest<br />

defense program ever.<br />

The F35 will be on display in <strong>the</strong> front<br />

<strong>of</strong> McCormick Place’s West Building in<br />

Booth W-100.<br />

Source: www.imts.com<br />

14 | PRECISION MANUFACTURING July | August 2010