Journal of the Minnesota Precision Manufacturing Association

Journal of the Minnesota Precision Manufacturing Association

Journal of the Minnesota Precision Manufacturing Association

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Industry Pr<strong>of</strong>ile Yeager Machine<br />

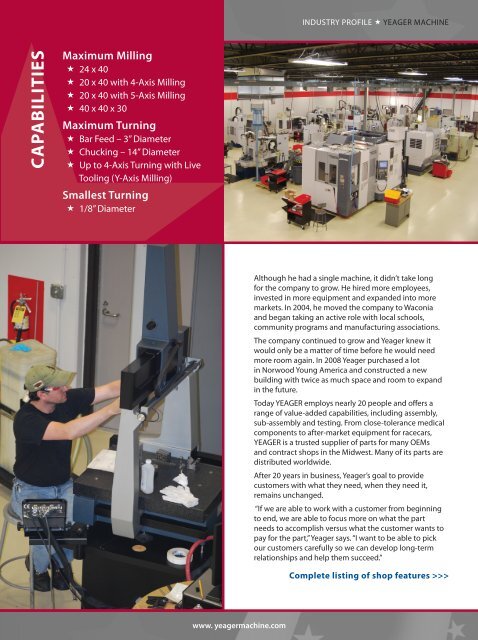

CAPABILITIES<br />

Maximum Milling<br />

24 x 40<br />

20 x 40 with 4-Axis Milling<br />

20 x 40 with 5-Axis Milling<br />

40 x 40 x 30<br />

Maximum Turning<br />

Bar Feed – 3” Diameter<br />

Chucking – 14” Diameter<br />

Up to 4-Axis Turning with Live<br />

Tooling (Y-Axis Milling)<br />

Smallest Turning<br />

1/8” Diameter<br />

Although he had a single machine, it didn’t take long<br />

for <strong>the</strong> company to grow. He hired more employees,<br />

invested in more equipment and expanded into more<br />

markets. In 2004, he moved <strong>the</strong> company to Waconia<br />

and began taking an active role with local schools,<br />

community programs and manufacturing associations.<br />

The company continued to grow and Yeager knew it<br />

would only be a matter <strong>of</strong> time before he would need<br />

more room again. In 2008 Yeager purchased a lot<br />

in Norwood Young America and constructed a new<br />

building with twice as much space and room to expand<br />

in <strong>the</strong> future.<br />

Today YEAGER employs nearly 20 people and <strong>of</strong>fers a<br />

range <strong>of</strong> value-added capabilities, including assembly,<br />

sub-assembly and testing. From close-tolerance medical<br />

components to after-market equipment for racecars,<br />

YEAGER is a trusted supplier <strong>of</strong> parts for many OEMs<br />

and contract shops in <strong>the</strong> Midwest. Many <strong>of</strong> its parts are<br />

distributed worldwide.<br />

After 20 years in business, Yeager’s goal to provide<br />

customers with what <strong>the</strong>y need, when <strong>the</strong>y need it,<br />

remains unchanged.<br />

“If we are able to work with a customer from beginning<br />

to end, we are able to focus more on what <strong>the</strong> part<br />

needs to accomplish versus what <strong>the</strong> customer wants to<br />

pay for <strong>the</strong> part,” Yeager says. “I want to be able to pick<br />

our customers carefully so we can develop long-term<br />

relationships and help <strong>the</strong>m succeed.”<br />

Complete listing <strong>of</strong> shop features >>><br />

www. yeagermachine.com