Machinery Lubrication July August 2008

Machinery Lubrication July August 2008

Machinery Lubrication July August 2008

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

FROM THE FIELD<br />

How Effective Is Your<br />

<strong>Lubrication</strong> Program?<br />

JARROD POTTEIGER<br />

The path to lubrication excellence can be difficult to navigate.<br />

It begins when individuals and organizations<br />

become aware of the importance of their lubrication<br />

program, its impact on productivity and its direct effect on<br />

the bottom line. Once this enlightenment has occurred,<br />

comprehensive training in best practices is acquired and the<br />

organization can consider what the lubrication program<br />

should be and where they wish to take it.<br />

However, to get to Point B, Point A must first be determined.<br />

Even if the goals and objectives are defined, be they broad or<br />

narrow in scope, they can be difficult to reach. With the goals<br />

identified, a step-wise strategy must be developed. The first step<br />

is to assess the current situation. After all, the best map in the<br />

world is useless if you’re not properly oriented.<br />

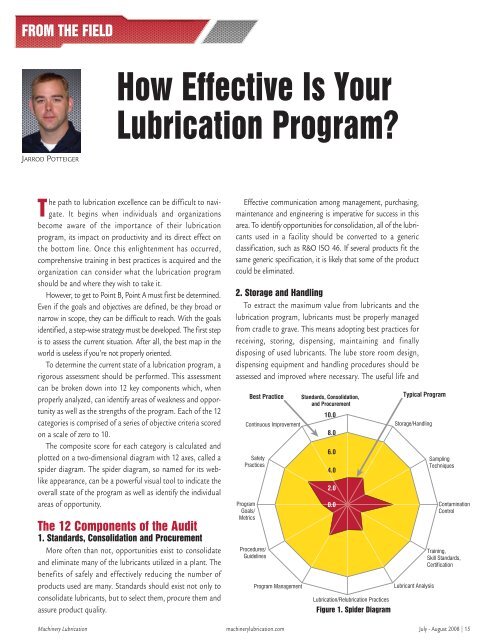

To determine the current state of a lubrication program, a<br />

rigorous assessment should be performed. This assessment<br />

can be broken down into 12 key components which, when<br />

properly analyzed, can identify areas of weakness and opportunity<br />

as well as the strengths of the program. Each of the 12<br />

categories is comprised of a series of objective criteria scored<br />

on a scale of zero to 10.<br />

The composite score for each category is calculated and<br />

plotted on a two-dimensional diagram with 12 axes, called a<br />

spider diagram. The spider diagram, so named for its weblike<br />

appearance, can be a powerful visual tool to indicate the<br />

overall state of the program as well as identify the individual<br />

areas of opportunity.<br />

The 12 Components of the Audit<br />

1. Standards, Consolidation and Procurement<br />

More often than not, opportunities exist to consolidate<br />

and eliminate many of the lubricants utilized in a plant. The<br />

benefits of safely and effectively reducing the number of<br />

products used are many. Standards should exist not only to<br />

consolidate lubricants, but to select them, procure them and<br />

assure product quality.<br />

Effective communication among management, purchasing,<br />

maintenance and engineering is imperative for success in this<br />

area. To identify opportunities for consolidation, all of the lubricants<br />

used in a facility should be converted to a generic<br />

classification, such as R&O ISO 46. If several products fit the<br />

same generic specification, it is likely that some of the product<br />

could be eliminated.<br />

2. Storage and Handling<br />

To extract the maximum value from lubricants and the<br />

lubrication program, lubricants must be properly managed<br />

from cradle to grave. This means adopting best practices for<br />

receiving, storing, dispensing, maintaining and finally<br />

disposing of used lubricants. The lube store room design,<br />

dispensing equipment and handling procedures should be<br />

assessed and improved where necessary. The useful life and<br />

Program<br />

Goals/<br />

Metrics<br />

Best Practice<br />

Continuous Improvement<br />

Safety<br />

Practices<br />

Procedures/<br />

Guidelines<br />

Program Management<br />

Standards, Consolidation,<br />

and Procurement<br />

10.0<br />

8.0<br />

6.0<br />

4.0<br />

2.0<br />

0.0 00<br />

<strong>Lubrication</strong>/Relubrication Practices<br />

Figure 1. Spider Diagram<br />

Typical Program<br />

Storage/Handling<br />

Lubricant Analysis<br />

Sampling<br />

Techniques<br />

Contamination<br />

Control<br />

Training,<br />

Skill Standards,<br />

Certification<br />

<strong>Machinery</strong> <strong>Lubrication</strong> machinerylubrication.com <strong>July</strong> - <strong>August</strong> <strong>2008</strong> 15