Machinery Lubrication July August 2008

Machinery Lubrication July August 2008

Machinery Lubrication July August 2008

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CASE STUDY<br />

Storage and Dispensing<br />

Systems Complement Lube<br />

Room Procedure<br />

BY LARRY KING, THE IFH GROUP, INC.<br />

Beaver Valley Power Station (BVPS) is a nuclear power<br />

plant near Shippingport, Pa., 34 miles from Pittsburgh.<br />

The plant has two Westinghouse pressurized water reactors<br />

capable of producing 970 and 920 megawatts of power,<br />

respectively. It is owned by First Energy Nuclear Operating<br />

Corporation. Unit 1 has been in commercial operation since<br />

1976, and Unit 2 commenced commercial operation in<br />

<strong>August</strong> 1987.<br />

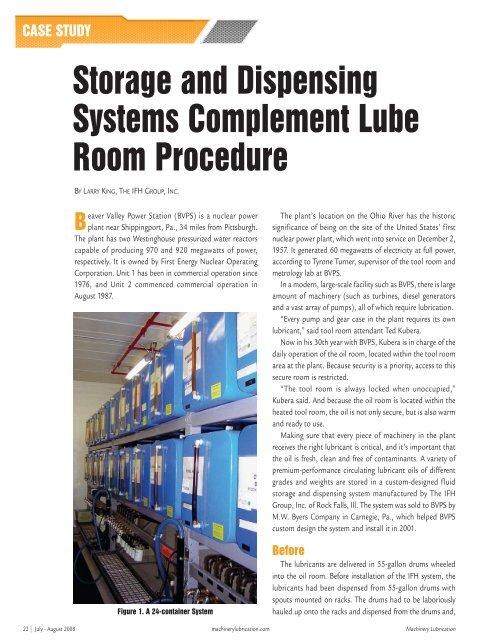

Figure 1. A 24-container System<br />

The plant’s location on the Ohio River has the historic<br />

significance of being on the site of the United States’ first<br />

nuclear power plant, which went into service on December 2,<br />

1957. It generated 60 megawatts of electricity at full power,<br />

according to Tyrone Turner, supervisor of the tool room and<br />

metrology lab at BVPS.<br />

In a modern, large-scale facility such as BVPS, there is large<br />

amount of machinery (such as turbines, diesel generators<br />

and a vast array of pumps), all of which require lubrication.<br />

“Every pump and gear case in the plant requires its own<br />

lubricant,” said tool room attendant Ted Kubera.<br />

Now in his 30th year with BVPS, Kubera is in charge of the<br />

daily operation of the oil room, located within the tool room<br />

area at the plant. Because security is a priority, access to this<br />

secure room is restricted.<br />

“The tool room is always locked when unoccupied,”<br />

Kubera said. And because the oil room is located within the<br />

heated tool room, the oil is not only secure, but is also warm<br />

and ready to use.<br />

Making sure that every piece of machinery in the plant<br />

receives the right lubricant is critical, and it’s important that<br />

the oil is fresh, clean and free of contaminants. A variety of<br />

premium-performance circulating lubricant oils of different<br />

grades and weights are stored in a custom-designed fluid<br />

storage and dispensing system manufactured by The IFH<br />

Group, Inc. of Rock Falls, Ill. The system was sold to BVPS by<br />

M.W. Byers Company in Carnegie, Pa., which helped BVPS<br />

custom design the system and install it in 2001.<br />

Before<br />

The lubricants are delivered in 55-gallon drums wheeled<br />

into the oil room. Before installation of the IFH system, the<br />

lubricants had been dispensed from 55-gallon drums with<br />

spouts mounted on racks. The drums had to be laboriously<br />

hauled up onto the racks and dispensed from the drums and,<br />

22 <strong>July</strong> - <strong>August</strong> <strong>2008</strong> machinerylubrication.com <strong>Machinery</strong> <strong>Lubrication</strong>