Machinery Lubrication July August 2008

Machinery Lubrication July August 2008

Machinery Lubrication July August 2008

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CONTAMINATION CONTROL<br />

Managing Water<br />

Contamination to Maintain<br />

Effective Steel Mill <strong>Lubrication</strong><br />

BY GREGORY J. SEDELMEIER, SHELL GLOBAL SOLUTIONS (U.S.) INC.<br />

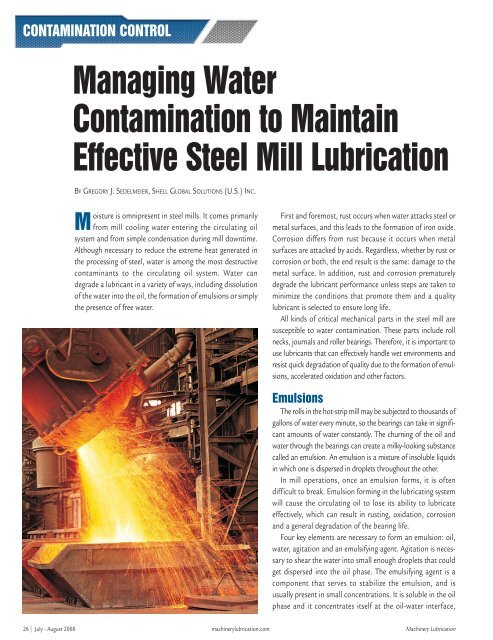

Moisture is omnipresent in steel mills. It comes primarily<br />

from mill cooling water entering the circulating oil<br />

system and from simple condensation during mill downtime.<br />

Although necessary to reduce the extreme heat generated in<br />

the processing of steel, water is among the most destructive<br />

contaminants to the circulating oil system. Water can<br />

degrade a lubricant in a variety of ways, including dissolution<br />

of the water into the oil, the formation of emulsions or simply<br />

the presence of free water.<br />

First and foremost, rust occurs when water attacks steel or<br />

metal surfaces, and this leads to the formation of iron oxide.<br />

Corrosion differs from rust because it occurs when metal<br />

surfaces are attacked by acids. Regardless, whether by rust or<br />

corrosion or both, the end result is the same: damage to the<br />

metal surface. In addition, rust and corrosion prematurely<br />

degrade the lubricant performance unless steps are taken to<br />

minimize the conditions that promote them and a quality<br />

lubricant is selected to ensure long life.<br />

All kinds of critical mechanical parts in the steel mill are<br />

susceptible to water contamination. These parts include roll<br />

necks, journals and roller bearings. Therefore, it is important to<br />

use lubricants that can effectively handle wet environments and<br />

resist quick degradation of quality due to the formation of emulsions,<br />

accelerated oxidation and other factors.<br />

Emulsions<br />

The rolls in the hot-strip mill may be subjected to thousands of<br />

gallons of water every minute, so the bearings can take in significant<br />

amounts of water constantly. The churning of the oil and<br />

water through the bearings can create a milky-looking substance<br />

called an emulsion. An emulsion is a mixture of insoluble liquids<br />

in which one is dispersed in droplets throughout the other.<br />

In mill operations, once an emulsion forms, it is often<br />

difficult to break. Emulsion forming in the lubricating system<br />

will cause the circulating oil to lose its ability to lubricate<br />

effectively, which can result in rusting, oxidation, corrosion<br />

and a general degradation of the bearing life.<br />

Four key elements are necessary to form an emulsion: oil,<br />

water, agitation and an emulsifying agent. Agitation is necessary<br />

to shear the water into small enough droplets that could<br />

get dispersed into the oil phase. The emulsifying agent is a<br />

component that serves to stabilize the emulsion, and is<br />

usually present in small concentrations. It is soluble in the oil<br />

phase and it concentrates itself at the oil-water interface,<br />

26 <strong>July</strong> - <strong>August</strong> <strong>2008</strong> machinerylubrication.com <strong>Machinery</strong> <strong>Lubrication</strong>