Design of two-span trapezoidal roof sheeting - Steel-stainless.org

Design of two-span trapezoidal roof sheeting - Steel-stainless.org

Design of two-span trapezoidal roof sheeting - Steel-stainless.org

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Job No. Sheet 1 <strong>of</strong> 6 Rev A<br />

CALCULATION SHEET<br />

Job Title<br />

Subject<br />

Client<br />

RFCS Stainless <strong>Steel</strong> Valorisation Project<br />

<strong>Design</strong> Example 11 – <strong>Design</strong> <strong>of</strong> a <strong>two</strong>-<strong>span</strong> <strong>trapezoidal</strong><br />

ro<strong>of</strong> <strong>sheeting</strong><br />

Made by JG/AO Date Feb 2006<br />

RFCS<br />

Checked by GZ Date March 2006<br />

DESIGN EXAMPLE 11 – DESIGN OF A TWO-SPAN TRAPEZOIDAL ROOF SHEETING<br />

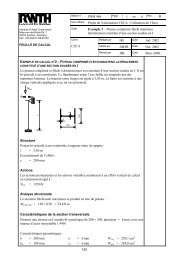

This example deals with a <strong>two</strong>-<strong>span</strong> <strong>trapezoidal</strong> ro<strong>of</strong> <strong>sheeting</strong> with a thickness <strong>of</strong> 0,6<br />

mm from <strong>stainless</strong> steel grade 1.4401 CP500, i.e. cold worked to a yield strength <strong>of</strong><br />

500 N/mm 2 . Comparisons will be made to a similar <strong>sheeting</strong> <strong>of</strong> grade 1.4401 in the<br />

annealed condition, i.e. fy = 240 N/mm 2 (see also <strong>Design</strong> Example 3).<br />

If the nominal yield strength in all directions <strong>of</strong> the sheet is not guaranteed by the<br />

producer it should be reduced to 80% <strong>of</strong> its value. In this example it is assumed that<br />

the strength was not guaranteed in order to demonstrate this.<br />

Section 3.2.4<br />

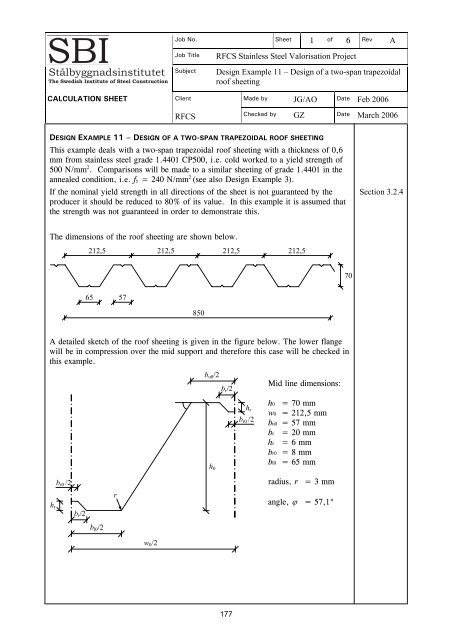

The dimensions <strong>of</strong> the ro<strong>of</strong> <strong>sheeting</strong> are shown below.<br />

212,5 212,5 212,5 212,5<br />

70<br />

65 57<br />

850<br />

A detailed sketch <strong>of</strong> the ro<strong>of</strong> <strong>sheeting</strong> is given in the figure below. The lower flange<br />

will be in compression over the mid support and therefore this case will be checked in<br />

this example.<br />

b u0 /2<br />

h 0<br />

b r /2<br />

h r<br />

b r0 /2<br />

Mid line dimensions:<br />

h0 = 70 mm<br />

w0 = 212,5 mm<br />

bu0 = 57 mm<br />

br = 20 mm<br />

hr = 6 mm<br />

br0 = 8 mm<br />

bl0 = 65 mm<br />

h r<br />

b r0 /2<br />

b r /2<br />

r<br />

radius, r = 3 mm<br />

angle, ϕ = 57,1°<br />

b l0 /2<br />

w 0 /2<br />

177

Job No. Sheet 2 <strong>of</strong> 6 Rev A<br />

CALCULATION SHEET<br />

Job Title<br />

Subject<br />

Client<br />

RFCS Stainless <strong>Steel</strong> Valorisation Project<br />

<strong>Design</strong> Example 11 – <strong>Design</strong> <strong>of</strong> a <strong>two</strong>-<strong>span</strong> <strong>trapezoidal</strong><br />

ro<strong>of</strong> <strong>sheeting</strong><br />

Made by JG/AO Date Feb 2006<br />

RFCS<br />

Checked by GZ Date March 2006<br />

Data<br />

Span length<br />

L = 3,5 m<br />

Load q = 1,4 kN/m 2<br />

Self weight g = 0,07 kN/m 2<br />

Sheeting thickness<br />

t = 0,6 mm<br />

Width <strong>of</strong> support<br />

ss = 100 mm<br />

Yield strength fy = 0 ,8× 500 = 400 N/mm 2<br />

Modulus <strong>of</strong> elasticity E = 200 000 N/mm 2<br />

Partial factor γM0 = 1,1<br />

Partial factor γM1 = 1,1<br />

Load factor<br />

γG = 1,35 (permanent loads)<br />

Load factor γQ = 1,5 (variable loads)<br />

Table 3.5<br />

Table 2.1<br />

Table 2.1<br />

Section 2.3.2<br />

Section 2.3.2<br />

Effective section properties<br />

Maximum width-to-thickness ratios<br />

Table 4.1<br />

max( bl0 / t, bu0 / t) = bl0<br />

/ t = 108 < 400<br />

h / t = 117 < 400<br />

0<br />

Location <strong>of</strong> the centroidal axis when the web is fully effective<br />

Effective width <strong>of</strong> the compression flange Section 4.4.1<br />

bl0<br />

− br<br />

235 E<br />

bp<br />

= = 22,5 mm ε = = 0,75<br />

Table 4.2<br />

2<br />

fy<br />

210000<br />

bp<br />

/ t<br />

Table 4.3<br />

k<br />

σ<br />

= 4<br />

λp<br />

= = 0,883<br />

Eq. 4.2<br />

28, 4ε<br />

kσ<br />

0,772 0,125<br />

ρ = 0,714<br />

2<br />

λ<br />

− λ<br />

= b = ρb<br />

= 16,1 mm<br />

Eq. 4.1a<br />

eff,l p Table 4.3<br />

p<br />

p<br />

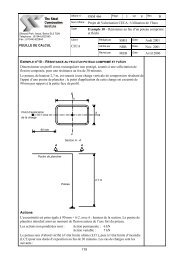

Reduced thickness <strong>of</strong> the flange stiffener: Section 4.5.3<br />

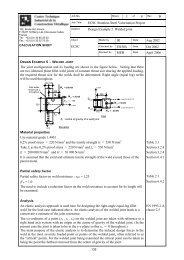

The lower compressed flange is shown in detail below.<br />

b p b eff,l /2<br />

t sl<br />

Intermediate stiffener<br />

e s<br />

A s , I s<br />

b s<br />

178

Job No. Sheet 3 <strong>of</strong> 6 Rev A<br />

CALCULATION SHEET<br />

Job Title<br />

Subject<br />

Client<br />

RFCS Stainless <strong>Steel</strong> Valorisation Project<br />

<strong>Design</strong> Example 11 – <strong>Design</strong> <strong>of</strong> a <strong>two</strong>-<strong>span</strong> <strong>trapezoidal</strong><br />

ro<strong>of</strong> <strong>sheeting</strong><br />

Made by JG/AO Date Feb 2006<br />

Effective thickness <strong>of</strong> the inclined part <strong>of</strong> the stiffener<br />

⎛<br />

2<br />

br<br />

b<br />

⎞<br />

r0 2<br />

⎜<br />

⎛ − ⎞<br />

+ h ⎟<br />

r<br />

t<br />

⎜<br />

⎜<br />

2<br />

⎟<br />

⎝ ⎠ ⎟<br />

trl<br />

=<br />

⎝<br />

⎠<br />

= 0,85 mm<br />

h<br />

A b b t ht<br />

r<br />

RFCS<br />

Checked by GZ Date March 2006<br />

2<br />

s<br />

= (<br />

eff,l<br />

+<br />

r0) + 2<br />

r rl<br />

= 24,62 mm<br />

Figure 4.3<br />

hr<br />

bht<br />

r0 r<br />

+ 2hr trl<br />

e<br />

2<br />

s<br />

= = 2, 41 mm<br />

A<br />

s<br />

The second moment <strong>of</strong> area for the stiffener is calculated with <strong>two</strong> strips <strong>of</strong> width 15t<br />

adjacent to the stiffener (smaller terms neglected)<br />

2 3<br />

2 2 2 ⎛hr ⎞ trlhr<br />

4<br />

Is = 2× 15 t es + br0t( hr − es) + 2ht r rl⎜<br />

− es⎟<br />

+ 2 = 159,1 mm<br />

⎝ 2 ⎠ 12<br />

2<br />

2 ⎛br − br0<br />

⎞<br />

s r r0<br />

b = 2 h + ⎜ + b = 24,97 mm<br />

2<br />

⎟<br />

⎝ ⎠<br />

2<br />

4 s p p s<br />

b 3<br />

l<br />

s<br />

Figure 4.3<br />

Ib (2b + 3 b)<br />

= 3,07 = 251,0 mm<br />

Eq. 4.9<br />

t<br />

2<br />

⎛w0 −bu0 −bl0<br />

⎞ 2<br />

w<br />

= + h0 = 83,4 mm<br />

⎜<br />

⎝<br />

d p s<br />

2<br />

⎟<br />

⎠<br />

b = 2b + b = 70,0 mm<br />

Eq. 4.11<br />

k<br />

s<br />

+ 2b<br />

w d<br />

wo<br />

= =<br />

sw<br />

+ 0,5bd<br />

1, 37<br />

Eq. 4.10<br />

lb s<br />

w<br />

= 3, 01> 2 kw = kwo = 1,37 Eq. 4.7<br />

4, 2k E I t<br />

σ = = 557,5 N/mm<br />

4 (2 3 )<br />

λ<br />

3<br />

w<br />

s<br />

cr,s 2<br />

As bp bp + bs<br />

f<br />

y<br />

d<br />

= = 0,85 <br />

d d<br />

σ<br />

cr,s<br />

2<br />

Eq. 4.3<br />

χ = 1, 47 − 0, 723λ<br />

= 0,86<br />

Eq. 4.16<br />

tred = χdt<br />

= 0,51 mm<br />

Optionally iterate to refine the value <strong>of</strong> the reduction factor for buckling <strong>of</strong> the<br />

stiffener.<br />

prEN 1993-<br />

1-3, clause<br />

5.5.3.3 (3)<br />

179

Job No. Sheet 4 <strong>of</strong> 6 Rev A<br />

CALCULATION SHEET<br />

Job Title<br />

Subject<br />

Client<br />

RFCS Stainless <strong>Steel</strong> Valorisation Project<br />

<strong>Design</strong> Example 11 – <strong>Design</strong> <strong>of</strong> a <strong>two</strong>-<strong>span</strong> <strong>trapezoidal</strong><br />

ro<strong>of</strong> <strong>sheeting</strong><br />

Made by JG/AO Date Feb 2006<br />

RFCS<br />

Checked by GZ Date March 2006<br />

Distance to the neutral axis from the compressed flange (fully effective web)<br />

2<br />

A = A i<br />

= 84,0 mm<br />

e<br />

c<br />

tot<br />

∑<br />

∑<br />

Ae<br />

i i<br />

= = 36,3 mm<br />

A<br />

tot<br />

Effective cross-section <strong>of</strong> the web Section 4.4.1<br />

h0 − ec<br />

2<br />

ψ =− =− 0,929<br />

k σ<br />

= 7,81− 6,29ψ + 9,78ψ<br />

= 22,1<br />

e<br />

Table 4.3<br />

c<br />

bp,w = sw = 83,4 mm<br />

0,772 0,125<br />

ρ = 0, 490<br />

λ<br />

− λ<br />

= <br />

s<br />

p<br />

2<br />

p<br />

λ<br />

b<br />

/ t<br />

p,w<br />

p<br />

= = 1,391<br />

Eq. 4.2<br />

28,4ε<br />

kσ<br />

b<br />

b<br />

1−ψ<br />

p,w<br />

eff,w<br />

= ρ =<br />

eff,1<br />

= 0, 4beff,w<br />

= 8, 47 mm seff,2 beff,w<br />

21,2 mm<br />

Eq. 4.1a,<br />

Table 4.3<br />

= 0,6 = 12,7 mm<br />

Table 4.3<br />

Effective cross section properties per half corrugation<br />

∑<br />

∑<br />

Aeff,tot = Aeff, i<br />

= 70,8 mm<br />

e<br />

A<br />

e<br />

eff, i eff, i<br />

eff,c<br />

= =<br />

Aeff,tot<br />

∑ ∑<br />

2<br />

40,0 mm<br />

( ) 2 4<br />

Itot = Ieff,i + Aeff,i ec − eeff,i = 51710 mm<br />

Bending resistance per unit width (1m) Section 4.7.4<br />

1000 mm<br />

I = Itot<br />

= 486685 mm<br />

0,5w<br />

W<br />

eff,l<br />

I<br />

= = 12165 mm<br />

e<br />

c<br />

0<br />

3<br />

4<br />

W<br />

eff,u<br />

= I<br />

16227 mm<br />

h − e<br />

=<br />

0 c<br />

3<br />

Weff,l < Weff,u Weff,min = Weff,l<br />

Mc,Rd = Weff,min fy γ<br />

M0<br />

= 4, 42 kNm<br />

Eq. 4.29<br />

180

Job No. Sheet 5 <strong>of</strong> 6 Rev A<br />

CALCULATION SHEET<br />

Job Title<br />

Subject<br />

Client<br />

RFCS Stainless <strong>Steel</strong> Valorisation Project<br />

<strong>Design</strong> Example 11 – <strong>Design</strong> <strong>of</strong> a <strong>two</strong>-<strong>span</strong> <strong>trapezoidal</strong><br />

ro<strong>of</strong> <strong>sheeting</strong><br />

Made by JG/AO Date Feb 2006<br />

RFCS<br />

Checked by GZ Date March 2006<br />

Resistance to local transverse forces at intermediate support<br />

Resistance to local transverse forces per unit width (1 m)<br />

α = 0,15 (for <strong>sheeting</strong> pr<strong>of</strong>iles) and la = ss<br />

1000 mm<br />

R = αt f E − r t + l t + ϕ γ<br />

2<br />

( 1 0,1 / ) ⎡0,5 0,02 / ⎤( 2,4 ( /90)<br />

)<br />

2<br />

w,Rd y ⎣<br />

a ⎦<br />

M1<br />

0,5w0<br />

Rw,Rd = 20,9 kN<br />

prEN 1993-<br />

1-3, Eq.<br />

6.20c, 6.19b<br />

and 6.18<br />

Interaction between bending moment and transverse force<br />

The maximum bending moment will appear at the intermediate support where it will<br />

interact with the support reaction and therefore the following checks must be<br />

performed.<br />

M<br />

Ed<br />

1<br />

M ≤ FEd<br />

MEd<br />

FEd<br />

≤ 1<br />

+ ≤ 1, 25<br />

R<br />

M R<br />

c,Rd<br />

w,Rd<br />

c,Rd<br />

w,Rd<br />

prEN 1993-<br />

1-3, Eqs.<br />

6.28a-c<br />

<strong>Design</strong> load per unit width (1 m) Section 2.3.2<br />

qd = γ<br />

Gg+ γ<br />

Qq= 2,20 kN/m<br />

Eq. 2.3<br />

The design load, qd, gives the following bending moment and support reaction at the<br />

intermediate support.<br />

2<br />

qL<br />

5<br />

M<br />

Ed<br />

= = 3,37 kNm FEd<br />

= qL=<br />

9,63 kN<br />

8<br />

4<br />

M<br />

Ed<br />

0,76<br />

M = FEd<br />

MEd<br />

FEd<br />

= 0, 46<br />

+<br />

R<br />

M R<br />

= 1, 22 OK<br />

c,Rd<br />

w,Rd<br />

c,Rd<br />

w,Rd<br />

Deflection at serviceability limit state<br />

For verification in the serviceability limit state the effective width <strong>of</strong> compression<br />

elements should be based on the compressive stress in the element under serviceability<br />

limit state loading. The maximum compression stress is calculated as follows. A<br />

conservative approximation is made based on Weff,min from ultimate limit state.<br />

( q+<br />

g) L<br />

2<br />

prEN 1993-<br />

1-3, clause<br />

5.5.1(4)<br />

M<br />

Ed,ser<br />

= = 2, 25 kNm<br />

Section 2.3.4<br />

8<br />

M<br />

Ed,ser 2<br />

σ<br />

com,Ed,ser<br />

= = 186 N/mm<br />

W<br />

eff,min<br />

Now, the effective section properties are determined as before but with fy replaced by<br />

σcom,Ed,ser. The calculations will not be shown here but the interesting results are:<br />

I = 573 150 mm 4<br />

Wu = 15 866 mm 3<br />

Wl = 16 919 mm 3<br />

181

Job No. Sheet 6 <strong>of</strong> 6 Rev A<br />

CALCULATION SHEET<br />

Job Title<br />

Subject<br />

Client<br />

RFCS Stainless <strong>Steel</strong> Valorisation Project<br />

<strong>Design</strong> Example 11 – <strong>Design</strong> <strong>of</strong> a <strong>two</strong>-<strong>span</strong> <strong>trapezoidal</strong><br />

ro<strong>of</strong> <strong>sheeting</strong><br />

Made by JG/AO Date Feb 2006<br />

RFCS<br />

Checked by GZ Date March 2006<br />

Determination <strong>of</strong> the deflection:<br />

Secant modulus corresponding to the stresses in the tension and compression flange<br />

respectively.<br />

M<br />

Ed,ser 2<br />

σ<br />

1,Ed,ser<br />

= = 142 N/mm<br />

W<br />

u<br />

M<br />

σ<br />

2,Ed,ser<br />

= = 133 N/mm<br />

W<br />

E<br />

E<br />

Ed,ser 2<br />

l<br />

E<br />

= = 199 604 N/mm<br />

s,1 n−1<br />

E ⎛σ<br />

⎞<br />

1,Ed,ser<br />

1+ 0,002<br />

f ⎜<br />

y<br />

f ⎟<br />

⎝ y ⎠<br />

E<br />

= = 199 730 N/mm<br />

n−<br />

E ⎛σ<br />

⎞<br />

2,Ed,ser<br />

1+ 0,002<br />

f ⎜<br />

y<br />

f ⎟<br />

⎝ y ⎠<br />

s,2 1<br />

Es,1 + Es,2 2<br />

Es<br />

= = 199 667 N/mm<br />

2<br />

2<br />

2<br />

n = 7,0<br />

As a simplification, the variation <strong>of</strong> Es along the length <strong>of</strong> the member may be<br />

neglected and the minimum value <strong>of</strong> Es <strong>of</strong> that member may conservatively be used<br />

throughout its length, i.e.<br />

Es = Es,1 = 199 603 N/mm 2<br />

The permitted deflection is L/300 = 11,7 mm<br />

1+<br />

33<br />

x= L= 1, 47 m (location <strong>of</strong> maximum deflection)<br />

16<br />

( ) 4 3 4<br />

g+ q L ⎛ x x x ⎞<br />

δ = ⎜ − 3 + 2 10,4 mm<br />

3 4 ⎟=<br />

48Es,1I ⎝L L L ⎠<br />

OK<br />

Appendix C<br />

Appendix C<br />

Table C.1<br />

Appendix C<br />

Comparison with <strong>sheeting</strong> in grade 1.4401 in the annealed condition<br />

The bending resistance per unit width <strong>of</strong> identical <strong>sheeting</strong> in grade 1.4401 in the<br />

annealed condition (fy = 240 N/mm 2 ) is:<br />

Mc,Rd = 3,22 kNm<br />

and the resistance to local transverse forces is:<br />

Rw,Rd = 16,2 kN<br />

With <strong>sheeting</strong> made from grade 1.4401 in the annealed condition, the <strong>span</strong> must be<br />

reduced to 2,9 m compared to 3,5 m for material in the cold worked strength<br />

condition. Hence, <strong>sheeting</strong> made from cold worked material enables the <strong>span</strong> to be<br />

increased, meaning that the number <strong>of</strong> secondary beams or purlins could be reduced,<br />

leading to cost reductions.<br />

182