Issue n. 3 - April 2005Download pdf - BLM GROUP

Issue n. 3 - April 2005Download pdf - BLM GROUP

Issue n. 3 - April 2005Download pdf - BLM GROUP

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

down from 2∏ hours to 45 minutes. Other benefits<br />

include the cutting speed for thick-wall tube<br />

which, thanks to the ADIGE CNC control system<br />

determining the cutting parameters automatically,<br />

gives lower cycle times.”<br />

To achieve one’s expectations<br />

“ Also from a quality point of view,” Rui goes on,<br />

“ we have increased our levels of performance<br />

and expectancy; with in-line monitoring and<br />

control of all the parts produced, we have a<br />

guarantee of consistency within the design tolerances.<br />

This control is equally important for the<br />

internal integrity of thin wall tubes. Equally beneficial<br />

is that the components come off finishmachined<br />

and clean, needing no further operations.<br />

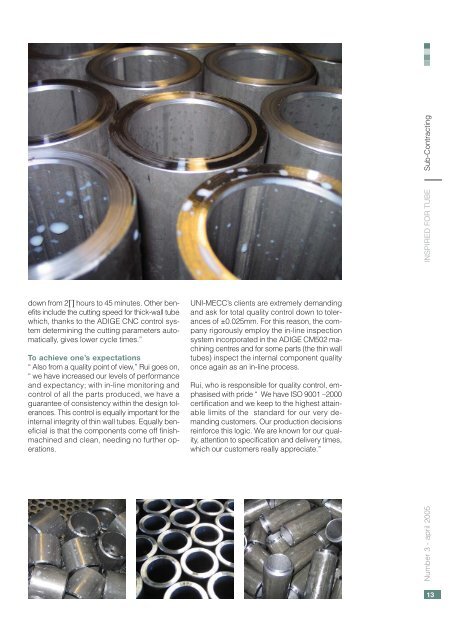

UNI-MECC’s clients are extremely demanding<br />

and ask for total quality control down to tolerances<br />

of ±0.025mm. For this reason, the company<br />

rigorously employ the in-line inspection<br />

system incorporated in the ADIGE CM502 machining<br />

centres and for some parts (the thin wall<br />

tubes) inspect the internal component quality<br />

once again as an in-line process.<br />

Rui, who is responsible for quality control, emphasised<br />

with pride “ We have ISO 9001 –2000<br />

certification and we keep to the highest attainable<br />

limits of the standard for our very demanding<br />

customers. Our production decisions<br />

reinforce this logic. We are known for our quality,<br />

attention to specification and delivery times,<br />

which our customers really appreciate.”<br />

Number 3 - april 2005 INSPIRED FOR TUBE Sub-Contracting<br />

13