4 Chopper-Controlled DC Motor Drive

4 Chopper-Controlled DC Motor Drive

4 Chopper-Controlled DC Motor Drive

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

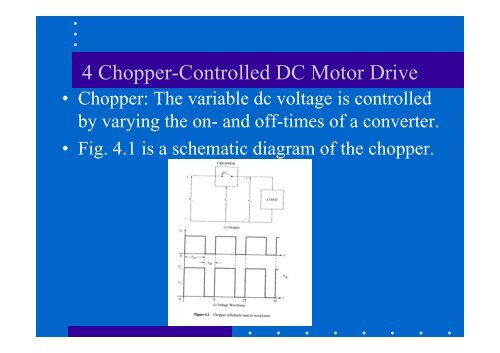

4 <strong>Chopper</strong>-<strong>Controlled</strong> <strong>DC</strong> <strong>Motor</strong> <strong>Drive</strong><br />

• <strong>Chopper</strong>: The variable dc voltage is controlled<br />

by varying the on- and off-times of a converter.<br />

• Fig. 4.1 is a schematic diagram of the chopper.

• Its frequency of operation is<br />

f<br />

1<br />

+ t<br />

c =<br />

=<br />

(ton<br />

off )<br />

1<br />

T<br />

and its duty cycle is defined as<br />

d<br />

=<br />

t<br />

T<br />

on<br />

• Assuming that the switch is ideal, the<br />

average output is<br />

t<br />

V<br />

on<br />

dc = Vs<br />

=<br />

T<br />

dV<br />

s<br />

• varying the duty cycle changes the output<br />

voltage.

• The duty cycle d can be changed in two ways:<br />

(i) varying the on-time (constant switching<br />

frequency).<br />

(ii) varying the chopping frequency.<br />

• Constant switching frequency has many<br />

advantages in practice.

4.3 Four-Quadrant <strong>Chopper</strong> Circuit<br />

• Fig. 4.2 is the chopper circuit with transistor<br />

switches.

• Fig. 4.3 is first-quadrant operation.

• Fig. 4.4 is first-quadrant operation with zero<br />

voltage across the load.

• Fig. 4.5 voltage and current waveforms in<br />

first-quadrant operation.

• Fig. 4.6 second-quadrant operation

• Fig. 4.7 voltage and current waveforms in<br />

second-quadrant operation.

• Fig. 4.8 Modes of operation in the third<br />

quadrant.

• Fig. 4.9 waveform in third-quadrant operation

• Fig. 4.10 Waveforms in fourth-quadrant<br />

operation.

4.4 <strong>Chopper</strong> for inversion<br />

• Converter: <strong>DC</strong> ⇒ <strong>DC</strong> (different voltage)<br />

• The chopper is the building block for that:<br />

AC ⇒ <strong>DC</strong> ⇒ <strong>DC</strong>(different voltage)

4.5 <strong>Chopper</strong> with other power devices<br />

• MOSFETs, IGBTs, GTOs, or SCRs are<br />

used for different power level.<br />

• The MOSFET and transistor choppers are<br />

used at power levels up to 50kW.

4.6 Model of The <strong>Chopper</strong><br />

• The transfer function of the chopper is<br />

G<br />

r<br />

K<br />

(s) =<br />

r<br />

sT<br />

1+<br />

2<br />

where K r = V s /V cm , V s is the source voltage,<br />

and V cm is the maximum control voltage.<br />

• Increasing the chopping frequency decreases<br />

the delay time, and its becomes a simple gain.

4.7 Input to the chopper<br />

• The chopper input: a battery or a rectified ac<br />

supply.<br />

• Fig. 4.11 is the chopper with rectified circuit.

• Its disadvantage: it cannot transfer power from<br />

dc link into ac mains.<br />

• Fig. 4.12 <strong>Chopper</strong> with regeneration capability

• The generating converter has to be operated<br />

at triggering angles greater that 90.

4.8 Other <strong>Chopper</strong> Circuits<br />

• Fig. 4.13 one- and two-quadrant operation.

4.9 Steady-state analysis ...<br />

• 4.9.1 Analysis by averaging<br />

• The average armature current is<br />

I<br />

av<br />

Vdc<br />

− E<br />

=<br />

R<br />

a<br />

where V dc = dV s<br />

• The electromagnetic torque is<br />

T av = K b I av = K b (dV s -K b w m )/R a (N·m)

• The normalized torque is<br />

T<br />

en<br />

=<br />

T<br />

T<br />

av<br />

b<br />

/ V<br />

/ V<br />

b<br />

b<br />

=<br />

K<br />

b<br />

(dV<br />

K<br />

s<br />

b<br />

− K<br />

I R<br />

b<br />

a<br />

b<br />

ωm<br />

) /<br />

/ V<br />

b<br />

V<br />

b<br />

=<br />

dVn<br />

− ω<br />

R<br />

an<br />

mn<br />

,<br />

p.u.<br />

I<br />

R<br />

where R<br />

b a<br />

an = , p.u. V<br />

s<br />

V<br />

n = , p.u. ω<br />

m<br />

mn = , p.u.<br />

b<br />

Vb<br />

ωb<br />

• 4.9.2 Instantaneous steady-state computation<br />

(including harmonics)<br />

• The equations of the motor for on and off times<br />

(continuous current conduction)<br />

di<br />

V E R i L<br />

a<br />

s = + a a + a<br />

dt<br />

di<br />

0 = E + R i L<br />

a<br />

a a + a ,<br />

dt<br />

,<br />

0<br />

dT<br />

≤<br />

≤<br />

t<br />

t<br />

V<br />

≤<br />

≤<br />

dT<br />

T<br />

ω

• Fig. 4.15 The waveform of applied voltage<br />

and armature current.

• The solutions of the above equations:<br />

t<br />

V E<br />

i (t)<br />

s − T<br />

(1 e a T<br />

) I e a<br />

a = − + a0 , 0 < t <<br />

R<br />

i<br />

a<br />

(t)<br />

= −<br />

a<br />

E<br />

R<br />

a<br />

(1 − e<br />

−<br />

1<br />

t<br />

−<br />

T<br />

a<br />

) +<br />

I<br />

a1<br />

e<br />

where T a = L a /R a (Armature time constant)<br />

t 1 = t - dT<br />

• By using boundary condition<br />

I<br />

a1<br />

=<br />

V (1 − e<br />

s<br />

R<br />

a<br />

(1 − e<br />

−dT / T<br />

−T / T<br />

a<br />

a<br />

)<br />

)<br />

−<br />

E<br />

R<br />

−<br />

1<br />

t<br />

−<br />

T<br />

a<br />

a<br />

t<br />

,<br />

I<br />

dT<br />

a0<br />

≤<br />

=<br />

t<br />

≤<br />

V (e<br />

s<br />

R<br />

a<br />

dT<br />

dT<br />

(e<br />

dT / T<br />

T / T<br />

a<br />

a<br />

−1)<br />

−1)<br />

−<br />

E<br />

R<br />

a

• The critical duty cycle: the limiting or<br />

minimum value of duty cycle for<br />

continuous current; I a0 equates to zero.<br />

• The relevant equations for discontinuous<br />

current-conduction mode<br />

V<br />

s<br />

=<br />

E<br />

+<br />

R<br />

a<br />

i<br />

a<br />

+<br />

L<br />

di<br />

dt<br />

di<br />

0 = E + R i L<br />

a<br />

a + a , dT ≤ t ≤ tx<br />

dt<br />

with i a (t x + dT) = 0; i a (0) = 0<br />

a<br />

a<br />

,<br />

0<br />

≤<br />

t<br />

≤<br />

a +<br />

dT<br />

dT

• Hence,<br />

i<br />

a<br />

I<br />

a1<br />

(t<br />

x<br />

=<br />

Vs<br />

−<br />

R<br />

a<br />

+ dT) = −<br />

E<br />

(1 − e<br />

E<br />

R<br />

a<br />

−dT /<br />

(1 − e<br />

Ta<br />

t<br />

−<br />

T<br />

x<br />

a<br />

)<br />

) +<br />

• tx is evaluated from (4.25) and the above<br />

eqs. as<br />

tx = Ta<br />

loge[1<br />

+<br />

I<br />

a1<br />

R<br />

E<br />

a<br />

]<br />

I<br />

a1<br />

e<br />

t<br />

−<br />

T<br />

x<br />

a

• The solution for the armature current in<br />

three time segments is<br />

V E<br />

i (t)<br />

s −<br />

(1 e a<br />

a = − ), 0 < t <<br />

R<br />

i<br />

a<br />

(t)<br />

=<br />

I<br />

a1<br />

e<br />

a<br />

(t−dT)<br />

−<br />

T<br />

a<br />

−<br />

−<br />

t<br />

T<br />

E<br />

R<br />

a<br />

(1 − e<br />

dT<br />

(t−dT)<br />

−<br />

T<br />

ia (t) = 0, (tx<br />

+ dT) < t <<br />

a<br />

),<br />

T<br />

dT<br />

≤<br />

t<br />

≤<br />

t<br />

x<br />

- dT

4.10 Rating of the device<br />

• The rms value of the power switch current<br />

I<br />

t<br />

=<br />

2<br />

max<br />

I<br />

2T<br />

(T + dT) =<br />

1+<br />

d<br />

2<br />

max<br />

• The average diode current<br />

I<br />

1−<br />

d<br />

= ( ) ⋅<br />

2<br />

d I max<br />

⋅ I

• Transistor and diode currents for motoring<br />

operation in the continuous-conduction mode.

4.11 Pulsating Torque<br />

• The average of the harmonic torque is zero.<br />

• High-performance applications require the<br />

pulsating torque to be minimum.<br />

• The applied voltage is resolved into Fourier<br />

components as<br />

V<br />

where<br />

= V +<br />

∞ a ∑ n=1<br />

A<br />

sin(nω<br />

a (t)<br />

n c t n )<br />

dT<br />

V a = Vs<br />

= dV<br />

T<br />

A<br />

n<br />

2V<br />

=<br />

s<br />

nπ<br />

s<br />

nω<br />

dT<br />

sin<br />

c<br />

2<br />

ω<br />

θ<br />

c<br />

n<br />

2π<br />

= 2πf<br />

c =<br />

T<br />

π nωcdT<br />

= −<br />

2 2<br />

+<br />

θ

• The armature current is expressed as<br />

i<br />

a<br />

A<br />

(t) = I<br />

n<br />

av +<br />

∞<br />

∑n<br />

= 1 sin(nωct<br />

+ θn<br />

− φ<br />

Zn<br />

Va<br />

− E<br />

Iav<br />

Zn<br />

= R<br />

Ra<br />

−1<br />

R<br />

φ cos {<br />

a<br />

n =<br />

}<br />

2 2 2<br />

R + n ω L<br />

where<br />

= a c a<br />

a<br />

c<br />

2<br />

a<br />

n<br />

)<br />

+<br />

jnω<br />

L<br />

• The input power is<br />

P<br />

i<br />

=<br />

V<br />

a<br />

⎧V aI<br />

⎪<br />

= ⎨<br />

⎪+<br />

V<br />

⎩<br />

a<br />

(t)i<br />

av<br />

a<br />

+ I<br />

(t)<br />

av<br />

∑<br />

∞<br />

n = 1<br />

sin(nω<br />

t + θ<br />

∞ An<br />

∑ = ω + θ − φ +<br />

∞<br />

n 1 sin(n ct<br />

n n)<br />

∑n<br />

=<br />

Z<br />

n<br />

A<br />

n<br />

c<br />

n<br />

)<br />

1<br />

A<br />

(<br />

Z<br />

2<br />

n<br />

n<br />

sin(nω<br />

c<br />

t + θ<br />

n<br />

)sin(nω<br />

c<br />

t + θ<br />

n<br />

− φ<br />

n<br />

⎫<br />

⎪<br />

⎬<br />

)) ⎪<br />

⎭

4.12 Closed-loop operation<br />

• Fig. 4.20 is the closed-loop speed-controller<br />

dc motor drive.

• The current controller can be<br />

(i) Pulse-Width-Modulation (PWM) controller<br />

(ii) Hysteresis controller<br />

Fig. 4.21 shows on- and off-time for PWM

• Fig. 4.22 is the implementation of PWM<br />

current controller.

• Fig. 4.24 shows hysteresis-controlled operation<br />

a<br />

*<br />

a<br />

i ≤ i − ∆i,<br />

set v =<br />

*<br />

a<br />

a<br />

V<br />

i a ≥ i + ∆i,<br />

reset va<br />

=<br />

s<br />

0

• Fig. 4.23

• Fig. 4.25 is realization of hysteresis controller.