PR ODUCT INF ORMA TION Soft form edging - industrie.pfleiderer ...

PR ODUCT INF ORMA TION Soft form edging - industrie.pfleiderer ...

PR ODUCT INF ORMA TION Soft form edging - industrie.pfleiderer ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>PR</strong><strong>ODUCT</strong> <strong>INF</strong><strong>ORMA</strong><strong>TION</strong><br />

<strong>Soft</strong> <strong>form</strong> <strong>edging</strong><br />

Product description<br />

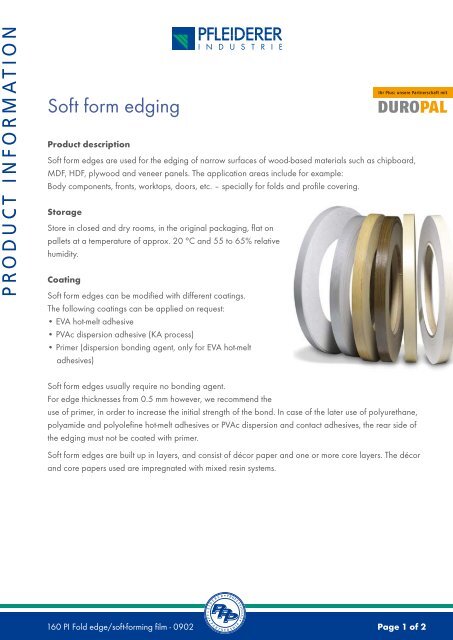

<strong>Soft</strong> <strong>form</strong> edges are used for the <strong>edging</strong> of narrow surfaces of wood-based materials such as chipboard,<br />

MDF, HDF, plywood and veneer panels. The application areas include for example:<br />

Body components, fronts, worktops, doors, etc. – specially for folds and profile covering.<br />

Storage<br />

Store in closed and dry rooms, in the original packaging, flat on<br />

pallets at a temperature of approx. 20 °C and 55 to 65% relative<br />

humidity.<br />

Coating<br />

<strong>Soft</strong> <strong>form</strong> edges can be modified with different coatings.<br />

The following coatings can be applied on request:<br />

• EVA hot-melt adhesive<br />

• PVAc dispersion adhesive (KA process)<br />

• Primer (dispersion bonding agent, only for EVA hot-melt<br />

adhesives)<br />

<strong>Soft</strong> <strong>form</strong> edges usually require no bonding agent.<br />

For edge thicknesses from 0.5 mm however, we recommend the<br />

use of primer, in order to increase the initial strength of the bond. In case of the later use of polyurethane,<br />

polyamide and polyolefine hot-melt adhesives or PVAc dispersion and contact adhesives, the rear side of<br />

the <strong>edging</strong> must not be coated with primer.<br />

<strong>Soft</strong> <strong>form</strong> edges are built up in layers, and consist of décor paper and one or more core layers. The décor<br />

and core papers used are impregnated with mixed resin systems.<br />

160 PI Fold edge/soft-<strong>form</strong>ing film - 0902 Page 1 of 2

<strong>PR</strong><strong>ODUCT</strong> <strong>INF</strong><strong>ORMA</strong><strong>TION</strong><br />

Application<br />

Before working, fold edges and core panels must be stored under normal climatic conditions, since faulty<br />

bonding may otherwise occur. Fold edges can be applied using normal EVA, polyamide, polyolefine and<br />

polyurethane hot-melt adhesives in edge bonding systems.<br />

PVAc dispersion, condensation resin and contact adhesives are used in edge presses or for manual application.<br />

Please refer to the instructions of the machine or adhesive manufacturers.<br />

Surface textures<br />

Smooth matt, pearl, soft, wood pore, gloss<br />

Production batch sizes/packaging units<br />

Production <strong>form</strong>: Roll<br />

Winding: 150 mm core diameter<br />

Thicknesses: 0.15 to 0.5 mm<br />

Widths: from 16 to 700 mm<br />

Standard width 700 mm<br />

Roll length: 50 m, 100 m, 150 m, 200 m, to size (from 50 m)<br />

Décors: All décors from the Duropal door collection. Further décors available on request.<br />

Dimensional tolerances<br />

Edge thicknesses ± 0.1mm<br />

Edge width ± 0.2mm<br />

Edge lengths ± 1.0 m from 50 m length<br />

A service of<br />

PFLEIDERER Industrie GmbH • Product Management<br />

Holzstraße 6 - 10 • D-33332 Gütersloh • Telephone: 0 52 41 / 8 71 - 0 • Telefax: 0 52 41 / 8 71 - 9 87<br />

e-mail: produktmanagement@<strong>pfleiderer</strong>.com • Internet: www.<strong>industrie</strong>.<strong>pfleiderer</strong>.com<br />

160 PI Fold edge/soft-<strong>form</strong>ing film - 0902 Page 2 of 2