PR ODUCT INF ORMA TION Melamine-faced panels (MFC/MFMDF)

PR ODUCT INF ORMA TION Melamine-faced panels (MFC/MFMDF)

PR ODUCT INF ORMA TION Melamine-faced panels (MFC/MFMDF)

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>PR</strong><strong>ODUCT</strong> <strong>INF</strong><strong>ORMA</strong><strong>TION</strong><br />

<strong>Melamine</strong>-<strong>faced</strong> <strong>panels</strong> (<strong>MFC</strong>/<strong>MFMDF</strong>)<br />

<strong>Melamine</strong>-<strong>faced</strong> <strong>panels</strong> from PFLEIDERER are extremely versatile in use, although they are used primarily<br />

for furniture production. Further application possibilities are found in the areas of interior wall panelling,<br />

suspended ceilings and ceiling panelling, construction installations and general interior design.<br />

<strong>Melamine</strong>-<strong>faced</strong> <strong>panels</strong> are only of limited suitability for horizontal surfaces subject to high loads, such as<br />

counters, shelves or kitchen worktops.<br />

For such applications, we recommend the use of DUROPAL high-pressure laminates (HPL).<br />

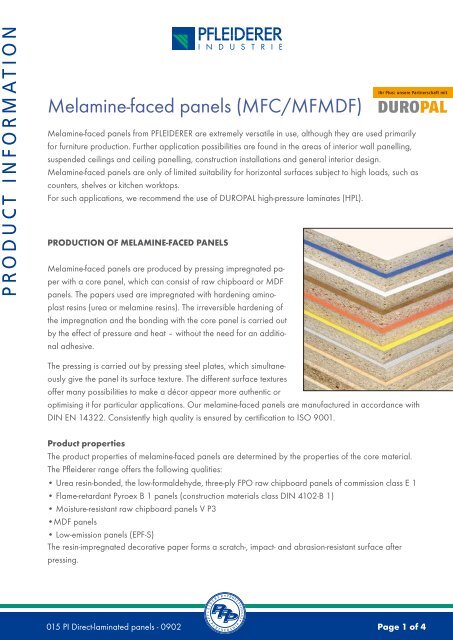

<strong>PR</strong><strong>ODUCT</strong>ION OF MELAMINE-FACED PANELS<br />

<strong>Melamine</strong>-<strong>faced</strong> <strong>panels</strong> are produced by pressing impregnated paper<br />

with a core panel, which can consist of raw chipboard or MDF<br />

<strong>panels</strong>. The papers used are impregnated with hardening aminoplast<br />

resins (urea or melamine resins). The irreversible hardening of<br />

the impregnation and the bonding with the core panel is carried out<br />

by the effect of pressure and heat – without the need for an additional<br />

adhesive.<br />

The pressing is carried out by pressing steel plates, which simultaneously<br />

give the panel its surface texture. The different surface textures<br />

offer many possibilities to make a décor appear more authentic or<br />

optimising it for particular applications. Our melamine-<strong>faced</strong> <strong>panels</strong> are manufactured in accordance with<br />

DIN EN 14322. Consistently high quality is ensured by certification to ISO 9001.<br />

Product properties<br />

The product properties of melamine-<strong>faced</strong> <strong>panels</strong> are determined by the properties of the core material.<br />

The Pfleiderer range offers the following qualities:<br />

• Urea resin-bonded, the low-formaldehyde, three-ply FPO raw chipboard <strong>panels</strong> of commission class E 1<br />

• Flame-retardant Pyroex B 1 <strong>panels</strong> (construction materials class DIN 4102-B 1)<br />

• Moisture-resistant raw chipboard <strong>panels</strong> V P3<br />

•MDF <strong>panels</strong><br />

• Low-emission <strong>panels</strong> (EPF-S)<br />

The resin-impregnated decorative paper forms a scratch-, impact- and abrasion-resistant surface after<br />

pressing.<br />

015 PI Direct-laminated <strong>panels</strong> - 0902 Page 1 of 4

<strong>PR</strong><strong>ODUCT</strong> <strong>INF</strong><strong>ORMA</strong><strong>TION</strong><br />

Cleaning instructions<br />

<strong>Melamine</strong>-<strong>faced</strong> <strong>panels</strong> (<strong>MFC</strong>/<strong>MFMDF</strong>) can be cleaned using all normal household cleaning agents,<br />

although no highly abrasive cleaning materials should be used. Please note our cleaning instructions for<br />

<strong>MFC</strong>/<strong>MFMDF</strong> <strong>panels</strong>.<br />

Technical data and material properties<br />

Edge properties Requirements to DIN EN 14322 Pfleiderer <strong>panels</strong><br />

Standard <strong>panels</strong> Break-outs up to 10 mm ≤ 5 mm<br />

Rough cuttings Break-outs up to 3 mm ≤ 3 mm<br />

Surface faults:<br />

Points ≤ 2 mm2/m2 ≤ 2 mm²/m²<br />

Lengthwise faults ≤ 20 mm2/m2 ≤ 20 mm²/m²<br />

Distortion:<br />

Thickness ≥ 15<br />

(only for balanced build-up of the<br />

surfaces)<br />

Behaviour under abrasion stress to<br />

DIN EN 14322<br />

≤ 2 mm/m ≤ 2 mm/m<br />

WR turns<br />

1 < 150<br />

2 ≥ 150<br />

3A ≥ 350<br />

3B ≥ 650<br />

4 ≥ 1,000<br />

Behaviour under scratch stress to DIN<br />

EN 14322<br />

Stress 1.5 N No continuous track<br />

Insensitivity to marks<br />

Decorative <strong>panels</strong> must be insensitive to<br />

the mark- or stain-forming materials speci<br />

fied in DIN EN 14322, Appendix A.<br />

Printed décors (stone and wood<br />

reproductions and fantasy décors)<br />

Plain colours depending on layer<br />

thickness<br />

Plain colours depending on layer<br />

thickness<br />

Plain colours depending on layer<br />

thickness<br />

Plain colours depending on layer<br />

thickness<br />

> 1.5 N<br />

(The value 1 – 1.2 N is achieved for<br />

the surfaces SO and SM)<br />

PFLEIDERER <strong>panels</strong> fulfil the required<br />

values with a contact time of 16 hours.<br />

Heat sources (e.g. coffee machines, printers, faxes etc.) should not have any direct contact with the panel, since this can<br />

otherwise lead to the formation of cracks due to drying out.<br />

All the above technical properties apply exclusively for normal climatic conditions (temperature, air humidity, light etc.).<br />

Further information on subjects such as bending strength, transverse tensile strength, thickness<br />

swelling etc. can be found in the product information sheets on core materials<br />

The values specified for raw chipboard <strong>panels</strong> also apply for decorative <strong>panels</strong>.<br />

015 PI Direct-laminated <strong>panels</strong> - 0902 Page 2 of 4

<strong>PR</strong><strong>ODUCT</strong> <strong>INF</strong><strong>ORMA</strong><strong>TION</strong><br />

THE RIGHT SURFACE FOR EVERY REQUIREMENT<br />

Depending on the area of application, different requirements are placed on melamine-<strong>faced</strong> <strong>panels</strong>.<br />

Scratch resistance<br />

The scratch resistance increases with the coarseness of the surface texture and the lightness of the décor<br />

(visual effect). Smooth textures have a reduced scratch resistance (see technical data). Pearl or butt textures<br />

(e.g. MP) should be used wherever possible for areas subject to heavy scratch stresses (as a rule<br />

horizontal). Smooth textures (e.g. SM) are not suitable.<br />

Sensitivity to marks/stains<br />

The sensitivity to marks/stains increases with the smoothness of the surface texture and the darkness of the<br />

décor. If increased resistance is required, pearl or butt textures (e.g. MP) should be used. Smooth textures<br />

(e.g. SM) are not suitable.<br />

Ease of cleaning<br />

The ease of cleaning increases with the closeness and gloss of the surface texture.<br />

Abrasion resistance<br />

The abrasion resistance depends solely on the paper properties of the décor used. Plain décors produce<br />

the best values here, since these papers are dyed (see also technical data). Printed décors (wood, stone<br />

and fantasy décors) produce lower values, since only the imprint serves for the abrasion resistance. The<br />

surface texture used plays no part in the abrasion resistance.<br />

Surface smoothness<br />

The surface smoothness depends on the core panel used. Very good results can be achieved with raw<br />

chipboard <strong>panels</strong> in terms of surface smoothness. For the very highest requirements, we recommend the<br />

use of MDF <strong>panels</strong>.<br />

Surface gloss<br />

The surface gloss depends solely on the surface texture chosen. All our surface textures fall below the limit<br />

value of 0.45 specified in the office furniture standard DIN 4554.<br />

015 PI Direct-laminated <strong>panels</strong> - 0902 Page 3 of 4

<strong>PR</strong><strong>ODUCT</strong> <strong>INF</strong><strong>ORMA</strong><strong>TION</strong><br />

Classification of surface textures<br />

Construction materials class<br />

B2 (normally inflammable),<br />

except for Pyroex B1 (low inflammability)<br />

Smooth textures<br />

Recommended application<br />

horizontal vertical<br />

SM – Silk matt n<br />

SO - Soft n<br />

EG – High gloss n<br />

Butt texture VV – Top velvet n n<br />

Pearl textures<br />

Wood textures<br />

MP – Miniperl n n<br />

SP – Superperl n n<br />

TR – Trevista n<br />

TF – Trefugo n<br />

RU – Rustica n<br />

Decorative texture PO - Polish n<br />

Material properties of surface textures:<br />

• hygienic and easy to care for<br />

• anti-static colourfast and heat-resistant<br />

• scratch-, impact- and abrasion-resistant<br />

• insensitive to the effects of normal household fluids, pastes etc.<br />

• approved for direct contact with foodstuffs<br />

A service of<br />

PFLEIDERER Industrie GmbH • Product Management<br />

Holzstraße 6 - 10 • D-33332 Gütersloh • Telephone: 0 52 41 / 8 71 - 0 • Telefax: 0 52 41 / 8 71 - 9 87<br />

e-mail: produktmanagement@pfleiderer.com • Internet: www.industrie.pfleiderer.com<br />

015 PI Direct-laminated <strong>panels</strong> - 0902 Page 4 of 4