PR ODUCT INF ORMA TION Melamine-faced panels (MFC/MFMDF)

PR ODUCT INF ORMA TION Melamine-faced panels (MFC/MFMDF)

PR ODUCT INF ORMA TION Melamine-faced panels (MFC/MFMDF)

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>PR</strong><strong>ODUCT</strong> <strong>INF</strong><strong>ORMA</strong><strong>TION</strong><br />

Cleaning instructions<br />

<strong>Melamine</strong>-<strong>faced</strong> <strong>panels</strong> (<strong>MFC</strong>/<strong>MFMDF</strong>) can be cleaned using all normal household cleaning agents,<br />

although no highly abrasive cleaning materials should be used. Please note our cleaning instructions for<br />

<strong>MFC</strong>/<strong>MFMDF</strong> <strong>panels</strong>.<br />

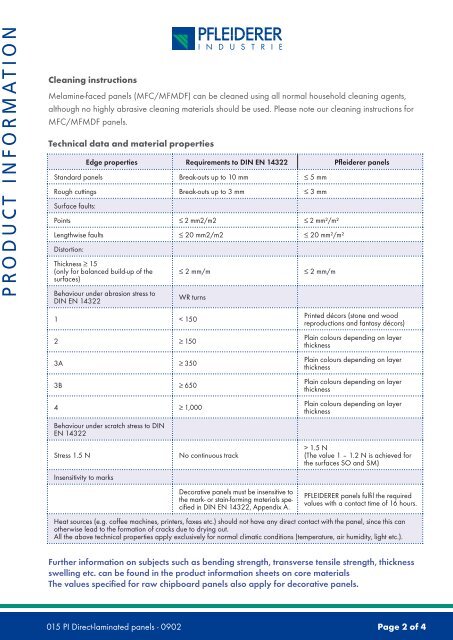

Technical data and material properties<br />

Edge properties Requirements to DIN EN 14322 Pfleiderer <strong>panels</strong><br />

Standard <strong>panels</strong> Break-outs up to 10 mm ≤ 5 mm<br />

Rough cuttings Break-outs up to 3 mm ≤ 3 mm<br />

Surface faults:<br />

Points ≤ 2 mm2/m2 ≤ 2 mm²/m²<br />

Lengthwise faults ≤ 20 mm2/m2 ≤ 20 mm²/m²<br />

Distortion:<br />

Thickness ≥ 15<br />

(only for balanced build-up of the<br />

surfaces)<br />

Behaviour under abrasion stress to<br />

DIN EN 14322<br />

≤ 2 mm/m ≤ 2 mm/m<br />

WR turns<br />

1 < 150<br />

2 ≥ 150<br />

3A ≥ 350<br />

3B ≥ 650<br />

4 ≥ 1,000<br />

Behaviour under scratch stress to DIN<br />

EN 14322<br />

Stress 1.5 N No continuous track<br />

Insensitivity to marks<br />

Decorative <strong>panels</strong> must be insensitive to<br />

the mark- or stain-forming materials speci<br />

fied in DIN EN 14322, Appendix A.<br />

Printed décors (stone and wood<br />

reproductions and fantasy décors)<br />

Plain colours depending on layer<br />

thickness<br />

Plain colours depending on layer<br />

thickness<br />

Plain colours depending on layer<br />

thickness<br />

Plain colours depending on layer<br />

thickness<br />

> 1.5 N<br />

(The value 1 – 1.2 N is achieved for<br />

the surfaces SO and SM)<br />

PFLEIDERER <strong>panels</strong> fulfil the required<br />

values with a contact time of 16 hours.<br />

Heat sources (e.g. coffee machines, printers, faxes etc.) should not have any direct contact with the panel, since this can<br />

otherwise lead to the formation of cracks due to drying out.<br />

All the above technical properties apply exclusively for normal climatic conditions (temperature, air humidity, light etc.).<br />

Further information on subjects such as bending strength, transverse tensile strength, thickness<br />

swelling etc. can be found in the product information sheets on core materials<br />

The values specified for raw chipboard <strong>panels</strong> also apply for decorative <strong>panels</strong>.<br />

015 PI Direct-laminated <strong>panels</strong> - 0902 Page 2 of 4