DUROPAL HPL-Compact PR ODUCT INF ... - industrie.pfleiderer.com

DUROPAL HPL-Compact PR ODUCT INF ... - industrie.pfleiderer.com

DUROPAL HPL-Compact PR ODUCT INF ... - industrie.pfleiderer.com

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>PR</strong><strong>ODUCT</strong> <strong>INF</strong>ORMATION<br />

<strong>DUROPAL</strong> <strong>HPL</strong>-<strong>Compact</strong><br />

<strong>DUROPAL</strong> <strong>HPL</strong>-<strong>Compact</strong> <strong>com</strong>bines decoration and safety to make the ideal material for professional<br />

interior design – with the primary benefits being hygiene and durability. With the post-formable <strong>DUROPAL</strong><br />

<strong>HPL</strong>-<strong>Compact</strong>, we offer quality which can be formed and bent exactly as your customer requires.<br />

This enables individual design solutions to meet the highest demands and quality specifications. The<br />

product and colour match range allows consistent design in accordance with requirements using<br />

decorative panels, <strong>DUROPAL</strong> <strong>HPL</strong>, <strong>DUROPAL</strong> <strong>HPL</strong>-<strong>Compact</strong> and <strong>DUROPAL</strong> <strong>HPL</strong> elements.<br />

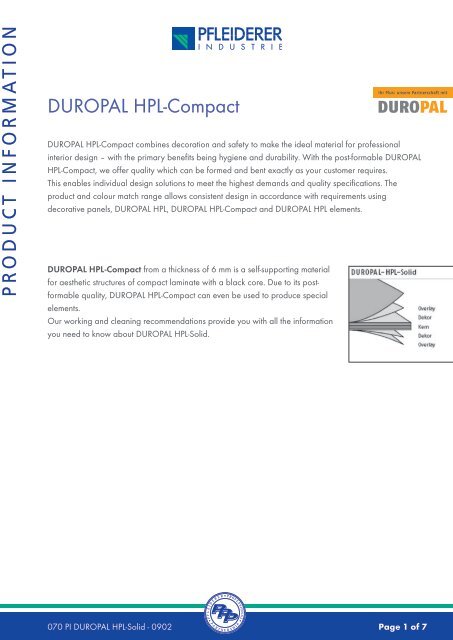

<strong>DUROPAL</strong> <strong>HPL</strong>-<strong>Compact</strong> from a thickness of 6 mm is a self-supporting material<br />

for aesthetic structures of <strong>com</strong>pact laminate with a black core. Due to its postformable<br />

quality, <strong>DUROPAL</strong> <strong>HPL</strong>-<strong>Compact</strong> can even be used to produce special<br />

elements.<br />

Our working and cleaning re<strong>com</strong>mendations provide you with all the information<br />

you need to know about <strong>DUROPAL</strong> <strong>HPL</strong>-Solid.<br />

070 PI <strong>DUROPAL</strong> <strong>HPL</strong>-Solid - 0902 Page 1 of 7

<strong>PR</strong><strong>ODUCT</strong> <strong>INF</strong>ORMATION<br />

PLUS POINTS OF <strong>DUROPAL</strong> <strong>HPL</strong>-COMPACT<br />

Solid<br />

• Extremely resistant <strong>DUROPAL</strong> <strong>HPL</strong> to EN 438<br />

• Self-supporting function from a thickness of 6 mm<br />

• Can be profiled like solid wood<br />

Forming<br />

• <strong>DUROPAL</strong> <strong>HPL</strong>-<strong>Compact</strong> in post-forming quality from 10 mm radius<br />

Decorative<br />

• Wide design variety with over 200 décors and 3 surface textures<br />

• Available in many décors in the product and colour match range<br />

• High colourfastness<br />

Safe<br />

• In thicknesses 6, 8, 10, 12, 13 and 15 mm optionally available in low-inflammability quality to<br />

DIN 4102/B1<br />

• Moisture-resistant and insensitive to frost and heat<br />

• Resistant to organic solvents<br />

Individual<br />

• Almost unlimited colour <strong>com</strong>binations<br />

Whether indoors or outdoors, <strong>DUROPAL</strong> <strong>HPL</strong>-<strong>Compact</strong> is the ideal covering for tables, cabinets, partition<br />

elements, wall panelling or walls for operating theatres subject to extreme requirements. It can also be<br />

used as impact protection or in vehicle manufacture. Corners and edges are no problem, because one of<br />

the plus points of this <strong>com</strong>pact laminate is its formability and the possibility of producing elements with a<br />

tight radius.<br />

<strong>DUROPAL</strong> <strong>HPL</strong>- <strong>Compact</strong> is also available to several safety standards and creates freedom for personal<br />

design solutions.<br />

070 PI <strong>DUROPAL</strong> <strong>HPL</strong>-Solid - 0902 Page 2 of 7

<strong>PR</strong><strong>ODUCT</strong> <strong>INF</strong>ORMATION<br />

Areas of application<br />

Multi-purpose: Whether in laboratories, hospitals or sanitation areas – <strong>DUROPAL</strong> <strong>HPL</strong>-<strong>Compact</strong> is suitable<br />

in interior design particularly for applications with demanding hygiene standards. High-quality shop-fittings,<br />

kitchen worktops, office furniture, ships’ cabins and railway carriages also have to <strong>com</strong>ply with these high<br />

quality requirements.<br />

At the same time, it must also meet versatile design requirements. <strong>DUROPAL</strong> <strong>HPL</strong>-<strong>Compact</strong> is also ideal<br />

for use in exterior areas, such as maintenance-free roof eaves, children’s play areas, camping sites and<br />

open-air pools not subject to official approval. Here too, high durability, long-term moisture resistance and<br />

attractive colours are all in demand.<br />

Duropal <strong>HPL</strong>-Solid<br />

Product /<br />

quality<br />

Duropal <strong>HPL</strong>-Solid<br />

B2, black core,<br />

post-formable 1)<br />

1) Only the surface layer is post-formable after routing out the core<br />

Product properties<br />

Surface<br />

textures<br />

Sizes in mm Thickness in mm<br />

Length Width 3.0 6.0 8.0 10.0 12.0 13.0 15.0<br />

VV, MP, TR 4,100 1,300 n n n n n n n<br />

Something you can count on: Our <strong>DUROPAL</strong> high-pressure laminates (<strong>HPL</strong>) are durable, versatile in use<br />

and available in many attractive décors. In order to ensure the best possible product use and enduring<br />

aesthetics, please note the chemical, mechanical and physical properties of our <strong>DUROPAL</strong> high-pressure<br />

laminates (<strong>HPL</strong>).<br />

With regard to the <strong>com</strong>bustion characteristics, protection against the emission of formaldehyde and the<br />

surface finishing, there are slight differences between <strong>DUROPAL</strong> <strong>HPL</strong> and <strong>DUROPAL</strong> <strong>HPL</strong>-<strong>Compact</strong>. All<br />

other points apply for both high-pressure laminates.<br />

070 PI <strong>DUROPAL</strong> <strong>HPL</strong>-Solid - 0902 Page 3 of 7

<strong>PR</strong><strong>ODUCT</strong> <strong>INF</strong>ORMATION<br />

Chemical properties<br />

The surface finish of <strong>DUROPAL</strong> <strong>HPL</strong> and <strong>DUROPAL</strong> <strong>HPL</strong>-<strong>Compact</strong> is resistant to contact with most <strong>com</strong>mon<br />

chemicals and substances.<br />

Cleaning agents such as acetone and substances such as vinegar, coffee or blood leave behind no<br />

residues on the surface. Nor will there be any changes to the surface if any of the following example list<br />

of substances are spilt on the surface and only left there for a short time (10–15 minutes).<br />

The panels must therefore be wiped down with a wet cloth and then rubbed dry within 10–15 minutes!<br />

Substance Chemical formula Substance Chemical formula<br />

Formic acid (over 10%) HCOOH<br />

Paints and adhesives<br />

(chemically hardening)<br />

Aminosulphuric acid (up to 10%) NH 2 SO 3 Methylene blue C 16 H 18 N 3 CIS<br />

Anilin dyes Millon’s reagent OHg 2 NH 2 CI<br />

Inorganic acids (up to 10%) Sodium hydrogen sulphate NaHSO4<br />

Arsenic acid (up to 10%) H 3 AsO 4 Sodium hypochloride NaOCI<br />

Boric acid H 3 BO 3 Sodium thiosulphate Na 2 S 2 O 3<br />

Iron (II) chloride solution FeCI 2 Sodium hydroxide (over 10%) NaOH<br />

Iron (III) chloride FeCI 3 Nylander’s reagent<br />

Esbach’s reagent Oxalic acid COOH x COOH<br />

Fuchsine solution C 19 H 19 N 3 O Phosphoric acid (up to 10%) H 3 PO 4<br />

Hair dyes and bleaches Picric acid C 6 H 2 OH(NO 2 ) 3<br />

Iodine solution J Mercury dichromate HgCr 2 O 7<br />

Limescale remover Nitric acid (up to 10%) HNO 3<br />

Potassium hydroxide (over 10%) KOH Hydrochloric acid (up to 10%) HCI<br />

Potassium chromate K 2 CrO 4 Sulphuric acid (up to 10%) H 2 SO 2<br />

Potassium dichromate K 2 Cr 2 O 7 Sulphurous acid (up to 10%) H 2 SO 3<br />

Potassium hydrogen sulphate KHSO 4 Silver nitrate AgNO 3<br />

Potassium iodide KJ Mercury dichloride solution HgCI 2<br />

Potassium permanganate KMnO 4<br />

Gentian violet C 24 H 28 N 3 CI<br />

Hydrogen peroxide (3-30%<br />

perhydrol)<br />

070 PI <strong>DUROPAL</strong> <strong>HPL</strong>-Solid - 0902 Page 4 of 7<br />

H 2 O 2

<strong>PR</strong><strong>ODUCT</strong> <strong>INF</strong>ORMATION<br />

The following chemicals will destroy the surface of <strong>DUROPAL</strong> <strong>HPL</strong> and must therefore be removed immediately,<br />

otherwise the surface will be<strong>com</strong>e dull and rough after only short exposure.<br />

Chemical, in concentrations<br />

greater than approx. 10%<br />

Chemical formula<br />

Chemical, in concentrations<br />

greater than approx. 10%<br />

Chemical formula<br />

Nachfolgend Aminosulphurous beispielhaft acid aufgeführte NH SOChemikalien H führen zur Phosphoric Zerstörung acidder <strong>DUROPAL</strong>-<strong>HPL</strong>-Oberfläche<br />

H PO 2 3 3 4<br />

und müssen unmittelbar entfernt werden. Schon nach kurzer Einwirkungszeit wird die Oberfläche matt<br />

Arsenic acid H AsO Hydrochloric acid HCI<br />

3 4<br />

und rau!<br />

Chrome-sulphuric acid K Cr O + H SO 2 2 7 2 4 Sulphuric acid H SO 2 4<br />

Fluoric acid HF Hydrogen bromide HBr<br />

Aqua regia HNO 3 + HCI = 1 : 3<br />

Changes to the <strong>DUROPAL</strong> <strong>HPL</strong> surface will also occur under frequent exposure to the following aggressive<br />

gases.<br />

Chemical Chemical formula Chemical Chemical formula<br />

Bromine Br 2 Sulphur dioxide SO 2<br />

Chlorine CI 2 Acid vapour<br />

Nitrous vapours N x O Y<br />

Mechanical and physical properties<br />

For information on mechanical and physical properties, see the product information “Mechanical and<br />

physical properties of <strong>DUROPAL</strong> <strong>HPL</strong>”.<br />

Combustion characteristics<br />

<strong>DUROPAL</strong> <strong>HPL</strong> and <strong>DUROPAL</strong> <strong>HPL</strong>-Solid are suitable for preventive fire protection, and in low-inflammability<br />

quality are approved for the manufacture of construction elements to DIN 4102 / B1 – construction<br />

material classes to DIN 4102<br />

The following applies for <strong>DUROPAL</strong> <strong>HPL</strong>:<br />

non-dripping, non-softening construction material classes to DIN 4102<br />

• Post-formable quality: B2 (normally inflammable)<br />

• Low-inflammability quality: B1<br />

• Application in the maritime area IMO Res. A 653(16)B, US Coast Guard ASTM E84 / NFPA 255 (A+C)<br />

070 PI <strong>DUROPAL</strong> <strong>HPL</strong>-Solid - 0902 Page 5 of 7

<strong>PR</strong><strong>ODUCT</strong> <strong>INF</strong>ORMATION<br />

Physiological properties<br />

<strong>DUROPAL</strong> <strong>HPL</strong> and <strong>DUROPAL</strong> <strong>HPL</strong>-Solid are physiologically harmless and suitable for use in rooms in<br />

which foodstuffs are stored, processed and consumed. The property id confirmed by a safety declaration<br />

of the ISEGA-Forschungs- und Untersuchungs-GmbH (tested to DIN EN 1186 and DIN EN 13130).<br />

Protection against emission of formaldehyde from core materials<br />

When <strong>DUROPAL</strong> <strong>HPL</strong> is used in <strong>com</strong>bination with a core material, <strong>DUROPAL</strong> <strong>HPL</strong>, even at very low thicknesses,<br />

provides effective protection against the possible diffusion of formaldehyde out of the core material.<br />

Anti-static characteristics<br />

The specific surface resistance of <strong>DUROPAL</strong> <strong>HPL</strong> under normal environmental conditions lies between<br />

1x10 9 and 1x10 12 Ω (tested to DIN EN 61340). <strong>DUROPAL</strong> <strong>HPL</strong> surfaces therefore do not build up an<br />

electrostatic charge very easily, and do not attract dust..<br />

Quality monitoring<br />

PFLEIDERER guarantees for <strong>DUROPAL</strong> <strong>HPL</strong> the maintenance of the following standards, e.g. with regard to<br />

the product properties:<br />

• EN 438: 2005, ISO 4586 Part 1: 2004, DIN EN ISO 9001: 2000<br />

and the <strong>com</strong>bustion characteristics:<br />

• DIN 4102, AFNOR NFP 92.501, B/S 476 – parts 6.7, Eco-norm B 3800-1<br />

Colours and surface textures<br />

The <strong>com</strong>prehensive selection of colours and surface textures of our <strong>DUROPAL</strong> high-pressure laminates<br />

enables them to be used in a wide range of application areas. We will be happy to advise you in the<br />

choice of the right solution for you.<br />

For further processing, <strong>DUROPAL</strong> <strong>HPL</strong> is sanded lengthwise ready for bonding.<br />

For the rear side of <strong>DUROPAL</strong> <strong>HPL</strong>-Solid, the same specifications apply as for the front side.<br />

Product and colour match<br />

One décor – many possibilities: In the product and colour match range, melamine-faced chipboard<br />

panels, <strong>DUROPAL</strong> high-pressure laminates (<strong>HPL</strong>) and edges can be <strong>com</strong>bined in the same décor –<br />

exactly to your requirements.<br />

070 PI <strong>DUROPAL</strong> <strong>HPL</strong>-Solid - 0902 Page 6 of 7

<strong>PR</strong><strong>ODUCT</strong> <strong>INF</strong>ORMATION<br />

Over- and under-deliveries<br />

Minor faults due to production and raw materials, which do not impair the product quality and are permitted<br />

for 1st-choice materials, are assessed according to sorting regulations (based on EN 438, Part 3,<br />

and the international ISO standard). We also reserve the right to make slight over- or under-deliveries<br />

resulting from production requirements, in accordance with the PFLEIDERER delivery conditions.<br />

Storage<br />

The material should ideally be stored in closed rooms under normal ambient conditions (temperature<br />

18–25 °C, relative air humidity 50–65 %).<br />

The material must always be stored horizontally, with the edges flush, on a level surface, and be covered<br />

with plastic film. The top panel must be <strong>com</strong>pletely covered by a cover board.<br />

Disposal<br />

<strong>DUROPAL</strong> <strong>HPL</strong> and <strong>DUROPAL</strong> <strong>HPL</strong>- <strong>Compact</strong> can be safely burned and incinerated in officially approved<br />

industrial incineration units.<br />

A service of<br />

PFLEIDERER Industrie GmbH • Product Management<br />

Holzstraße 6 - 10 • D-33332 Gütersloh • Telephone: 0 52 41 / 8 71 - 0 • Telefax: 0 52 41 / 8 71 - 9 87<br />

e-mail: produktmanagement@<strong>pfleiderer</strong>.<strong>com</strong> • Internet: www.<strong>industrie</strong>.<strong>pfleiderer</strong>.<strong>com</strong><br />

070 PI <strong>DUROPAL</strong> <strong>HPL</strong>-Solid - 0902 Page 7 of 7