Happy Halloween - Dorr-Oliver Alumni

Happy Halloween - Dorr-Oliver Alumni

Happy Halloween - Dorr-Oliver Alumni

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

VOLUME 7, No.2 "PEOPLE ARE OUR MOST IMPORT ANT ASSET" SEPTEMBER 1980<br />

<strong>Happy</strong> <br />

<strong>Halloween</strong>

TRICK OR TREAT <br />

<strong>Halloween</strong> or all Hallows' Eve, now<br />

mostly celebrated by children in the<br />

United States, was originally a festival<br />

of fire and the dead. It is the evening of<br />

October 31 , the night before the<br />

Christian festival of All Hallows' or All<br />

Saints Day . All Hallows' Day<br />

commemorates the saints and martyrs<br />

and was first introduced in the 7th<br />

century.<br />

Bonfires on high hills were a feature<br />

of old <strong>Halloween</strong> rites. Originally they<br />

were probably meant to provide light<br />

and heat which would help the sun<br />

through the winter.<br />

Ghosts and fairies were supposed to be<br />

seen and witches were supposed to hold<br />

high revel on All Hallows' Eve.<br />

During Queen Victoria's time people<br />

went from house to house wearing<br />

masks and costumes representing<br />

ghosts and goblins that lurked in the<br />

night. Food offerings were put out for<br />

the ghosts. The masks are now worn by<br />

children who visit neighbors for the food<br />

offerings which once belonged to the<br />

ghosts or to play the tricks which<br />

witches were supposed to have done on<br />

this night.<br />

The belief in witches is universal with<br />

striking similarities in beliefs found in<br />

different societies. Witches are believed<br />

to possess supernatural powers that<br />

enable them to cast spells causing havoc<br />

and destruction. Witches are often<br />

accused of appearing in spectral form to<br />

haunt their victims. During the Salem<br />

Witch Trials in 1692 a witness claimed<br />

to see spectral images of the accused<br />

right in the courtroom. An accusation of<br />

witchcraft was all that was necessary to<br />

convict the accused.<br />

Witches are believed to travel at night<br />

by flying through the air on<br />

broomsticks. Although most of us think<br />

of witches as women actual studies show<br />

that men comprise a higher proportion<br />

of those accused.<br />

Haunts are ghosts that walk the same<br />

place at the same time, as regularly as<br />

clockwork. Some ghosts appear in<br />

costumes of their own period and others<br />

appear wearing sheets. There are ghost<br />

legends in which animals are prevalent.<br />

They are also tales of ghostly inanimate<br />

objects such as The Flying Dutchman<br />

and the French ship La Belle Rosalie.<br />

Appearances of blood stains are a<br />

form of ghost as are the ghostly lights<br />

that appear instead of visual<br />

apparitions. The Poltergeists, meaning<br />

noisy spirit, tosses objects around and is<br />

considered a mischievious ghost.<br />

The last category of ghosts is the eerie<br />

feelings, such as sensations of cold that<br />

have been experienced by some<br />

observers.<br />

Along with the traditional stories and<br />

objects of <strong>Halloween</strong> there is a new one.<br />

The one of the "Great Pumpkin",<br />

faithfully waited for each year by Linus<br />

and Sally as they spend the night in the<br />

pumpkin patch.<br />

Ghosts and witches are the first<br />

images to come to mind when we think<br />

of <strong>Halloween</strong>. Volumes of literature<br />

have been written and many studies<br />

made on both these subjects.<br />

There are several forms of ghosts.<br />

Some apparitions are able to<br />

materialize and appear in visual forms;<br />

some giving the appearance of solidity.<br />

Many attempts have been made to<br />

photograph ghosts but they are<br />

notoriously camera shy.<br />

A <strong>Dorr</strong>-<strong>Oliver</strong> employee ready for<br />

"Trick or Treat".<br />

Page 2

Cooky's Corner<br />

Being able to cut down on meal<br />

preparation time and still provide a<br />

good meal is a challenge to working<br />

cooks. Thanks to the technology of<br />

Microwave Ovens, valuable time<br />

becomes available for other tasks.<br />

Microwave Ovens don't cook by filling<br />

up with heat like conventional ovens.<br />

Microwaves enter food and cause the<br />

moisture or liquid to vibrate. The<br />

friction of vibrating molecules causes<br />

the food to heat. Besides the time saving,<br />

microwave cooking costs about 1/2 of<br />

conventional cooking.<br />

Using the right cookware and<br />

following recipe instructions for<br />

cooking time guarantees a good, tasty<br />

meal with time left for other interests.<br />

Here are two of my favorite and often<br />

used recipes.<br />

QUICK GLAZED<br />

SWEET POTATOES<br />

1/4 cup packed brown sugar<br />

1 tablespoon orange flavored breakfast<br />

powder drink<br />

2 teaspoons cornstarch<br />

1/2 cup cold water<br />

3 tablespoons butter or margarine<br />

1 - 18 oz. can vaeuum packed sweet<br />

potatoes (or use fresh - cook first)<br />

In lY2 quart casserole combine brown<br />

sugar, orange drink, cornstarch and<br />

water. Cook uncovered on full power for<br />

2 minutes till mixture thickens and<br />

bubbles, stirring after each minute. Stir<br />

in butter. Add potatoes, stirring to coat<br />

with mixture. Cook, uncovered, on full<br />

power for 4 minutes or till heated<br />

through, turning each potato over once.<br />

Total cooking time 6 minutes. Recipe<br />

yields -1 servings.<br />

SWEET AND SOUR PORK<br />

lY2 lb. lean pork shoulder<br />

cut in 2" x W' strips<br />

1/2 cup water<br />

1 can (1 lb. 4 oz.) pineapple chunks<br />

1/3 cup brown sugar<br />

2 tablespoons cornstarch<br />

1/4 cup vinegar<br />

2Y2 tablespoons soy sauce<br />

1/2 teaspoon salt<br />

1 small green pepper, cut in strips<br />

1/4 cup thinly sliced onion<br />

Cook pork until brown about 10-12<br />

minutes on full power, stirring<br />

occasionally. Add 1/2 cup water. Cover.<br />

Cook on "simmer" for 20 minutes or<br />

until tender, stirring every 5 minutes.<br />

Drain pineapple, reserving syrup.<br />

Combine sugar and cornstarch; add<br />

pineapple syrup, vinegar, soy sauce, and<br />

salt. Add liquid mixture to pork. On full<br />

power cook for 10 minutes or until gravy<br />

thickens, stirring occasionally. Add<br />

green pepper, pineapple and onion<br />

slices. Cook on full power 3 to 4 minutes<br />

or until thoroughly hot. Serve over rice.<br />

Total cooking time - 45 minutes. Recipe<br />

yields 7 servings.<br />

<strong>Halloween</strong> <br />

Safety Tips <br />

1. Have children wear reflective<br />

costumes.<br />

2. Caution children to go only to houses<br />

where they know the people living<br />

there.<br />

3. Tell children to bring all treats home<br />

before eating any.<br />

This gives you a chance to check the<br />

type of treats.<br />

4. Small children should be accompanied<br />

by an adult.<br />

5. Masks can be dangerous, limiting<br />

your childs vision. Try using the<br />

make up available instead.<br />

Household Hints<br />

When purchasing beef, remember<br />

that it takes 1/4 to 1/2 pound of boneless<br />

meat for each serving. Allow about 1/2<br />

pound for bone-in meat.<br />

You can sometimes touch up a scratch<br />

on wood furniture with mascara of the<br />

right shade.<br />

The strong aroma of an onion is stored<br />

in its roots. To avoid tears, never peel<br />

one from the bottom.<br />

To send plant cuttings through the<br />

mail, slip ends in a dampened sponge,<br />

place all in a plastic bag and tie securely<br />

at the top. Box in a stong cardboard box<br />

and they will arrive safely and alive at<br />

their destination.<br />

~IAnnOUnCfmmrr I<br />

OCTOBER 7 & 14 - Stamford Engineering<br />

employees visit to Hazleton<br />

plant.<br />

OCTOBER 10 - United Way Drive.<br />

OCTOBER 17 - President Dan<br />

Gillespie visits Hazleton plant.<br />

DECEMBER 20 - Christmas Party at<br />

Mother of Grace Hall. Music by the<br />

Modern Chords.<br />

Page H

The Design<br />

Engineer<br />

Service Pin Dinner<br />

John Vecolitis and Rich Neithamer<br />

say THEY would never do this!<br />

The designer sat at his drafting board.<br />

A wealth of knowledge in his head was<br />

stored.<br />

Like what can be done on a radial drill<br />

A turret lathe or a vertical mill.<br />

But above all things a knack he had<br />

Of driving gentle machinists completely<br />

mad.<br />

So, he mused as he thoughtfully<br />

scratched his bean<br />

Just how can I make this thing hard to<br />

machine?<br />

If I make this body perfectly straight<br />

The job ought to come out first rate.<br />

But t'would be so easy to machine and<br />

bore<br />

That it would never make a machinist<br />

sore. <br />

So I'll put a compound angle there <br />

And a couple of tapers to make them <br />

swear<br />

Now BRASS would do for this little<br />

gear,<br />

But it's too easy to machine I fear,<br />

So just to make a machinists squeal<br />

I'll have him machine it from tunsten<br />

steel.<br />

And I'll put the holes that hold the cap<br />

Down underneath, where they can't be<br />

tapped.<br />

Now if they make THIS it will be just<br />

luck<br />

Because it can't be held with a dog or<br />

chuck,<br />

And it can't be drilled, planed nor<br />

ground<br />

So I think my design is unusually sound.<br />

He sat back, his plan he surveyed,<br />

The SCREWIEST thing he had ever<br />

made.<br />

He shouted in glee, success at last<br />

This cockeyed thing CAN'T EVEN BE<br />

CAST!<br />

Page 4<br />

On Friday, September 5, 125 persons<br />

attended a Service Pin Dinner given in<br />

honor of 76 <strong>Dorr</strong>-<strong>Oliver</strong> employees who<br />

have reached milestones in their service<br />

to the company.<br />

The invocation was given by Tom<br />

Toth.<br />

Following the dinner Pat Neligan,<br />

Manager of Industrial Relations,<br />

introduced the speakers. Congratulations<br />

to the pin recipients were offered<br />

by Eugene Kokinda, Plant Manager;<br />

Judy Griesing, President of OPEIU,<br />

Local 202; Marty Corbett, Business<br />

ManagerofIAM:Jim Hiza, Presidentof<br />

Local 1648, lAM; Harold Miller,<br />

Controller, U.S. Region; Bob Ciociola,<br />

Manager of Data Processing Operations<br />

and Don <strong>Oliver</strong>, Corporate Director of<br />

Personnel.<br />

The gUest speaker was Ben Kish, a<br />

former NFL football star who played<br />

for the Philadelphia Eagles. Mr. Kish<br />

entertained the gathering with stories<br />

about football stars and coaches that he<br />

has known during his career. After his<br />

speech he answered questions from the<br />

audience about football. Everyone<br />

enjoyed his talk immensely.<br />

The presentation of pins was made by<br />

Pat Neligan, Don <strong>Oliver</strong> and Gene<br />

Kokinda with assistance from Mary<br />

Romano and Rose Trego.<br />

**** <br />

Special "gifts" were presented to the<br />

recipients of the 40 Year pins. Francis<br />

Brislin received a coin changer to wear<br />

on his belt so his pockets don't wear out<br />

and Fred Dute was presented with a 40<br />

pound . bag of fertilizer to help his<br />

garden grow.<br />

The following employees received<br />

service pins: 40 Years of Service- F.<br />

Brislin. F. Dute. 35 Years of Service<br />

E. Cancerius, F . Fellin, P. Holic, J .<br />

Kulsa, N. Pawlowski, M. Williams. 30<br />

Years of Service-J. Egger, J. Fox, C.<br />

Funk, T. Hollick, G. Koch, J . Lutsky, F.<br />

Massage, P. Moisey, A. Morrell, K.<br />

Radley, M. Rusnock, J . Rutecki, N.<br />

Secunda, P. Stasukonis, E. Vack, C.<br />

Yuhas, J . Yurcho. 20 Years of Service<br />

J . Braskey, N. Dziak, G. Esa, E.<br />

Fedorshak, T. Fidishun, W. Floating, J.<br />

Grace, E. Harris, D. Hoegg, W. Jones, R.<br />

Kisenwether, J . Klinger, S. Kogoy, R.<br />

Kolhush. G. Korba, E. Lally, J. Lettiere,<br />

M. Lopocinski, M. Moser, G. Oakes, J .<br />

Orlik, J . Quinn, J . Rayno, J . Redash, J.<br />

Richenderfer, J. Rooney, A. Rouse, S.<br />

Sabrowsky, M. Simchock, C. Schaeffer,<br />

J . Schrum, R. Stank, J. Valagene. P.<br />

Wandishin, P. Wanuga, J . Williams, K.<br />

Witanek. 15 Years of Service- R.<br />

Stanek. 10 Years of Service- F.<br />

Amorose, R. Corrado, E. Madochick, D.<br />

Milheim, J. Pil\us, A. Rodriquez, C.<br />

Sanko, T. Schiefer, M. Thaler.<br />

****

SERVICE PIN DINNER <br />

Plant Manager Gene Kokinda with 40 year pin<br />

recipients Francis Brislin and Fred Dute.<br />

Recipient of 30 year pins Elwood Arnold, Mary<br />

Stanziola and Mike Portonova with Gene Kokinda.<br />

Fred Dute with aHttle something for the garden.<br />

Francis Brislin ready to make change.<br />

Page 5

SEEK-A-WORD <br />

The follow ing words pertaining to fall<br />

and <strong>Halloween</strong> can be found in the<br />

puzzle.<br />

APPLES<br />

AUTUMN<br />

BLACK CAT<br />

BROOMSTICK<br />

CAULDRON<br />

CEMETERY<br />

CORN STALKS<br />

COSTUME<br />

DOUGHNUTS<br />

FOOTBALL<br />

GHOSTS<br />

GOBLINS<br />

HALLOWEEN<br />

HAUNTED HOUSE<br />

HOMECOMING<br />

INDIAN CORN<br />

LEAVES<br />

MAGIC<br />

MASKS<br />

PUMPKINS<br />

SCARECROW<br />

SPOOKS<br />

TREATS<br />

WITCHES<br />

weD X Y PAL V E 0 A B R S Q E S UO HOE T N U A H E<br />

E B LAC K CAT RIP 0 F F 0 F YOU 0 B LIP S RAe<br />

A 0 A 0 REM U T S OC R 0 R C E R Y N M C H 0 S E S W H<br />

T 0 J P I V M R 0 L N J U N K HAL L S E MAR 0 Y J 0 0<br />

H E L U P U E E 0 H S T S 0 R REG E MeN N E RUN A R<br />

R U 0 M Y L C H T R I S WIT I N H rEO F ALe LIN C<br />

E F OP N W E R H E E MI S E A COR B M L L P E Q Y A 0<br />

Y 0 L K R [ E SAN R A S 0 J T eRA RIO L H R N U E R<br />

L S RI GAL E L S F Y P A I L BAN 0 N V A U Y L RAN<br />

PU S N TEA R HAL LOW E E N Z N 0 G E B V 0 U 0 Y S<br />

S HI S TOT GIN G E 0 C W X Y Z Y MAY T R B J 0 R T<br />

CA S E Y REA 0 K H R K J ODE Y G S E 0 0 S T H N A A<br />

DOW E E 0 W N S B H R S T S OH GET B NOW AND M L<br />

o 0 K S NOW M A A L G Z ARC A N H I F U F THE N I K<br />

G H 0 A S T P U M P K I Y 0 I L U L 0 C A U LOT H IN S<br />

A P P L eRA T I J I L NOT E 0 L J K A L K 0 F YOU A<br />

U A elL 0 0 UGH NUT S N G I V E M E Y H EAR T G 0<br />

TUG 0 B N I A 0 W K E E M N I N 0 I A NCO R N BUM P<br />

U A S P R I N G J U 0 L Y REG N S V I GOG U T S AN 0<br />

MA S K S B Y M Y WI N DOW N l E N N U R CUT E WA S<br />

T HE F ALL I N G S NOW 0 R se A R E C ROW i F T S<br />

<strong>Dorr</strong>-<strong>Oliver</strong> Sports Quiz <br />

l. In what year was the Heisman<br />

Trophy awarded for the first time?<br />

2. Name three members of the 1960<br />

<strong>Dorr</strong>-<strong>Oliver</strong> City Ind ustrial<br />

Softball champs. still working at<br />

<strong>Dorr</strong>-<strong>Oliver</strong> Inc.<br />

3. Which great Quarterback holds the<br />

career TD record in the NFL?<br />

1. John Unitas<br />

2. George Blanda<br />

3. Fran Tarkenton<br />

4. How far is the pitchers rubber from<br />

home plate?<br />

1. 55'-5"<br />

2. 60'-6"<br />

3. 70'-5"<br />

5. Who was the winner of the 1977<br />

Fiesta Bowl?<br />

l. Pittsburgh<br />

2. Penn State<br />

3. Arizona State<br />

6. Which player holds the New York<br />

Met's record for hitting the most<br />

home runs in a season?<br />

l. Willie Mays<br />

2. Cleon Jones<br />

3. Dave Kingman<br />

7. Which NFL team holds the record<br />

for scoring the most points in a<br />

single game?<br />

1. Dallas Cowboys<br />

2. Washington Redskins <br />

~. Detriot Lions <br />

8. What do baseball players call the<br />

hand on which they don't wear a<br />

glove.<br />

9. Who was the first tight end to lead<br />

the National Football Conference in<br />

receiving?<br />

l. Charlie Sanders<br />

2. Bob Tucker<br />

3. Mike Ditka<br />

lO. Which slugger belted more home<br />

runs in World Series play?<br />

l. Babe Ruth<br />

2. Mickey Mantle<br />

3. Reggie Jackson<br />

Answer on page 16<br />

Page 6

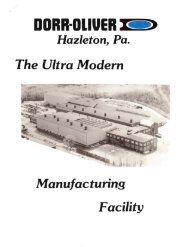

1980 PLANT EXPANSION <br />

History will be made at <strong>Dorr</strong>-<strong>Oliver</strong><br />

Hazleton in the 80's. We have started<br />

early with the announcement of the<br />

expansion of our high bay assem bly area<br />

and the Centrifugal assembly area.<br />

With an exception of a small area<br />

added to our machine shop in the mid<br />

1970's, the planned addition is the first<br />

major expansion of the facility in twenty<br />

years. The two-million dollar plus<br />

expansion will include a 16,000 sq. ft.<br />

addition with a high bay plus a major<br />

reorganization of the bay that includes<br />

fabrication as well as assembly of<br />

filtration equipment.<br />

To many people it seems like forever<br />

since this project started. In reality it<br />

has been just over a year. Itstarted as a<br />

concept on a piece of mylar in Mike<br />

Pasquarello's office. It developed into a<br />

reality through the efforts, knowledge<br />

and imagination of many people.<br />

Many will recall the meetings that<br />

went into the planning of this expansion.<br />

A large floor plan was placed on a wall<br />

in the office area. Shop personnel were<br />

invited to study the plan. Meetings were<br />

then held between management and<br />

these shop personnel to collectively<br />

arrive at a plan which would best serve<br />

the objectives of this planned expansion.<br />

The input of the shop people, the people<br />

with first hand knowledge of some ofthe<br />

problems we have faced, was a valuable<br />

dimension in the final plan which was<br />

developed.<br />

Over the past five years the machine<br />

shop has developed into a modern, well<br />

equipped, productive shop. Everyone<br />

who works in the shop and those who<br />

have had an opportunity to visit the<br />

shop, have marveled at the new modern<br />

tools. Two of the most modern computer<br />

numberically controlled boring Mills<br />

have been producing parts which<br />

previously we did not have the<br />

capability to produce. A computer<br />

numerically controlled turning center<br />

coupled with a CNC grinding machine<br />

have revolutionized the machining of<br />

shafts in our shop. In this same issue of<br />

DoTell are the details of the new<br />

Cincinnati Milacron Universal Chucker<br />

which joins the growing list of modern<br />

machine tools.<br />

This new expansion allows us to do<br />

some of this modernization in the<br />

fabrication area. Three major machines<br />

which will hetp to modernize the<br />

fabrication area are the Thermal<br />

Machining Center, the Longitudinal<br />

Seamer and the Traveling Head Roll<br />

Planisher. The Thermal Machining<br />

Center will allow us to plasma burn<br />

sheet and plate stock accurately in two<br />

dimensions from a program. The<br />

Longitudinal Seam Welder will<br />

automatically weld an entire seam. The<br />

Traveling Head Roll Planisher will<br />

flatten the weld seam and form the<br />

cylindrical joint. Prior to the acquisition<br />

of this equipment this work was mainly<br />

manual in nature, costly in time and of a<br />

lesser quality that can be expected from<br />

this new equipment.<br />

Of major importance in the planning<br />

of the project has been the opportunity<br />

to improve our material handling. With<br />

this new concept in the manufacture of<br />

our filtration product line the material<br />

will flow through our shop in an orderly<br />

fashion. This will eliminate the hazards<br />

of repetitive handling and in turn<br />

reduce the risk of exposure to accidents.<br />

The orderly flow of material will<br />

improve production and also quality. A<br />

review of the layout will show the flow of<br />

material that has been planned with this<br />

expansion. Raw material flows into the<br />

north end of the shop. As it flows<br />

through the shop it is cut, formed,<br />

welded, assembled and machined as<br />

required. As the material progresses<br />

through the shop the skill of the <strong>Dorr</strong><br />

<strong>Oliver</strong> Hazleton employees along with<br />

modern equipment transforms it into<br />

some of the finest filtration equipment<br />

in the world. At the south end of the<br />

huge bay the product is shipped.<br />

The filtration product line is a<br />

highly competitive field and plant<br />

manager, Gene Kokinda states "the<br />

project is designed to improve<br />

productivity to increase the<br />

companys' competitiveness."<br />

In addition to the filtration bay two<br />

other major areas will be improved,<br />

the centrifugal assembly area and<br />

paint spray operations.<br />

With the advent of the H-36<br />

MercoBowl, the advances in the<br />

centrifugal area, and the changing<br />

needs in the market place, this line of<br />

business has grown tremendously. This<br />

means that additional assembly and<br />

testing area is required to meet this<br />

marketing demand. The ability of the<br />

new machine tools to produce quality<br />

centrifugal parts and the expansion and<br />

reorganization of the centrifugal<br />

assembly area will enable us to<br />

maintain our top position in this market<br />

place.<br />

Along with all of our production and<br />

quality requirements major improvements<br />

will be made in another<br />

dimension of doing business and that is<br />

safety. Safety, Production and Quality<br />

are inseparable in the success of any<br />

business. Some specific areas where<br />

safety will be enchanced are:<br />

Page 7

Material handling-less handling<br />

will be required and the fewer times a<br />

part is handled the less chance there is<br />

for an accident. In addition and directly<br />

related to material handling is<br />

additional space. This was desperately<br />

needed to safely improve our material<br />

handling. The equipment we use to<br />

handle material will also be considered<br />

in this project.<br />

Of major importance in material ·<br />

handling will be the installation of a<br />

twenty ton crane. The size and weight of<br />

filtration equipment has increased<br />

dramatically in recent years. The<br />

twenty ton crane in use with the existing<br />

thirty ton crane will meet the needs to<br />

handle this equipment safely.<br />

Housekeeping-Overall housekeeping<br />

will be improved. Planning welding<br />

outlets, electrical outlets, air<br />

connections, etc. will enable us to keep<br />

the aisles clear.<br />

Floor drains in areas where normally<br />

wet operations take place will help to<br />

reduce hazards in this area.<br />

In the expansion of the centrifugal<br />

test operations, safety will be a major<br />

consideration. Underground tanks,<br />

location of drains and electrical<br />

equipment have all been planned into<br />

this operation.<br />

Of prime importance is the<br />

installation of a new paintspray facility.<br />

This will replace the antiquated spray<br />

booth which is now in use. Thts has been<br />

a pressing need for several years.<br />

Plant Manager Kokinda summed up<br />

the·news of the expansion in perspective<br />

to Hazleton, Hazleton Manufacturing<br />

and the corporation stating:<br />

"It's been a matter of community and<br />

personal pride that <strong>Dorr</strong>-<strong>Oliver</strong><br />

Hazleton has been in this same location<br />

for over 60 years and continues to grow."<br />

"This years planned growth is the<br />

result of marketable products, a<br />

reputation for service and quality.<br />

reliable production, a cooperative staff,<br />

and the manufacturing experience of<br />

the <strong>Dorr</strong>-<strong>Oliver</strong> Hazleton employees."<br />

"This diverse team of employees<br />

represen ts a com bination of<br />

mangement, supervision, skilled<br />

machinists. welders and assemblers,<br />

support personnel, and a skilled office<br />

force."<br />

"The history of the plant has been one<br />

of continued growth in capacity and<br />

importance to its worldwide<br />

organization and to the eommunity<br />

itself."<br />

Page 8<br />

History ofthe <br />

Hazleton Plant <br />

This is a picture of the plant as it appeared in 1948. Notice that the bay that<br />

connects the assembly shop to the machine shop is missing. The high bay at the<br />

back of the assembly shop and the fabrication bay do not exist and the merco<br />

shop and storage have not yet been built. Also note that one wing ofthe office is<br />

not yet built.<br />

This picture was taken in 1,957 showing the fabrication bay just after<br />

completion.

The Hazleton Plant as it appears today.<br />

History reveals that Ernest J. Sweetland, an inventor<br />

whose career parallelled that of E. L. <strong>Oliver</strong> and Dr. <strong>Dorr</strong>,<br />

played the major role in the company's early development in<br />

Hazleton. The inventor of the Sweetland Filter and a pioneer<br />

in industrial filtration, he became president of the United<br />

Filter Corporation, a company formed from the American<br />

and Kelly Filter Companies and the Sweetland Filter Press<br />

Company. This company had its beginning in 1907.<br />

In 1919 Sweetland looked for a plantsite. He found aplant<br />

in Hazleton with a foundry, office & machine shop. It was<br />

situated on thirteen acres of land, most of it wooded. He<br />

purchased the site, that of the present plant-and moved in.<br />

Almost immediately, plans were made for expanding the<br />

30,000 sq. ft. facilities and by the endof 1920, additions were<br />

completed bringing the total to 53,000 sq. ft. The company's<br />

products, the Sweetland Pressure Filter, American Disc<br />

Filter and Plate and Frame Presser found welcome<br />

markets, principally in the sugar producing industry and<br />

the metallurgical fields.<br />

In 1923, the manufacture of Kelly Filter was added at the<br />

plant and the period from 1920 to 1928 was marked with<br />

sizable growth for both the company and the plant itself. A<br />

pattern shop and storage building was completed in 1925<br />

and the following year a north wing was added to the office<br />

building.<br />

Then in 1928, a second era in the history of the plant<br />

began. This is the year that the United Filter Corp. and the<br />

<strong>Oliver</strong> Continuous Filter Corp. merged to form the <strong>Oliver</strong><br />

United Filters, Inc. The merger increased the combined<br />

operations line of products measurably. The staff in<br />

Hazleton increased and in 1929, an expansion of the facility,<br />

which included a fabricating shop and a laboratory, was<br />

completed. Many filters of <strong>Oliver</strong> origin began to appear on<br />

the assembly floor and in 1937 the original foundry building<br />

was converted to an assembly shop to accommodate the<br />

widened line of products manufactured. The outbreak of<br />

World War II brought United States industry to a hectic<br />

pace. In 1942, alongside bay was added to the assembly shop<br />

to provide for expanding production. Notable during this<br />

period was the production of <strong>Oliver</strong> Synrub Filters built for<br />

the government for their synthetic rubber program. This<br />

was an important contribution to the company's war-time<br />

effort. The important post-war expansion of the Hazleton<br />

facility took place in 1947 when the capacity of the<br />

fabricating shop was doubled and a sizable addition to the<br />

assembly shop was completed.<br />

January I, 1955 was the beginning of the third and most<br />

important period in the history of the plant. This marked the<br />

merging of the <strong>Dorr</strong> Company and <strong>Oliver</strong> United Filters,<br />

Inc. to form <strong>Dorr</strong>-<strong>Oliver</strong>, Inc. An unprecedented increase of<br />

equipment orders quickly filled the plant facility and<br />

sharply raised the number of employees. By 1956, volumes of<br />

orders entered by the company became too great for its<br />

production capacity and it was decided to undertake an<br />

expansion of the Hazleotn plant. Fabricating shop space was<br />

again doubled and the service departments gained much<br />

needed additional floor space. This capacity increase,<br />

sizable as it was, was not enough to balance production with<br />

sales and in late 1956, a second capacity increase was<br />

announced. Under this program, assembly shop space was<br />

enlarged to twice its 1947 proportions while the service<br />

shops again received increased space. Much new equipment<br />

was installed and offices were completely renovated and<br />

enlarged.<br />

Additional phases of this expansion were increased in<br />

outside storage area and material handling facilities and the<br />

purchase of an unoccupied lot adjacent to the plant site and<br />

its conversion into an improved parking area for employees<br />

to supplement the overcrowded existing lot.<br />

While <strong>Dorr</strong>-<strong>Oliver</strong> was experiencing this unprecedented<br />

growth, the Hazleton area was going through some of its<br />

most trying times. There was a drastic decrease in coal<br />

mining operations and related employment. <strong>Dorr</strong>-<strong>Oliver</strong><br />

emerged as a major industrial leader, providing stable<br />

employment while unemployment ran rampant throughout<br />

the area. The firm played an important role in the industrial<br />

rebuilding of the area in conjunction with Can-Do,<br />

Hazleton's industrial development organization. <strong>Dorr</strong><br />

<strong>Oliver</strong> management and its employees actively supported a<br />

Can-Do drive for funds to acquire property for industrial use<br />

and the construction of shells to attract industrial prospects.<br />

In 1960, another expansion was completed at the Hazleton<br />

plant which brought the size of the plant to in excess of<br />

222,000 sq. ft. In 1961 the centrifugal line of business was<br />

transferred from the company's facility in Oakland,<br />

California to Hazleton. In 1963, another major equipment<br />

line, sedimentation, was transferred to Hazleton. This line of<br />

equipment had been manufactured in the company's<br />

operation in Denver, Colorado. The last decade and more<br />

importantly the last five years has seen millions of dollars in<br />

new machine tools being installed in the hazleton plant.<br />

These new machine tools have enabled the Hazleton facility<br />

to increase production, reduce costs, and reduce lead time<br />

required to ship products to the customer.<br />

Looking back, the history of the plant has been one of<br />

continued growth in capacity and importance to its worldwide<br />

organization and to the community itself. In 1919, 50<br />

employees managed a small foundry and shop. In the mid<br />

1950's the employment grew to 250 people and today it is just<br />

under 500 capable, skilled personnel.<br />

Page 9

Battery<br />

Storage<br />

~<br />

,<br />

Plate Storage<br />

Area,<br />

Hand<br />

Burn<br />

Area<br />

CNC Gantry<br />

Burning Machine<br />

Steel Storsge Racks<br />

i5<br />

0<br />

0<br />

I<br />

0<br />

~ I<br />

0<br />

0<br />

0 Plate Storage<br />

I Area --"<br />

0 f<br />

Deburr <br />

Area <br />

:I :I<br />

Pipe Cut-Off 0<br />

Machine<br />

Layout<br />

Table<br />

l'<br />

::I<br />

11163 Band Saw ':,.-------.<br />

~<br />

Pipe

Longitudinal<br />

Weld Sea mer<br />

Drum Lathe #89<br />

Weld<br />

Platen<br />

Weld<br />

Platen<br />

Weld Platen<br />

J::!ll ~29 p"" S""<br />

oooe<br />

Weld<br />

Weld<br />

11203 Plate Rolls<br />

". Sh.., Platen Platen<br />

Trap Pipe Weld<br />

, Drum Sheils,<br />

Drum Shell Leveling Platform<br />

:I :r :r ,I' "'~I, f<br />

lder Weld Weld<br />

>Sed Pipe PunCh to Platen Platen<br />

ope MaChIne<br />

IRound Pice Tesll<br />

Round Pipe<br />

Storage<br />

Trap Pipe<br />

Test<br />

~<br />

Pipe Storage<br />

Weld<br />

Platen<br />

Weld<br />

Platen<br />

1120 Shear<br />

Welding Area<br />

i1<br />

1117 PunCh '-__"_<br />

DSM & Assy.<br />

c:Jt:==l<br />

LlOTabie ~<br />

Roll<br />

#33 Brake<br />

Assembly Area<br />

Bead Blast<br />

Area

1t206 Positioner<br />

EJ<br />

Filtration Shop<br />

I<br />

I<br />

I<br />

I<br />

I<br />

L_<br />

Water Test<br />

& Wash Area<br />

.><<br />

o Drum Lathe 1182<br />

in<br />

"0<br />

to<br />

(I)<br />

I<br />

A.rea<br />

Final Assy.<br />

Area<br />

--<br />

Positioner<br />

~ Drum Assembly ~ I<br />

.~. ,.,,..,h )J :r<br />

r----------l llr---- lOr'<br />

Vending<br />

I<br />

I Ladder & Staging I I i Supervisor Office<br />

I Storage !<br />

.l__________ I <br />

J<br />

D<br />

I<br />

Quality Control<br />

Balancing Area I I('office<br />

-~ • I<br />

:r :I<br />

I<br />

I<br />

j<br />

Merco Assembly <br />

Area <br />

Merco Shop<br />

: ---'? 1750 Gal. Capacity<br />

Machine Area -<br />

Replaces Existing Assy.<br />

Shop Area<br />

Resl Rooms - Replaces Existing ""' <br />

Assy. Mezz. Area<br />

Underground Water Tank<br />

~========' --8~ 8~~~6:8<br />

Star Delta Starter Panels<br />

/' ~<br />

O.H. Door<br />

H<br />

, ,<br />

:r c _<br />

1--<br />

Plan View<br />

Filtration Fabric~<br />

and<br />

Assembly Ba~

Covered <br />

Loading <br />

Dock <br />

J<br />

Dock / j-<br />

Leveler<br />

o . .J .t:lc>oA 1------t::::I<br />

lD··.... ,.·...~<br />

Fork Lift Truck Ramp<br />

B~ Floor<br />

Portable Shipping Scale<br />

Scale<br />

o<br />

I<br />

c:i<br />

~ Table Saw 11487<br />

rr=rr1J[trdi.<br />

Radial Arn Saw 11485 <br />

Dust Collector 11495 <br />

H • I ~. :~t 0 I I :I<br />

Paint Storage & <br />

Lubrication Storage <br />

M<br />

-H<br />

O.H. Door<br />

Equipment<br />

- -- - --' ID<br />

--- - - - --=c:>=<br />

Access<br />

'<br />

Ltion<br />

T

Modern Machine Tools <br />

Shown below in our plant, are several of the most the progress that has b~en made in our machining<br />

modern machine tools marketed today. They indicate capabilities in the past 3 years.<br />

48" Giddings & Lewis Computer Numberically Controlled<br />

Boring Mill - Inset - RC <strong>Dorr</strong>clone part being machined.<br />

Above-Warner & Swasey Stepmaster Numerically Controlled<br />

Grinder. Below-Cincinnati Milacron Computer Numerically<br />

Controlled Chucker.<br />

60" Giddings & Lewis Computer<br />

Numerically Contolled Boring Mill.<br />

Page 10

Management Reaction to Improvement Program <br />

We asked the managers for their<br />

reaction to the Hazleton Plant<br />

Improvement Program. Here is their<br />

reply.<br />

The expansion of the<br />

Hazleton plant reflects<br />

the recognition by our<br />

Corporate Management<br />

of the viability of <strong>Dorr</strong><br />

<strong>Oliver</strong> Hazleton as the<br />

major manufacturing<br />

arm of our Domestic<br />

Operations. This decision tells me that<br />

the work force at Hazleton has been<br />

given a high merit rating by our<br />

management staff and they are telling<br />

us that this investment will generate a<br />

work environment that will be<br />

competitive. lasting and personally<br />

rewarding.<br />

From a purely financial perspective.<br />

we are anticipating that our plant<br />

expansion will provide us with a cost<br />

effective method of margin<br />

identification by product line. This<br />

should enable us to effectively stress our<br />

more profitable areas and hereby gain<br />

an advantage in a very competitive<br />

market place. This should ultimately<br />

provide <strong>Dorr</strong>-<strong>Oliver</strong> Hazleton with a<br />

real (i.e. not just inflation) increase in<br />

total shipments and gross margin.<br />

In summary. the Hazleton plant<br />

expansion is an expression of optimism<br />

by all concerned., and that fairly well<br />

"sums up" my reaction to our expansion<br />

program.<br />

AHan Cope. Assistant Division<br />

ControHer.<br />

I am pleased that our<br />

management has shown<br />

continued confidence in<br />

the Hazleton operation<br />

by approving this<br />

expansion. As a result of<br />

the expansion I expect<br />

to see Hazleton produce<br />

more filters. faster. more economically<br />

and of improved quality due to the<br />

better control and flow of material in the<br />

shop plus the more centralized<br />

responsibility for the fabrication.<br />

welding and assembly operations.<br />

John Tough, Manager of Quality<br />

Control.<br />

Our departments<br />

activities on the Plant<br />

Expansion Project<br />

began many months ago<br />

when the initial feasibility<br />

of the project was<br />

first discussed. Since an<br />

expansion of a manufacturing<br />

facility must be based on a<br />

sound business decision. it was<br />

necessary for us to gather the data from<br />

various sources and then convey to<br />

Corporate Management what<br />

production advantages would be gained<br />

by expanding the Hazleton manufacturing<br />

facility.<br />

Presently we are probably<br />

approaching the height of our planning<br />

activities. Without a doubt. everyone in<br />

the department has and will have<br />

varying degrees of input and<br />

responsibility toward the project.<br />

I personally am excited about our<br />

contribution to date as well as in the<br />

months to come when all of the physical<br />

improvements will begin to take place. I<br />

know that this expansion will provide<br />

the Hazleton facility with a great<br />

opportunity to be productive and<br />

progressive in the future.<br />

George Hardish. Manager of<br />

Manufacturing Engineering.<br />

We are blessed with a<br />

unique situation concerning<br />

the approval of<br />

the Hazleton Plant<br />

Improvement Program.<br />

By expanding in the<br />

Filter bay we are able to<br />

re-Iay out the fabrication<br />

and assembly of <strong>Dorr</strong>-<strong>Oliver</strong> filters.<br />

It's not often that an older established<br />

manufacturing facility is afforded the<br />

opportunity to expand in a logical<br />

means. utilizing the expertise of the<br />

employees more efficiently and at the<br />

same· time updating the state of the art<br />

in the mMufacturing process. In total a<br />

functional filtration bay will enable us<br />

to meet the competition and get a better<br />

slice of the pie.<br />

Mike PasquareHo, Manager of<br />

Manufacturing.<br />

The Plant Improvement<br />

Program certainly<br />

means a continuation of<br />

manufacturing operations<br />

here in Hazleton.<br />

The recent plant<br />

closing in the area such<br />

as Wagner Electric.<br />

Prestolite. KBI. Futura. J. Bass and<br />

others has had a devastating impact on<br />

employment. While other plants were<br />

closing we have hired 22 employees in<br />

the shop since August 1979.<br />

The worker with 10 to 25 years service<br />

at the plant should be especially<br />

thankful that <strong>Dorr</strong>-<strong>Oliver</strong> will be<br />

continuing operations. These are the<br />

people that have the most difficult time<br />

with re-employment.<br />

Also. I hope the increased space and<br />

the new layout of the filter bay will give<br />

the plant the potential to expand again<br />

in the future and. therefore. job bidding<br />

and promotions will become a reality<br />

and not just dreams.<br />

Pat N eJigan, Manager ofIndustrial<br />

Relations.<br />

Mike PasquareHo. Manager of<br />

Manufacturing, points to floor plan<br />

of Plant Improvement that hangs on<br />

the waH in the office.<br />

Page 11

DORR-OLIVER<br />

IN REVIEW<br />

Distance Runner <br />

GOLF CHAMP <br />

Page 12<br />

L. to R.-T. Toth, R. Murray, J.<br />

Braskey, C. Ravina.<br />

Bob Murray, of our Manufacturing<br />

Engineering Dept. won the 1980 <strong>Dorr</strong><br />

<strong>Oliver</strong> Fogelsville Golf tournament with<br />

a good round of 73.<br />

The tournament was held on Sept. 28<br />

at the Mahoning · VaHey golf course.<br />

Twenty-two golfers from Hazleton and<br />

Allentown facilities participated. Other<br />

Hazleton golfers scores were: Tom Toth<br />

- 89, John Braskey - 90, Chuck Ravina<br />

96 ~nd Dave Smith - 107. The Hazleton<br />

golfers -did quite well, with Murray's<br />

title, plus John Braskey closest to the pin<br />

on #7, Dave Smith Closest to the pin on<br />

#8, and Chuck Ravina took longest drive<br />

honors on #17. Joe Hnat of Fogelsville,<br />

won the low gross trophy with a great<br />

81, plus the longest drive on #18.<br />

Chuck Ravina, Inventory Control<br />

Filtration Dept., was a participant in<br />

the 3rd Annual Philadelphia Distance<br />

Run, held on September 21, at 12th and<br />

Market Sts., Philadelphia. The 13.1<br />

half-marathon, one of America's most<br />

prestigious races took the runners on a<br />

memorable course through historic<br />

streets of Philadelphia and long<br />

picturesque drives of Fairmount Park.<br />

4,506 runners from the United States,<br />

Canada, England, Europe and New<br />

Zealand were entered.<br />

Chuck, who has been running since<br />

April, finished the course in 2 hours and<br />

20 seconds. He also was a finisher in the<br />

following 6.2 mile races held this<br />

summer: Jim Thorpe Memorial Run<br />

Jim Thorpe, Pa., Lady of Fatima Run'<br />

Elmhurst, Pa., l

CHINA-A NATION ON THE MOVE <br />

Minerals Processing<br />

Screens. These DS~ Rapifine®<br />

screens are used in classification<br />

after regrinding in modern<br />

taconite plants .<br />

~zm 0 }!J!tDSM®Rapifine®<br />

~~mmTM~~~~~~~Mu~<br />

Foa15H~Ir¥ 0<br />

China, the world's most populous nation,<br />

is in the process of modernizing the<br />

country.<br />

China, is aware that it had isolated<br />

itself technically over the past few years<br />

and is reaching out for higher<br />

technology. The national goals, called<br />

the "Four Modernizations" are the<br />

modernization of agriculture, industry,<br />

defense and science by the year 2000.<br />

In keeping with China's goals, on June<br />

28, 1980 <strong>Dorr</strong>-<strong>Oliver</strong>, Hazleton hosted<br />

the Shandong Gold Mine Project Team.<br />

The engineering firm of Davy McKee of<br />

San Mateo, California has been<br />

retained to modernize their gold mine<br />

operation and arranged for the Project<br />

Team to visit a number of<br />

manufacturing plants who supply<br />

equipment for mining.<br />

Visiting with us were: Luo<br />

Zhengxing, Project Manager, Yang<br />

Dali, Project Engineer, Van Xinyu,<br />

Beneficiation Engineer; Hu Wenyu,<br />

Mechanical and Electrical Engineer;<br />

Van Hongbo, Mining Engineer; Li<br />

Kunyu, Beneficiation Engineer; Li<br />

Yunxiang, Mining Engineer; Zeng<br />

Tianlan, Interpreter. Davy McKee<br />

personnel who accompanied the Project<br />

Team were: K. F. Thiel, Project<br />

Manager; Shang W. Lin, Project<br />

Engineer; Dr. C. F. Acton, Senior<br />

Engineer, Process; W. S. Lam,<br />

Supervising Engineer and S. Chow,<br />

Supervising Engineer. Coordinating<br />

the project from Stamford was Art<br />

McKenna, Senior Sales Engineer.<br />

Luo Zhengxing, Project Manager, is<br />

an experienced engineer who is familiar<br />

with <strong>Dorr</strong>-<strong>Oliver</strong> equipment and<br />

appreciated the opportunity to see the<br />

equipment being manufactured.<br />

Upon their arrival at the Hazleton<br />

plant the visitors were shown a 20<br />

minute video tape of all <strong>Dorr</strong>-<strong>Oliver</strong><br />

equipment. The tape presentation,<br />

which was in Chinese, had been<br />

prepared for an iron ore presentation<br />

given a few months ago in San<br />

Francisco.<br />

The group toured the shop where they<br />

had an opportunity to observe the<br />

equipment they were interested in<br />

being manufactured. We were pleased<br />

with their professional reaction to the<br />

presentation and tour as was reflected<br />

by the nature of the questions they asked<br />

regarding our equipment and<br />

manufacturing.<br />

The entire presentation had to be<br />

translated. The translating was<br />

superbly handled by Zeng Tianlan,<br />

Beijing, China who was the interpreter<br />

for the group.<br />

Mr. McKenna expressed his<br />

appreciation to the people in the<br />

Hazleton plant by saying the "Hazleton<br />

plant organized everything beautifully<br />

for trre tour."<br />

Solid-bowl centrtfuge. This<br />

<strong>Dorr</strong>-<strong>Oliver</strong> MercoBowi®<br />

centrifuge washes and dewaters<br />

yellowcake in a uranium mill .<br />

7CR.~~itlJlH.,m 0<br />

}!~ <strong>Dorr</strong><br />

<strong>Oliver</strong> MercoBowl®.{,'mli~rell!!<br />

1JDlr~S1" 1lt1r'1JD~:..t6t~.!:jJBt* 0<br />

Excerpts from an advertising<br />

pamphlet written in Chinese with the<br />

English interpretation.<br />

Page 13

~I SPORTS I <br />

D-O Bowling News<br />

The <strong>Dorr</strong>-<strong>Oliver</strong> bowling league is off<br />

to a good-start. The league bowls every<br />

Thursday evening at the Bowl Arena,<br />

West Hazleton. The Dynamics<br />

defending league champs will try to win<br />

their second straight crown. Members<br />

of the Dynamics: Joe Ferrare, Fred<br />

Washko, Bill Jones, Tim Sterba, Jim<br />

Zola, Mike Rusnock and Gene Ballick. A<br />

few of the top keglers to watch this<br />

season are: John (Slick) Feschuk, Al<br />

Thomas, Chris Burnes, Karl Guenther,<br />

J. Stank and Jim (Pir.ate) Forbes,<br />

Peggy Hunsicker of our Repair order<br />

Department, met long time idol former<br />

Yankee great, Chris Chambliss ata twinight<br />

double header, on July 25,1980, at<br />

Veterans Stadium, Philadelphia. Peggy<br />

met Chris at the Stadium Hilton, where<br />

he took time out from his busy schedule,<br />

to sign autographs and have several<br />

pictures taken with her.<br />

On Feb. 3, the Eagles football team<br />

played a benefit basketball game<br />

against Hazleton area teams, at St.<br />

Joseph's gym. Peggy was fortunate to<br />

meet the following Eagle football<br />

players: Curtis Bunche-DE, LeRoy<br />

Harris-FB, Ray Phillips-LB, Dennis<br />

Harrison-DE, Guy Morris-C" Larry<br />

Barnes-FB and Quarterback Ron<br />

Jaworski.<br />

Peggy is a loyal follower of the New<br />

York Yankees, the Pittsburgh Pirates<br />

and Chris Chambliss of the Atlanta<br />

Braves.<br />

NFL Football <br />

Predictions <br />

SUPER BOWL XV<br />

Jan. 25, 1981<br />

Philadelphia Eagles - 2R<br />

Pittsburgh Steelers - 10<br />

1980 League Predictions<br />

NATIONAL<br />

AMERICAN<br />

Driveheads C-400<br />

Dynamics<br />

Centershafts<br />

Prototypes<br />

Kellys<br />

DSM<br />

Digesters<br />

Champions: Driveheads<br />

DEDICATED <br />

BOWLERS <br />

Three <strong>Dorr</strong>-<strong>Oliver</strong> ladies, have been<br />

members of the Friday women's<br />

bowling league for several years.<br />

Helene Miller, Secretary to George<br />

Hardish, Manufacturing Engineering;<br />

Kathy Witanek, Accounting Dept., and<br />

Louise Palermo, Accounting Dept., are<br />

the only remaining D-O employees from<br />

the once all <strong>Dorr</strong>-<strong>Oliver</strong> bowling league.<br />

The girls are now members of the<br />

Heavenly Bodies Women's league,<br />

which bowl every Friday at 7 p.m. at the<br />

Valley Lanes, Sybertsville. Helene, is a<br />

member of Venus, Kathy and Louise<br />

bowl on Jupiter. Wives of <strong>Dorr</strong>-<strong>Oliver</strong><br />

employees also bowling include:<br />

Kathleen Mary, Jean Tough, Carol<br />

Wash~o, Joan Ferrare, Janet<br />

Witkowski and Mary Corrado. Helene,<br />

Kathy, and Louise are good bowlers,<br />

who have won numerous honors through<br />

the years.<br />

DORR-OLIVER <br />

GOLF NEWS <br />

The 1980 <strong>Dorr</strong>-<strong>Oliver</strong> golf league is<br />

history. Len Zigretti and John Yeager<br />

crushed John Braskey and Ray Gurgal<br />

for the "A" division championship and<br />

. Jim Forbes and Frank Liotta dumped<br />

John Tough and Mike Palushock to win<br />

the "B" division crown. The D-O golf<br />

league played all their matches at the<br />

Sugarloaf golf course.<br />

Ron Corrado was the best golfer,<br />

shooting an average of 38. Tom Toth<br />

won the Most Improved Golfer with a 43<br />

average. Last season he averaged 47.<br />

In the D-O Open, Ron Corrado shot a<br />

great score of 72 at the beautiful Briar<br />

Heights golf course, Berwick. Ron is a<br />

former MMI star athlete, and is active<br />

in bowling, baseball and basketball.<br />

Low net honors went to J. Bereznak-68.<br />

Closest to pin-#7 J. Braskey, #9 J.<br />

Rooney, #12 R. Corrado, and #13 J.<br />

Tough.<br />

The following <strong>Dorr</strong>-<strong>Oliver</strong> offi~ers<br />

made the 1980 golf season a huge<br />

success:<br />

President - John Rooney <br />

Vice-President - Don Baran <br />

Secretary - Ron Corrado <br />

Treasurer - John Braskey <br />

Rules Committee: Len Zigretti, Tom<br />

Toth and Ed Sipple.<br />

Nothing increases your golf score like<br />

witnesses.<br />

<strong>Dorr</strong>-<strong>Oliver</strong> Annual Bowling Outing<br />

Page 14

Apprentice Educational New Machine<br />

Awarded Diploma Opportunities Installed<br />

Joseph Teprovich, Apprentice<br />

Machinist, received a diploma in<br />

Machinist Trades from the International<br />

Correspondence School. Joe was<br />

presented with the diploma at the<br />

Service Pin Dinner held September 5.<br />

In order to qualify for admission into<br />

the Apprenticeship Program the<br />

applicant must pass a required<br />

standard test. For completion of the<br />

program the trainee must serve 8,000<br />

hours in training on various machines<br />

and pursue courses of study in the trade.<br />

Joe completed 46 units of related<br />

study in 11 months, maintaining an<br />

average grade of 98.6. To date he has<br />

completed approximately 3.000 hours of<br />

machine time.<br />

The Apprenticeship Program is<br />

sDonsored by <strong>Dorr</strong>-<strong>Oliver</strong>, Inc. and the<br />

Pennsylvania Apprenticeship and<br />

Training Council.<br />

Attends Seminar<br />

Leonard Payne and Dave Wilson.<br />

, Methods Engineers. attended a Work<br />

Measurement Techniques Workshop<br />

September 22 thru September 26. The<br />

seminar was held at the Hershey<br />

Convention Center.<br />

It is the policy of <strong>Dorr</strong>-<strong>Oliver</strong><br />

Incorporated to encourage and assist<br />

employees in improving their skills and<br />

qualifications through education and<br />

training. This assistance is available to<br />

all regular <strong>Dorr</strong>-<strong>Oliver</strong> employees<br />

through its Corporate Tuition Refund<br />

Program which now pays 100% tuition.<br />

During 1979, 12 employees attended<br />

courses at the local colleges. For the fall<br />

1980 semister we have 26 employees<br />

attending school for an increase of 116%.<br />

The following employees have taken<br />

advantage of the Tuition Refund<br />

Program and attended/or are now<br />

registered for the 1980 Fall Term.<br />

Luzerne County Community<br />

College-F. Amorose, M. P. Chomo. W.<br />

Dinsmore, H. Floyd, E. Gill, J. Griesing,<br />

W. Jones, R. Petronio, J. Potash, C.<br />

Puza, C. Ravina.<br />

Penn State University-So Broton, G.<br />

Danko, G. Hardish, W. Jones, R.<br />

Neithamer.<br />

Wilkes College-W. Jones, P.<br />

Neligan.<br />

Bloomsburg State College-G.<br />

Hardish, C. Ravina.<br />

Lackawanna Junior College-R.<br />

Stanek, R. Trego.<br />

Hazleton Vocational Technical-T.<br />

Brogan, C. Cancerious, G. Danko, K.<br />

Dinsmore, W. Kisenwether. L.<br />

Longazel. R. MacNeal, F. Mainiero, J.<br />

Mishkin.<br />

A good boss is someone who takes a<br />

littl~ more than his share of the blame<br />

and a little less than his share of the<br />

credit.<br />

The trouble with people who talk too<br />

fast is that they often say something they<br />

haven't thought of yet.<br />

Installation of a new Cincinnati<br />

Milacron 18" Universal Chucker was<br />

recently completed. The machine is<br />

computer numerically controlled and<br />

will be primarily used for chucking.<br />

Large shafts up to 80" in length Cll.!""! also<br />

be machined in the Chucker.<br />

The machine has a dual turret slant<br />

bed and is equipped with two hydraulic<br />

operated omni rests which allow for full<br />

turn through capacity when doing bar<br />

work. It also has as standard a<br />

countercentrifugal chuck.<br />

The Chucker was primarily<br />

purchased to do work now performed on<br />

manual engine lathes, turret lathes, and<br />

vertical turret lathes.<br />

The Chucker allows for greater<br />

clearance with less intereference when<br />

mach·ining shaft type work.<br />

Parts from all three product groups<br />

will be machined on the Chucker.<br />

The Cincinnati Milacron 18"<br />

Universal Chucker adds another<br />

dimension of productivity to<br />

manufacturi ng of parts through<br />

utilization of computer numerically<br />

controlled machinery.<br />

Attend Tool Show<br />

From September 8 - 12 eight <strong>Dorr</strong><br />

<strong>Oliver</strong> employees attended the<br />

International Machine Tool Show. The<br />

show was held in Chicago and was the<br />

largest manufacturing exhibition ever<br />

held in the United States. There were<br />

1000 exhibitors showing $100 million<br />

worth of equipment.<br />

Attending were: Gene Kokinda. Mike<br />

Pasquarello, George Hardish, Joe<br />

Mestrow, Joe Williams. Mike Schlacter,<br />

Rich Stanek, and Mike Feller.<br />

Page 16

NEW HIRES<br />

RETIREES <br />

L. to R.-Charles Dinofrio, Jeffrey Fendrick, Howard<br />

Freed, Richard Mikula, Tom Haydu, Carl Chuckra, Jr.<br />

Edmund Mellas retired Joseph Campana retirin<br />

August. He was ed in August. Joe was a<br />

employed with <strong>Dorr</strong> welder in the Plate shop.<br />

<strong>Oliver</strong> for 29 years. Ed He was with the<br />

was a welder in the company 24 years.<br />

Plate shop.<br />

Sports Quiz Answers<br />

1. Presented by the Downtown 5. Penn State beat Arizona State - 42- 8. The meat hand.<br />

Athletic Club of New York to Jay 30. 9. Bob Tucker - Hazleton Native<br />

Berwanger a back for the 6. Dave Kingman - 37 home runs in snared 59 passes in 1971, for the<br />

University of Chicago-1935. 1976. New York Giants.<br />

2. Mike Rusnock, John Yurcho and 7. The Washington Redskins - Nov. 27, 10. It's Mickey Mantle of the New York<br />

Gary Houser. 1966, the Skins defeated the hapless Yankees with 18 home runs and<br />

3. Fran Tarkenton - 317 touchdowns - New York Giants by the Babe Ruth is second with 15.<br />

a record established from 1961-77. Phenomenal score of 72-41. The <br />

4. 60'-6"<br />

combined score is also the NFL<br />

record.<br />

DORHLIUER :z.><br />

FIRST CLASS<br />

Page 16