Welcome to Dorr-Oliver's Open House - Dorr-Oliver Alumni

Welcome to Dorr-Oliver's Open House - Dorr-Oliver Alumni

Welcome to Dorr-Oliver's Open House - Dorr-Oliver Alumni

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

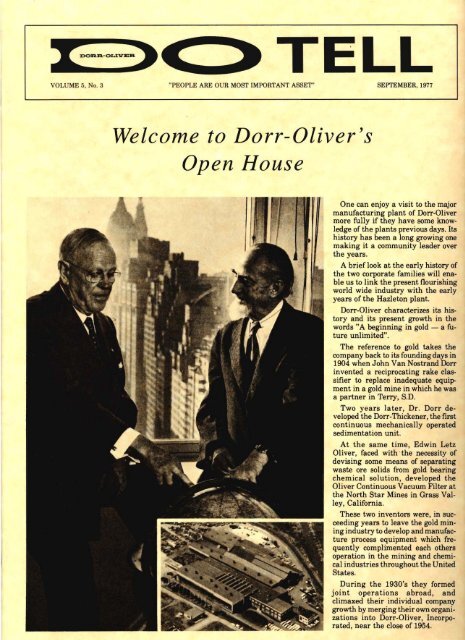

TELL<br />

VOLUME 5, No.3 "PEOPLE ARE OUR MOST IMPORTANT ASSET" SEPTEMBER,1977<br />

<strong>Welcome</strong> <strong>to</strong> <strong>Dorr</strong>-<strong><strong>Oliver</strong>'s</strong> <br />

<strong>Open</strong> <strong>House</strong> <br />

One can enjoy a visit <strong>to</strong> the major<br />

manufacturing plant of <strong>Dorr</strong>-<strong>Oliver</strong><br />

more fully if they have some knowledge<br />

of the plants previous days. Its<br />

his<strong>to</strong>ry has been a long growing one<br />

making it a community leader over<br />

the years.<br />

A brief look at the early his<strong>to</strong>ry of<br />

the two corporate families will enable<br />

us <strong>to</strong> link the present flourishing<br />

world wide industry with the early<br />

years of the Hazle<strong>to</strong>n plant.<br />

<strong>Dorr</strong>-<strong>Oliver</strong> characterizes its his<strong>to</strong>ry<br />

and its present growth in the<br />

words "A beginning in gold - a future<br />

unlimited".<br />

The reference <strong>to</strong> gold takes the<br />

company back <strong>to</strong> its founding days in<br />

1904 when John Van Nostrand <strong>Dorr</strong><br />

invented a reciprocating rake classifier<br />

<strong>to</strong> replace inadequate equipment<br />

in a gold mine in which he was<br />

a partner in Terry, S.D.<br />

Two years later, Dr. <strong>Dorr</strong> developed<br />

the <strong>Dorr</strong>-Thickener, the first<br />

continuous mechanically operated<br />

sedimentation unit.<br />

At the same time, Edwin Letz<br />

<strong>Oliver</strong>, faced with ' the necessity of<br />

devising some means of separating<br />

waste ore solids from gold bearing<br />

chemical solution, developed the<br />

<strong>Oliver</strong> Continuous Vacuum Filter at<br />

the North Star Mines in Grass Valley,<br />

California.<br />

These two inven<strong>to</strong>rs were, in succeeding<br />

years <strong>to</strong> leave the gold mining<br />

industry <strong>to</strong> develop and manufacture<br />

process equipment which frequently<br />

complimented each others<br />

operation in the mining and chemical<br />

industries throughout the United<br />

States.<br />

During the 1930's they formed<br />

joint operations abroad, and<br />

climaxed their individual company<br />

growth by merging their own organizations<br />

in<strong>to</strong> <strong>Dorr</strong>-<strong>Oliver</strong>, Incorporated,<br />

near the close of 1954.

While all of this was taking place the Hazle<strong>to</strong>n plant was<br />

having its own auspicious beginning.<br />

Ernest J . Sweetland, an inven<strong>to</strong>r whose career paralleled<br />

that ofE. L. <strong>Oliver</strong> and Dr. <strong>Dorr</strong>, played the major role in the<br />

company's early development in Hazle<strong>to</strong>n. The inven<strong>to</strong>r of<br />

the Sweetland Filter and a pioneer in industrial filtration, he<br />

became president of the United Filter Corporation, a company<br />

formed from the American and Kelly Filter Companies<br />

and the Sweetland Filter Press Company. This company had<br />

its beginning in 1907.<br />

In 1919Sweetland looked for a plant site. He found a plant<br />

in Hazle<strong>to</strong>n with a foundry, office & machine shop. It was<br />

situated on thirteen acres of land, most of it wooded. He<br />

purchased the site, that ofthe present plant - and moved in.<br />

Almost immediately, plans were made for expanding the<br />

30,000 sq. ft. facilities and by the end of 1920, additions were<br />

completed bringing the <strong>to</strong>tal <strong>to</strong> 53,000 sq. ft. The company's<br />

products, the Sweetland Pressure Filter, American Disc Filter<br />

and Plate and Frame Presser found welcome markets,<br />

principally in the sugar producing industry and the metallurgical<br />

fields.<br />

In 1923, the manufacture of Kelly Filter was added at the<br />

plant and the period from 1920 <strong>to</strong> 1928 was marked with<br />

sizable growth for both the company and the plant itself. A<br />

pattern shop and s<strong>to</strong>rage building was completed in 1925 and<br />

the following year a north wing was added <strong>to</strong> the office building.<br />

Then in 1928, a second era in the his<strong>to</strong>ry of the plant began.<br />

This is the year that the United Filter Corp. and the <strong>Oliver</strong><br />

Continuous Filter Corp. merged <strong>to</strong> form the <strong>Oliver</strong> United<br />

Filters, Inc. The merger increased the combined operations<br />

line of products measurably. The staff in Hazle<strong>to</strong>n increased<br />

and in 1929, an expansion of the facility, which included a<br />

fabricating shop and a labora<strong>to</strong>ry, was completed. Many filters<br />

of <strong>Oliver</strong> origin began <strong>to</strong> appear on the assembly floor<br />

and in 1937 the original foundry building was converted <strong>to</strong> an<br />

assembly shop <strong>to</strong> accommodate the widened line of products<br />

manufactured.The outbreak of World War II brought United<br />

States industry <strong>to</strong> a hectic pace. In 1942, a long side bay was<br />

added <strong>to</strong> the assembly shop <strong>to</strong> provide for expanding production.<br />

Notable during this period was the production of <strong>Oliver</strong><br />

Synrub Filters built for the government for their synthetic<br />

rubber program. This was an important contribution <strong>to</strong> the<br />

company's war-time effort. The important post-war expansion<br />

of the Hazle<strong>to</strong>n facility <strong>to</strong>ok place in 1947 when the<br />

capacity of the fabricating shop was doubled and a sizable<br />

addition <strong>to</strong> the assembly shop was completed.<br />

January 1, 1955 was the beginning of the third and most<br />

important period in the his<strong>to</strong>ry ofthe plant. This marked the<br />

merging ofthe <strong>Dorr</strong>Company and <strong>Oliver</strong> United Filters, Inc.<br />

<strong>to</strong> form <strong>Dorr</strong>-<strong>Oliver</strong>, Inc. An unprecedented increase of<br />

equipment orders quickly filled the plant facility and sharply<br />

raised the number of employees. By 1956, volumes of orders<br />

entered by the company became <strong>to</strong>o great for its production<br />

capacity and it was decided <strong>to</strong> undertake an expansion ofthe<br />

Hazle<strong>to</strong>n plant. Fabricating shop space was again doubled<br />

and the service departments gained much needed additional<br />

floor space. This capacity increase, sizable as it was, was not<br />

enough <strong>to</strong> balance production with sales and in late 1956, a<br />

second capacity increase was announced. Under this program,<br />

assembly shop space was enlarged <strong>to</strong> twice its 1947<br />

proportions while the service shops again received increased<br />

space. Much new equipment was installed and offices were<br />

completely renovated and enlarged.<br />

Additional phases of this expansion were increased in outside<br />

s<strong>to</strong>rage area and material handling facilities and the<br />

purchase of an unoccupied lot adjacent <strong>to</strong> the plant site and<br />

its conversion in<strong>to</strong> an improved parking area for employees<br />

<strong>to</strong>· supplement the overcrowded existing lot.<br />

While <strong>Dorr</strong>-<strong>Oliver</strong> was experiencing this unprecedented<br />

growth, the Hazle<strong>to</strong>n area was going through some of its most<br />

trying times. There was a drastic decrease in coal mining<br />

operations and related employment. <strong>Dorr</strong>-<strong>Oliver</strong> emerged as<br />

a major industrial leader, providing stable employment<br />

while unemployment ran rampant throughout the area. The<br />

firm played an important role in the industrial rebuilding of<br />

the area in conjunction with Can-Do, Hazle<strong>to</strong>n's industrial<br />

development organization. <strong>Dorr</strong>-<strong>Oliver</strong> management and its<br />

employees actively supported a Can-Do drive for funds <strong>to</strong><br />

acquire property for industrial use and the construction of<br />

shells <strong>to</strong> attract industrial prospects.<br />

In 1960, another expansion was completed at the Hazle<strong>to</strong>n<br />

plant which brought the size of the plant <strong>to</strong> in excess of<br />

222,000 sq. ft. In 1961 the centrifugal line of business was<br />

transferred from the company's facility in Oakland, California<br />

<strong>to</strong> Hazle<strong>to</strong>n. In 1963, another major equipment line,<br />

sedimentation, was transferred <strong>to</strong> Hazle<strong>to</strong>n. This line of<br />

equipment had been manufactured in the company's operation<br />

in Denver, Colorado. The last decade and more importantly<br />

the last fi ve years has seen millions of dollar in new<br />

machine <strong>to</strong>ols bein g installed in the Hazle<strong>to</strong>n plant. These<br />

new machine <strong>to</strong>ols have enabled the Hazle<strong>to</strong>n facility <strong>to</strong><br />

increase production, reduce costs, and reduce lead time required<br />

<strong>to</strong> ship products <strong>to</strong> the cus<strong>to</strong>mer. A new addition is<br />

under construction at the present time. When this addition is<br />

completed, the engine lathe section and the surface grinding<br />

equipment will be moved in.<br />

As this equipment is moved, preparation will be made for<br />

the installation of a Giddings and Lewis computernumerically<br />

controlled boring mill. This new machine <strong>to</strong>ol<br />

will cost a half million dollars.<br />

Looking back, the his<strong>to</strong>ry of the plant has been one of<br />

continued growth in capacity and importance <strong>to</strong> its worldwide<br />

organization and <strong>to</strong> the community itself. In 1919,50<br />

employees ma naged a small foundry and shop. In the<br />

mid-1950's the employment grew <strong>to</strong> 250 people and <strong>to</strong>day itis<br />

just under 500 capable, skilled personnel. This diverse team<br />

of employees represent a combination of management,<br />

supervision, skilled machinists, welders and assemblers, and<br />

support personnel, and a skilled office force.<br />

When you walk through the Hazle<strong>to</strong>n manufacturing segment<br />

of <strong>Dorr</strong>-<strong>Oliver</strong>, Inc., you will become witness <strong>to</strong> its great<br />

heritage.<br />

Note: A great deal of the information in this article came {rom a (o rmer Plant<br />

Manager, Wilbur Evans. We thank him for his kind cooperation.<br />

N<br />

LEGgND""<br />

~I, ""N T Xi!0WTH<br />

o O IUQ,l\; 1~ 1... ~ "',.::: ~oo M . "<br />

[] I~ O~~O~o. l :~ ' ~~o~~ !)<br />

~ 14 OO:IIt~ , :;~ "'!O~.. l.<br />

~ ... · ° o;lt~ :~ l"~:~4-"<br />

~ 1i~. o~: ~~~T. ~~~o<br />

o 'I' !.IOI! 'PU"" " TOI....t.t.<br />

..AZL.L TO" \Ire. Pl"NI ....1 ....<br />

Pa!.!.tt .".T 10T...."- ~..f. ..... <br />

IS . OOO .Q -': 1 .

DO-TELL - From P. Stern<br />

I would like <strong>to</strong> extend my welcome <strong>to</strong> our <strong>Open</strong> <strong>House</strong> <strong>to</strong> the<br />

employees of the Hazle<strong>to</strong>n facility and their families and<br />

friends.<br />

Over the past two <strong>to</strong> three years, <strong>Dorr</strong>-<strong>Oliver</strong> has made a<br />

corporate commitment <strong>to</strong> the plant by purchasing new<br />

equipment, machines and a variety of other items which<br />

improve productivity and working conditions for our employees.<br />

I am sure you have seen the new machines being<br />

installed. We plan <strong>to</strong> continue <strong>to</strong> improve the plant in the<br />

future.<br />

As you <strong>to</strong>ur the facility <strong>to</strong>day, I hope you have an opportunity<br />

<strong>to</strong> meet with your fellow employees and enjoy your day<br />

here at <strong>Dorr</strong>-<strong>Oliver</strong>.<br />

DO-TELL - From E. Kokinda<br />

<strong>Welcome</strong> <strong>to</strong> <strong>Dorr</strong>-<strong><strong>Oliver</strong>'s</strong> <strong>Open</strong> <strong>House</strong>.<br />

As a life-time resident of the Hazle<strong>to</strong>n area, I am particularly<br />

proud <strong>to</strong> have my neighbors visit us here at the<br />

Hazle<strong>to</strong>n facility.<br />

It is with a matter of personal and community pride that I<br />

call your attention <strong>to</strong> the fact that <strong>Dorr</strong>-<strong>Oliver</strong> has been in<br />

this same location for almost 60 years. We have grown over<br />

the years and this year again we are building a new addition<br />

<strong>to</strong> the plant and installing advanced machinery, and this<br />

planned growth will continue in<strong>to</strong> 1978.<br />

The cooperation and good will of all employees will enable<br />

us <strong>to</strong> grow here in Hazle<strong>to</strong>n.<br />

Have a good visit.<br />

Seated t. <strong>to</strong> r.: George Hardish, Manager Manufacturing and Engineering;<br />

John Tough, Quality Control Manager; Eugene Kokinda, Plant Manager;<br />

John Yeager, Plant Superintendent.<br />

Standing: Allan Cope, Assistant Controller; Charles Andrews, Manager of<br />

Data Processing; John Leshko, Production & Inven<strong>to</strong>ry Control Manager;<br />

Robert Stelma, Superintendent Second Shift; Pat Neligan, Industrial Relations<br />

Manager; George Gyurko, Purchasing Agent.<br />

The Management of <strong>Dorr</strong>-<strong>Oliver</strong> welcomes everyone <strong>to</strong> our<br />

<strong>Open</strong> <strong>House</strong>. We thank you for your in~rest in the company<br />

and its activities. We have been a neighbor and friend in our<br />

community for many years and it is nice <strong>to</strong> have you visit<br />

with us. We hope that your <strong>to</strong>ur of the facility will be an<br />

interesting and enjoyable experience.<br />

Judy Griesing, President of Local 202 of the Office & Professional<br />

Employees International Union and Vi<strong>to</strong> Bove,<br />

President of Lodge 1648 of the International Association of<br />

Machinistsjoin with the management of<strong>Dorr</strong>-<strong>Oliver</strong>, Inc. <strong>to</strong><br />

welcome you <strong>to</strong> our <strong>Open</strong> <strong>House</strong>.<br />

During recent months both labor and management have<br />

been making efforts, through joint meetings, <strong>to</strong> reach a better<br />

understanding ofeach other. Producing a quality product for<br />

our cus<strong>to</strong>mer is a common goal for both groups.<br />

We would also like <strong>to</strong> take this opportunity <strong>to</strong> say "thank<br />

you" <strong>to</strong> the members ofour respective labor organizations for<br />

the time and effort they have extended <strong>to</strong> help make this<br />

<strong>Open</strong> <strong>House</strong> a success.

OFFICE PERSONNEL <br />

Office Services<br />

Data Processing Programmers & Supervisor!<br />

Seated: R. Petronio<br />

Standing; I. <strong>to</strong> r.: J. Grie.ing,<br />

J. Hollick. J. Capozzelli<br />

I. <strong>to</strong> r. front row: M. Heintzleman,<br />

E. Lazo, J. Wendt<br />

Back row: D. Moscon, J. Willard,<br />

V. Kashulon, G. <strong>House</strong>r ,<br />

R. Grozier<br />

The Office Services group is responsible for all the support functions<br />

in the office operation. These responsibilties include communications,<br />

reproduction services, office supplies and furnishings,<br />

secretarial serv ices and mail services.<br />

Data Processing Keypunch Opera<strong>to</strong>rs<br />

Purchasing<br />

I. <strong>to</strong> r.: J. Snyder, B. ShafTer<br />

C. Kashi, N. Tarselli<br />

Seated: F. Amorose<br />

I. <strong>to</strong> r. standing: B. Steward, T.<br />

Toth , J. Potash, M. L.<br />

McBrearty, M. Arnold<br />

Second row: M. Dorso, J. Ferrare,<br />

J. Fetter, B. Facinelli<br />

The Purchasing Department places thousands oforders each year<br />

for everything from a 2 cent nut or bolt <strong>to</strong> a half million dollar<br />

machine <strong>to</strong>ol. The annual volume of orders placed by this department<br />

is in excess of 12 million dollars.<br />

I. <strong>to</strong> r.: A. Wolbert, J. Cienki<br />

E. Porreca, E. Franek, M<br />

Mumie<br />

Cost Accounting<br />

I. 10 r. sealed: J. Kulina, L.<br />

Palermo <br />

Second row: J. Feschuk, E. <br />

O'Grodnick, K Witanek, B. <br />

Evert, W. Coli <br />

Third row : S. Yarish , C.<br />

Sanko, R. Witkowski, N.<br />

Cio<strong>to</strong>la, J. Phillips, N.<br />

Palucci, A. Hopeck<br />

Cost Accounting is the area where the final accumulation of all<br />

costs, labor and material are audited and charged <strong>to</strong> the jobs.<br />

The Data Processing department in Hazle<strong>to</strong>n serves <strong>Dorr</strong>-Olive<br />

facilities throughout the world. It is a hub of much of the company'<br />

activity and its service continues <strong>to</strong> grow.<br />

Accounts Payable<br />

Scheduling<br />

Sealed: M. Thaler<br />

I. <strong>to</strong> r. standing: N. Postupack<br />

K. <strong>House</strong>r, J. Phillips, B<br />

Boyer<br />

I. <strong>to</strong> r. slanding: H. Floyd, J.<br />

Bra.key, C. McGlynn, D. Undeck,<br />

R. Corrado<br />

Seated: R. Leshko, M. Rusnock<br />

Accounts Payable department is responsible for the payment 0<br />

all bills for the entire corporation. Each week hundreds ofthousand<br />

of dollars are mailed from this department <strong>to</strong> pay the companie<br />

obligations.<br />

The Scheduling department is the group that sets the priority for<br />

what will be machined or fabricated on a given day. They keep<br />

ilr.r.lIrilt.p rpr.orns of<br />

Note: A number of people were absent or on vacation when the pictures weI<br />

taken. They are valued em loyees and we are sorr we missed them.

The major portion of Parts Service comes out of our Allen<strong>to</strong>wn<br />

facility. We still do almost a half million dollars a month in Parts<br />

Service orders in Hazle<strong>to</strong>n and these people consolidate the effort.<br />

Production & Inven<strong>to</strong>ry Control<br />

Manufacturing Engineering<br />

Seated: W. Dinsmore, L. Sims,<br />

B. Stanziola <br />

Standing, I. <strong>to</strong> r.: C. Puza, J. <br />

McNeal, F. Washko, T. On<br />

drey, J. Shewack, E. Siwski, <br />

D. Magavich, J. Foz, E. <br />

Jacoby, R. Antinozzi, E. <br />

Skitski, C. Ravina, D. Smith, <br />

D. Baran.<br />

I. <strong>to</strong> r. front row: M. Yatsula,<br />

B. Murray, J. Liwstansky, M. <br />

Gabriel. <br />

Back row: D. Dargay, M. Fel<br />

ler, J. Zola, J. Vecolitis. <br />

The Production Control department is responsible for the planning<br />

and ordering of material for the manufacture of our products.<br />

Inven<strong>to</strong>ry Control functions are also located in this department.<br />

Quality Control<br />

The Manufacturing group consists of industrial engineers and<br />

<strong>to</strong>ol designers. The I.E.'s evaluate job performance, times and cost.<br />

Programming of numerically controlled machines originate in this<br />

department. Also coordinated in this department is the purchase of<br />

all new machine <strong>to</strong>ols. The <strong>to</strong>ol designers design and draw <strong>to</strong>oling<br />

required <strong>to</strong> manufacture new products. Plant layout is another<br />

function of this department.<br />

Seated: F. Roman<br />

Standing: S. Bro<strong>to</strong>n, W.<br />

Jones, F. Bamesevitch<br />

Seated: B. Zukovich<br />

Standing: W. Hess, L. Payne<br />

The Quality Assurance group makes certain that products manufactured<br />

in the plant conform <strong>to</strong> the specifications called out on the<br />

drawing. They are also a liaison between cus<strong>to</strong>mers and vendors on<br />

quality related problems.<br />

Traffic<br />

The Methods Engineers, working from engineering drawings,<br />

determine the machining, fabricating and assembly requirements.<br />

They select the machines which will best do the job from a quality<br />

and time standpoint and route the job <strong>to</strong> those machines in the<br />

proper sequence. They also establish times and request <strong>to</strong>oling if<br />

required.<br />

I. <strong>to</strong> r.: G. Gurinowich. M. P.<br />

Chomo<br />

Personnel<br />

As <strong>Dorr</strong>-<strong>Oliver</strong> continues <strong>to</strong> design larger equipment, the problems<br />

of the Traffic department grow. It is a challenge <strong>to</strong> build this<br />

huge equipment and it is an equal challenge <strong>to</strong> find ways <strong>to</strong> ship it.<br />

Next issue ofDo-Tell will show how we shipped the 32' filter that we<br />

are presently fabricating.<br />

Seated: R. Trego<br />

Standing: M. Romano, D.<br />

Polanesky<br />

Repair Parts<br />

Seated: B. Geisick, P. <strong>House</strong>knecht<br />

Standing: R. Leshko<br />

These are the people who do such a fine job in handling all<br />

employees Personnel requirements. Few people realize the amount<br />

of work that is required in the administration of an adequate industrial<br />

relations program. The phone never ceases <strong>to</strong> ring and they<br />

always seem <strong>to</strong> have the answers.

:.. ;. -/:.:. •.~'<br />

. ' ~ s 1<br />

Machine Shop<br />

G.Danko<br />

R. Stanek<br />

J. Lowery W. Harring<br />

The machine shop in DOlT-<strong>Oliver</strong>, Hazle<strong>to</strong>n is a large well equipped<br />

shop capable of producing high quality machined parts. It co n<br />

tains many modern machine <strong>to</strong>ols and a compliment of capable<br />

opera<strong>to</strong>rs. Parts range in size from fractions of an inch <strong>to</strong> fourteer<br />

feet in diameter and lengths up <strong>to</strong> 41 feet. Crane facilities car<br />

handle ten <strong>to</strong>n in the main bay and twenty <strong>to</strong>n in the east bay.<br />

Engine Lathe Opera<strong>to</strong>rs<br />

Engine Lathe Opera<strong>to</strong>rs Second Shift<br />

l. <strong>to</strong> T.: R. Lohenitz, B. Gulas, W. Waneo, T. Fidishun, S. Kogoy , E. Wasileski,<br />

C. Eroh<br />

1. <strong>to</strong> T.: G . Deeb, G. Gerhard, T. Trovitch. A. Golumbeski, T. Hischar<br />

Engine lathes are used where limited numbers of operations are<br />

required, quantities are small, or threading operations are required<br />

where dies are not available. Also they are capable ofclose <strong>to</strong>lerance<br />

cutting. Included in the engine lathe pho<strong>to</strong> are the tracer lat<br />

opera<strong>to</strong>rs. The tracer lathe performs machining operations {olio<br />

ing the con<strong>to</strong>urs of a template.

Thrret Lathe Opera<strong>to</strong>rs<br />

Thrret Lathe Opera<strong>to</strong>rs Second Shift<br />

I. <strong>to</strong> r.: M. Moser, J. Noga, E. Rusnock<br />

A turret lathe is used when turning, boring and facing operations<br />

are required on a large number ofpieces. Required <strong>to</strong>ols are set up in<br />

a revolving turret. As the <strong>to</strong>ols are needed <strong>to</strong> perform an operation<br />

VTL & Boring Mill Opera<strong>to</strong>rs<br />

I. <strong>to</strong> r.: S. Holloman, P. Warkolla<br />

the turret is indexed <strong>to</strong> that <strong>to</strong>ol position and the machine is ready <strong>to</strong><br />

run. Die can also be set in the crOi5S slide <strong>to</strong>ol holder <strong>to</strong> perform<br />

standard threading operations.<br />

Boring Mill & VTL Opera<strong>to</strong>rs Second Shift<br />

I. <strong>to</strong> r. kneeling: D. Gray, M. Lapacinski, A. Vendel<br />

Standing: C. Pecile, W. Taney, E. Vack, B. Koch<br />

Vertical Turret Lathes have the same advantages as the Horizontal<br />

Turret Lathes but are used <strong>to</strong> machine larger parts which mLlst<br />

be rotated in a vertical position.<br />

Boring mills are used <strong>to</strong> machine parts which require turning,<br />

boring and facing operations. They are used <strong>to</strong> machine parts which<br />

Milling Machine Opera<strong>to</strong>rs<br />

I. <strong>to</strong> r. (irst row: J. Kaschak, R. Christman, D. Mika, C. Fritz<br />

Second row: V. Sherkness, C Lizbinski, C. Bums, B. Simkovich. G. Craigie<br />

lend themselves <strong>to</strong> being cut in an upright po~ition rather than a<br />

horizontal position as an engine lathe. The boring mill in the one<br />

pho<strong>to</strong>graph is capable of machining parts in excess of fourteen feet<br />

in diameter.<br />

Milling Machine Opera<strong>to</strong>rs Seco.nd Shift<br />

I. <strong>to</strong> r.: M. Heaney, J. Klinger, J. Rayno, R. GrafT, D. Boehmer, B. Gogola I. <strong>to</strong> r.: J. Valagene, F. Yaich, J. Fulmer, R. Mensinger, J. Ballick<br />

precisely <strong>to</strong> complete a bore on the other side ofa piece in the precise<br />

location it was bored on the first side. Also included in the pho<strong>to</strong><br />

graph is the planer-mill opera<strong>to</strong>r. A planer mill is used <strong>to</strong> machine<br />

large long, flat surfaces.<br />

Milling machines are used <strong>to</strong> machine flat surfaces. In the case of<br />

the Jig Mill shown in the pho<strong>to</strong>graph, flat surfaces can be machined,<br />

bores can be exactly located and machined and tap threading operations<br />

can be performed. Parts can be indexed and bores located

Machine Shop <br />

Drill Press Opera<strong>to</strong>rs<br />

Drill Press Opera<strong>to</strong>rs Second Shift<br />

I. <strong>to</strong> r. kneeling: J. Machey, C. Yuhas<br />

Standing: J. Welshko, G. Moser, D. Drunbor, J. Thoryk<br />

I. <strong>to</strong> r.: J. Petrilla, D. Fenkner, W. Farrell, C<br />

Rodriguez, R. Ulshafer<br />

Humes, D. Rockman, A<br />

Radial drill presses are used for a wide variety of cutting operations.<br />

One thinks of a drill press as a <strong>to</strong>ol used only <strong>to</strong> cut a round<br />

hole using a drill bit. Using proper <strong>to</strong>ol bars, cuting bars and bushings,<br />

we use drill presses <strong>to</strong> perform many boring operations. Also<br />

included in the pho<strong>to</strong>graph are tape drill opera<strong>to</strong>rs. The tape drills<br />

perform drilling operations from a punched tape. This allows the<br />

opera<strong>to</strong>r <strong>to</strong> drill an infinite variety of holes without having <strong>to</strong> lay the<br />

piece out or use expensive jigs or fixtures.<br />

Layout and Saw<br />

Machine Shop G.S.W. & Laborers<br />

I. <strong>to</strong> r.: E. Cann, W. Thomas, H. Barna, C. Weidenbach<br />

I. <strong>to</strong> r. kneeling: R. Banyas, T. Brogan<br />

Standing: L. Hruniuk, M. Ebert, R. MacNeal, G. Bit<strong>to</strong>rf

Fabrication Shop<br />

w. Snyder<br />

Boilermakers<br />

Crane Opera<strong>to</strong>rs<br />

I. <strong>to</strong> r. kneeling: G. Stetz, W. Faust, P. HoJic, J. Lutkavage, T. Palko<br />

Second row: N. Andrasi, J. Fendrick, A. Podraza, J. Medvetz<br />

Third row: J . Mainiero, J. Richenderfer, W. Weeks, H. Haberle, P. Lettiere,<br />

V. Stecker, J. Irving, E. Arnold<br />

Boilermakers Second Shift<br />

I. <strong>to</strong> r.: F. Olenik, J. Lengen, C. Walper, G. Greech , J. Kulsa, S. Scarcella, E.<br />

Harris<br />

Crane Opera<strong>to</strong>rs Second Shift<br />

I. <strong>to</strong> r. , {irts row: E. Washko, S. Reshetar, R. San<strong>to</strong>rski<br />

Second row: E. Trovitch, R. Rockovich, E. Galski, E. Cherny I, R. Pavlick, W.<br />

Denke, m<br />

Boilermakers perform all operations required <strong>to</strong> convert steel<br />

plate in<strong>to</strong> the sizes and forms needed <strong>to</strong> rn.ake finished parts <strong>to</strong><br />

drawing specification. They layout the plate, operate shears,<br />

punches, rolls or press brakes <strong>to</strong> transform fl a t plate in<strong>to</strong> an i nfi ni te<br />

variety ofsizes and shapes that conform <strong>to</strong> exact engineering drawing<br />

requirements.<br />

I. <strong>to</strong> r.: B. Denke. G. Kattner, V. Bove, C. Briglio, A. Urban<br />

Crane opera<strong>to</strong>rs perform many I ifts throughout the work shift and<br />

transport hundreds of <strong>to</strong>ns of' material in a day. Their broad knowledge<br />

of material handling enables them <strong>to</strong> make skilful lifts of<br />

many "hard <strong>to</strong> handle" object;;.

)<br />

]<br />

)<br />

- -- - -<br />

,<br />

f<br />

~<br />

..<br />

!~<br />

a:::<br />

cFFk2 AJ1J,I<br />

-<br />

I<br />

_~,e.."""",<br />

8()/L.J~.<br />

.<br />

_ ~AY.dro.t:i'<br />

rr=J I (y;> JEll] J I I<br />

/N ~/.N ~G3<br />

1 _~0i,- [i;"""<br />

Ld, ;}', e J 1<br />

4<br />

Ul "<br />

~ BAT7~ J<br />

I<br />

] _ _____ I I<br />

[<br />

J~'PP~<br />

=PT,<br />

r-:-~~~

!-' -~<br />

fo<br />

0<br />

~~<br />

i<br />

1'6<br />

~~~[<br />

L __________________ ~<br />

~I<br />

T<br />

:.::::.:::....:J<br />

T<br />

0 Q<br />

/c:.z ~7<br />

o<br />

1'/<br />

:----"1<br />

- I<br />

, ~~<br />

V ",,8<br />

l'<br />

/'9 "1<br />

[ ==:1<br />

S<br />

,tg<br />

"'-<br />

~I<br />

,<br />

'-(<br />

1 ----<br />

rl<br />

I<br />

0 I<br />

1<br />

0<br />

I<br />

J<br />

[] []J ~il<br />

I~<br />

;0;1 <br />

r<br />

r--- '<br />

L,\ ~,J<br />

..c.<br />

~jl<br />

i<br />

r<br />

~~L<br />

1 ---<br />

L _<br />

o /~G<br />

/;;;/<br />

l<br />

I<br />

~<br />

1<br />

[LAO~<br />

o.&K<br />

I<br />

U-VolilU~r<br />

, ••rN<br />

'\<br />

-t- - ---+----;- -.£=4<br />

T<br />

~"......r<br />

,_nv<br />

~ ,<br />

~<br />

~~----------- - -----------------<br />

I 1<br />

138<br />

o<br />

o<br />

---+E~U~I~-----T----~----r=--·--+--<br />

I I<br />

""f»4i/rf8L"I 4e'5A<br />

1-----~------~f~----~f-<br />

1/8 1<br />

~<br />

'<br />

[<br />

I<br />

N.eC" ~T (,A{I~IL'i..<br />

I<br />

I<br />

~T T T T<br />

,1-]- I I I I I I<br />

S7'ae''''~4 .<br />

,J'1A/,,-,r<br />

/\/fIre"<br />

s-;r,,¥6f'.<br />

~,.------,<br />

T T ~ T T

Welding<br />

Welders<br />

Welders Second Shift<br />

F. Brislin<br />

l. <strong>to</strong> r. {irst row, kneeling: J. Campana, W. Yurchak, P. Libonate, N. Secunda,<br />

J. Medvetz, A. Hartig, J. Redash, J. Grace <br />

Second row: E. Beish, L. Dejana, F. Fellin, J. Ritecki, J. Rushinski, E. Sipple, <br />

L. Tunilla<br />

Third row: C. Kozak, M. Marinock. F . Heckman, E. Lally, T. Kuritz, P.<br />

Stasukonis, M. Sentiwany, E. Mellas, P. Sabol<br />

Thru the years welding has changed dramatically and <strong>to</strong>days<br />

welder must have knowledge ofmany different welding techniques.<br />

Many of the welders in the Hazle<strong>to</strong>n plant are code certified.<br />

l. <strong>to</strong> r., {irst row: A. Kirschner, G. Brekke, J. Daniels. B. Cryder, T. Disca 1<br />

age, W. Lausterer<br />

Second row: C. Shaffer, V. Katzor, H. Bankes, W. Gilbert, F. Lutz, J. Jun<br />

Third row: J. Yuhas, G. Yuhas, E. Moore, P. Fidishun, L. Vi<strong>to</strong>, S. Cardinal.<br />

J. Vi<strong>to</strong><br />

Plate Shop G.S.W. & Laborers<br />

l. <strong>to</strong> r., kneeling: D. Briglio, R Kapuscinski, T. Kennedy, M. Stabert<br />

Standing: C. <strong>House</strong>knecht, R. Marolo, B. Shofran, S. Bitsko, B. Baran<br />

D. Drazenovich

Assembly Shop<br />

S. Tomushunis<br />

Assembly Second Shift<br />

I. <strong>to</strong> r. kneeling: G. Minnick, T. Gerhard, .J. Petrilla<br />

S econd row. G. Felter, G. Holly, C. Budwash, W. Frey, T. Tokash, W. <br />

Floating <br />

Third row. E. Corch, 1. Melkosky, E. Madochick, ,J. Biaare, N. Dzia k, J. <br />

Ellison<br />

,<br />

The Assembly Shop is divided in<strong>to</strong> four major areas, Filtration,<br />

Sedimentation, Centrifugal and DSM. The filtration assembly department<br />

assembles mainly drum filters in sizes ranging up <strong>to</strong> 13'6"<br />

in diameter and thirty two feet long. The fil ter drum in the largest of<br />

this equipment weighs in excess of thirty <strong>to</strong>n and the vat in excess of<br />

twenty <strong>to</strong>n.<br />

The sedimentation group assembles the drive mechanisms. The<br />

assembly of this equipment requires the installation of gearing <strong>to</strong><br />

exacting <strong>to</strong>lerances <strong>to</strong> assure a rei iabJe drive assembly. The largest<br />

of these drive assemblies is 130" in diameter and weighs approximately<br />

41 ,000 lbs. <strong>Dorr</strong>-<strong>Oliver</strong> center mechanisms drive equ ipment<br />

up <strong>to</strong> 400 ft. in diameter.<br />

The centrifugal group assembles and tests our high speed centrifuges.<br />

These centrifuges range in size from 9" which rotate at a<br />

speed of 9,000 RP.M. <strong>to</strong> 36" in diameter with a rotation speed of<br />

2,600 R.P.M. The equipment uses high speed rotation as its method<br />

of separation. The parts are made of stainless steel and require<br />

precision machining and exacting balancing. They are used mainly<br />

in the food industry. Other wide applications include the pharmaceutical<br />

and chemical industries.<br />

The DSM area fabricates a screen type filtration unit ranging ilJ<br />

size from 8" <strong>to</strong> 7 ft. It uses either a pressure or gravity type of f10w<br />

and the screen opening determines the magnitude ofthe separation.<br />

The assemblers job requires the ability <strong>to</strong> take finished parts, fit<br />

and precisely align them <strong>to</strong> drawing specification. The product lines<br />

made in Hazle<strong>to</strong>n require the s<strong>to</strong>cking of over 12,000 part numbered<br />

items plus many made special for jobs. This requires the assembler<br />

<strong>to</strong> have broad knowledge of our product lines.<br />

Sandblasting and painting operations are also a part of the assembly<br />

department.

Centrifugal Assembly <br />

C. Warg<br />

t. <strong>to</strong> r.: J. Hiza, E. Novitsky, W. Miller, A. Danko, 1. Cancerius<br />

Filtration Assembly<br />

J. Williams<br />

t. <strong>to</strong> r., {irts row: P. Notaro, A. Morrell, R. Barry, W. Gilbert, G. Koch, '<br />

Danko, J. Schrum<br />

Second row: K. Yanick, M. Baran, F. Massage, W. Miller, M. Chulock,'<br />

Gimbi<br />

Third row: A. Kendra, L. Tucci, P. Andrasko, J. Rooney<br />

Fourth row: P. Wanuga, S. Rossi<br />

DSM Assembly<br />

W. Field<br />

' t .<br />

' \J,I.<br />

t. <strong>to</strong> r.: F. Kusiak, M. Somits, B. Mastellar

Sedimentation Assembly <br />

S. Soika 1.10 rJirsl !'OW.' N . Lewis, M. Cichowic, J. McGee , J. Hubosky, J. Malitsky<br />

Second row: E. Evancho,J. Gomber, P. Moi~ey, G. Kibler, P. Kenvin, R. Todd<br />

G.S.W. & Burners Second Shift<br />

I. 10 r., (rani row: F . Hayes, G. DeRenzo, P. Walko, D. Mi'lheim <br />

Back row: P. Sabol, A. Malaska, P. Zakrewsky <br />

Inspection <br />

I<br />

•<br />

.'<br />

• I<br />

0<br />

" 1 '<br />

, . . .<br />

F. Dute t. <strong>to</strong> r., standing: M. Sanzie, M. Williams, V. Henry, A. S<strong>to</strong>lpe<br />

Kneeling: R. Berger, C. Es<strong>to</strong>k<br />

"What do you mean you rejected it!!" They accept many times the<br />

number they reject but there is an "oops" now and then and it is the<br />

Inspection department that catches it.

Toolroom & Tool Crib <br />

E. Gill I. <strong>to</strong> r., kneeling: T. Hollick, J. Zumar, B. Kisenwether<br />

Standing: J. Godinsky, J. Yurcho, C. Mattem, A. Sockolosky, J. Kreiger<br />

The <strong>to</strong>ol room and <strong>to</strong>ol crib are responsible for the maintenance,<br />

s<strong>to</strong>rage and issuing of all <strong>to</strong>ols, jigs and fixtures. Many of our jigs<br />

S<strong>to</strong>reroom<br />

and fixtures are made right in our own <strong>to</strong>ol room. All of our cutting<br />

<strong>to</strong>ols are sharpened in this area.<br />

Maintenance<br />

W. Gallo l. <strong>to</strong> r., (irst row: J. Schnorr, J. Leskosky, F. Getz, J. Pendal<br />

Second row: J. Mihal, G. Oakes, K. Radley, M. Zboray, N. Dubick, A.Drusda<br />

The S<strong>to</strong>reroom is the group responsible for about 12,000 numbered<br />

<strong>Dorr</strong>-<strong>Oliver</strong> parts and many more thousands of commercial<br />

items needed <strong>to</strong> sustain our production team.<br />

R. Deis I. <strong>to</strong> r., kneeling: V. Montefour, J. Quinn, A. Ferko<br />

Second row: G. Korba, P. Wandishin, R. Kisenwether<br />

If there is a group of unsung heroes, it has <strong>to</strong> be the Maintenance<br />

department. These are the guys who keep the place running, install<br />

the new equipment and wade through a pile of maintenance requests<br />

all marked "do me first."

Tool Crib, S<strong>to</strong>res,<br />

Inspection, Maintenance<br />

& Toolroom Second Shift<br />

l. <strong>to</strong> r., {irst row: J . Rusnock, M. Bredbenner, A. Miller<br />

Second row: A. Shimukonas. H. Beitel, D. Kingsbury<br />

Receiving <br />

M. Hydock l. <strong>to</strong> r., {irst row: G. Stronko, D. Ma<strong>to</strong>nte, G. Ballick, C. Cancerius<br />

Second row: C. Ammon, H. Malisko, S. Correll, D. Welliver. W. Jones<br />

Everything that purchasing buys ends up in the area where these<br />

men are working. Our Receiving group works in all kinds ofweather<br />

<strong>to</strong> see that the trucks are un loaded and the material checked in.<br />

They are also responsible <strong>to</strong> see that all raw material gets in<strong>to</strong> the<br />

shop on schedule.<br />

Shipping<br />

K. Guenther l. <strong>to</strong> r. , {ront row: L. Spivak, S. Gido. J. Kozak<br />

Back row: J. MatarelIi, M. Por<strong>to</strong>nova, J. Schafer, A. Schreibmaier<br />

We've built it and it's the best, then it's up <strong>to</strong> Shipping <strong>to</strong> do the<br />

rest. These are the guys that get the finest process equipment in the<br />

world from our shop floor <strong>to</strong> the cus<strong>to</strong>mer.

VTL Tool Changer Operation -<br />

simplicity of design.<br />

positive action,<br />

01 At the command 01 a " (" word, the ram<br />

posItions over the plck·up pomt.<br />

oJ<br />

The ram posillons down over Ihe <strong>to</strong>ol shank<br />

and drivIng keys.<br />

01 Th <strong>to</strong>ol coupler mechanIsm engages Wllh<br />

Ihe <strong>to</strong>ol<br />

oJ The coupler mechanISm Clamps the <strong>to</strong>ol 10<br />

the ram ,<br />

01 The ram positions out 01 the matrix and<br />

performs liS machinIng operallons,<br />

oJ<br />

The ram positIons back <strong>to</strong> the matrix at the<br />

command 01 a new "t" word<br />

01 The <strong>to</strong>ol is unclamped Irom Ihe ram<br />

oJ The coupl r dIsengages Irom Ihe 1001.<br />

01 The ram posillons up <strong>to</strong> clear tne <strong>to</strong>ol.<br />

oJ The maIn. Indexes <strong>to</strong> the nexl 1001.<br />

01 The <strong>to</strong>ol I. picked up, and machinIng<br />

resumes<br />

I I<br />

I<br />

I I<br />

I I<br />

I I<br />

tL~<br />

l _ J<br />

I •<br />

I I<br />

I<br />

Time is rapidly approaching when<br />

the new computer controlled Vertical<br />

Turning Center will arrive. This new<br />

Giddings and Lewis machine is the<br />

most modern boring mill available. The<br />

machine harnesses the power of a computer<br />

for most calculations enabling<br />

programmers <strong>to</strong> enter dimensions directly<br />

from the part print.<br />

All controls are located on a single<br />

station convenient <strong>to</strong> the opera<strong>to</strong>r. Variable<br />

information may be entered<br />

quickly through the keyboard.<br />

The machine will have a sixty inch<br />

table and a twelve station <strong>to</strong>ol changer.<br />

(See related diagram.)<br />

Another interesting feature is the<br />

diagnostic service. The machine is tied<br />

in<strong>to</strong> a computer diagnostic service. If<br />

you have a machining problem, the<br />

computer will search out the difficulty<br />

and print out the corrective action.<br />

..<br />

1I<br />

~<br />

:=: .. : ~<br />

• • - -:.- flU;lIICIIII(.t.<br />

- :. <br />

.. - ''''''<br />

.... _. <br />

~ ..~ .<br />

I Ni l'<br />

IIlf ll ~<br />

''tv·';' ~<br />

ADDRESS<br />

KEYBOARD<br />

OCTAL<br />

DECIMAL<br />

INCH<br />

000000<br />

000000<br />

00000000000<br />

!OOOOO<br />

! OOOOOOOOOOO<br />

00000<br />

0000000000<br />

BIT 00<br />

01<br />

02<br />

03<br />

04<br />

OS<br />

06<br />

07<br />

10<br />

11<br />

12<br />

13<br />

14<br />

15<br />

16<br />

17<br />

0 0<br />

0 0<br />

0 0<br />

0 0<br />

0 0<br />

0 0<br />

0 0<br />

0 0<br />

0 0<br />

0 0<br />

0 0<br />

0 0<br />

0 0<br />

0 0<br />

0 0<br />

0 0<br />

...-!!!1..!2lI11---...<br />

'~0u, "m" <br />

FOR TEST<br />

MODE "An<br />

PRESS TO ENTER<br />

TEST MODE "An<br />

USE TO ENTER <br />

MEMORY ADDRESS <br />

.. 1;' .,<br />

~.<br />

P'~<br />

~D 010 G [] [] 8 [J I£]rotdtj:<br />

L[j'tfo [J G G ~ [] ~l[] [J [J i<br />

[:][]O[]GGG . ~![][]81<br />

DOD - DO O:[J:[];]:D ..., '.--- DO:<br />

~ _. _..'<br />

-<br />

11.&\ 11' ~<br />

tun ,......<br />

fill "<br />

"" . "<br />

@ ~ @ @<br />

-<br />

IdUS'UOc;O_IROI<br />

CltU<br />

'L

<strong>Dorr</strong>-<strong>Oliver</strong> honors 104 for service <br />

Speakers at Pill Dinller I. /0 r.: Pat e li ga n. Indu stri al Relation Nt anager;<br />

Ru Raynor. Vi ce Pres id ent Operati on; Martin Corbett . Bu siness<br />

Represe nt ative I. A.M. ; Ge ne Koki nda. Pl ant Manage r; Judy Gri csin g.<br />

Pre ident O. & P. E. I. .; Vi <strong>to</strong> Bovc. I.M.A .; John Yeage r. Shop Superintenden<br />

t.<br />

I. /0 t:: Pat Ncligan. Ru Raynor, 35-year pin recipients Charles Weidenbach and<br />

Roland Deis, Gene Kokinda. John Yeager.<br />

<strong>Dorr</strong>-<strong>Oliver</strong>, Inc. has recognized 104 of its employes for<br />

years of service <strong>to</strong> the Hazle<strong>to</strong>n plant.<br />

The main address at the dinner meeting in the Lincoln<br />

Room of the Gus Genetti Mo<strong>to</strong>r Lodge was delivered by Russ<br />

Raynor, Stamford, Conn., vice president of operations.<br />

Raynor congratulated the honored employes and emphasized<br />

the company's intention <strong>to</strong> establish good communications<br />

at all levels of the corporation. He presented a<br />

20-year service pin <strong>to</strong> plant manager Gene Kokinda and a<br />

25-year service pin <strong>to</strong> Charles Andrews, manager of data<br />

processing.<br />

Other speakers included Martin Corbett, business agent<br />

for the International Association of Machinists; and Vi<strong>to</strong><br />

Bove, president of Lodge 1648, LA.M., and Judy Griesing,<br />

president of Local 202, Office and Professional Employees<br />

International Union. She talked about cooperation between<br />

her union and management.<br />

Pat Neligan, manager of industrial relations, was master<br />

of ceremonies. Remarks were offered by John Yeager, shop<br />

superintendent, and by Kokinda.<br />

Recipients of 35-year service pins were Ronald Deis, Carl<br />

Eroh, Thomas Kuritz, Vernon Stecker and Charles Weidenbach.<br />

Employees who received 30-year pins were Rudoph Antinozzi,<br />

Stephen Gido, Vernon Henry, John Kreiger, John<br />

Lowery, Robert Schaar, John Schafer and William Snyder.<br />

Twenty-five year service pin recipients were: Charles Andrews,<br />

Harry Barna, Francis Barnasevitch, Francis Donsecz,<br />

Gerald Evans, William Facinelli, Wilbur Field, Walter Gilbert,<br />

Earl Jacoby, Frank Lutz, John Matarelli, Edmund Mellas,<br />

J oseph Mestrow; Helene Miller, Anthony Podrasa,<br />

Charles Reimiller. J oseph Sotack, Bernard Stanziola, John<br />

Spock, Robert Todd and Harold Zboray.<br />

The following received 20-year service awards:<br />

Nicholas Andrasi, Harold Bankes, Michael Baran, Herman<br />

Beitel, Robert Berger, Edward Brugger, Joseph Campana,<br />

Michael Chulock, William Denke, Michael Dorso, Cornelius<br />

Es<strong>to</strong>k, Emil Evancho, Byron Evert, Warren Faust,<br />

Walter Gallo, Walter Ganc, Frederick Getz, Joseph Gomber,<br />

George Greech, Andrew Gregor, Herbert Grice, William<br />

Harring and Michael Hospodar.<br />

Gary <strong>House</strong>r, Michael Hudock, Paul Kenvin, Eugene<br />

Kokinda, J ohn Kozak, Felix Kusiak, Joseph Lengen, John<br />

Machey, J ohn McNeal, Joseph Mihal, Wesley Miller, Edward<br />

Novitsky, Francis Olenik, Thomas Ondrey, J ohn Pe<strong>to</strong>csky,<br />

Peter Sabol, Maurice Sanzl, Al Schreibmaier, Michael Sentiwany,<br />

Edwin Sipple, Robert Steward, J ohn S<strong>to</strong>ll, Lewis<br />

Tucci, William Wanco, Carl Warg, William Weeks, Ario Welliver,<br />

Joseph Welshko and John Yeager.<br />

Recipients of 15-year pins were: Mary Arnold, Daniel Dargay,<br />

J oseph Fertare, Karl Guenther, George Hardish, Mary<br />

Romano and John Tough.<br />

Ten-year pins were awarded <strong>to</strong>: Donald Baran, Gerald<br />

Brekke, Joseph Dewosky, Patrick Fid ishun, Joseph<br />

Hubosky, Joseph Juna, Pasquale Libonate, Eugene Moser,<br />

Stephen Reshetar, Ralph Stanziola and Raymond Ulshafer.