DORR-OlIUER - Dorr-Oliver Alumni

DORR-OlIUER - Dorr-Oliver Alumni

DORR-OlIUER - Dorr-Oliver Alumni

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

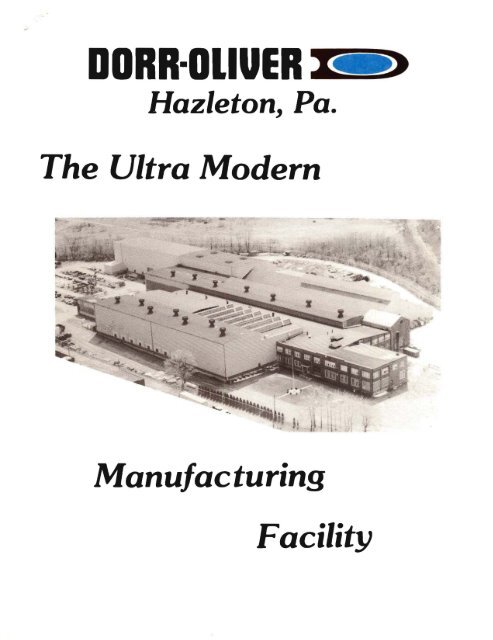

<strong>DORR</strong>-<strong>OlIUER</strong><br />

Hazleton, Pa.<br />

The Ultra Modern<br />

Manufacturing<br />

Facility

with modern equipment and skilled crci/tsp<br />

This Boring Mill is capable of machining<br />

parts 17'6" in diameter. The maximum<br />

clearance under the rail is 10 feet. This is<br />

the machine for the big jobs. Although it is<br />

not as sophisticated as our CNC machines.<br />

it like all of our conventional Boring Mills.<br />

has digital position readout (inset) for<br />

accuracy in machining.<br />

.. <br />

Left is aCincinnati Milicron CNC 18" Universal Chucker.<br />

The machine has a slant bed. Two axis design. Inset shows<br />

crown and boring turrets. Maximum diameter of part 20- Y2"<br />

and the maximum length between centers is 80".<br />

Above the Step-Master Automatic Computer Control<br />

grinding system has the capability to grind multiple diameters<br />

on the same part automatically in one continuous operation.<br />

Another feature of the machine is automatic inprocess gauging<br />

to check diametric tolerances.<br />

Left is the Okuma CNC Horizontal turning center. This is the<br />

machine for precision turning and threading operations.

<strong>DORR</strong>-OLIUER<br />

Hazleton. • • a facilit~[<br />

Machining<br />

One .~ 'r . .<br />

OJ Ihree CNc M. ~. <br />

achining<br />

Centers<br />

Above is a 48" Giddings & Lewis CNC <br />

Boring Mill. It has a turning capacity of <br />

60" and a height capacity of 48". <br />

Left 60" Giddings & Lewis CNC Boring<br />

Mill. This machine has a turning capacity<br />

of 72" diameter and a height capacity 84".<br />

Small inset shows machine cutting tapered<br />

surface, one of the infinite capabilities of<br />

the machine.

Hazleton Plant <br />

Manufacturing Capabilities <br />

MACHINING CAPABILITIES:<br />

CNC Turning <br />

Through 72" diameter x 84" long<br />

CNC Milling <br />

Through 39" width x 39" high x 59" long<br />

CNC Grinding <br />

Through 14" diameter x 60" long (between centers)<br />

Conventional Turning <br />

58" diameter x 42' long<br />

Vertical Boring Mill Capacity <br />

17' diameter x 10' high<br />

Conventional Milling <br />

Through 10' high x 16' long<br />

Radial Drilling <br />

Through 6' high x 14' diametR.r<br />

FABRICATION CAPABILITIES:<br />

CNC Plasma Burning and Layout<br />

Through 2" thick x 16' wide x 50' long<br />

Plate Rolling <br />

Through 7/16' thick x 12' long <br />

Minimum diameter 16" - Maximum diameter 14'<br />

Plate Shearing <br />

Through 3/4" thick x 10' wide (mild steel)<br />

Plate Forming <br />

Through 3/4" thick x 12' wide (mild steel)<br />

WELDING<br />

Semi-automatic and automatic MIG<br />

Automatic Weld Scamer <br />

12' weld length (MIG & sub-arc)<br />

Max. pI. thi(~kn(!ss - I"<br />

Automatic Welding Manipulator <br />

Capacity 14' diameter cylinder<br />

OTHER CAPABILITIES:<br />

Dynamic Balancing <br />

Through 72' diameter x 110" long<br />

5,000# maximum)<br />

Finished Assemblies <br />

Through 60 ton in weight<br />

Speed, vibration and temperature monitoring <br />

Of finished assemblies under operating conditions<br />

Paint Room<br />

20' wide x 18' high x 50' long working area<br />

Mobile Cranes <br />

Two (2) 22-ton units<br />

Drum Lathes <br />

One (1) 14' diameter x 45' long work piece<br />

One (1) 14' diameter x 27' long work piece<br />

Grit Blast Room <br />

16' wide x 18' high x 26' long working area<br />

A Word About Us ......... . <br />

The <strong>Dorr</strong>-<strong>Oliver</strong> Hazleton plant provides the<br />

capabilities for state-of-the-art machining and<br />

fabricating essential in today's demand ing<br />

marketplace. Housed in a 203,000 square foot<br />

facility, <strong>Dorr</strong>-<strong>Oliver</strong> is staffed with a group of<br />

experienced, enthusiastic and professional people<br />

who will work with you on any project or problem<br />

you may have.<br />

<strong>Dorr</strong>-<strong>Oliver</strong>'s 35,000 square foot machine shop<br />

utilizes a wide range of late model equipment<br />

featuring (11) highly advanced numerically<br />

controlled machine tools. Enjoying a world-wide<br />

reputation for quality and accuracy, <strong>Dorr</strong>-<strong>Oliver</strong>'s<br />

machine shop is ca pable of machining and grinding<br />

to .0005 tolerances.<br />

Sophistication is synonomous with fabrication at<br />

<strong>Dorr</strong>-Olive r. The shop is equipped with a CNC<br />

Plasma Burner and layout machine whi ch affords<br />

high quality and productivi ty. Plate rolling,<br />

shearing and forming capabilities are also<br />

available.<br />

<strong>Dorr</strong>-<strong>Oliver</strong> welders are certified in A.8.M.E.<br />

code welding and skilled in the application of semiautomatic<br />

and automatic mig. An in-house welding<br />

engineer provides technical expertise to solve your<br />

welding problems whether they be large or small.<br />

Technical expertise is provided to all levels of<br />

manufacturing from a fully staffed engineering<br />

department. An in-house CAD/CAM unit allows for<br />

efficient computerized programming and tool<br />

design. The Quality Assurance Department is<br />

staffed with experienced, capable personnel and<br />

excellent inspection equipment. Regardless of your<br />

inspection requirements, parts receive the highest<br />

quality inspection.<br />

<strong>Dorr</strong>-<strong>Oliver</strong> Hazleton has enjoyed an excellent<br />

reputation for many years in all phases of<br />

machining, fabrication and assembly.

" !Ople. • •<br />

DeVlieg Spiromatic Jig Mill provides<br />

precision boring and milling operations. It has a 4"<br />

diameter spindle. Equipped with Diatrol<br />

numerical control direct dialing dimensioning, it<br />

provides consistently reliable quality.<br />

Right DeVlieg Spiromatic Jig Mill with 6"<br />

spindle.<br />

The Monarch CNC Machining Center is a<br />

versatile drilling and milling machine. It has a<br />

positioning accuracy throughout travel of ±.0005".<br />

Positioning repeatability is ± .00025. The tool<br />

retrieval cabinet can be seen on the right of the<br />

machine.<br />

Heavy duty drilling operations can be performed<br />

on the 8' Giddings and Lewis-Bickford Radial Drill<br />

Press. This drill press has a heavy duty column and<br />

can be used for a wide range of drilling and boring<br />

operations.

ter Bay Fabrication Area<br />

ler Fabrication Bay is 58' wide x 610' long<br />

Right: Bertch Century II Hydraulic Drive Four<br />

role type, plate binding roll with front, rear and<br />

overhead supports.<br />

Assembly<br />

Left: Modern Filter Bay assembly area. Above<br />

Centrifugal Assembly area where the finest Centrifuges in<br />

the world are assembled. Below Sedimentation Assembly<br />

area where complex drive mechanisms are assembled.<br />

Paint Spray Booth<br />

20' wide x 50' long<br />

Two Thirty ton cranes located in the filter bay<br />

assembly and shipping areas. Also located in the<br />

area are a 20 ton and 10 ton bridge crane. Eighteen<br />

bridge type cranes are located throughout the plant<br />

area.

Fabrication <br />

The CNC Plasma Cutting System ca n burn material up to 2" thick and in widths up<br />

to 16' wide x 50' long. The machine cuts mild steel and stainless steel to any required<br />

size or shape. It also has total layout and center punching capabilities. Material lies on<br />

a table of water for smoke and fume free operation. Insetshows operator control panel.<br />

Left: Pacific Shear. Can shear mild steel plate 3/4" thick<br />

and stainless steel plate 1/ 2" thick in widths up to 10'.<br />

Below: 750 Ton Pacific Press Brake Capable of handling<br />

material 3/4" thick by 12'. With this machine and the skilled<br />

persons who operate it, simple bends or a complex cone can<br />

be formed.<br />

Lower Left: Automatic Weld Seamer Can weld plate I"<br />

thick up to 12' long using MIG or submerged arc.<br />

. ....."'"

The Toshiba 10BMC is a horizontal<br />

machining center. It has a pallet shuttle<br />

feature which allows the operator to set up<br />

a part while the other part is being<br />

machined. It has two 40" tables.<br />

It has a Y axis travel of 49" and an X axis<br />

travel of70". The Z axis travel stroke is39".<br />

The machine has a 60 station automatic<br />

tool changer.<br />

An adaptive control monitors tool life<br />

and an automatic shutdown if tool<br />

breakage occurs. It also has an automatic<br />

feed override to achieve maximum cutting<br />

efficiency.<br />

The drum turning lathe is one of the largest thread cutting lathes in the world. It has no lead screw,<br />

and cuts the thread by syncronized electical impulses. The lathe can swing 15 feet in diameter and<br />

handle lengths up to 50 feet. It can handle weights up to 50 ton.