Energy harvesting: a thin film approach - EE Times Europe

Energy harvesting: a thin film approach - EE Times Europe

Energy harvesting: a thin film approach - EE Times Europe

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

NEWS & TECHNOLOGY<br />

OPTOELECTRONICS<br />

<strong>EE</strong><strong>Times</strong> <strong>Europe</strong>: Highly integrated<br />

– does this mean that you<br />

integrate the driver circuitry onto<br />

the LED chip?<br />

M. Zeiler: Yes, for instance. This is<br />

one option. Also the connecting<br />

technology is designed to be as<br />

slim as possible. We always have<br />

solutions that are different. In addition,<br />

we have many promising<br />

contacts with large OEMs which<br />

are interested in our technology.<br />

If you look at the details, in the<br />

high-volume retrofit market it even<br />

makes sense to run a production<br />

in <strong>Europe</strong> – if you have a high<br />

degree of automation.<br />

<strong>EE</strong><strong>Times</strong> <strong>Europe</strong>: Where are your<br />

manufacturing locations?<br />

M. Zeiler: Every<strong>thin</strong>g but the chips<br />

are produced in St. Petersburg.<br />

In Dortmund we have R&D and a<br />

pilot production. Our high volume<br />

production is here in Landshut<br />

where we can use existing infrastructure<br />

(from LFoundry), clean rooms etc. We can rent the<br />

infrastructure with an option for further enlargement, ideal for<br />

mass production.<br />

<strong>EE</strong><strong>Times</strong> <strong>Europe</strong>: What’s your estimate of the LED market development<br />

for the future? Do you <strong>thin</strong>k LEDs will quickly displace<br />

CFLs?<br />

M. Zeiler: Yes and no. Quickly in the sense of the traditional<br />

lighting business, yes. This could happen in a time frame of<br />

three to five years while it took some 25 years for the CFL to<br />

gain significant market share in conventional lighting. But one<br />

should not expect a complete changeover. In certain market<br />

segments such as automotive or laptop display backlighting,<br />

LEDs conquered the markets very quickly. In general lighting,<br />

this won’t happen at the same speed. The established lighting<br />

companies do not move that fast. This is a clash of the cultures<br />

– conventional lighting and the fast-moving semiconductor<br />

industry.<br />

<strong>EE</strong><strong>Times</strong> <strong>Europe</strong>: Which market segments do you expect to<br />

grow the fastest? In which applications do LEDs gather acceptance<br />

most rapidly?<br />

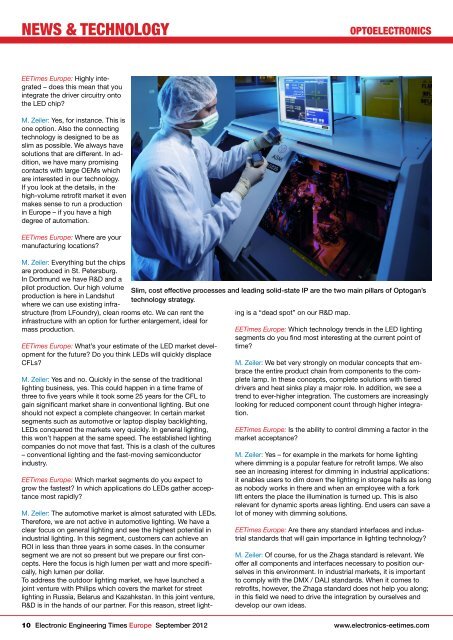

Slim, cost effective processes and leading solid-state IP are the two main pillars of Optogan’s<br />

technology strategy.<br />

M. Zeiler: The automotive market is almost saturated with LEDs.<br />

Therefore, we are not active in automotive lighting. We have a<br />

clear focus on general lighting and see the highest potential in<br />

industrial lighting. In this segment, customers can achieve an<br />

ROI in less than three years in some cases. In the consumer<br />

segment we are not so present but we prepare our first concepts.<br />

Here the focus is high lumen per watt and more specifically,<br />

high lumen per dollar.<br />

To address the outdoor lighting market, we have launched a<br />

joint venture with Philips which covers the market for street<br />

lighting in Russia, Belarus and Kazahkstan. In this joint venture,<br />

R&D is in the hands of our partner. For this reason, street lighting<br />

is a “dead spot” on our R&D map.<br />

<strong>EE</strong><strong>Times</strong> <strong>Europe</strong>: Which technology trends in the LED lighting<br />

segments do you find most interesting at the current point of<br />

time?<br />

M. Zeiler: We bet very strongly on modular concepts that embrace<br />

the entire product chain from components to the complete<br />

lamp. In these concepts, complete solutions with tiered<br />

drivers and heat sinks play a major role. In addition, we see a<br />

trend to ever-higher integration. The customers are increasingly<br />

looking for reduced component count through higher integration.<br />

<strong>EE</strong><strong>Times</strong> <strong>Europe</strong>: Is the ability to control dimming a factor in the<br />

market acceptance?<br />

M. Zeiler: Yes – for example in the markets for home lighting<br />

where dimming is a popular feature for retrofit lamps. We also<br />

see an increasing interest for dimming in industrial applications:<br />

it enables users to dim down the lighting in storage halls as long<br />

as nobody works in there and when an employee with a fork<br />

lift enters the place the illumination is turned up. This is also<br />

relevant for dynamic sports areas lighting. End users can save a<br />

lot of money with dimming solutions.<br />

<strong>EE</strong><strong>Times</strong> <strong>Europe</strong>: Are there any standard interfaces and industrial<br />

standards that will gain importance in lighting technology?<br />

M. Zeiler: Of course, for us the Zhaga standard is relevant. We<br />

offer all components and interfaces necessary to position ourselves<br />

in this environment. In industrial markets, it is important<br />

to comply with the DMX / DALI standards. When it comes to<br />

retrofits, however, the Zhaga standard does not help you along;<br />

in this field we need to drive the integration by ourselves and<br />

develop our own ideas.<br />

10 Electronic Engineering <strong>Times</strong> <strong>Europe</strong> September 2012 www.electronics-eetimes.com